Top cover assembly of secondary battery, and secondary battery

A technology of secondary batteries and components, applied in the field of energy storage components, can solve the problems of unstable resistance value, increased loop current, easy breakage, etc., and achieve the effect of maintaining stable resistance value

Active Publication Date: 2018-10-23

CONTEMPORARY AMPEREX TECH CO

View PDF11 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, if the metal is used for direct conduction, since the resistance value of the metal is generally in the milliohm level, the circuit current will increase when the battery is short-circuited, so it is easy to cause fire and other safety hazards.

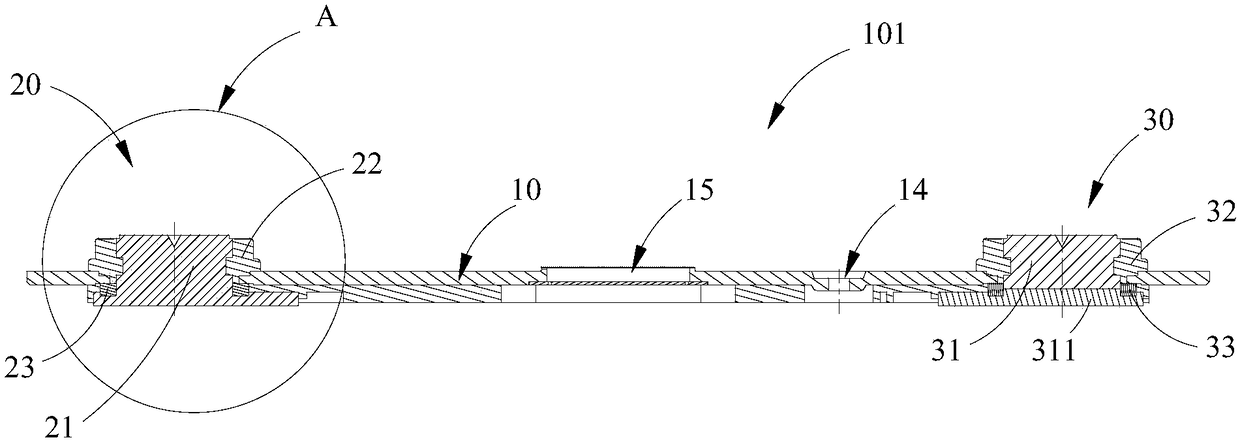

[0003] In order to solve the above problems, a specific method currently adopted is: make the upper plastic of the top cover structure into conductive plastic to realize the resistance connection between the first pole and the cover sheet, and the upper plastic is due to its material characteristics. As a result, its own compression performance is poor, and the first pole and the cover cannot produce a uniform extrusion force on the upper plastic as a whole, that is, during the use of the battery, the upper plastic cannot receive uniform compressive stress

Therefore, the contact area formed at the joint surface between the upper plastic and the cover sheet or the joint surface between the upper plastic and the first pole will be unstable (for example, with the effec

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

Login to View More

Abstract

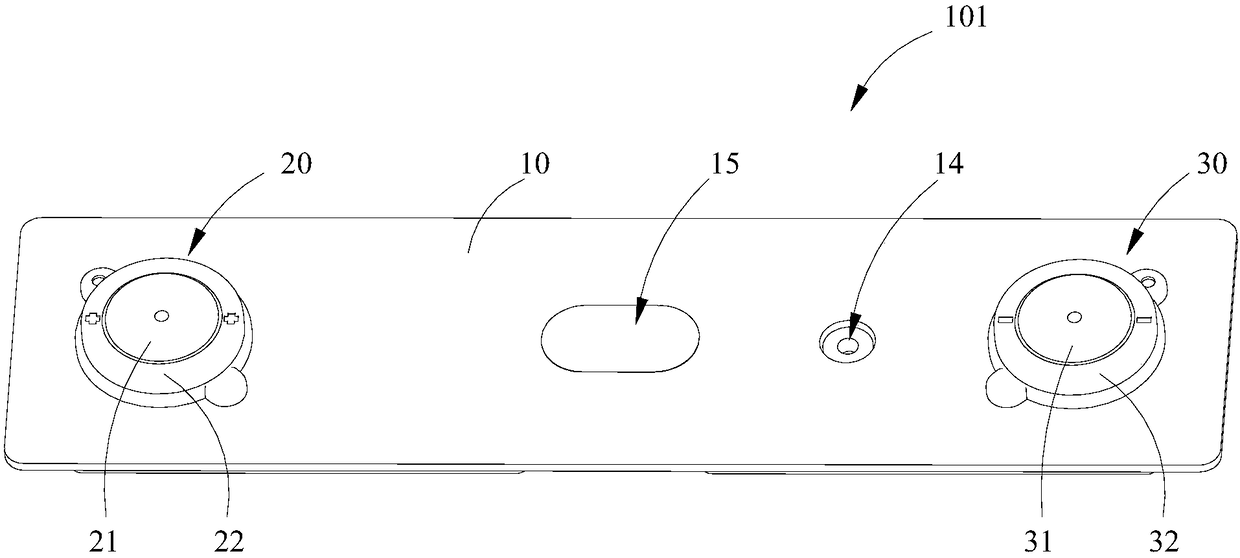

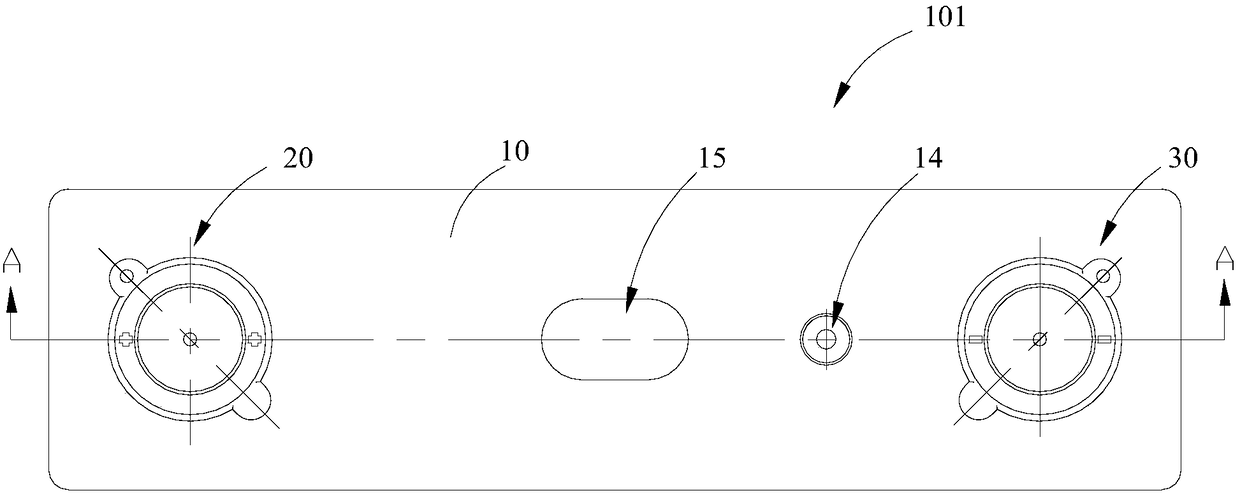

The invention provides a top cover assembly of a secondary battery, and the secondary battery. The top cover assembly of the secondary battery comprises: a top cover plate, which comprises a cover sheet that is provided with a first electrode leading-out hole; and a first pole assembly, which comprises a first pole and a conductive sealing ring, wherein the first pole is configured to pass throughthe first electrode leading-out hole, the conductive sealing ring surrounds the first pole, seals the first electrode leading-out hole and is in a compressed state, the first pole is electrically connected with the cover sheet through the conductive sealing ring, and the resistance of the conductive sealing ring is greater than the resistance of the first pole. According to the invention, the first pole and the cover sheet of the secondary battery can be electrically connected, and the resistance of a resistor arranged between and connected with the first pole and the cover sheet is always maintained stable, so the problem that instable resistance between the first pole and the cover sheet easily causes potential safety hazards like fires can be avoided.

Description

technical field [0001] The invention relates to the technical field of energy storage components, in particular to a top cover assembly of a secondary battery and the secondary battery. Background technique [0002] At present, in the field of power batteries, in order to ensure the safety of the battery during use, the battery cells are usually assembled with a hard shell, and the hard shell that houses the battery cells is generally made of metal materials. In order to ensure the safety of the secondary battery during use, a nail penetration test is usually required. However, if a metal is used to directly conduct the first pole and the shell, since the resistance value of the metal is generally in the milliohm level, the loop current formed when the battery is subjected to a nail penetration test will increase sharply, so it is easy to be damaged at the nail penetration place. Striking and causing fire and other safety hazards. And when the aluminum shell is used for as...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H01M2/04H01M2/08H01M2/06H01M50/147H01M50/172H01M50/176H01M50/184H01M50/188H01M50/193H01M50/198H01M50/55H01M50/553H01M50/567H01M50/593

CPCH01M2220/20H01M50/147H01M10/04H01M50/553H01M50/193H01M50/55H01M50/176H01M50/593H01M50/567H01M50/184H01M50/198H01M50/188Y02E60/10Y02P70/50H01M2200/20H01M50/152H01M50/325H01M50/578H01M50/3425H01M50/171

Inventor 郭志君孙名川王鹏朱涛声

Owner CONTEMPORARY AMPEREX TECH CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com