NTC chip electrode paste and method for preparing NTC chip using same

A chip electrode and paste technology, used in cable/conductor manufacturing, circuits, electrical components, etc., can solve the problem of difficult to meet the requirements of response speed, good consistency, and increasing reliability, electrode-chip interface gaps and voids There are many problems such as large difference in thermal expansion coefficient, etc., to achieve the effect of good strength and toughness, small difference in thermal expansion coefficient, and good resistance to cold and thermal shock.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

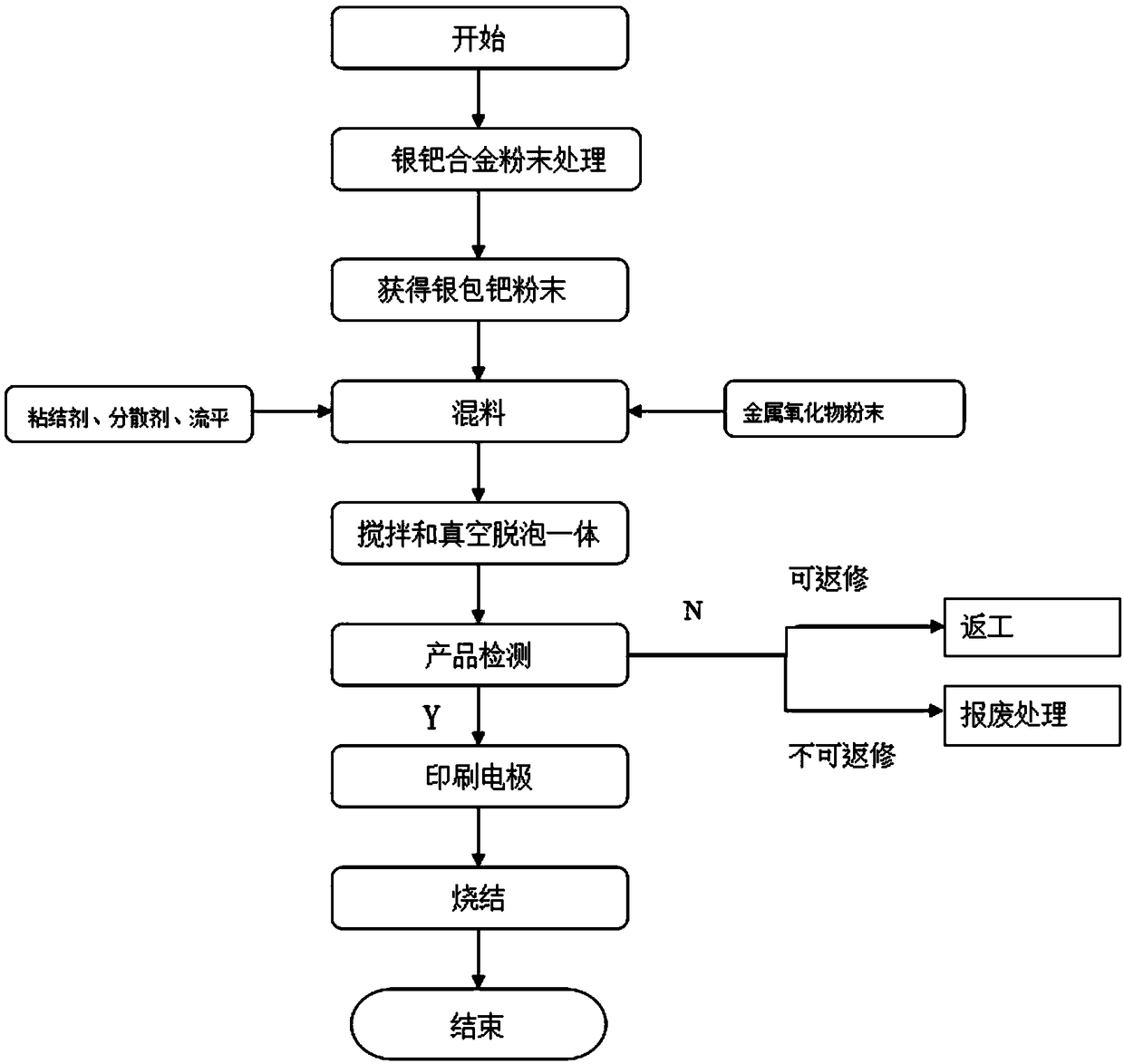

Method used

Image

Examples

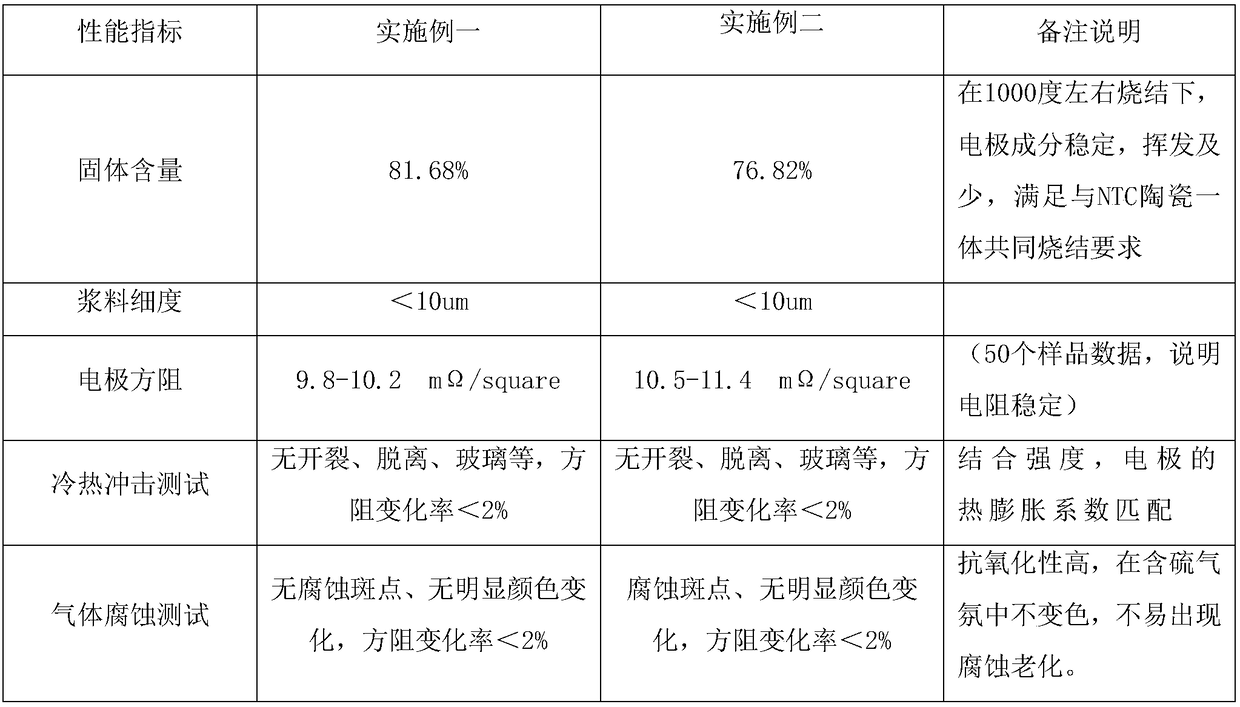

Embodiment 1

[0055] Silver-coated palladium powder is 73%, the silver-coated palladium powder is spherical, the powder particle size is 3-6um, and the thickness of silver-coated palladium is 15-20nm;

[0056] 6% metal oxide powder, the metal oxide powder is a combination of iron oxide and manganese dioxide metal oxide powder, the weight ratio of iron oxide and manganese dioxide metal oxide powder is 2:1, and the particle size of the powder is 120-500nm;

[0057] Solvent 9%, the solvent is butyl carbitol and DBE, and the weight ratio of the two solvents is 1:1;

[0058] 10.5% organic binder, the organic binder is American Eastman butyl cellulose CAB551-0.01 and Japanese Kuraray company Mowital B 60H, the weight ratio of butyl cellulose CAB551-0.01 and Mowital B 60H is 4:1;

[0059] Dispersant 0.3%, DISPERBYK-190 from BYK Company.

[0060] Defoamer 0.7%, BYK-055 of BYK Company.

[0061] Leveling agent 0.5%, BYK company is: BYK-333.

[0062] Add it into the container tank according to the ...

Embodiment 2

[0065] Silver-coated palladium powder 68%, the silver-coated palladium powder tail is nearly spherical, the powder particle size is 3-8um, and the thickness of silver-coated palladium is 8-16nm;

[0066] 5% metal oxide powder, the metal oxide powder is iron oxide and manganese dioxide metal oxide powder, the weight ratio of iron oxide and manganese dioxide metal oxide powder is 2:1, and the particle size of the powder is 120-500nm;

[0067] Solvent 12%, the solvent is butyl carbitol and DBE, and the weight ratio of the two solvents is 1:1;

[0068] Organic binder 13.5%, organic binder is American Eastman butyl cellulose CAB551-0.01 and Japanese Kuraray company Mowital B 60H, the weight ratio of butyl cellulose CAB551-0.01 and Mowital B 60H is 4:1;

[0069] Dispersant 0.3%, dispersant is DISPERBYK-190 of BYK company;

[0070] Defoamer 0.7%, defoamer is BYK-055 of BYK company;

[0071] The leveling agent is 0.5%, and the leveling agent is BYK-333 of BYK Company.

[0072] Add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com