Patents

Literature

44results about How to "High compressive stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultrasonic rolling recombination laser remelting method for improving fatigue property of welded joint

InactiveCN106283038AReduce frictionReduce roughnessMetallic material coating processesSurface layerMaterials processing

The invention relates to an ultrasonic rolling recombination laser remelting method for improving the fatigue property of a welded joint, and belongs to the field of material processing and surface strengthening. The method comprises the following steps: first, the surface modification of the welded joint is performed according to the laser remelting technology, and then ultrasonic surface rolling treatment is performed. Compared with a pure ultrasonic surface rolling processing method, the ultrasonic rolling recombination laser remelting method has the advantages that not only can surface nanocrystallization and ultra-low roughness of the welded joint be realized, but also the welded joint structure can be improved, welding defects can be eliminated, and the depth of a modified surface layer can be deepened, so that the fatigue strength of the welded joint is greatly improved.

Owner:JILIN UNIV

Heat treatment method for down-the-hole drill bit of high-wind pressure drilling tool, and drill bit

ActiveCN102703911AImprove toughness and plasticityHigh surface hardnessSolid state diffusion coatingFurnace typesNumerical controlHardness

The invention relates to a heat treatment method for a down-the-hole drill bit of a high-wind pressure drilling tool. The method comprises the following steps: heating the original down-the-hole drill bit to 750-850 DEG C for forging and beating, forming and die forging, conducting air cooling after heating at 900-950 DEG C for four hours to five hours, conducting furnace cooling to be lower than 200 DEG C after heating at 650-700 DEG C for four hours to five hours, carrying out numerical control machining according to size requirement, conducting carburization treatment at 900-950 DEG C, then conducting high-temperature tempering to the carburization treatment, machining, and conducting isothermal quenching at 850-900 DEG C. The invention further relates to a down-the-hole drill bit of the high-wind pressure drilling tool, which is manufactured by the heat treatment method. The down-the-hole drill bit is subjected to mechanical treatment after being heated and cooled for many times, so that the toughness and plasticity of the down-the-hole drill bit can be greatly improved, the surface hardness and compression stress of the down-the-hole drill bit can also be enhanced, and the fatigue resistance strength and the wear resistance of threads can be improved.

Owner:CHANGSHA HEIJINGANG IND CO LTD

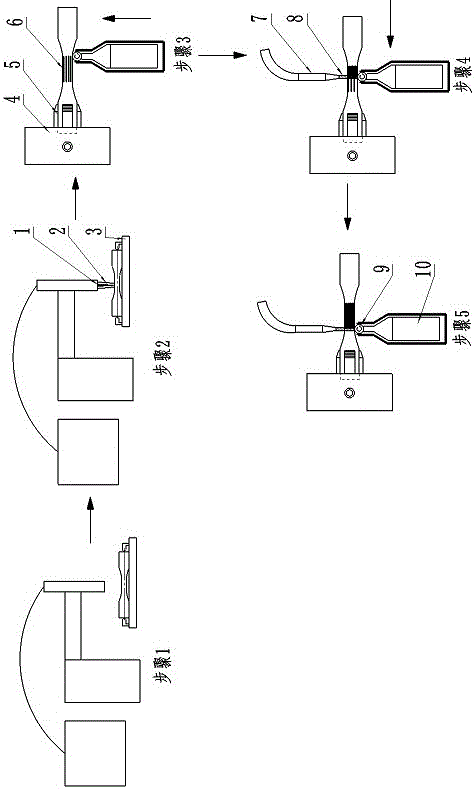

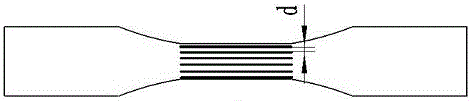

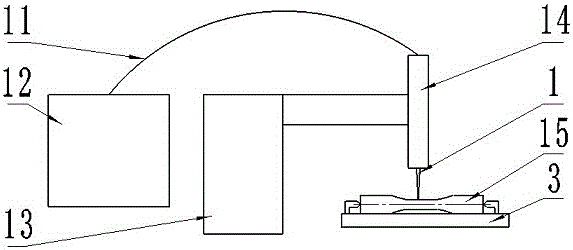

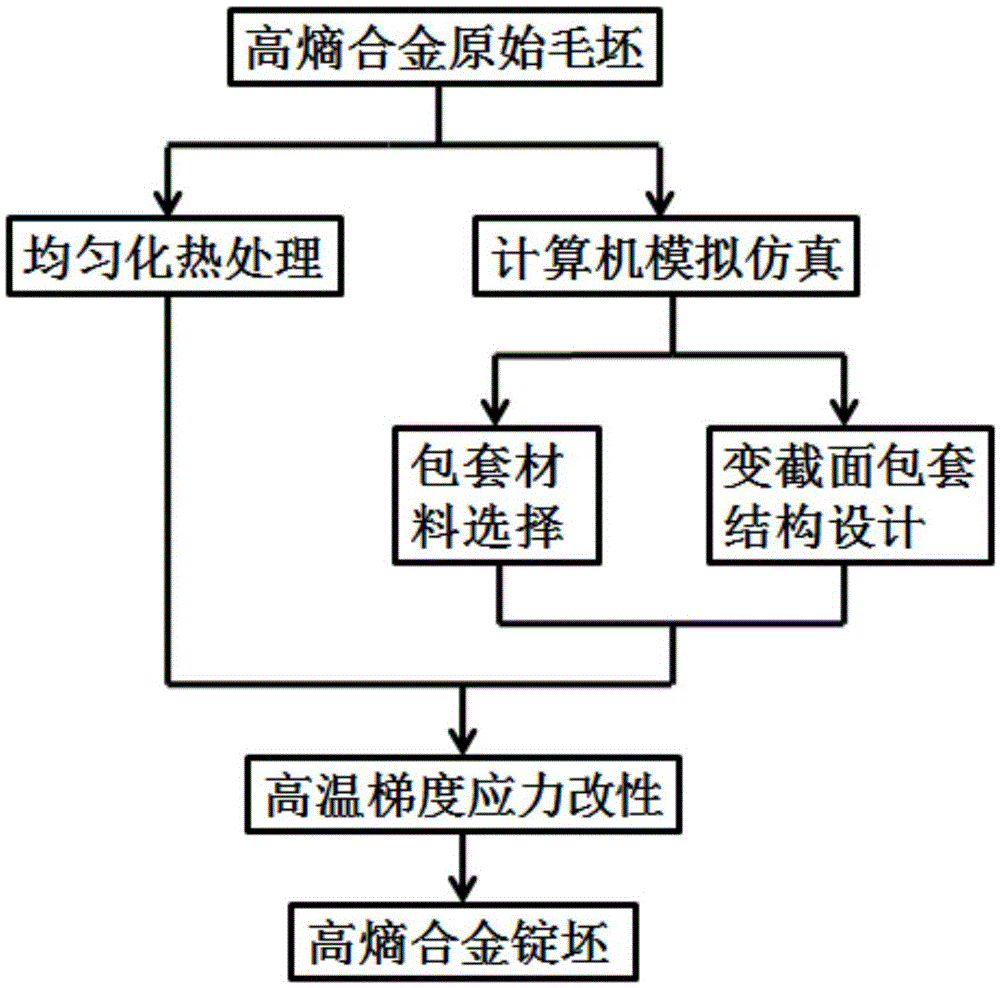

High-entropy alloy gradient stress modification technology

InactiveCN105543749AUniform and excellent tissue performanceEasy to useFine structureHigh entropy alloys

The invention relates to a gradient stress plasticity modification method which specially aims at damage control and fine structure regulation of high-entropy alloy material characteristics. The purpose of the method is to solve the problems that a high-entropy alloy casting state structure is mainly composed of bulky pine-tree crystals, and the comprehensive mechanical property of the high-entropy alloy casting state structure is poor. A preparation method mainly comprises the steps that a high-entropy alloy ingot is prepared; homogenization heat treatment, analogue simulation and canned forging are conducted; and a high-entropy alloy ingot blank is obtained. When the high-entropy alloy ingot is processed, preset variable cross-section canning is mainly adopted, the stress state of the interior of a high-entropy alloy material in the process is effectively controlled, and the gradient three-way compressive stress combined with deformation characteristics is formed. By means of the gradient stress plasticity modification method, initiation and propagation of microcracks induced by lattice distortion can be effectively inhibited finally, crystalline grains are refined, the comprehensive mechanical property is improved, and effective modification of the high-entropy alloy is achieved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

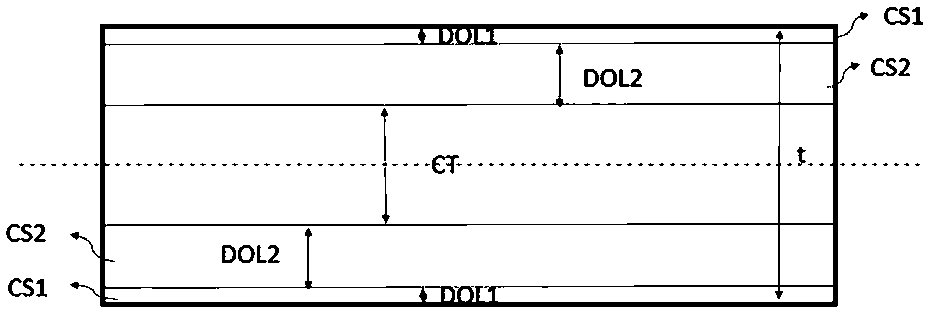

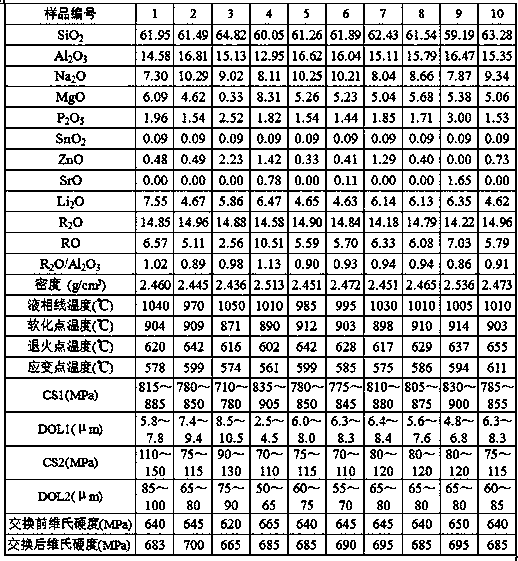

Lithium-aluminum-containing silicate glass capable of rapidly exchanging ions

InactiveCN108585481AHigh Vickers hardness valueImprove the ability to resist external damageGlass tempering apparatusLithiumSilicate glass

The invention belongs to the field of glass materials, and particularly relates to lithium-aluminum-containing silicate glass capable of rapidly exchanging ions. The glass comprises, in mole percent,58-68% of SiO2, 12-18% of Al2O3, 4-8% of Li2O, 7-11% of Na2O, 0.1-8% of MgO, 0-3% of ZnO, 0-2% of SrO, 1-4% of P2O5 and 0-0.5% of SnO2, wherein R2O / Al2O3 <= 1.2, 2.5 <=RO<= 11, the RO is summation ofdivalent cation oxides in the lithium-aluminum-containing silicate glass, and the R2O is summation of monovalent cation oxides in the lithium-aluminum-containing silicate glass. According to the glass, lithium and phosphorus components are simultaneously introduced into the glass, the content of sodium in the glass is reasonably controlled, and the depths of high-ionic exchanging layers can be rapidly exchanged, so that the scratch resistance of the glass is improved.

Owner:KORNERSTONE MATERIALS TECH

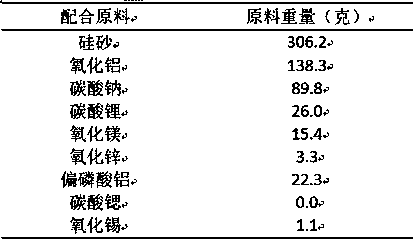

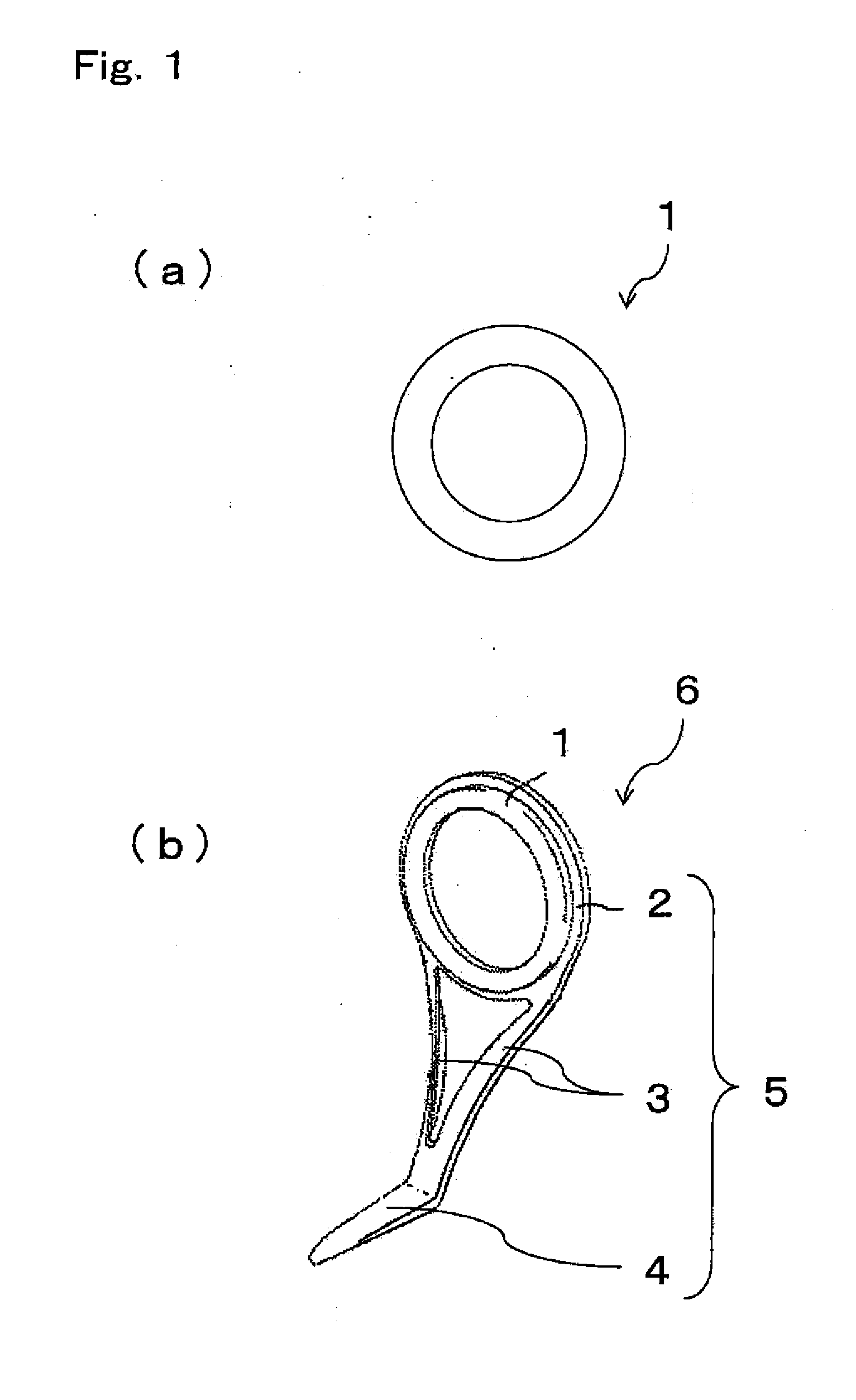

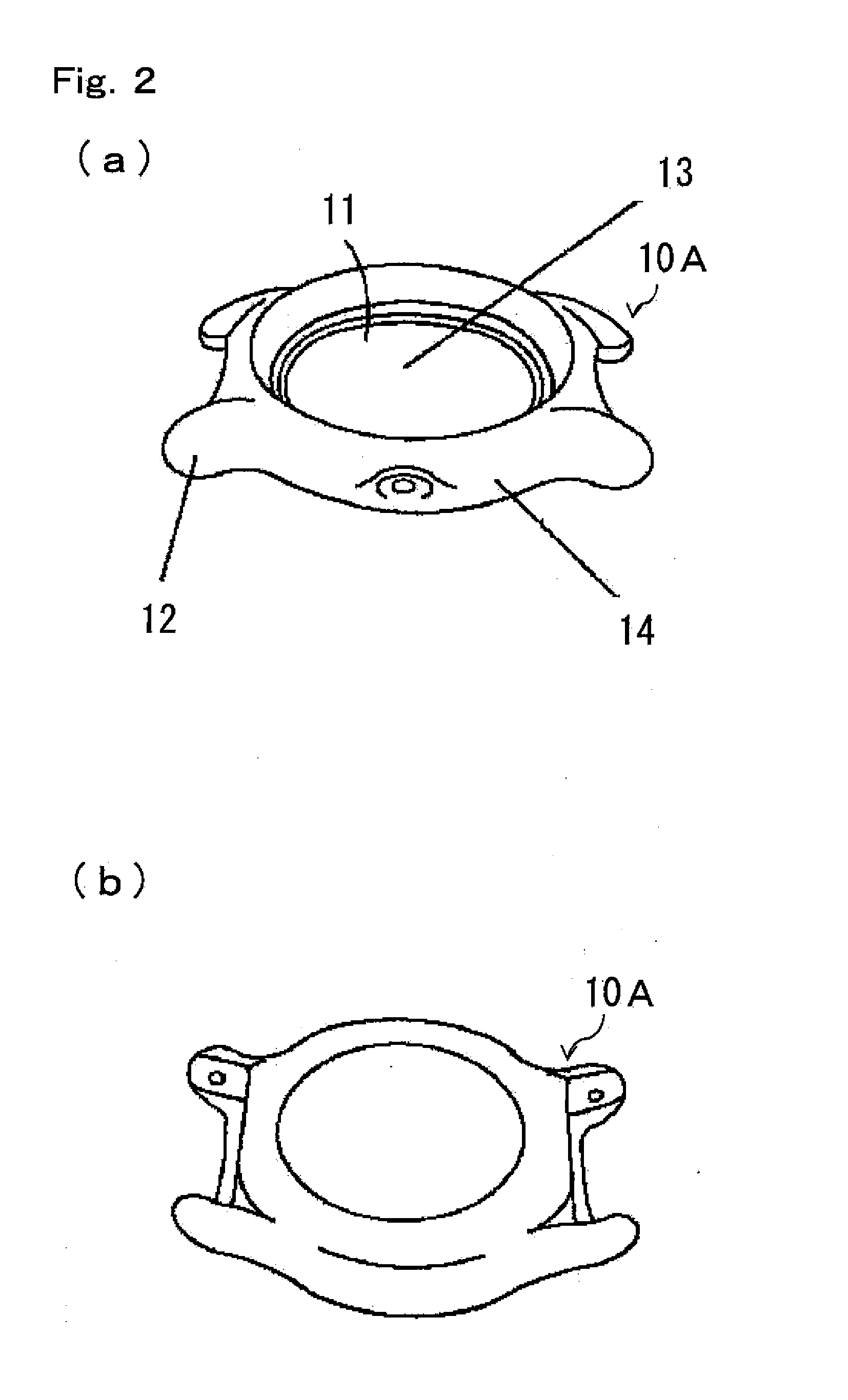

Ceramic for Decorative Part and Decorative Part Comprising the Same

InactiveUS20110104404A1High compressive stressImprove wear resistanceRodsClockwork casesCeramicCrystallite

A ceramic for decorative parts is provided which has excellent wearing resistance and can retain over long a gold color tone capable of giving a high-grade feeling, a feeling of aesthetic satisfaction, and spiritual comfortableness. Also provided is a decorative part comprising the ceramic. The ceramic for a decorative part is characterized by comprising 50 mass % or more titanium nitride, 6 mass % or more and 30 mass % or less unstabilized zirconia containing substantially no stabilizer, and nickel, the unstabilized zirconia having a crystal grain size smaller than the crystal grain size of the titanium nitride.

Owner:KYOCERA CORP

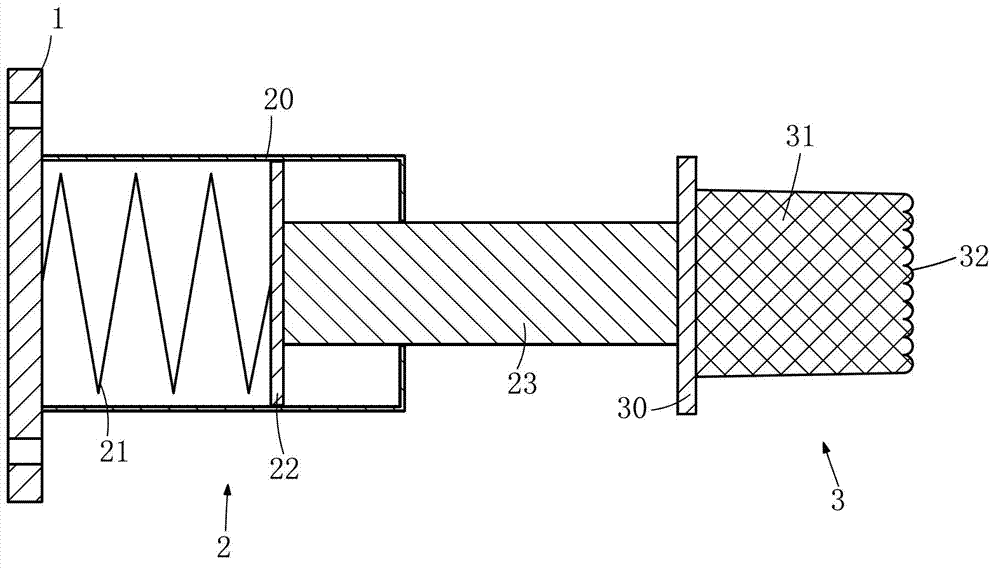

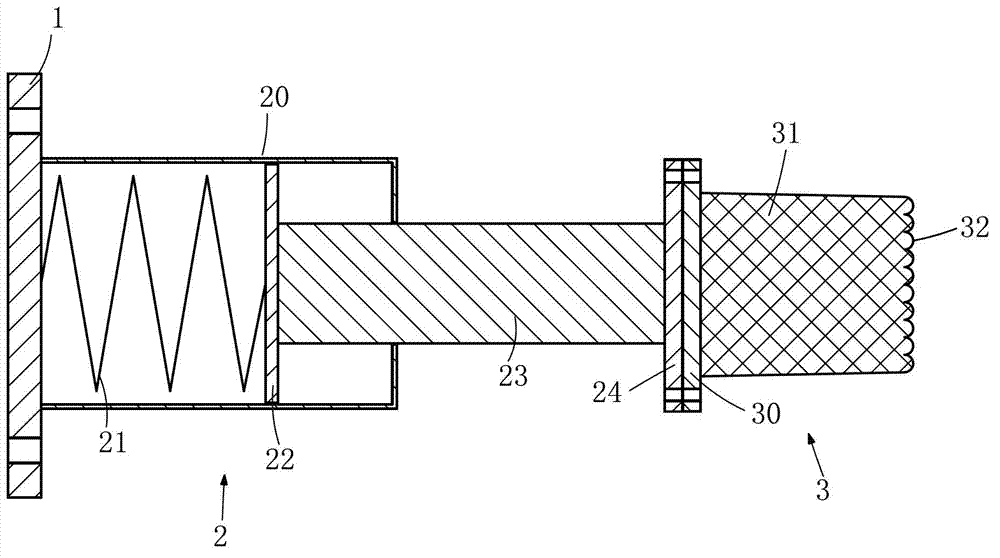

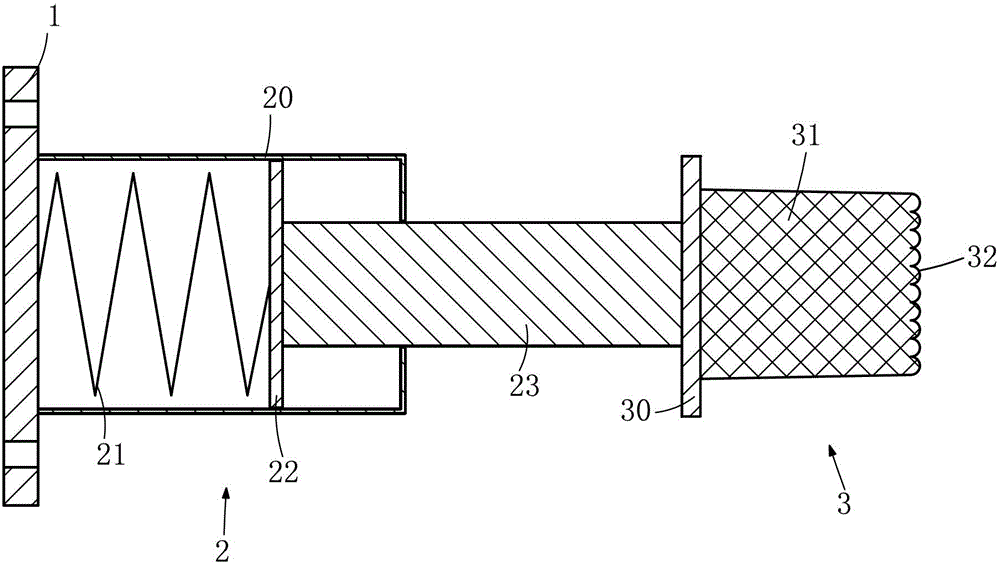

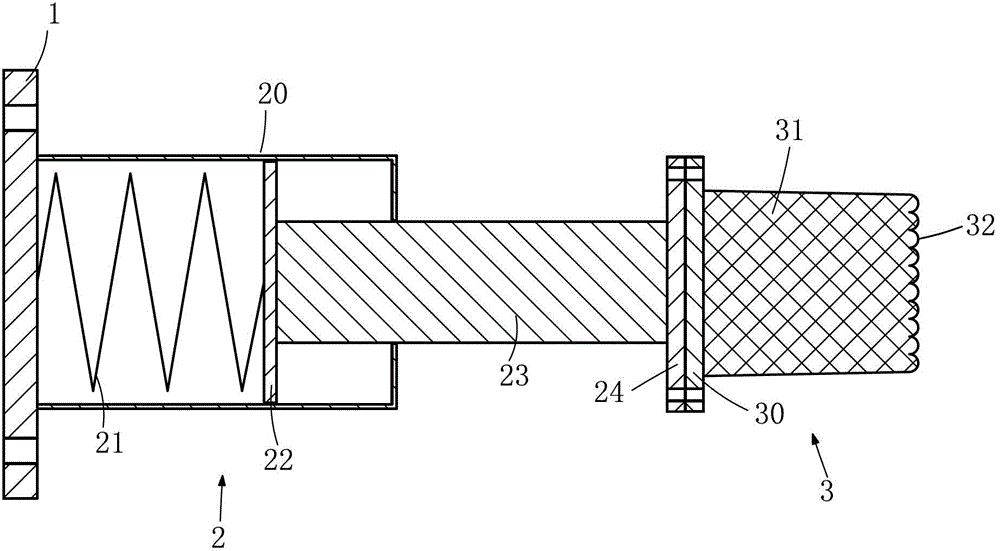

Composite buffer for crane

ActiveCN102730555AMeet the requirements of cushioning performancePlay a buffer roleShock absorbersRunwaysEngineeringPiston rod

The invention discloses a composite buffer for a crane and relates to the technical field of buffer equipment. The composite buffer comprises a base, wherein a primary buffer device is arranged on the base and comprises a shell which is fixed on the base; a spring is arranged in the shell; one end of the spring is fixed on the base, and the other end of the spring is connected with a piston; the other side of the piston is provided with a piston rod; one end of the piston rod penetrates out of the shell; the composite buffer also comprises a secondary buffer device; and the secondary buffer device is connected with one end of the piston rod which is exposed out of the shell. According to the composite buffer for the crane, the requirement of a large-tonnage crane on the buffer performance can be met, and the composite buffer is small in size, low in production cost, long in service life, wide in application range and suitable for popularization and application, can replace various buffers of different specifications and is an innovative product in the field.

Owner:昌乐县东田聚氨酯厂

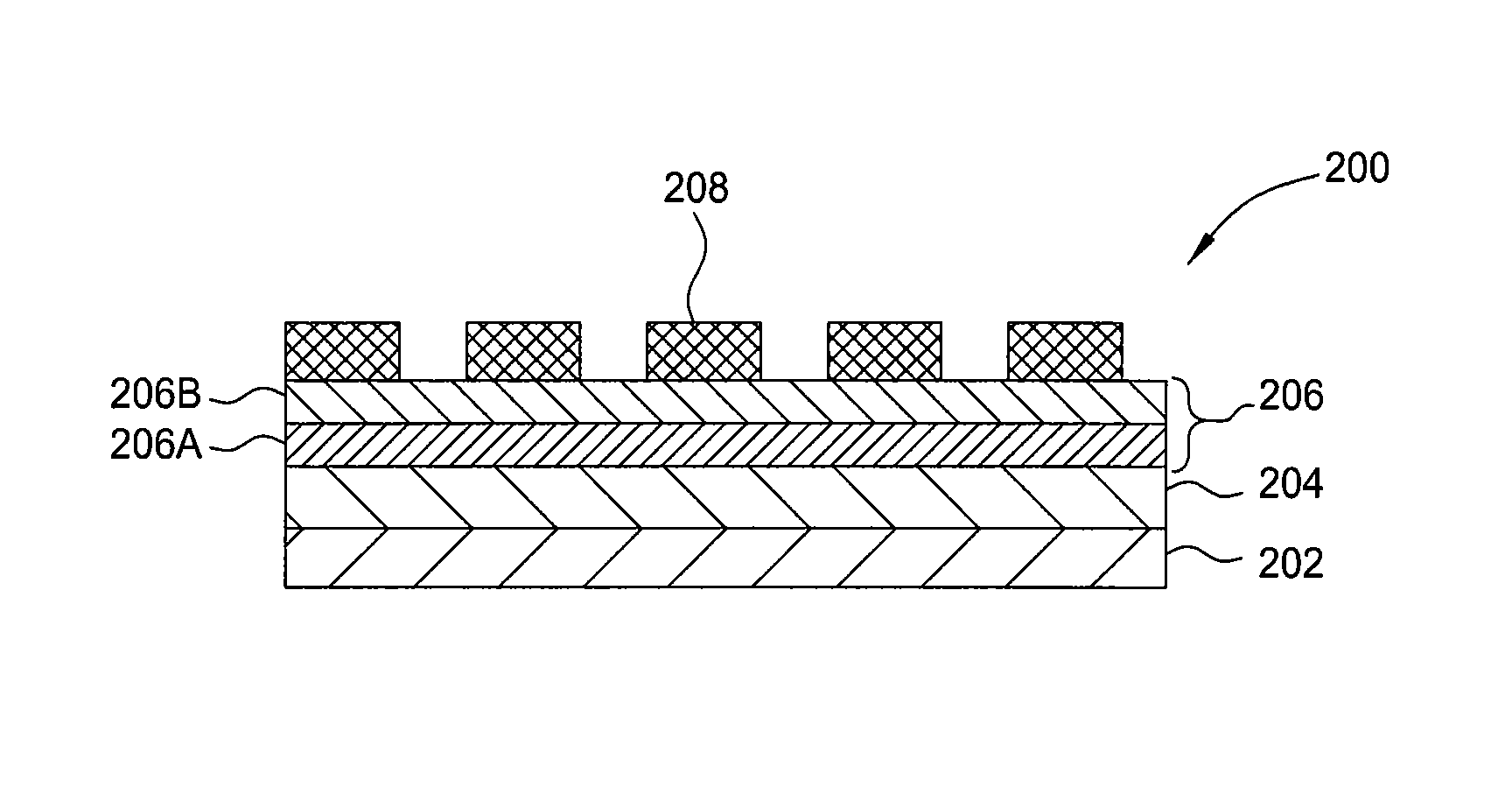

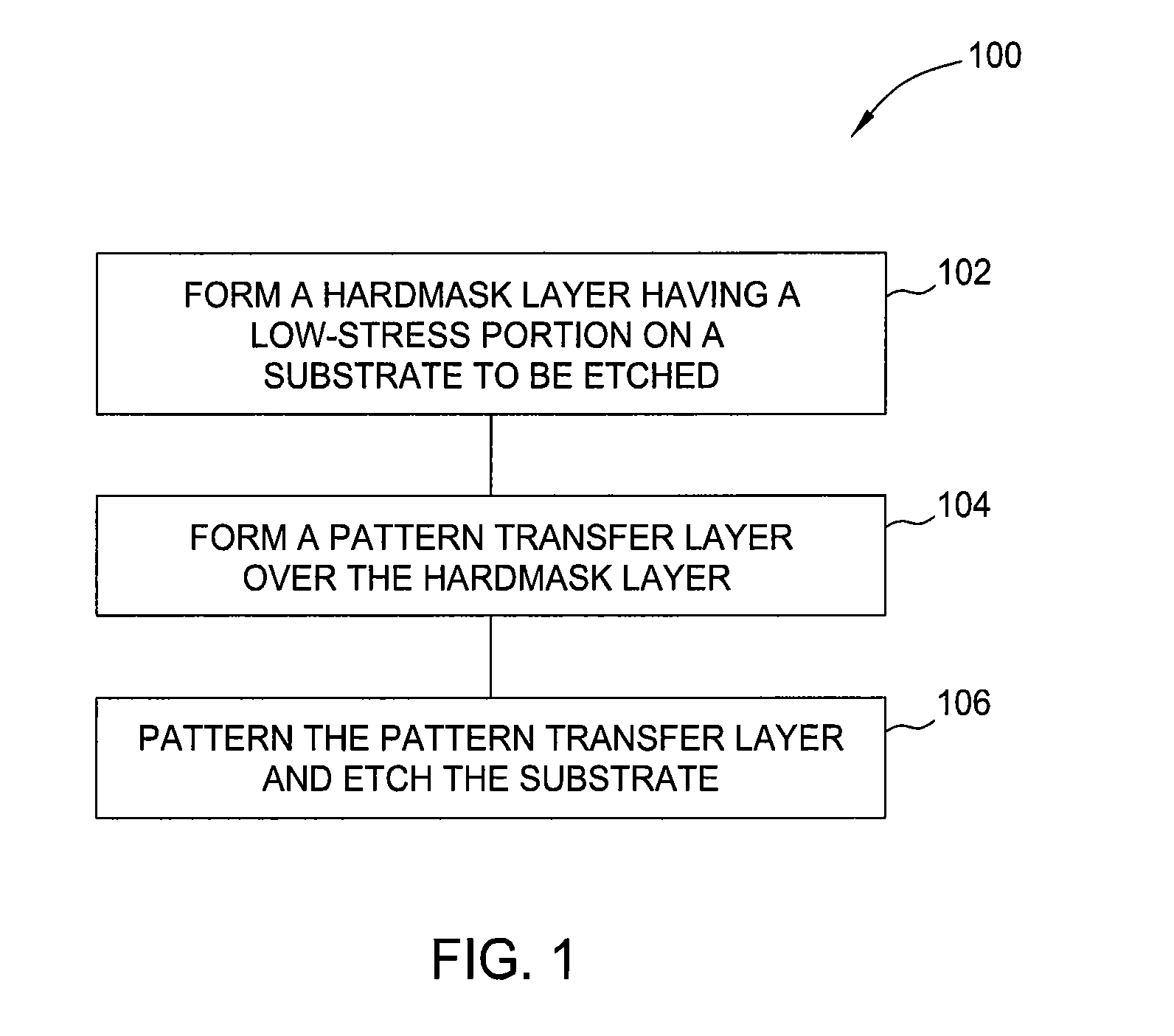

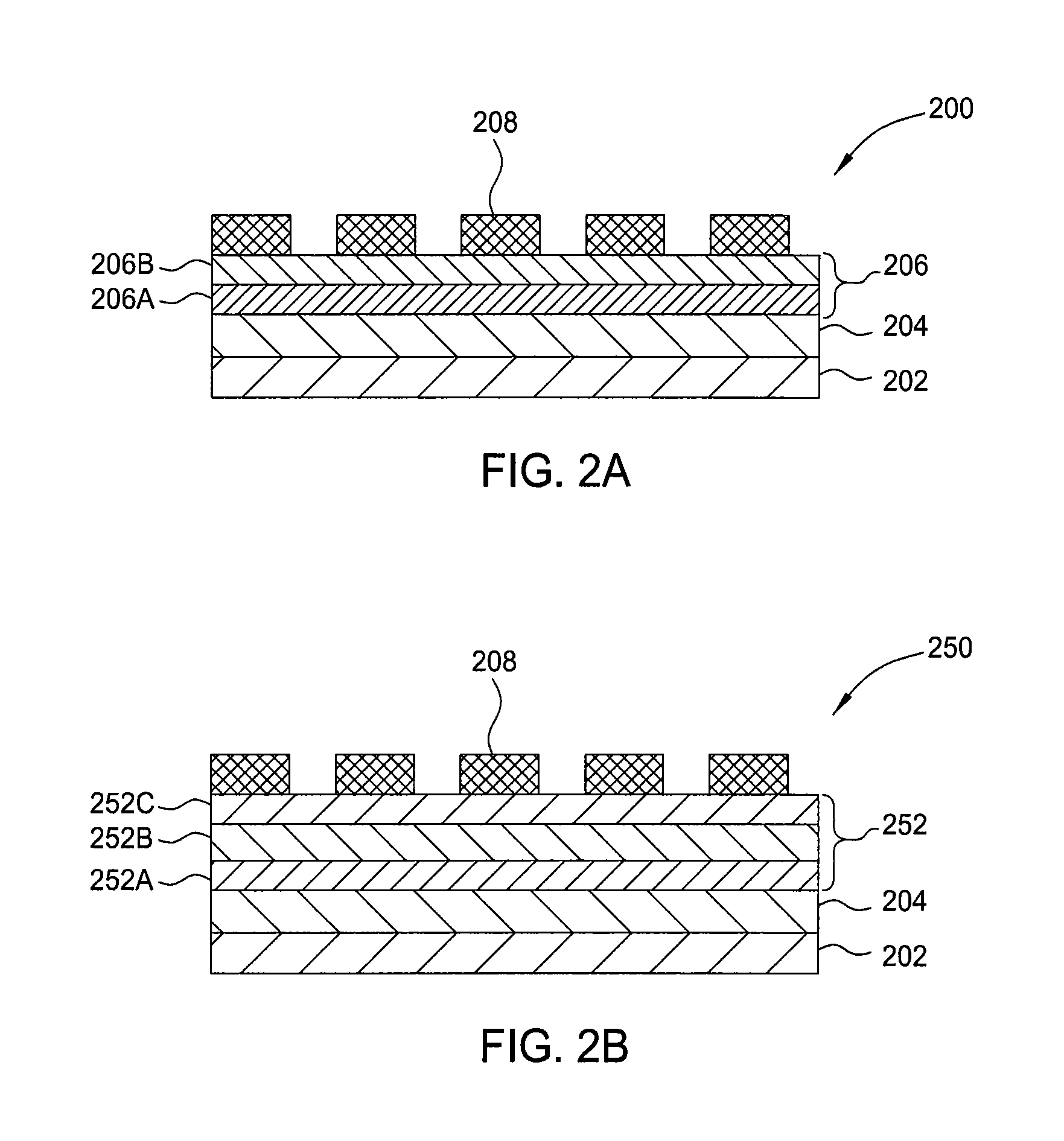

Composite removable hardmask

ActiveUS8252699B2Reduce compressive stressHigh compressive stressSemiconductor/solid-state device manufacturingPlasma techniqueStress levelDilution ratio

A method and apparatus for forming an amorphous carbon layer on a substrate is provided. A first portion of the amorphous carbon layer having a high stress level is formed from a hydrocarbon precursor having high dilution ratio, with optional amine precursor included to add stress-elevating nitrogen. A second portion of the amorphous carbon layer having a low stress level is formed on the first portion by reducing the dilution ratio of the hydrocarbon precursor and lowering or eliminating the amine gas. Pressure, temperature, and RF power input may be adjusted instead of, or in addition to, precursor flow rates, and different precursors may be used for different stress levels.

Owner:APPLIED MATERIALS INC

Rectangular spherical hinge adjusting gradient laminated rubber bearing for highway bridge

InactiveCN102677586ASimple structureEasy to manufactureBridge structural detailsBridge materialsSheet steelSteel ball

The invention discloses a rectangular spherical hinge adjusting gradient laminated rubber bearing for a highway bridge, which comprises a concrete bearing cushion and further comprises an concave arc steel plate and a bearing main body, wherein the concave arc steel plate is arranged in a beam; the bearing main body is arranged on the concrete bearing cushion; a steel spherical crown cylinder station is arranged at the top of the bearing main body; the top of the a steel spherical crown cylinder station is provided with a a steel spherical crown; and the spherical crown surface of the steel spherical crown is in fit with the concave arc surface of the concave arc steel plate. A steel plate can be arranged between the bearing main body and the concrete bearing cushion; a stainless steel plate is arranged between the steel plate and the bearing main body; and a polytetrafluoroethylene board is arranged between the stainless steel plate and the bearing main body. The rectangular spherical hinge adjusting gradient laminated rubber bearing for the highway bridge has a simple structure, is easy to manufacture and can be directly installed according to the longitudinal and transverse gradient requirements of the bridge, so that a leveling structure between the bearing and a beam body is omitted, the stress of the bearing is improved, the bearing is stressed in a balance mode, the bridge design is also simplified, the rectangular spherical hinge adjusting gradient laminated rubber bearing is convenient to install and replace and the bearing can be well suitable for the longitudinal and transverse gradients of the bridge.

Owner:CCCC SECOND HIGHWAY CONSULTANTS CO LTD

High-strength pressure resisting glass vessel and preparation method

ActiveCN108298825AImprove physical and chemical propertiesHigh mechanical strengthGlass vesselMixed materials

The invention discloses a high-strength pressure resisting glass vessel. The high-strength pressure resisting glass vessel is prepared from the following raw materials in parts by weight: 60 to 65 parts of quartz sand powder, 1 to 3 parts of alumina whisker, 0.1 to 0.3 part of borax, 0.1 to 1 part of zinc chloride, 1 to 5 parts of sodium silicate, 2 to 5 parts of feldspar, 3 to 8 parts of calciumcarbonate whisker, 2 to 5 parts of calcium sulfate whisker and 2 to 3 parts of silicon carbide whisker. A preparation method of the high-strength pressure resisting glass vessel comprises the following steps: firstly, weighing raw materials according to the weight ratio, crushing, sieving, stirring and mixing to obtain a mixed material; secondly, putting the mixed material in the first step into asmelting furnace and insulating to obtain a glass melt solution; thirdly, feeding the melt solution in the second step into a forming machine for forming to obtain glass vessels with different specifications and shapes; fourthly, putting the glass vessel in the third step into a continuous annealing furnace, annealing for 40 to 60 minutes, carrying out polishing treatment on a product after annealing is finished and obtaining a finished product after the polishing treatment is ended.

Owner:安徽晶晶玻璃制品有限公司

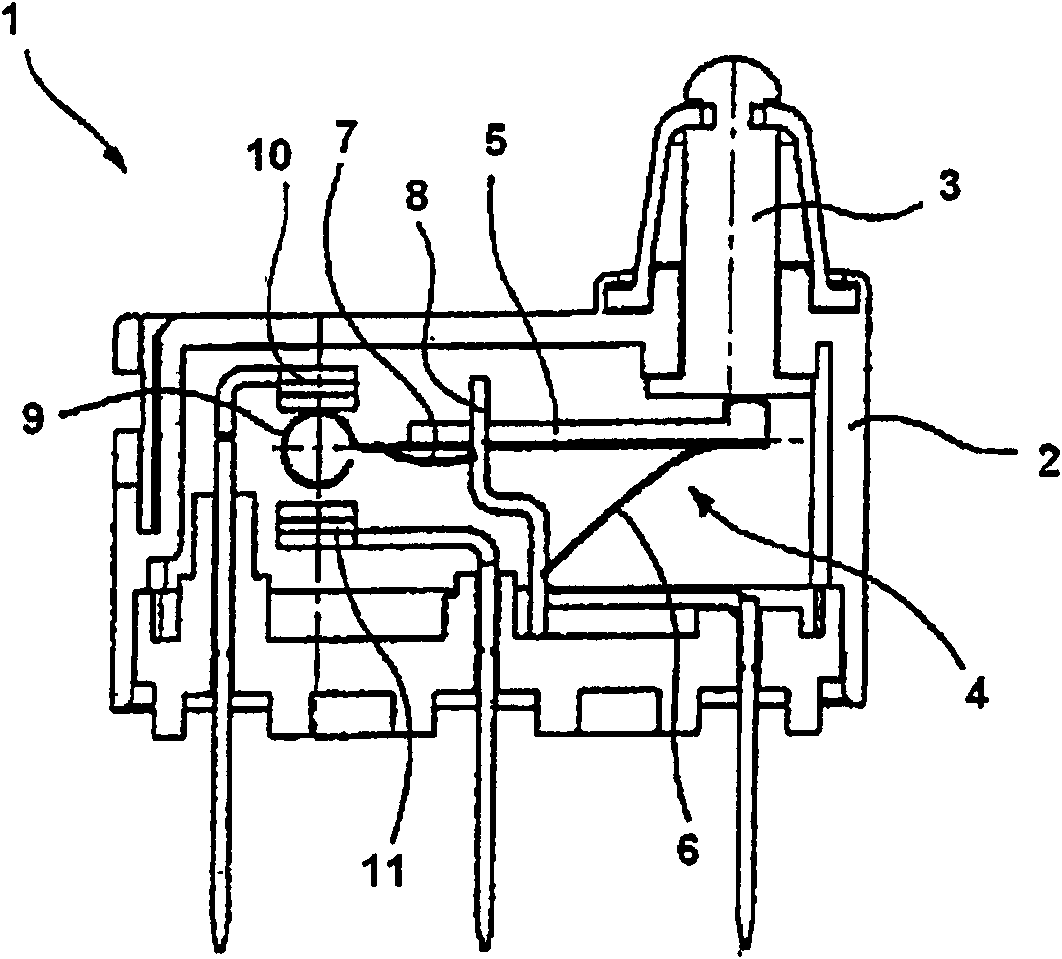

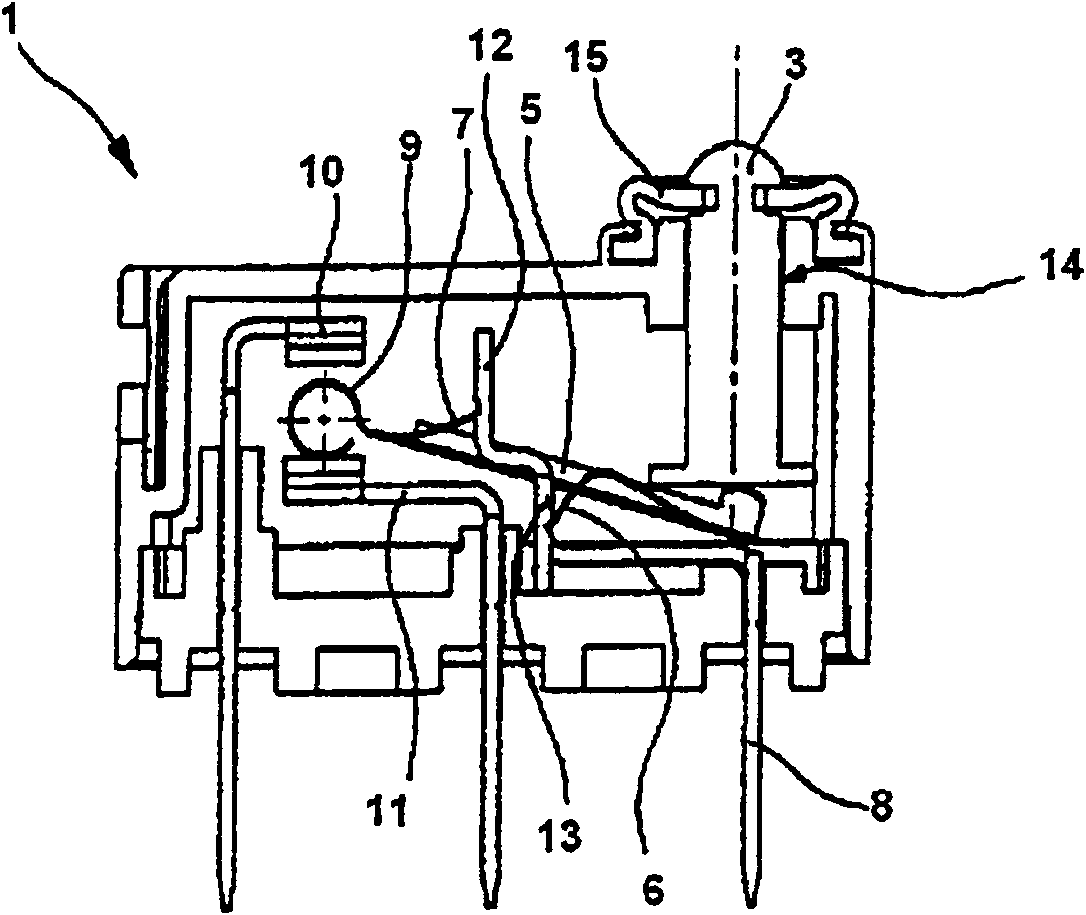

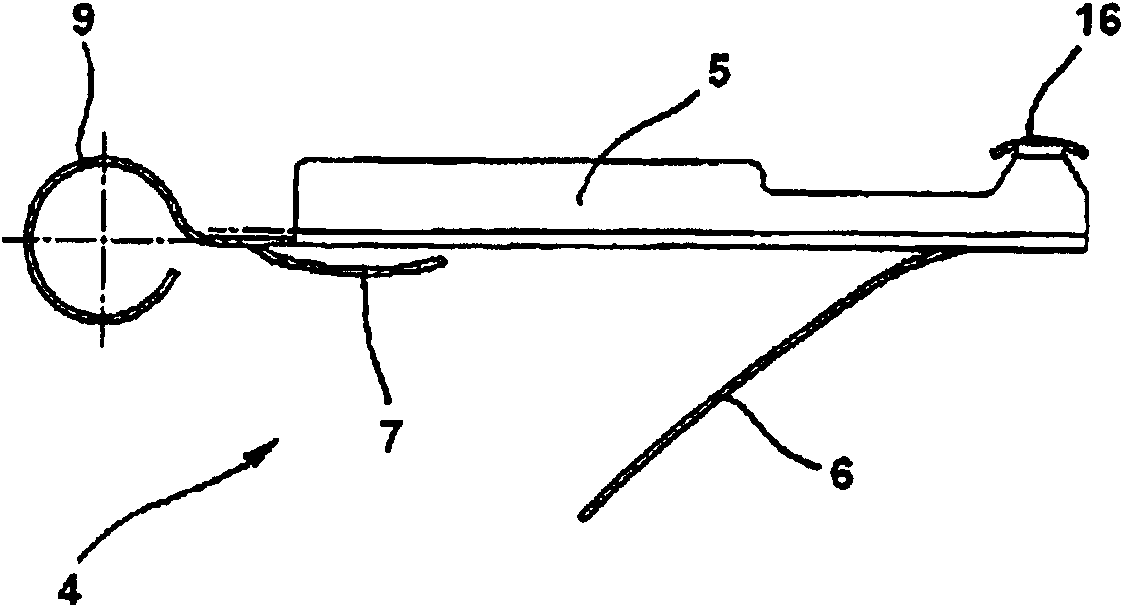

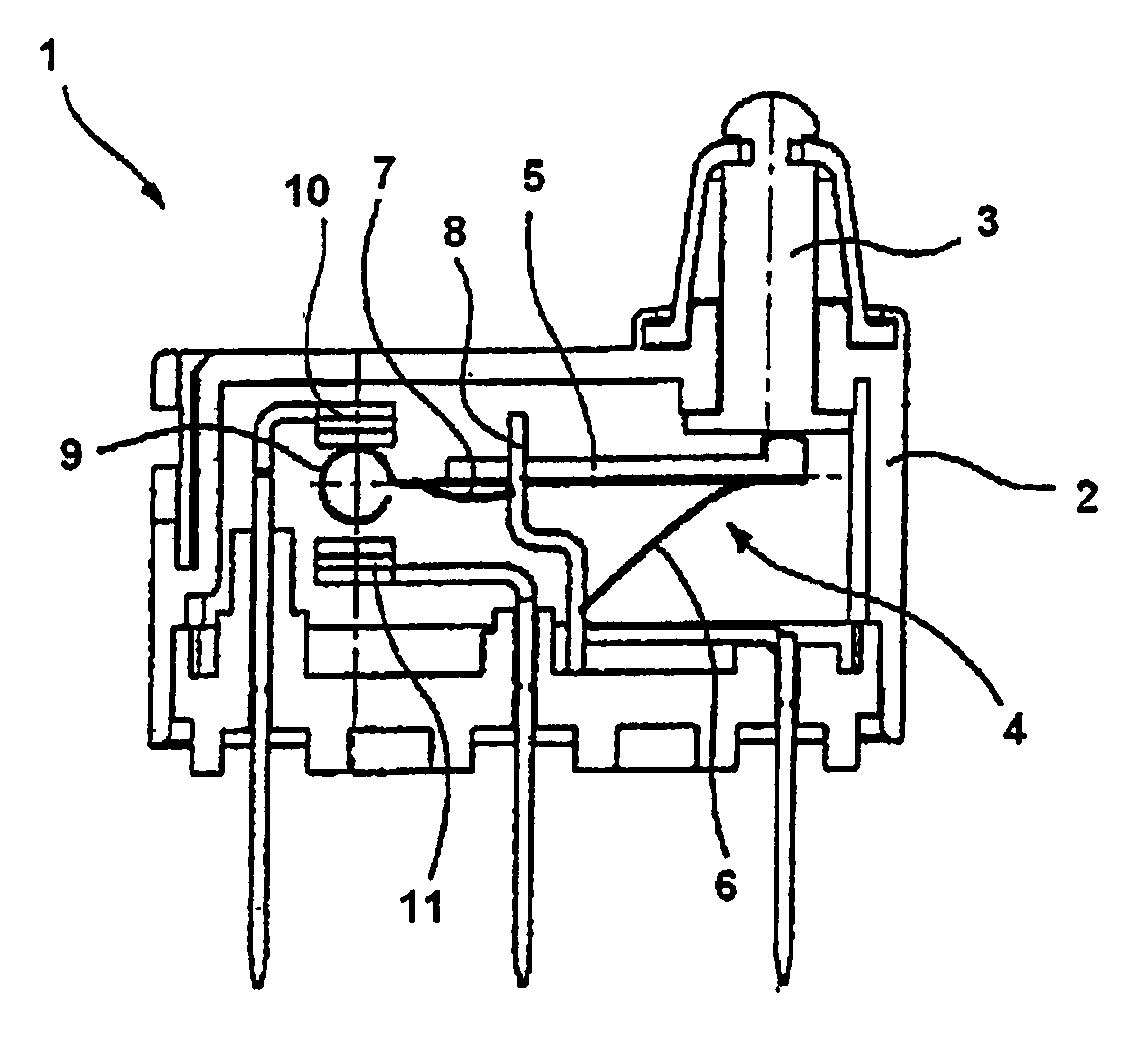

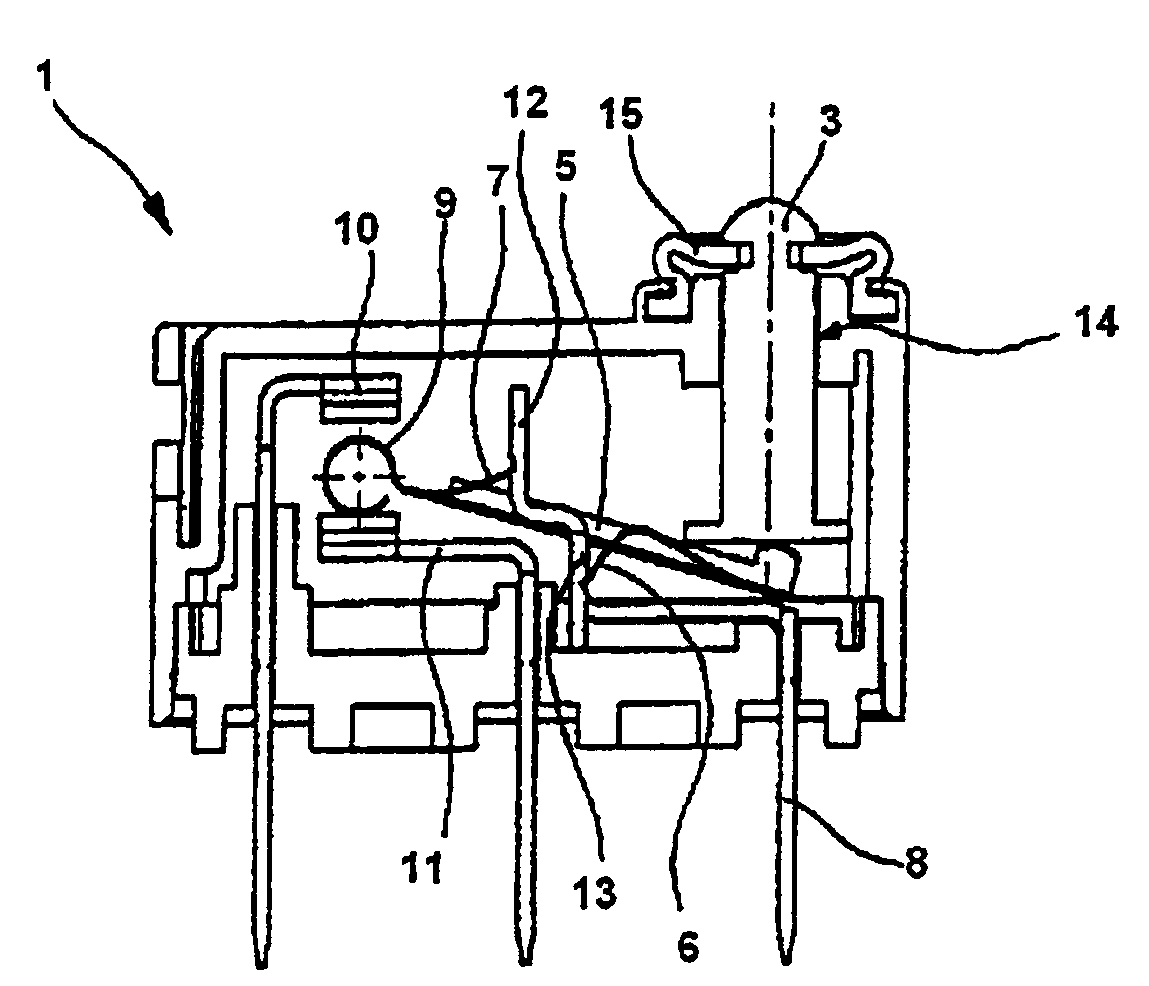

Microswitch

InactiveCN101685719APersistent steady stateImprove durabilitySnap-action arrangementsEngineeringControl switch

The present invention relates to a microswitch. In an electric switch, preferably a microswitch, the switch is provided with at least one contact spring transferred into different switching positionsby an actuating element and arranged at an anchor formed as an electrical contact. The contact spring has a closed spring frame; two spring tongues which are easy to bend and extend to opposite directions are fixed on the spring frame. A first spring tongue is formed as a resetting unit for the actuating element. A second spring tongue controls switching functions of a contact region of the springs. The tongues are engaged at surface regions of the anchor in a supporting manner such that the springs exhibit stable position during actuation.

Owner:JOHNSON ELECTRIC OLDENBURG

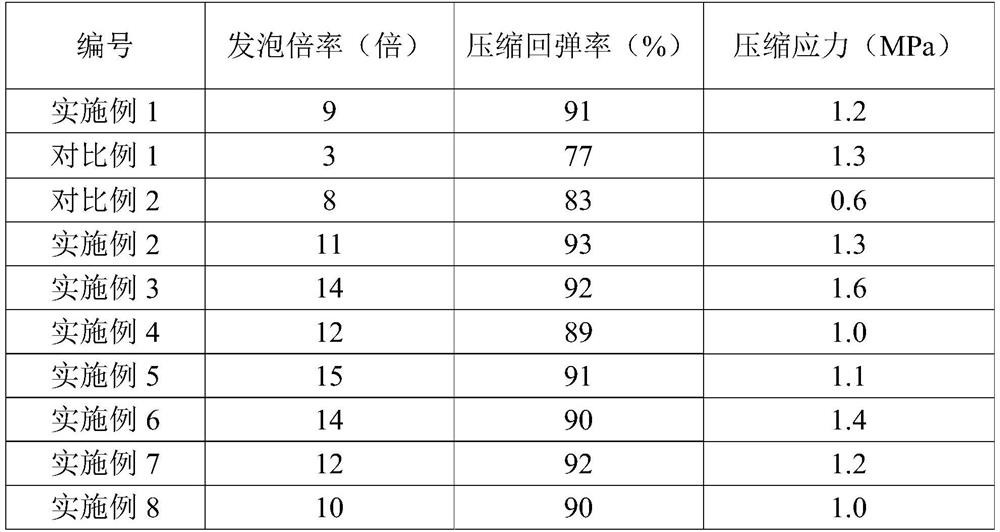

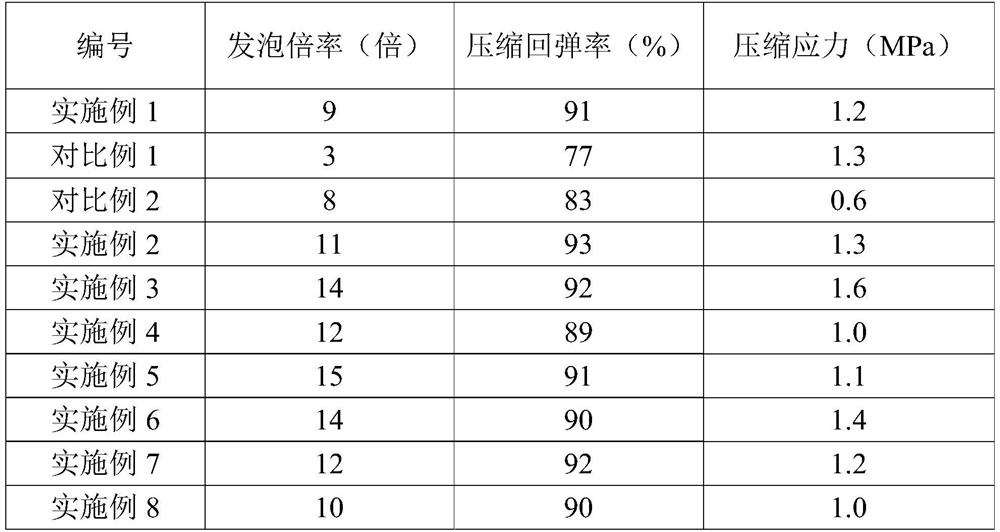

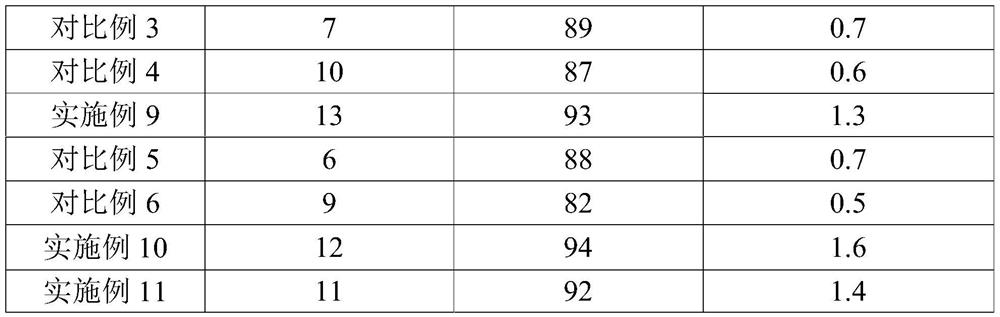

Fiber-reinforced polypropylene composition, foamed polypropylene composite material and preparation method of foamed polypropylene composite material

The invention relates to the field of modified polypropylene, and discloses a fiber-reinforced polypropylene composition, a foamed polypropylene composite material and a preparation method of the foamed polypropylene composite material. The fiber-reinforced polypropylene composition contains polypropylene, a polypropylene modifier, glass fibers, a foaming agent and a compatilizer. The preparation method of the polypropylene modifier comprises the following steps of: contacting the polar monomer grafted polypropylene in a composition I or a composition II with a component A for reaction, and extruding and granulating. The fiber-reinforced polypropylene composition provided by the invention can be used for preparing a foamed polypropylene composite material with higher foaming ratio, and the prepared foamed polypropylene composite material simultaneously has higher compression resilience and compression stress, namely has excellent compression performance, and can be used as a buffer material.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

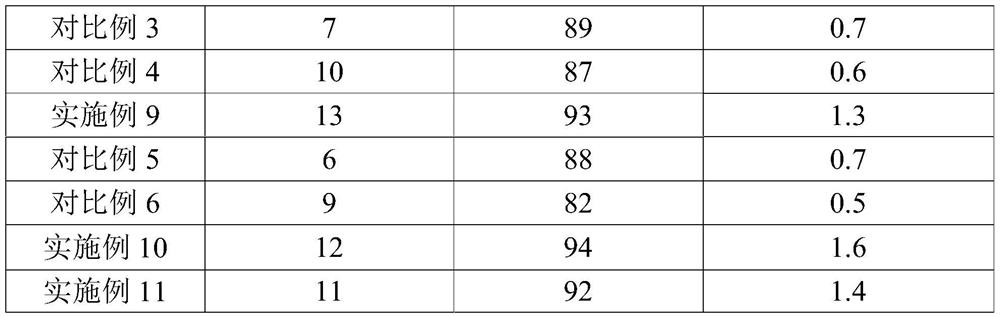

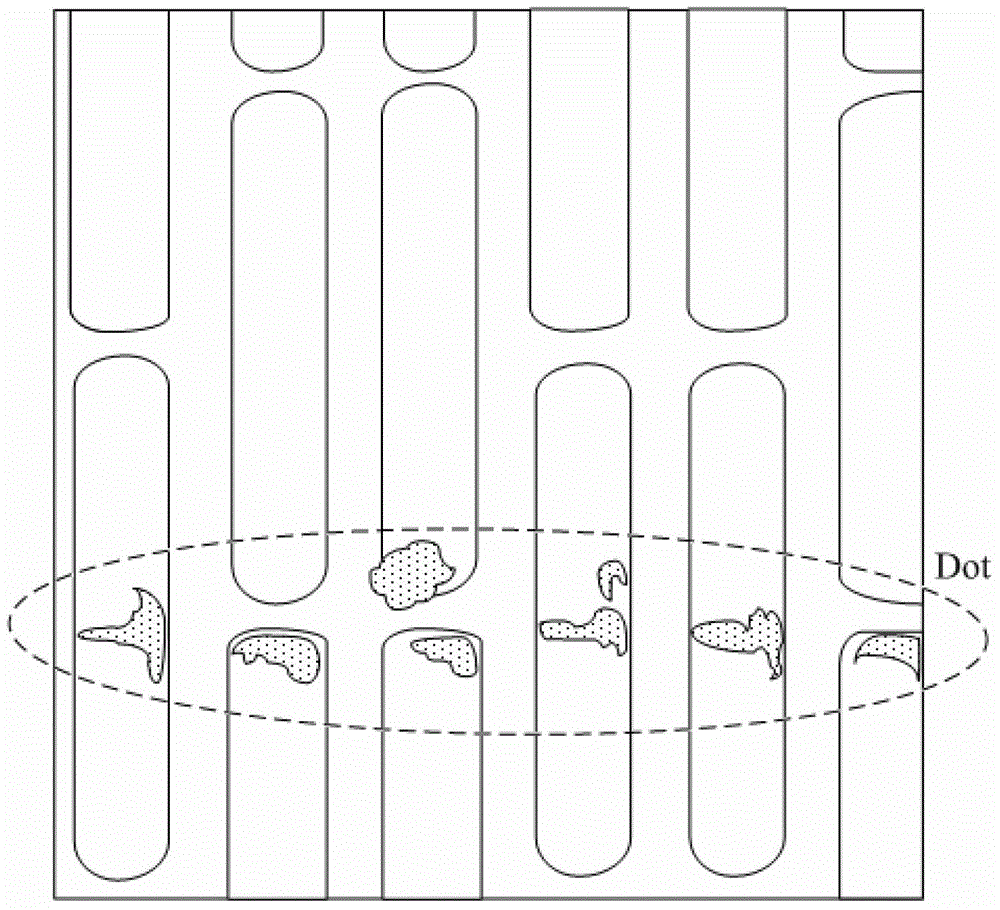

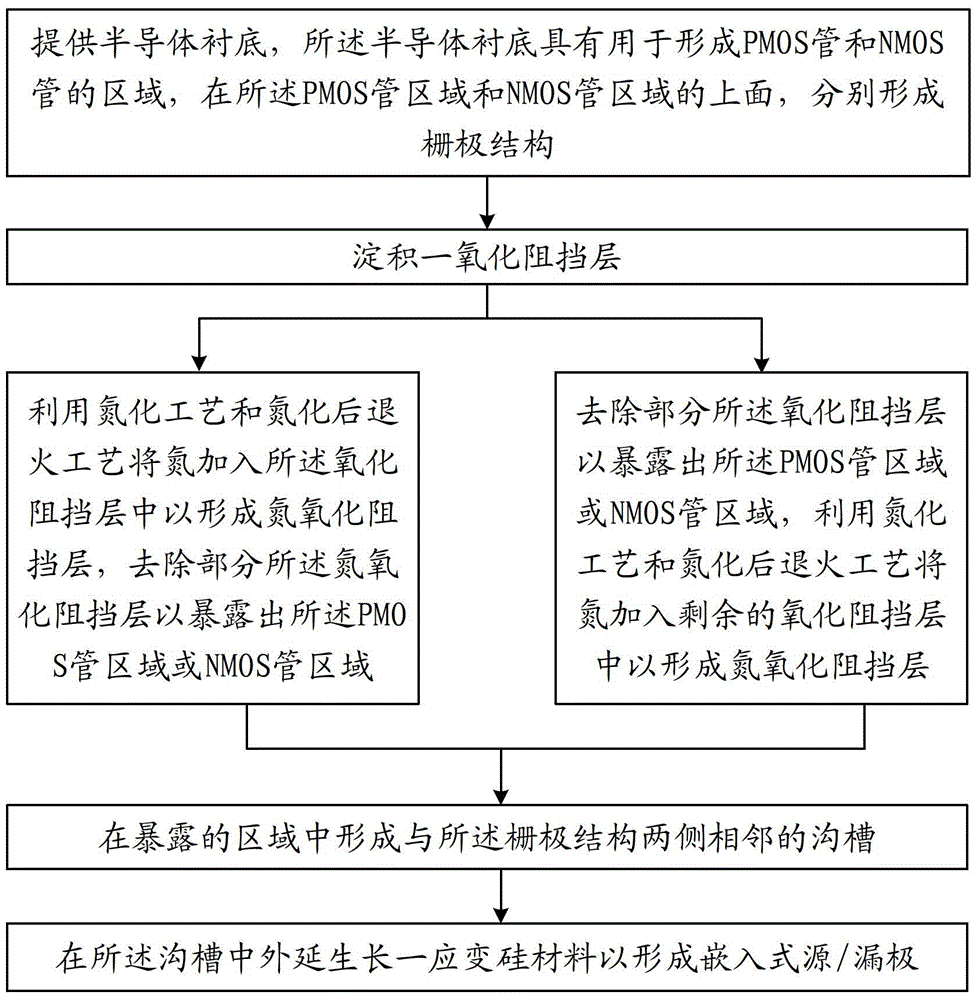

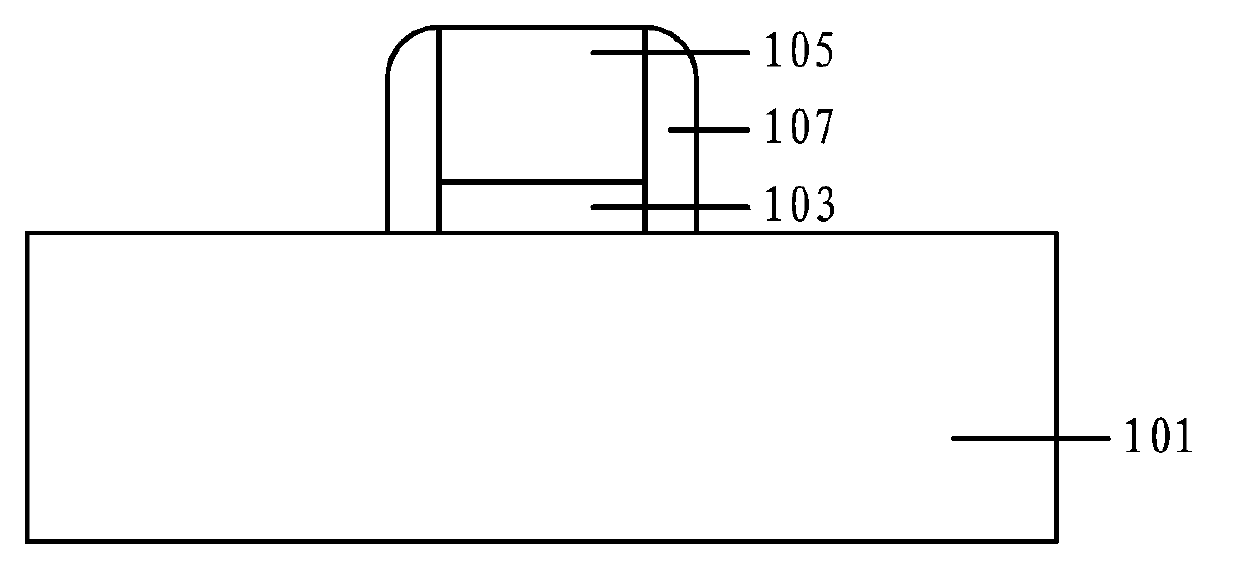

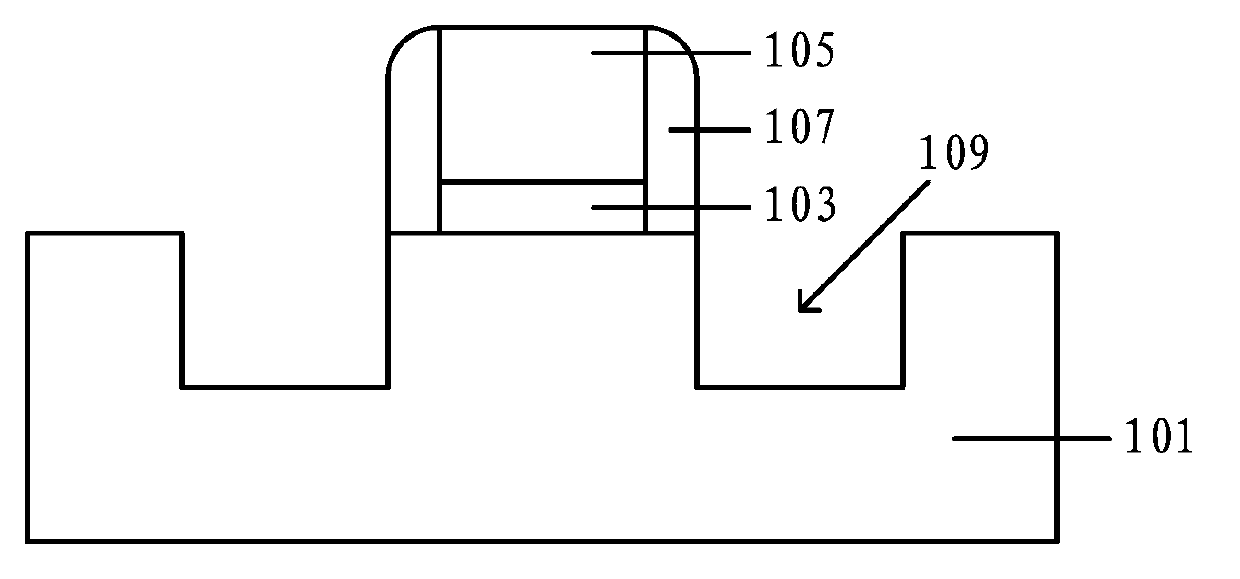

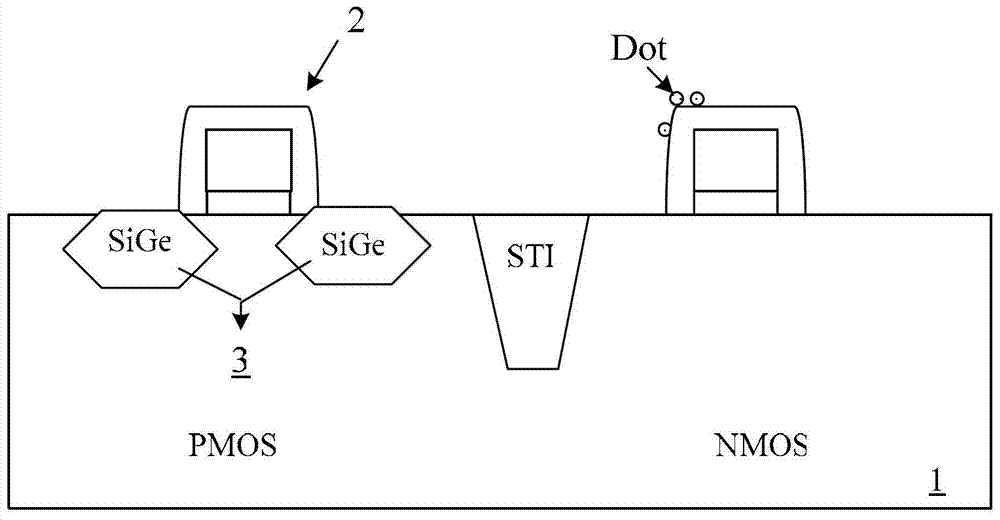

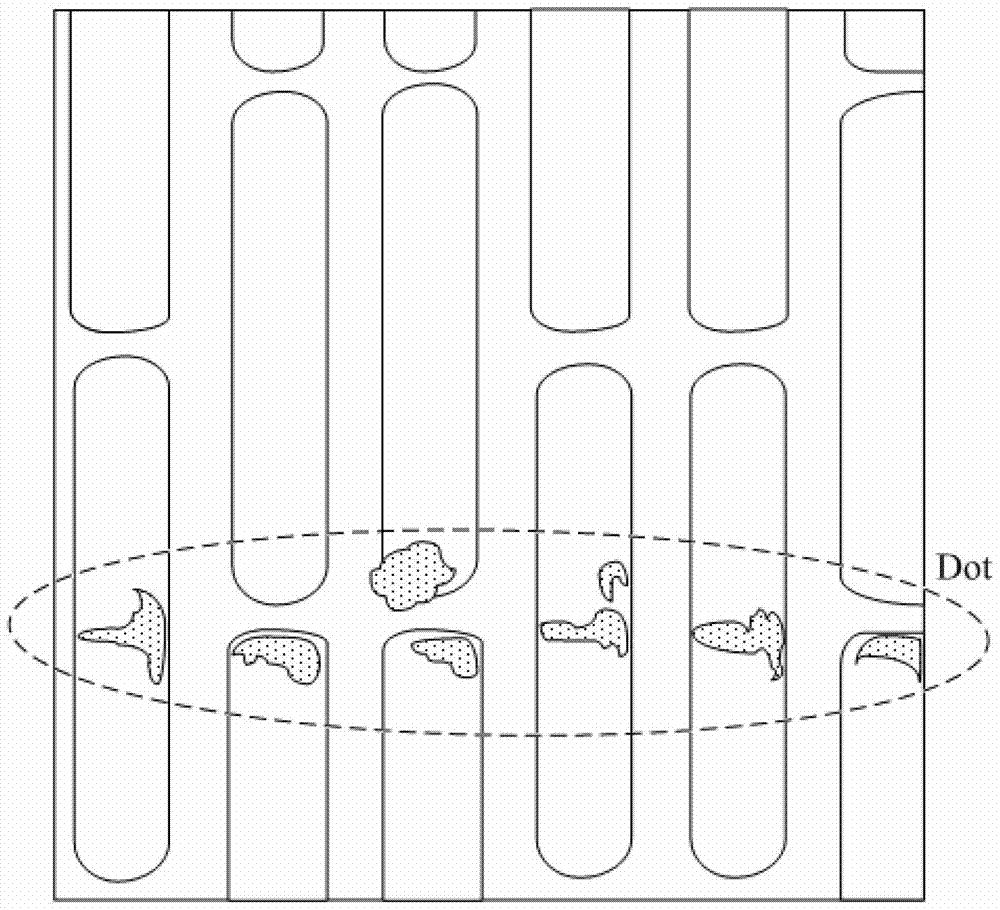

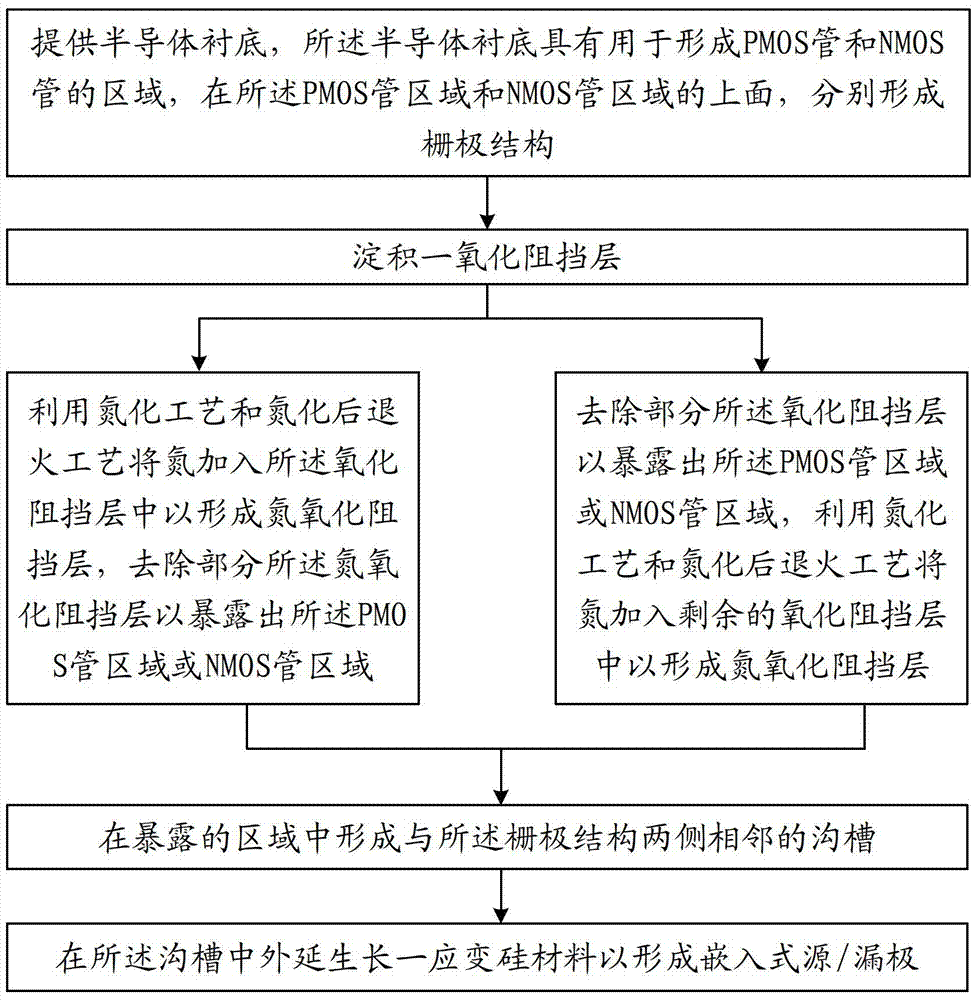

Method for manufacturing embedded source/drain MOS transistors

ActiveCN104465519AConstant ratePrevent adhesionSemiconductor/solid-state device manufacturingSemiconductor devicesElectrical conductorPartial oxidation

The invention provides a method for manufacturing embedded source / drain MOS transistors. The method comprises the steps that gate structures are formed on a PMOS transistor area and an NMOS transistor area formed on a semiconductor substrate respectively; an oxidation barrier layer is deposited; through a nitriding technology and a post-nitridation annealing technology, nitrogen is added to the oxidation barrier layer to form a nitrogen oxidation barrier layer, and a part of the nitrogen oxidation barrier layer is removed to expose the PMOS transistor area or the NMOS transistor area, or after a part of the oxidation barrier layer is removed to expose the PMOS transistor area or the NMOS transistor area, nitrogen is added to the remaining oxidation barrier layer to form the nitrogen oxidation barrier layer through the nitriding technology and the post-nitridation annealing technology; channels adjacent to the two sides of each gate structure are formed in the exposed area; strained silicon materials grow in the channels in an epitaxial mode to form the embedded source / drain MOS transistors. According to the method, the rate of epitaxial growth of the strained silicon materials in the channels is guaranteed, and the risk of pollution to the embedded source / drain MOS transistors can be lowered through the remaining oxidation barrier layer.

Owner:SEMICON MFG INT (SHANGHAI) CORP

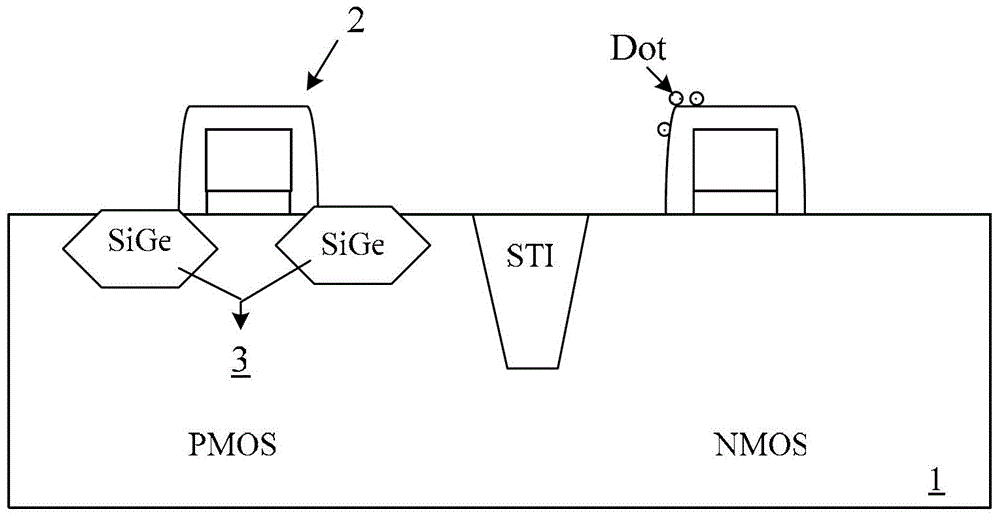

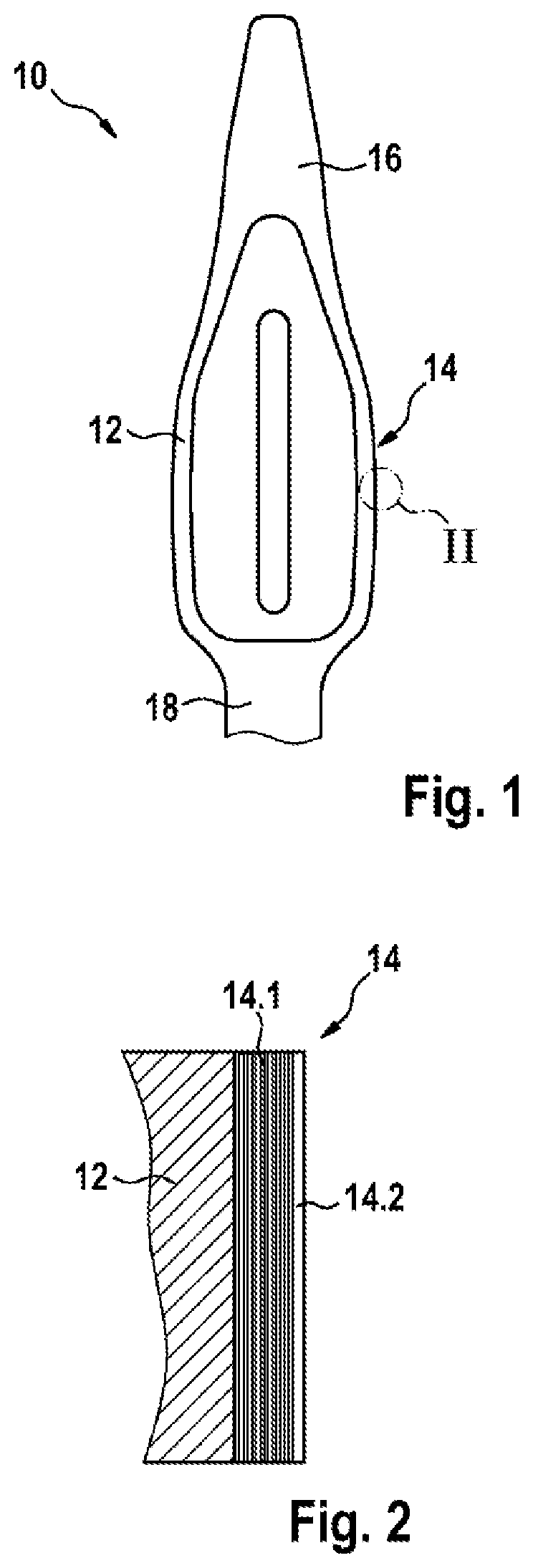

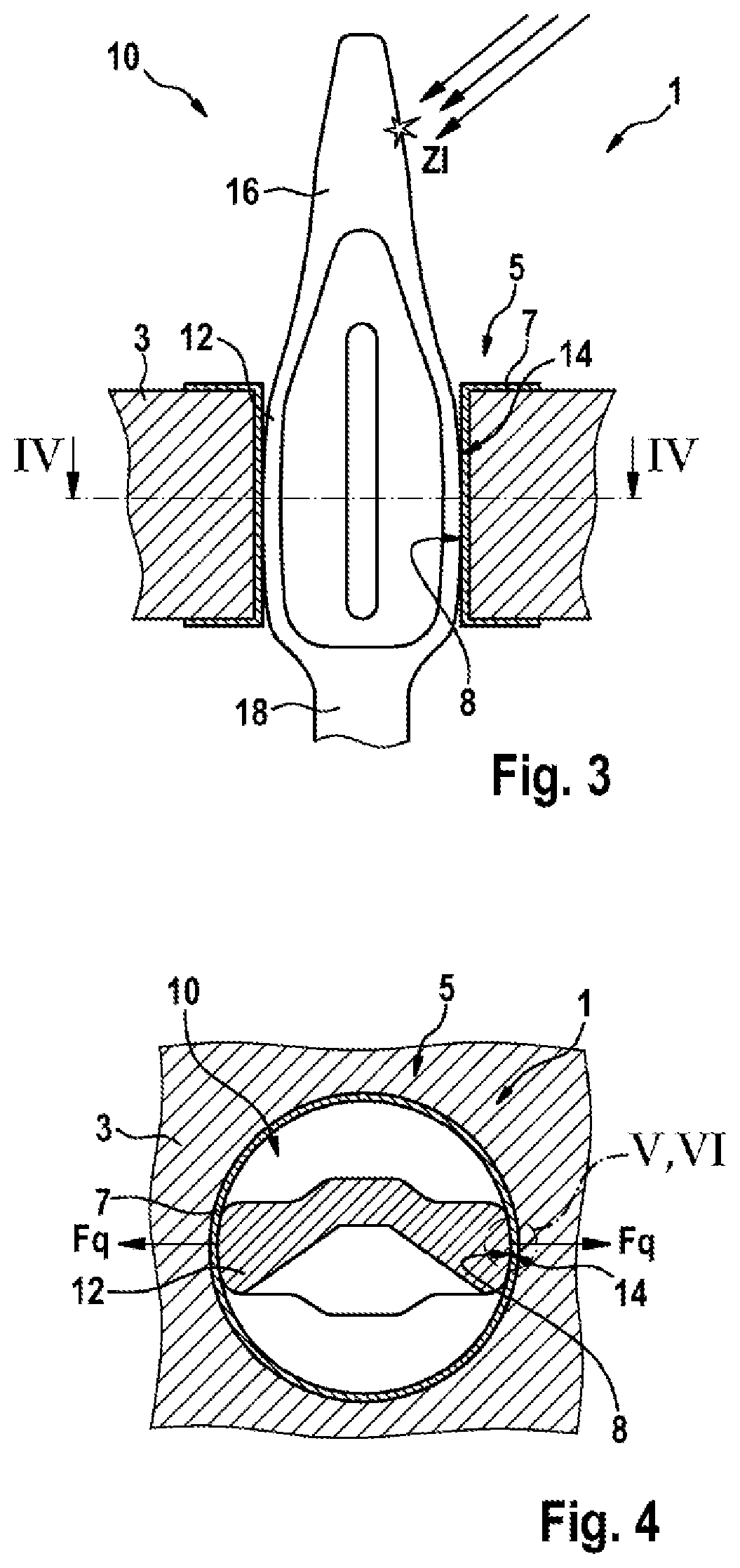

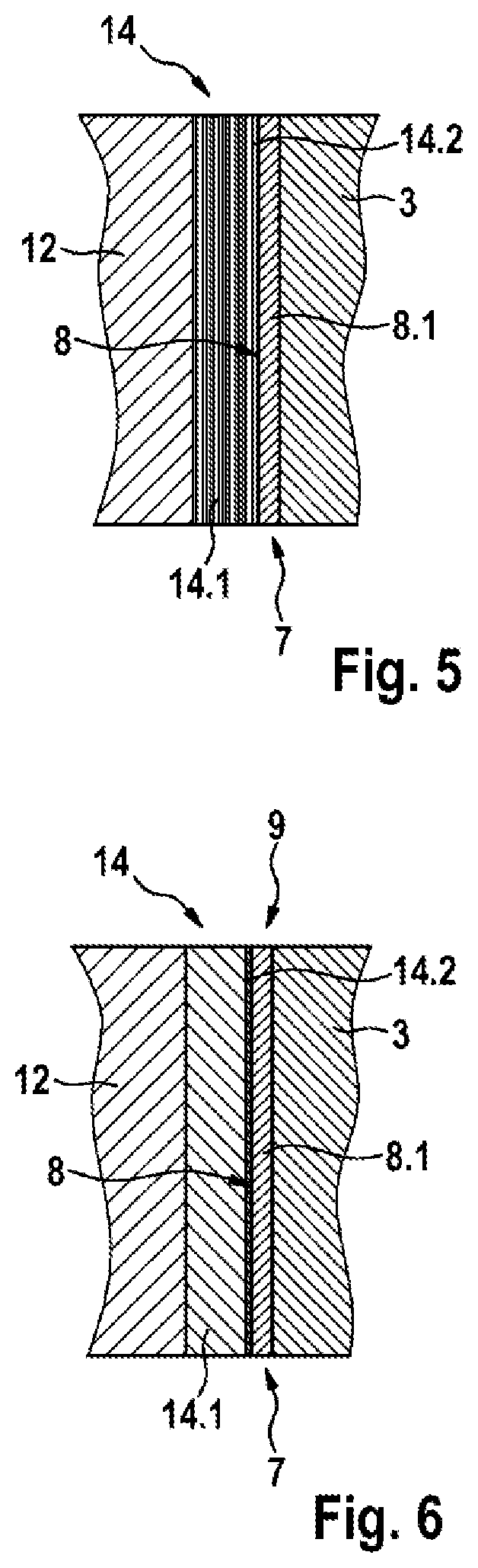

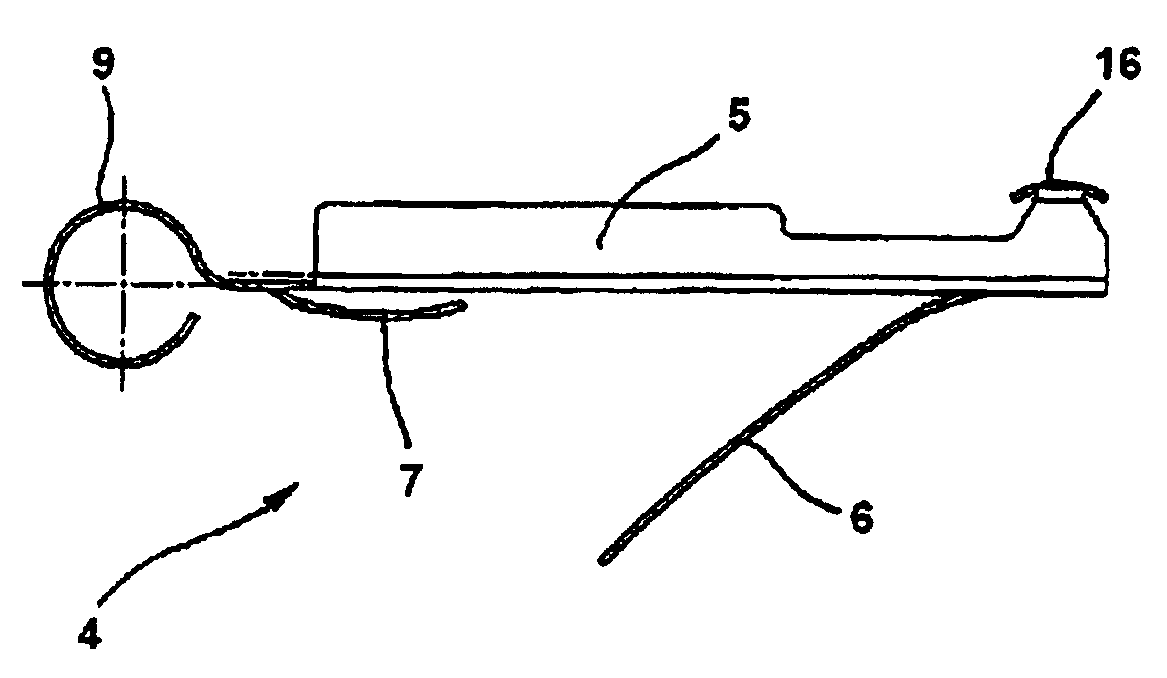

Press-in pin for an electrical contacting assembly

ActiveUS20200343655A1Improve carrying capacityReduce compressive stressLine/current collector detailsPrinted circuit aspectsConductive coatingEngineering

The invention relates to a press-in pin (10) for an electrical contacting assembly (1), having an elastic press-in region (12) and an electrically conductive coating (14). The invention further relates to a corresponding contacting assembly (1), and to a method for joining a press-in pin (10) and a metallized via (7). The coating (14) comprises a reactive multi-layer applied to the press-in pin (10) and a first contact layer applied to the reactive multi-layer.

Owner:ROBERT BOSCH GMBH

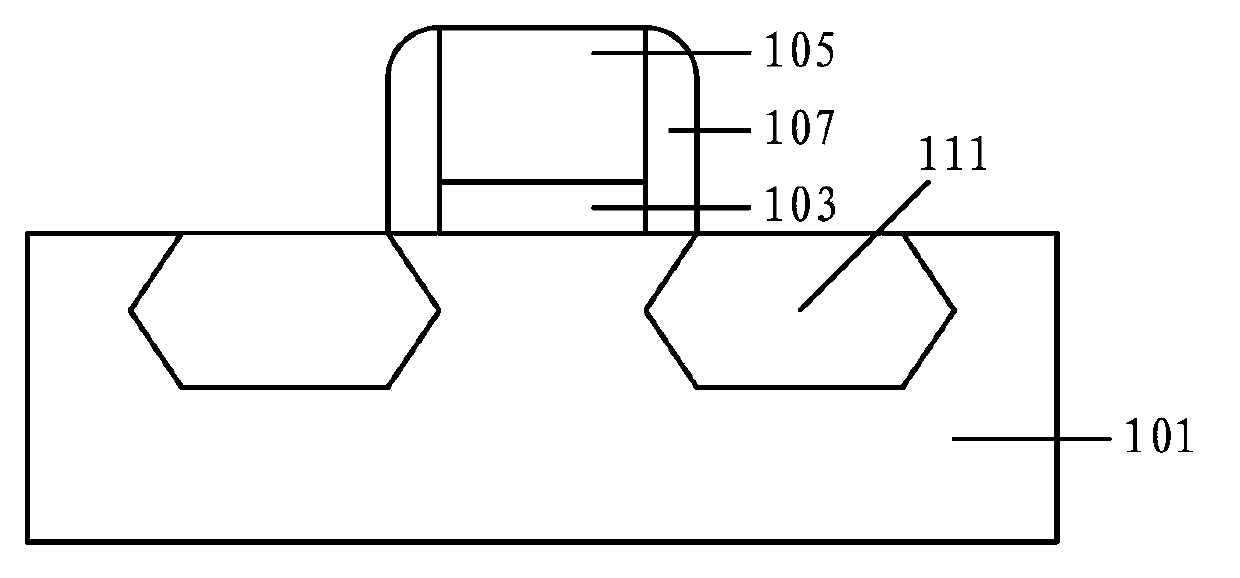

PMOS (P-channel metal oxide semiconductor) transistor and forming method thereof

InactiveCN103871889AReduce processing difficultyImprove performanceTransistorSemiconductor/solid-state device manufacturingEngineeringSemiconductor

The invention provides a PMOS (P-channel metal oxide semiconductor) transistor and a forming method of the PMOS transistor. The PMOS transistor comprises a semiconductor substrate, a grid electrode structure, a main side wall and a germanium-silicon layer, wherein the grid electrode structure is positioned on the semiconductor substrate, the main side wall is positioned on the side wall of the grid electrode structure, the germanium-silicon layer is positioned in the semiconductor substrate positioned at the two sides of the main side wall, and the germanium-silicon is in a step shape with the gradually reduced line width. The forming method of the PMOS transistor has the advantages that the process is simple, and the performance of the formed PMOS transistor is better.

Owner:SEMICON MFG INT (SHANGHAI) CORP

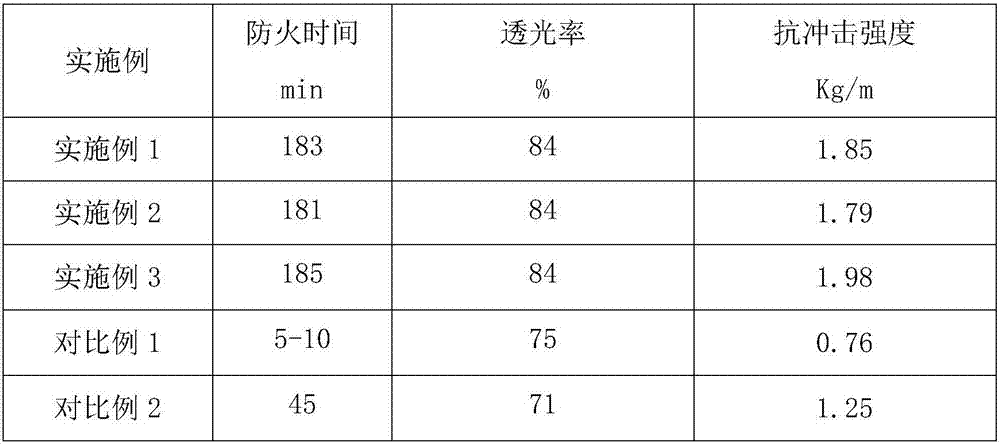

Single-layer fireproof tempered glass preparation method

InactiveCN107417080AHigh strengthGood weather resistanceGlass tempering apparatusHydrofluoric acidPotassium

The invention provides a single-layer fireproof tempered glass preparation method, and relates to the technical field of building materials. The preparation method comprises the following steps: (1) performing acid treatment on the surface of glass by using a mixed acid solution of nitric acid and hydrofluoric acid, then washing the acid treated glass, and performing drying and preheating; (2) sending the pre-processed glass in the step (1) into a glass tempering furnace to perform glass tempering, wherein the glass tempering temperature is in a range of 650-730 DEG C and the glass tempering time is in a range of 1-2 hours; (3) when the glass is tempered with heating, spraying a cesium-potassium salt solution with a certain composition twice, wherein a second spraying is performed 10-15 min after a first spraying is finished; and (4) taking out the tempered glass and performing air cooling molding, and finally performing cooling to obtain the single-layer fireproof tempered glass. The single-layer fireproof tempered glass provided by the invention is simple in preparation process, convenient in installation, high in impact resistance and high in weatherability.

Owner:DONGGUAN TAISHENG GLASS CO LTD

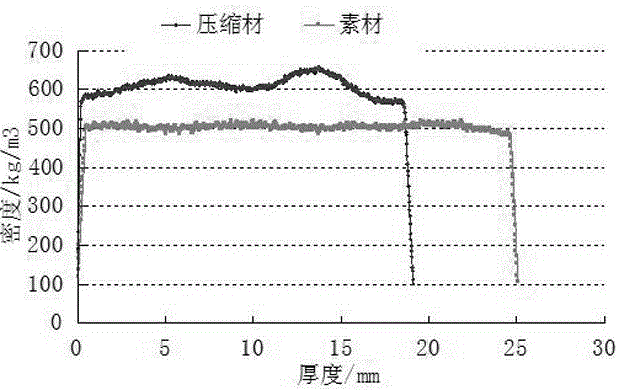

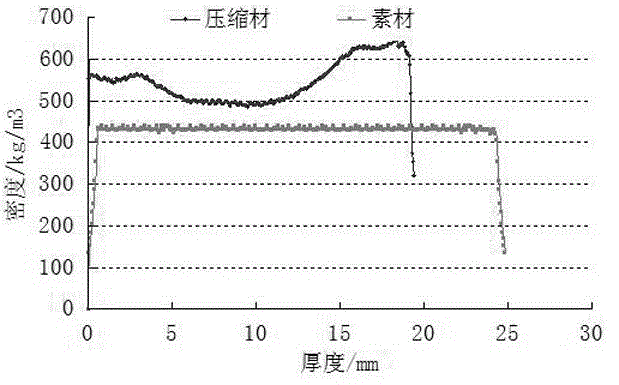

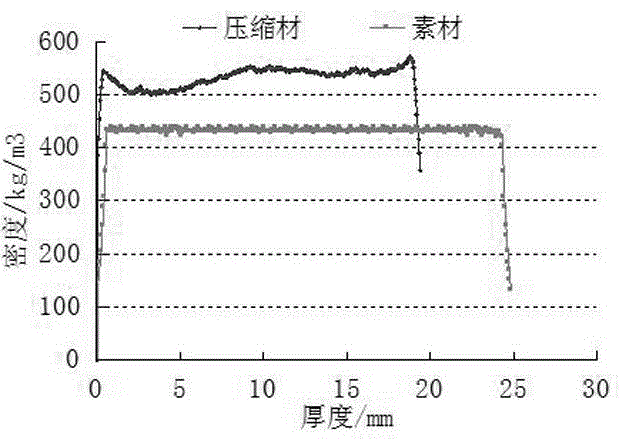

Integral reinforced solid wood section bar and manufacturing method thereof

ActiveCN103481348BSmall volume lossHigh strengthWood working apparatusFlat articlesSolid woodProcess engineering

The invention belongs to the technical field of wood function improvement and wood processing, and specifically discloses an integral reinforced solid wood profile and a manufacturing method thereof. The method comprises the following steps: under the condition of low moisture content (1-3%), the wood is subjected to integral compression treatment with low compression rate by adopting a heating and softening forming technology, so as to obtain an integral compressed material with uniform cross-sectional density. The method can effectively reduce the phenomenon of blasting and bubbling caused by excessive steam pressure inside the wood, greatly shorten the heat preservation time, and improve work efficiency. The overall compressed timber profile obtained by the method of the invention has good dimensional stability, is environmentally friendly and healthy, and can be used for manufacturing solid wood floors, solid wood furniture and as interior decoration materials.

Owner:江门健威家具装饰有限公司

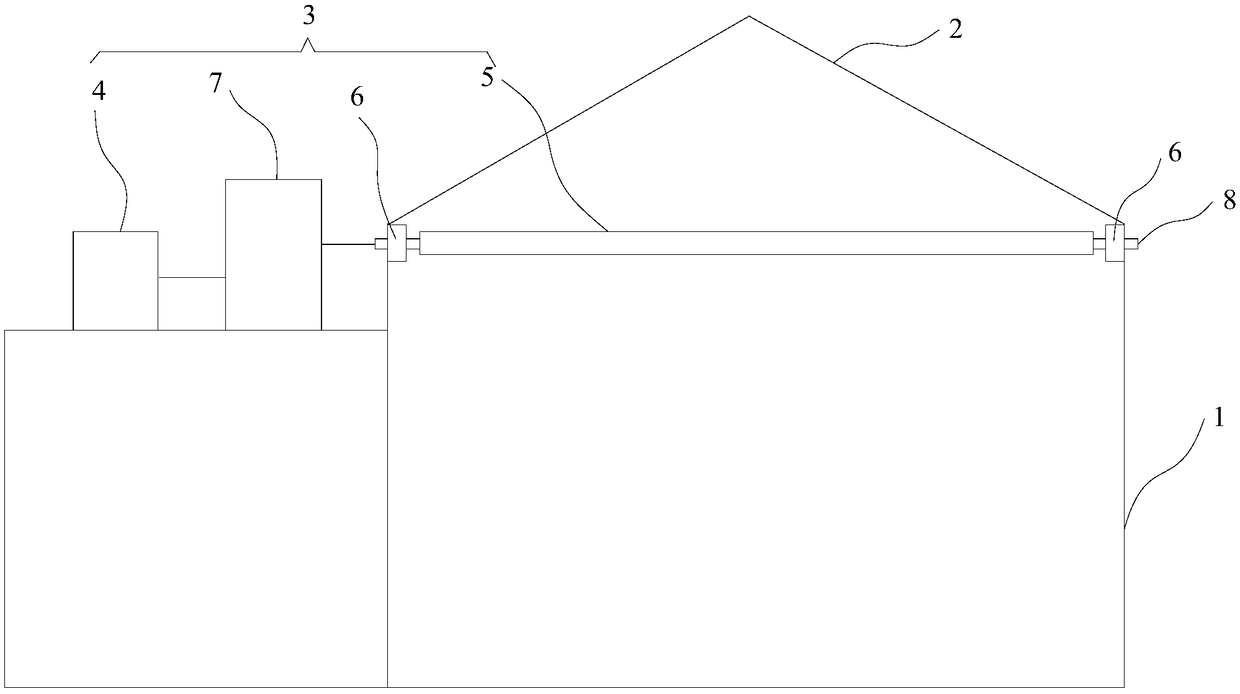

House used for livestock breeding

InactiveCN109349121AConducive to the growth of livestock and poultryLow costLivestock managementAnimal housingEngineeringSunlight

The invention discloses a house used for livestock breeding, and relates to the technical field of breeding houses. According to the house used for livestock breeding, the roof of the house is set asa double-layer roof, the upper roof layer is set as a light transmitting roof, and the lower roof layer is sets as a light-tight temperature preserving roof; the upper roof layer is made from a transparent material, and the lower roof layer is set as an overturn light blocking fence structure; the overturn light blocking fence structure comprises a controller, several light blocking fences, several supporting rods and several servo motors, the supporting rods are respectively and fixedly arranged at the two opposite ends of the inner side of the upper roof layer, and rotary shafts are respectively arranged at the two opposite ends of each light blocking fence; the two ends of each light blocking fence respectively penetrate through the supporting rods at the two ends through the rotary shafts and can rotate relative to the supporting rods at the two ends, and all the servo motors are connected with the rotary shafts at the ends and a controller. According to the house used for livestock breeding, natural sunlight can be effectively utilized for sterilizing and disinfecting the inside of the house, and the effect of preserving heat in the house is achieved.

Owner:广西乐业康辉生态养殖专业合作社

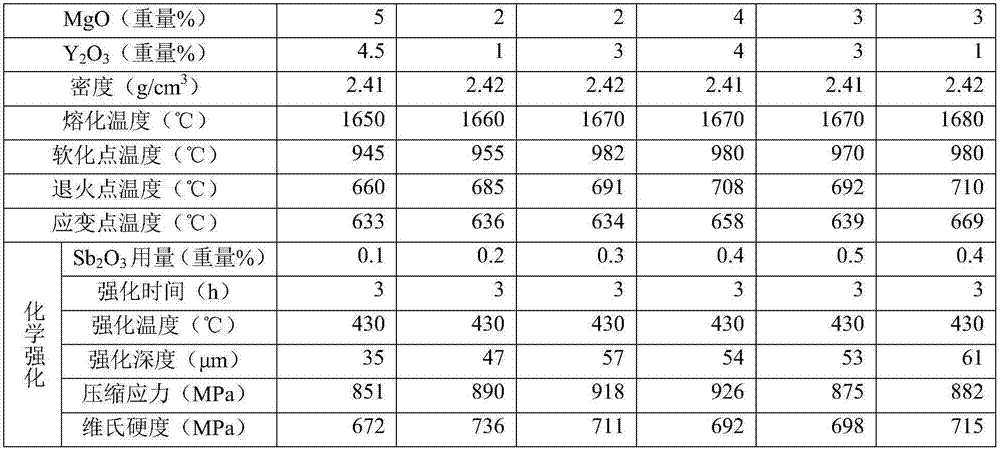

Glass composition and preparing method and application thereof

The invention discloses a glass composition and a preparing method and application thereof. The total weight of the glass composition is calculated as 100%, wherein the glass composition comprises 45-65wt% of SiO2, 12-25wt% of Al2O3, 0.5-15wt% of P2O5, 9-17wt% of Na2O, 0.1-5wt% of MgO, 0.1-5wt% of Y2O3 and unavoidable impurities; the invention further provides a preparing method and application of the glass composition in the preparation of a touch screen and / or a solar battery. The glass composition is loose in structure, suitable for chemical strengthening and processing, through short-time chemical strengthening, the deeper strengthening depth and the higher compressive stress and Vickers hardness can be obtained, and the anti-dropping ability of glass is improved.

Owner:东旭(营口)光电显示有限公司 +2

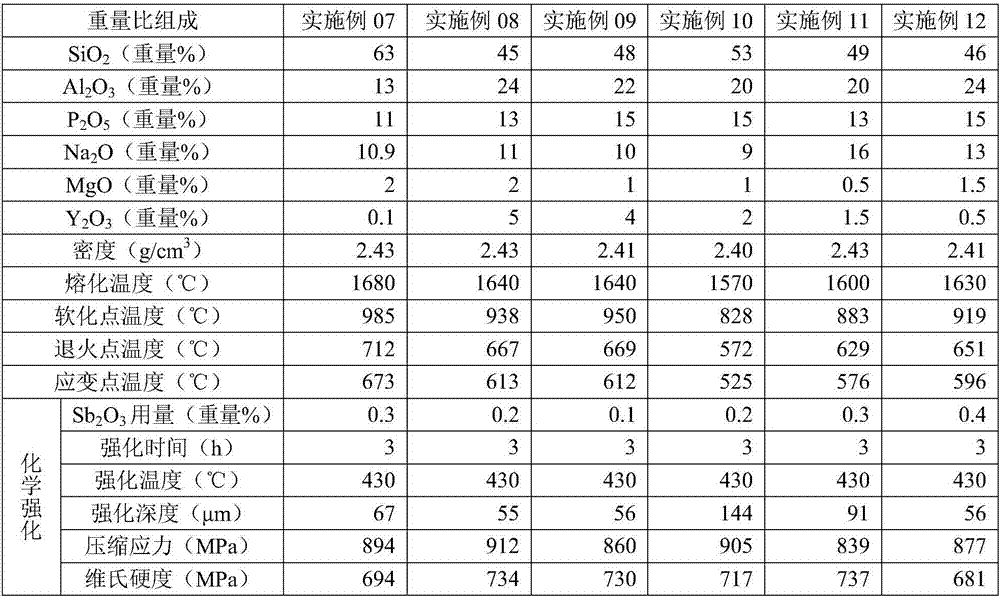

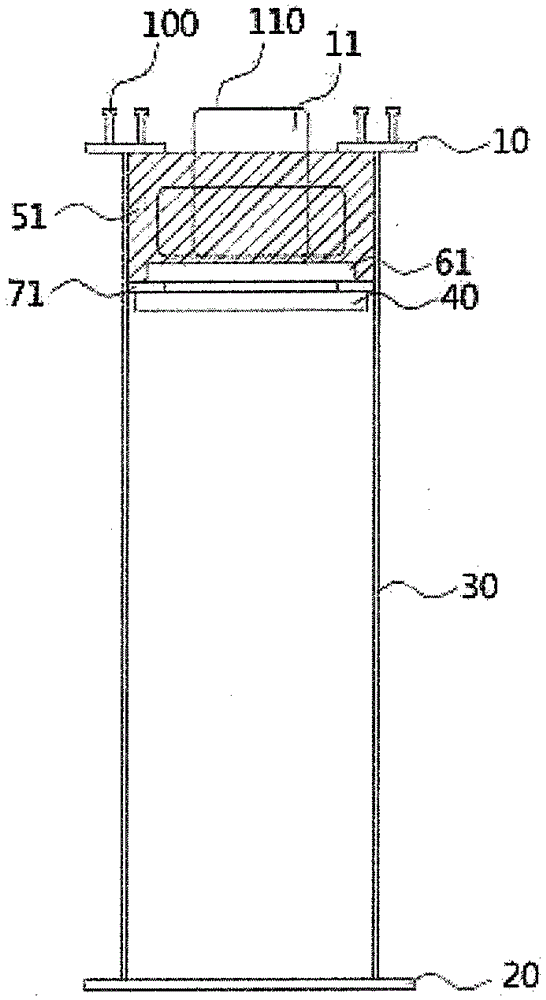

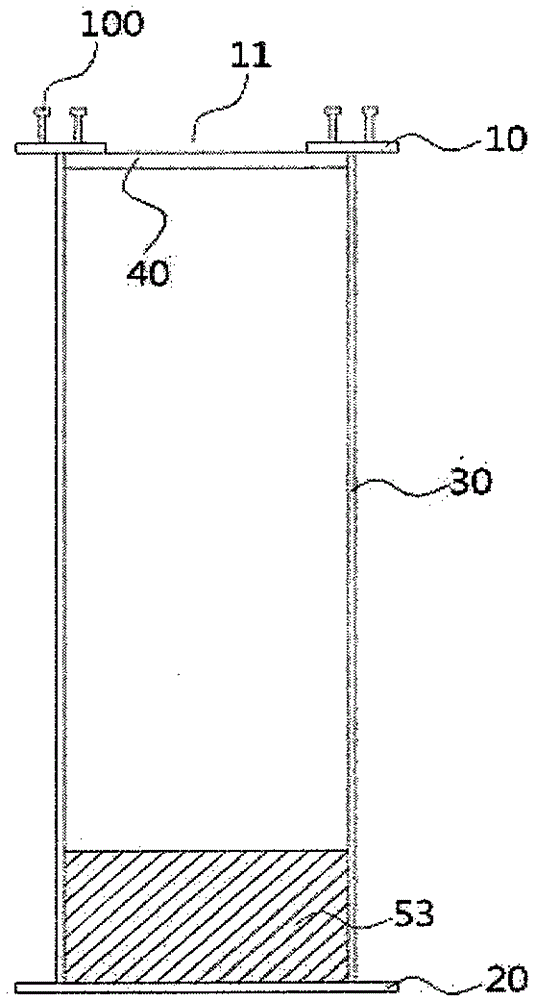

Combined box beam

The invention relates to a combined box beam which comprises a netted steel box beam and upper part concrete (51) poured on the upper side inside the steel box beam; the steel box beam comprises a steel beam upper flange (10), a steel beam lower flange (20) and a steel web plate (30), wherein an opening area (11) is longitudinally formed in the center of the steel beam upper flange (10); the steel beam lower flange (20) is formed a certain distance away from the steel beam upper flange (10); the steel web plate (30) is connected with the two sides of the steel beam upper flange (10) and the two sides of the steel beam lower flange (20), and the height of the steel web plate (30) is greater than the width of the steel beam upper flange (10) and the width of the steel beam lower flange (20). The composite box beam provided by the invention has the following benefit that as the width of each of the steel beam upper flange (10) and the steel beam lower flange (20) of the steel box beam is less than the height of the web plate, and a mesh shape is formed, the steel consumption of the steel beam upper flange (10) and the steel beam lower flange (20) is reduced, and the quantity of reinforcing components longitudinally or transversely arranged inside a bridge is reduced, therefore, the steel consumption is greatly reduced, and the manufacturing process is simplified.

Owner:BEIJING DISHENG KECHUANG CONSTR ENGCO +1

Composite buffer for crane

ActiveCN102730555BMeet the requirements of cushioning performancePlay a buffer roleShock absorbersRunwaysEngineeringPiston rod

The invention discloses a composite buffer for a crane and relates to the technical field of buffer equipment. The composite buffer comprises a base, wherein a primary buffer device is arranged on the base and comprises a shell which is fixed on the base; a spring is arranged in the shell; one end of the spring is fixed on the base, and the other end of the spring is connected with a piston; the other side of the piston is provided with a piston rod; one end of the piston rod penetrates out of the shell; the composite buffer also comprises a secondary buffer device; and the secondary buffer device is connected with one end of the piston rod which is exposed out of the shell. According to the composite buffer for the crane, the requirement of a large-tonnage crane on the buffer performance can be met, and the composite buffer is small in size, low in production cost, long in service life, wide in application range and suitable for popularization and application, can replace various buffers of different specifications and is an innovative product in the field.

Owner:昌乐县东田聚氨酯厂

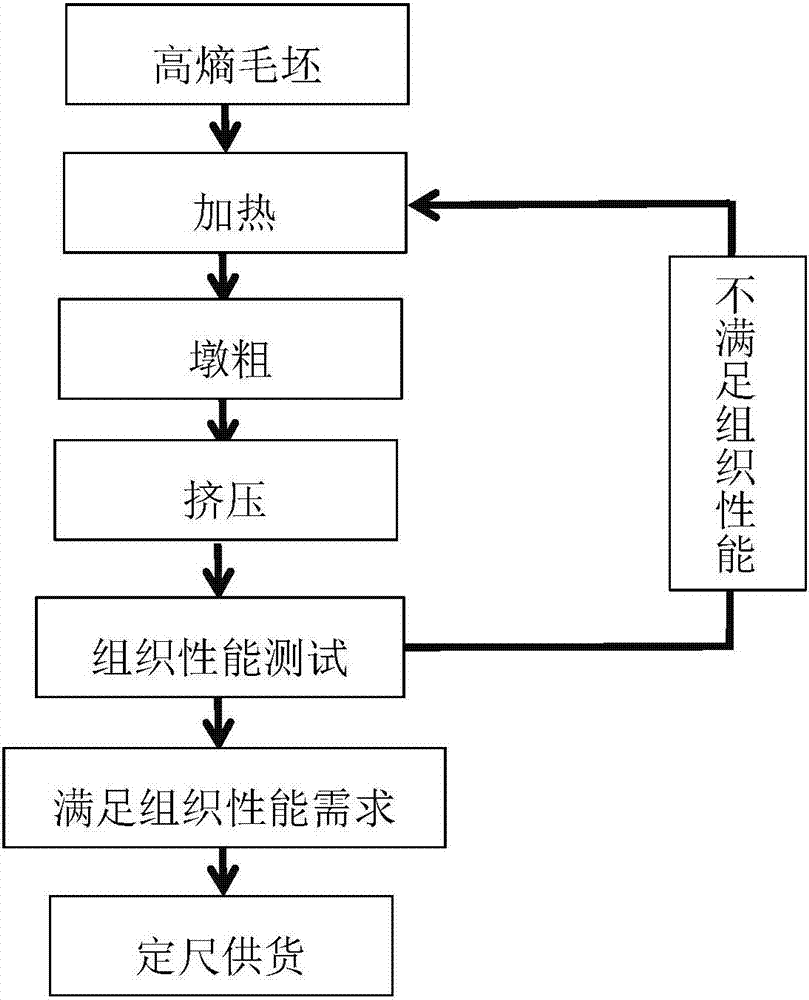

High-entropy alloy extruding and mounding composite modification technology

InactiveCN107881443AEasy to implementUniform and excellent tissue performanceStructure propertyHigh entropy alloys

The invention relates to a hot working and grain refinement plasticity modification technology dedicated to high-entropy alloy material and a method to prepare high-performance high-entropy alloy material. The invention aims to provide an extruding and mounding composite plasticity modification method dedicated to the service requirement of high-entropy alloy. Aiming at the hot-working characteristic of high-entropy alloy, the method of first mounding and then extruding, mounding after extruding and repeated mounding and extruding is adopted, so that the stress state in the high-entropy alloymaterial during the deformation process is effectively controlled, the three-directional compression stress is increased, generation and expansion of microcracks evoked by lattice deformation are effectively restrained, the grain is refined, the comprehensive mechanical performance is improved, and effective modification of the high-entropy alloy is realized. The extruding and mounding composite technology is easy to realize and low in cost; high-entropy alloy ingot blank material with uniform and excellent structure property can be obtained, and the service capacity is effectively improved; and with adoption of the method, large-scale application of the high-entropy alloy is promoted, and the mechanical performance of the high-entropy alloy can be effectively improved and controlled.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Fiber-reinforced polypropylene composition and foamed polypropylene composite material and preparation method thereof

The invention relates to the field of modified polypropylene, and discloses a fiber-reinforced polypropylene composition, a foamed polypropylene composite material and a preparation method thereof. The fiber-reinforced polypropylene composition contains polypropylene, a polypropylene modifier, glass fibers, a foaming agent and a compatibilizer; the preparation method of the polypropylene modifier comprises: combining the poles in combination I or II The grafted polypropylene with permanent monomer is contacted with component A to react and extruded to pelletize. The fiber-reinforced polypropylene composition provided by the present invention can prepare foamed polypropylene composite materials with a relatively high expansion ratio, and the prepared foamed polypropylene composite materials have both high compression resilience and compressive stress at the same time, That is, it has excellent compression properties and can be used as a cushioning material.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

A kind of high-strength corrosion-resistant glassware and preparation method thereof

The invention discloses high-strength and corrosion-resisting glassware and a preparation method thereof. The high-strength and corrosion-resisting glassware is prepared from the following raw materials in parts by weight: 80 to 85 parts of quartz sand, 2 to 5 parts of calcium oxide, 0.1 to 0.5 part of iron oxide, 0.3 to 0.5 part of titanium dioxide, 0.1 to 0.3 part of bismuth trioxide, 0.1 to 0.4part of magnesium oxide, 0.1 to 0.3 part of aluminum oxide, 2 to 4 parts of kaolin, 0.1 to 0.3 part of vanadium dioxide, 5 to 10 parts of sodium carbonate, 0.1 to 0.3 part of niobium dioxide, 0.1 to0.2 part of tellurium dioxide and 0.1 to 0.2 part of silver chloride. The preparation method comprises the following four steps: mixing the materials, smelting, molding, and inducing to nucleate. Theglassware prepared by the invention has the advantages of high mechanical strength and strong corrosion resistance and is suitable for being produced and applied in a large scale.

Owner:安徽晶晶玻璃制品有限公司

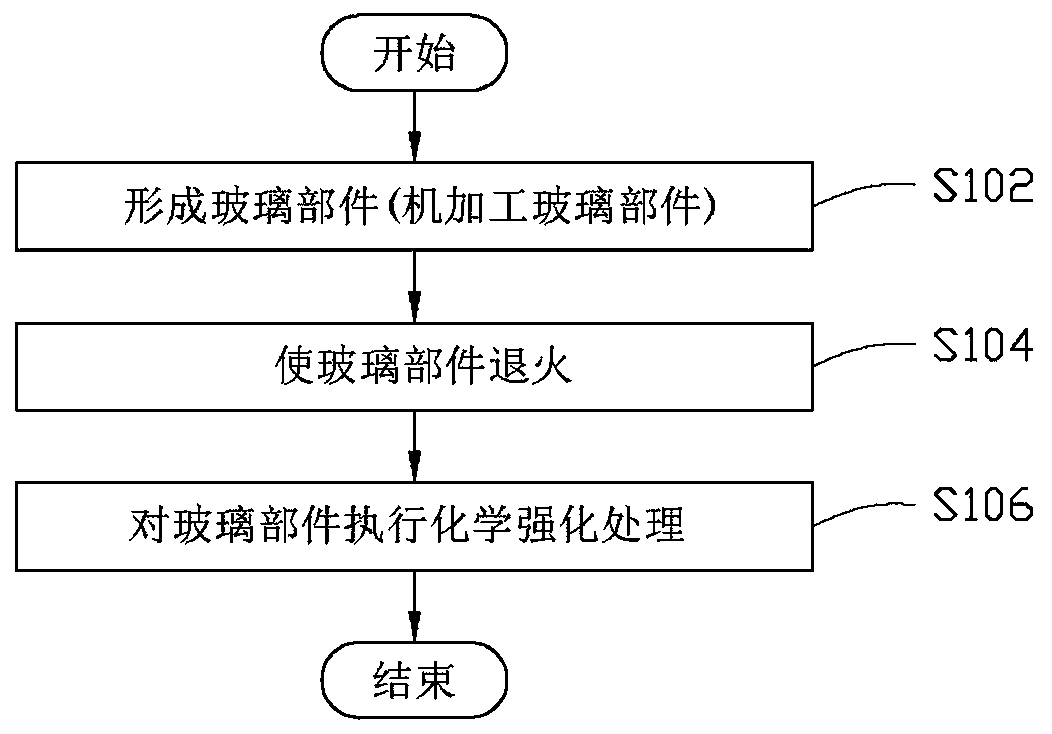

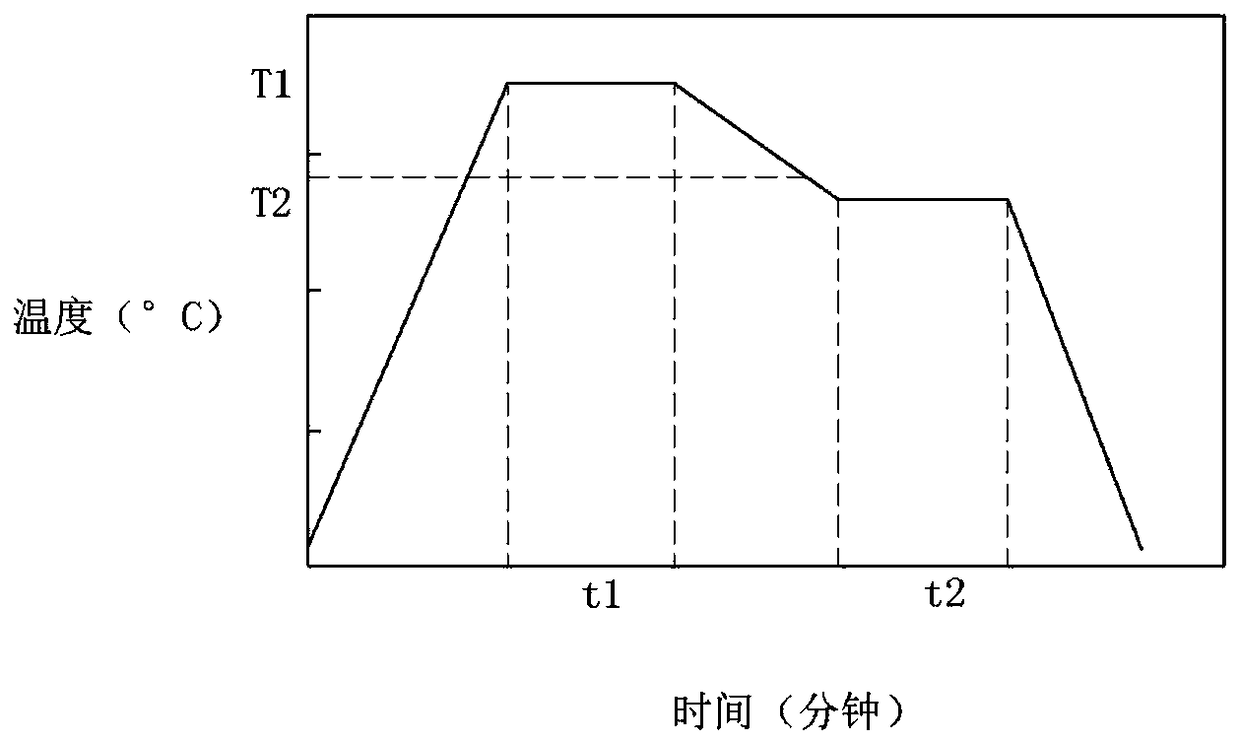

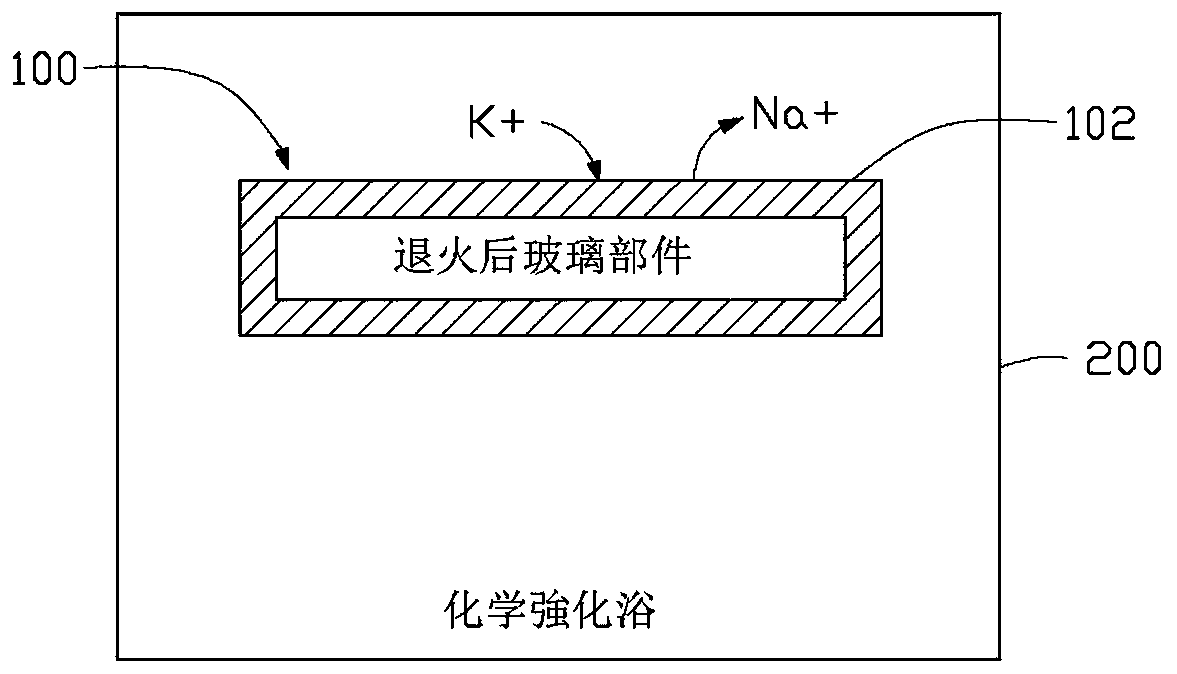

Strengthening treatment method for glass parts

ActiveCN105271661BGuaranteed depthHigh compressive stressGlass tempering apparatusComposite materialEnvironmental temperature

The present invention relates to a method for increasing strengthening behavior of glass. The method includes making a piece of glass, annealing the glass, and then chemically strengthening the glass. Annealing the glass includes heating the glass to a first temperature and maintaining the first temperature for a predetermined first period, cooling the glass to a second temperature and maintaining the second temperature for a predetermined second period, and cooling the glass to an environmental temperature. The first temperature exceeds the annealing temperature of the glass, and the second temperature is lower than the strain point temperature of the glass.

Owner:G TECH OPTOELECTRONICS CORP

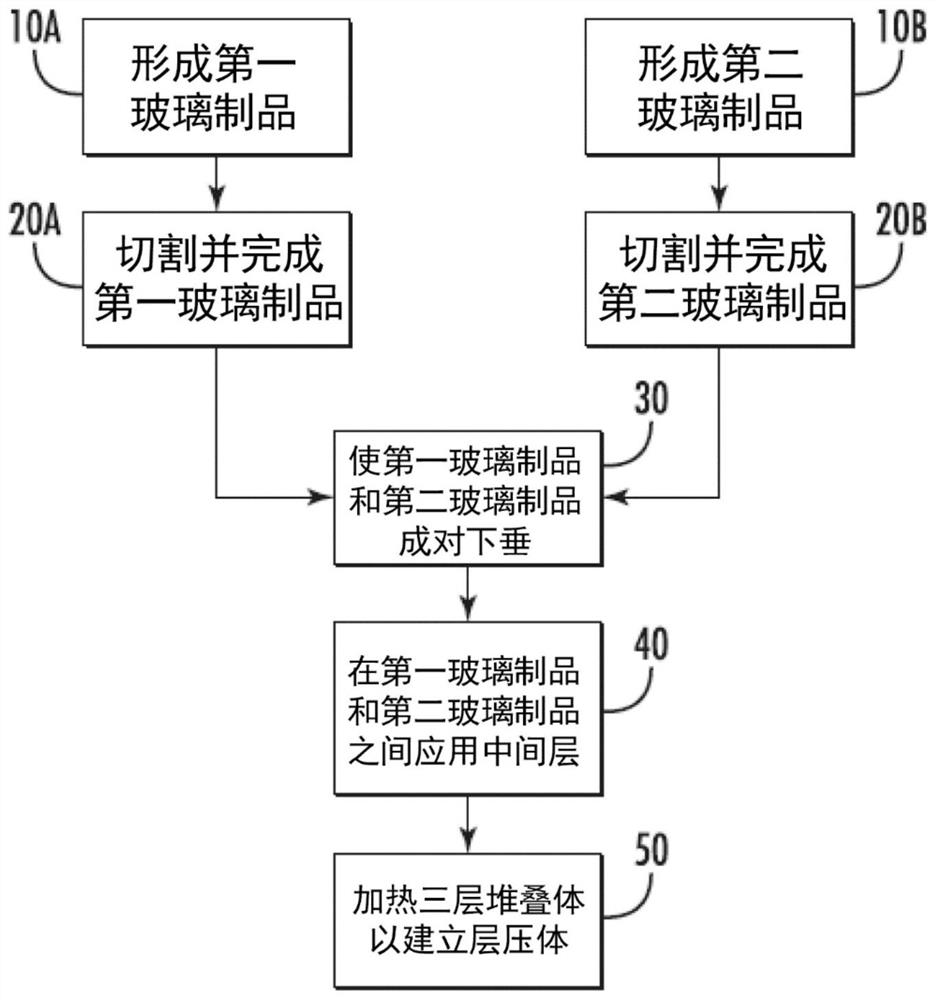

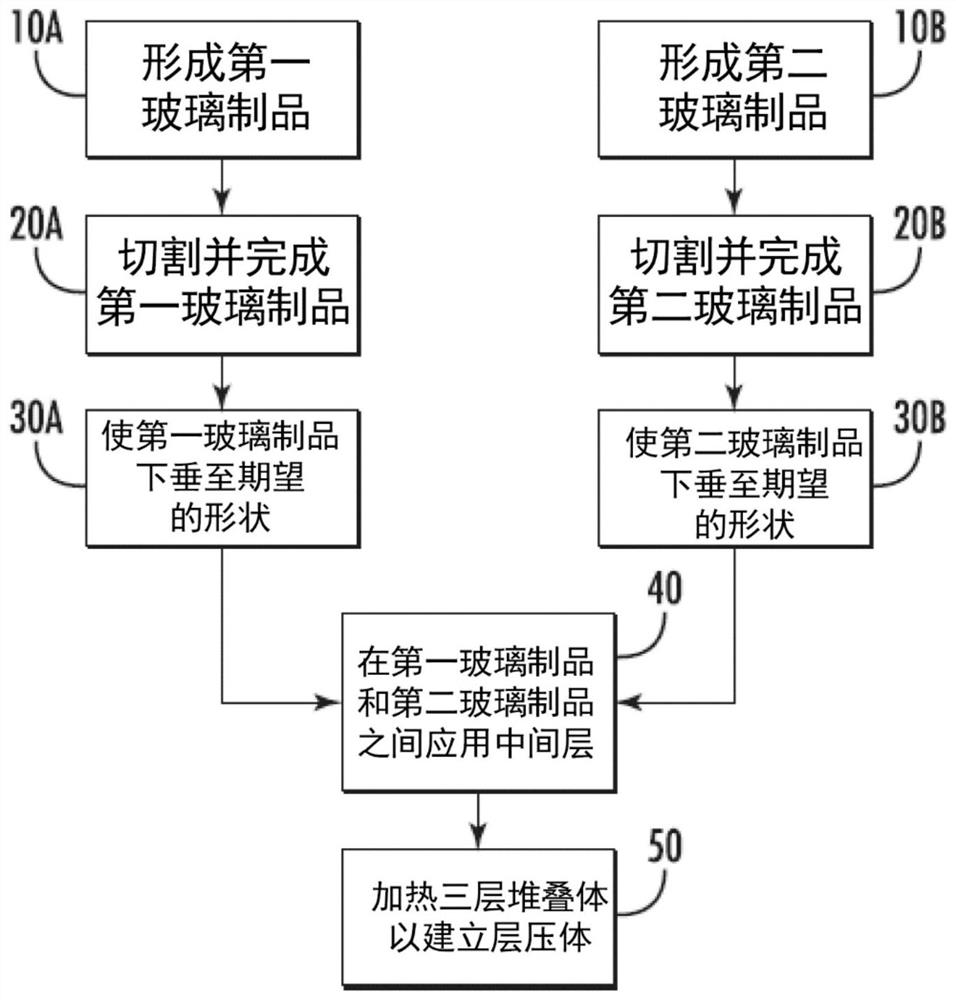

Chemically-strengthenable glasses for laminates

InactiveCN112340985ALow viscosityHigh compressive stressWindowsWindscreensOrganic chemistrySoftening

Disclosed herein glass articles having a glass composition. The glass composition includes SiO2 in an amount in a range from about 63 mol% to about 75 mol%; Al2O3 in an amount in a range from about 7mol% to about 13 mol%; R2O in an amount from about 13 mol% to about 24 mol%; P2O5 in an amount in a range from about 0 mol% to about 2 mol%; MgO is present in a range from about 0 mol% to about 10 mol%; ZnO is present in an amount in a range from about 0 mol% to about 10 mol%; and CaO, SrO, BaO and, F<->; or TiO2, ZrO2, and Cl<->; the glass article having an anneal point (DEG C) and a softening point (DEG C), and a relationship of (anneal point + softening point) / 2 in a range from about 625 DEG C to about 725 DEG C.

Owner:CORNING INC

Manufacturing method of embedded source/drain MOS transistor

ActiveCN104465519BConstant ratePrevent adhesionSemiconductor/solid-state device manufacturingSemiconductor devicesElectrical conductorNitrogen

The invention provides a method for manufacturing embedded source / drain MOS transistors. The method comprises the steps that gate structures are formed on a PMOS transistor area and an NMOS transistor area formed on a semiconductor substrate respectively; an oxidation barrier layer is deposited; through a nitriding technology and a post-nitridation annealing technology, nitrogen is added to the oxidation barrier layer to form a nitrogen oxidation barrier layer, and a part of the nitrogen oxidation barrier layer is removed to expose the PMOS transistor area or the NMOS transistor area, or after a part of the oxidation barrier layer is removed to expose the PMOS transistor area or the NMOS transistor area, nitrogen is added to the remaining oxidation barrier layer to form the nitrogen oxidation barrier layer through the nitriding technology and the post-nitridation annealing technology; channels adjacent to the two sides of each gate structure are formed in the exposed area; strained silicon materials grow in the channels in an epitaxial mode to form the embedded source / drain MOS transistors. According to the method, the rate of epitaxial growth of the strained silicon materials in the channels is guaranteed, and the risk of pollution to the embedded source / drain MOS transistors can be lowered through the remaining oxidation barrier layer.

Owner:SEMICON MFG INT (SHANGHAI) CORP

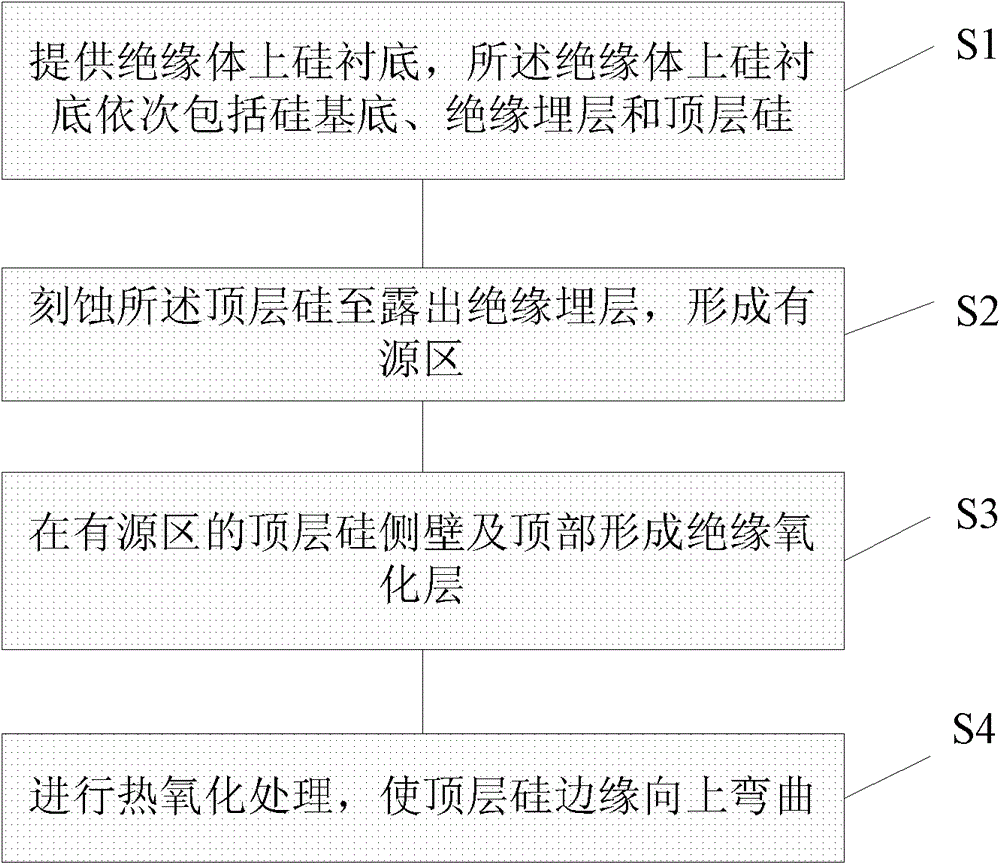

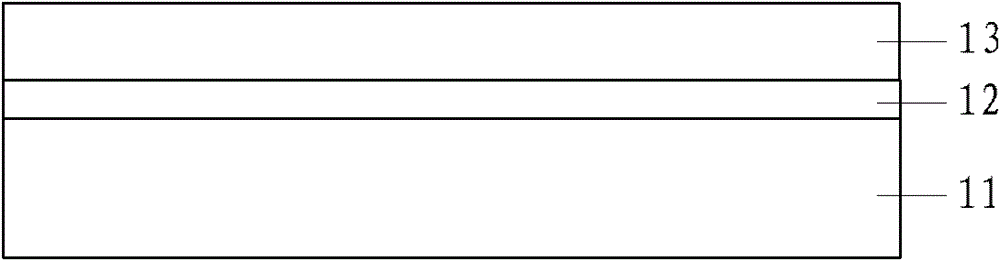

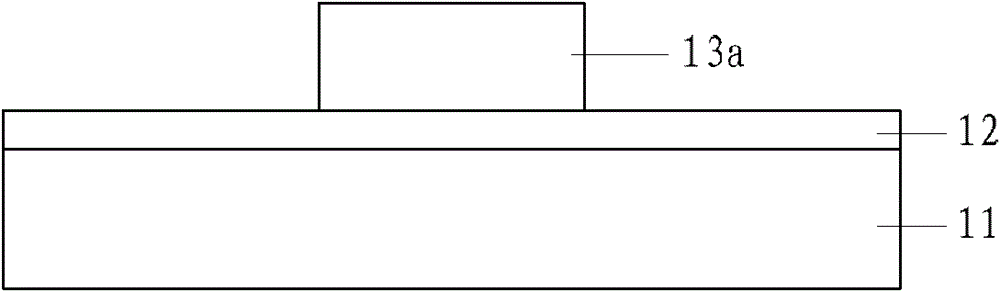

Semiconductor structure and formation method, pmos transistor and formation method

ActiveCN102184847BIncrease in sizeHigh compressive stressSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor structureP channel

The invention relates to a semiconductor structure and a forming method thereof, a PMOS (P-channel Metal Oxide Semiconductor) transistor and a forming method thereof. The forming method of the semiconductor structure comprises the following steps of: providing a silicon-on-insulator substrate, wherein the silicon-on-insulator substrate sequentially comprises a silicon base, an insulated buried layer and top layer silicon; etching the top layer silicon until the insulated buried layer is exposed to form an active region; forming insulated oxide layers on the side wall and the top of the top layer silicon in the active region; and performing thermal oxidization treatment to ensure that the top layer silicon is bent upwards. The invention further provides a semiconductor structure, a PMOS transistor structure formed on the semiconductor structure and a forming method of the PMOS transistor structure. The invention aims to perform thermal oxidization treatment on the top layer silicon in a PMOS transistor device region so that the edge of the top layer silicon is bent upwards, so that the compression stress of the top layer silicon is enhanced and the performance of a subsequently-manufactured PMOS device is enhanced.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

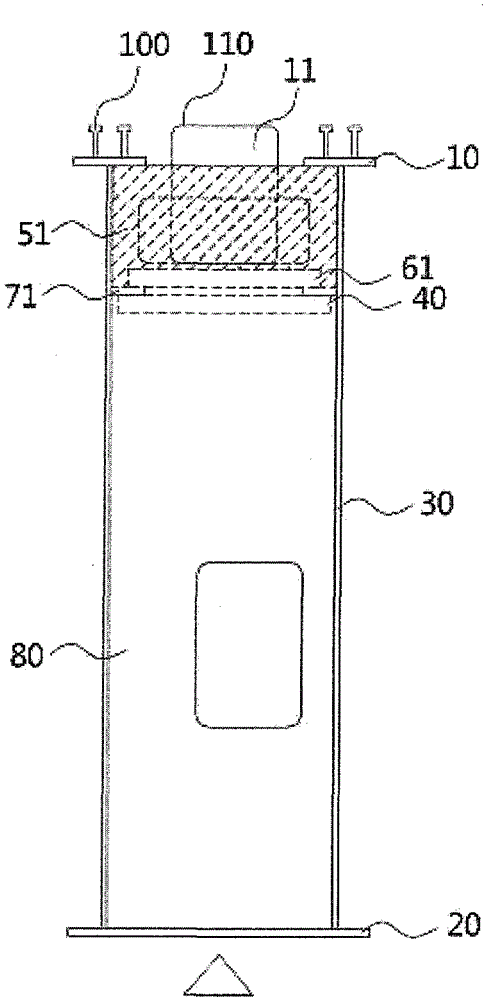

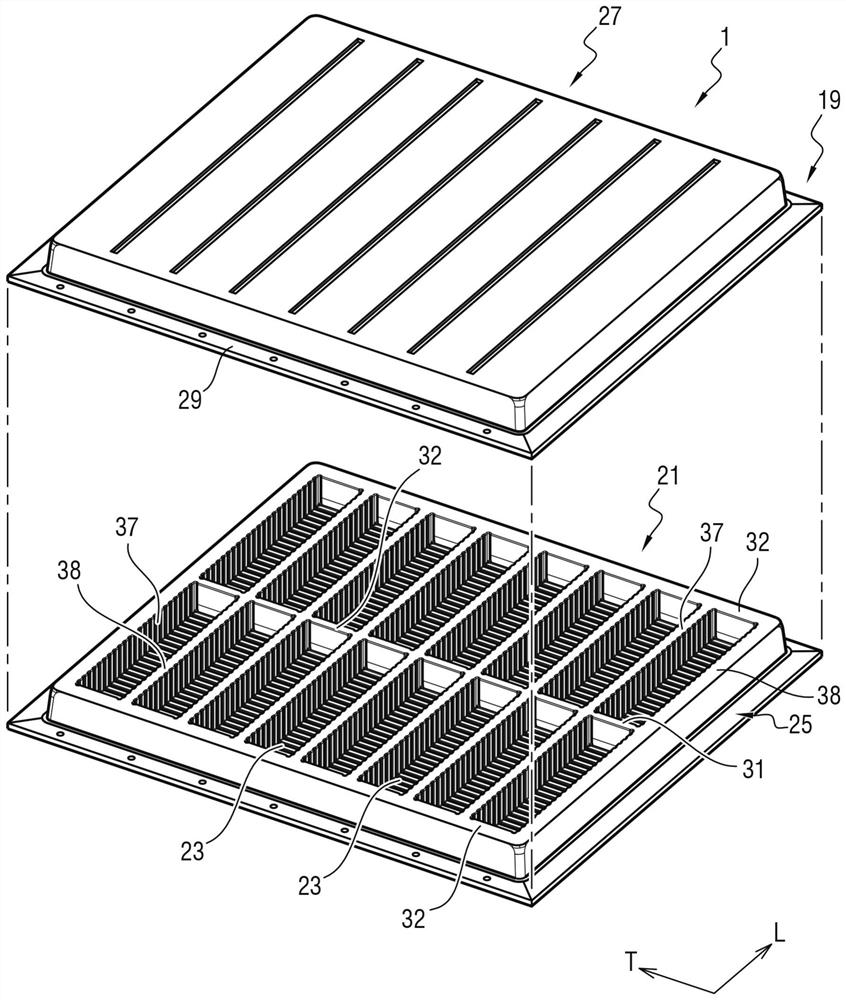

Power storage battery

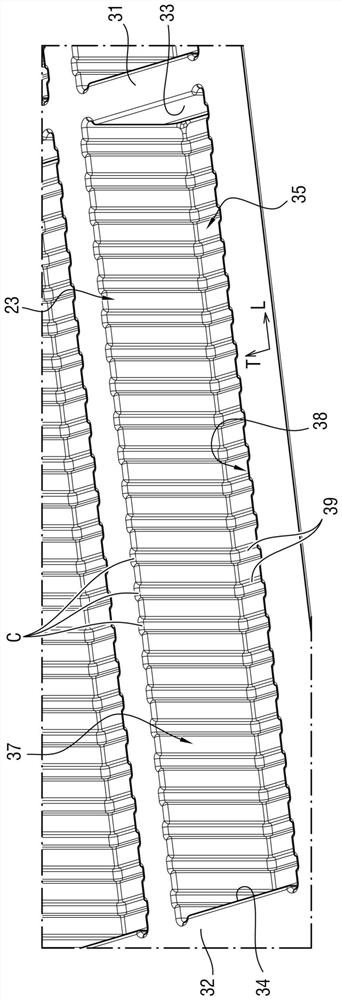

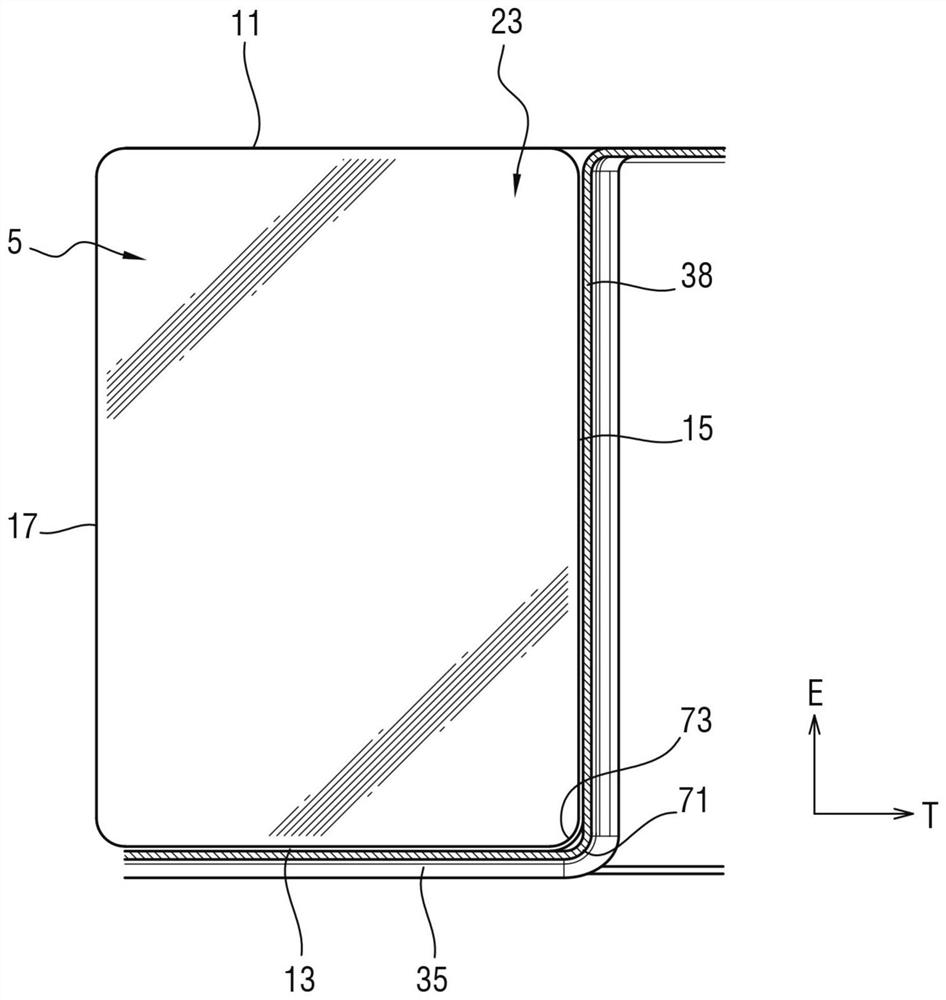

PendingCN114725595AHigh compressive stressSecondary cellsCell component detailsStructural engineeringMechanical engineering

The invention provides a power storage battery (1) comprising at least one module (3) comprising power storage battery cells (5), each power storage battery cell (5) having a nominal value thickness E0, and at least one compartment (23) for receiving the at least one module (3); at least one of the transverse walls (31, 32) of the compartment is made of an elastic material; when the module (3) is engaged in the compartment (23), the transverse walls (31, 32) exert a compressive stress on the module (3) adapted to maintain the power storage cell (5) substantially at its nominal thickness E0.

Owner:FAURECIA SYST DECHAPPEMENT

Microswitch

InactiveCN101685719BPersistent steady stateImprove durabilitySnap-action arrangementsEngineeringControl switch

The switch has contact springs (4) transferred into different switching positions by an actuating element and arranged at an anchor formed as an electrical contact. Spring tongues (6, 7) are arranged at a closed spring frame (5). One spring tongue is formed as a resetting unit for the actuating element. Another spring tongue controls switching functions of a contact region (9) of the springs. The tongues are engaged at surface regions of the anchor in a supporting manner such that the springs exhibit stable position during actuation, where the surface regions are turned away from each other.

Owner:JOHNSON ELECTRIC OLDENBURG

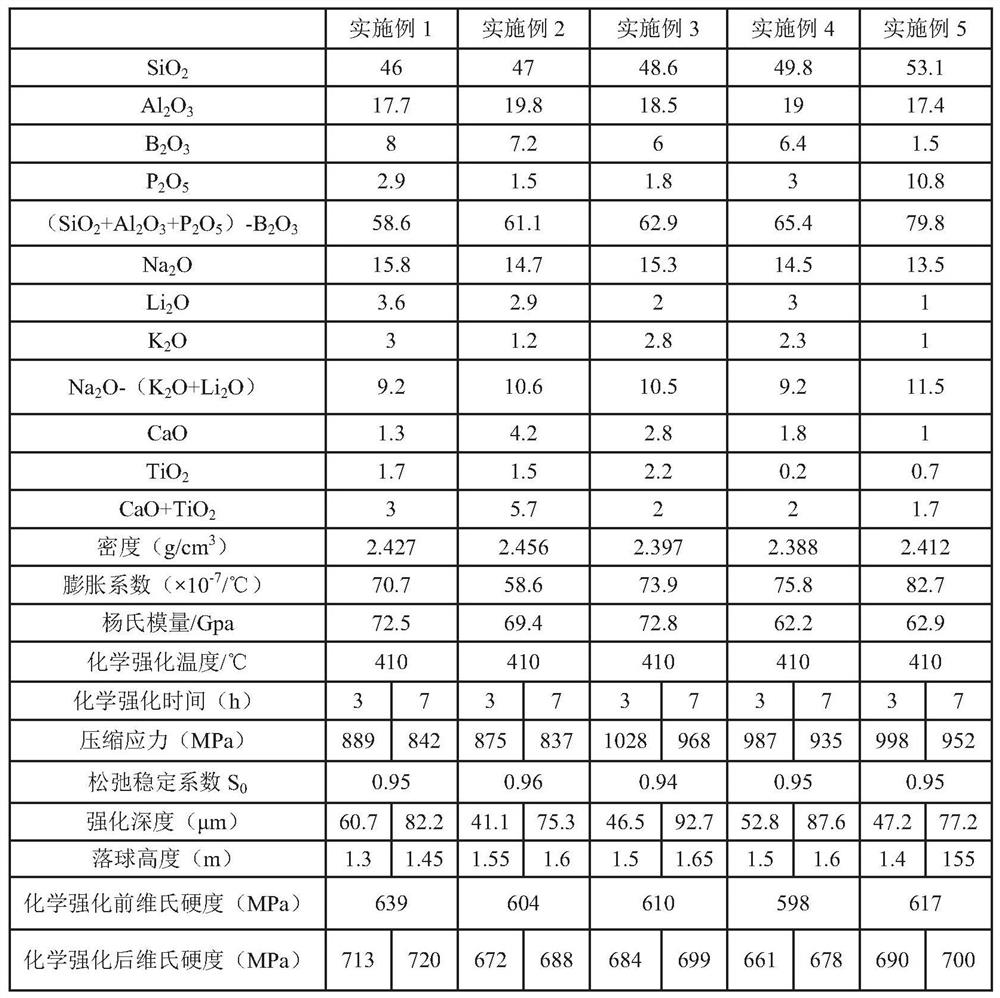

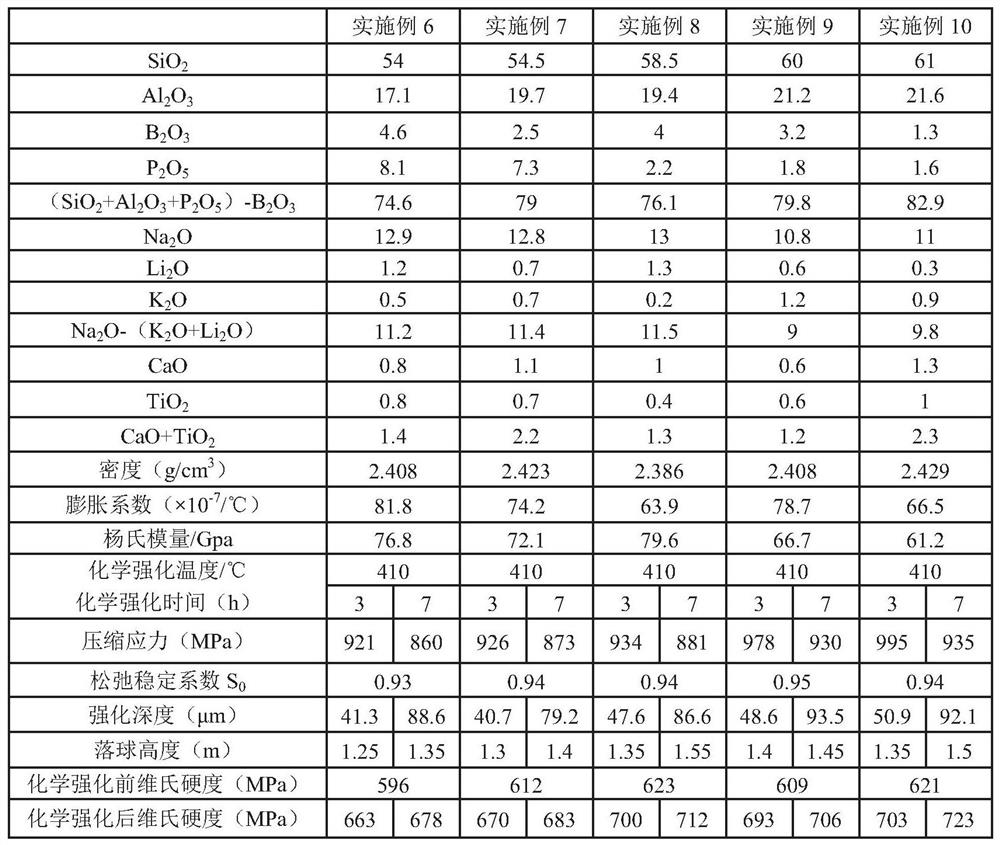

Composition for glass, glass, preparation method and application thereof

ActiveCN107892472BImprove performanceImprove the strengthening effectGlass shaping apparatusInput/output processes for data processingDisplay deviceStress relaxation

The invention relates to the field of glass materials, and discloses a composition for glass, glass and a preparation method and application thereof. The composition for glass of the present invention, based on the total weight of the composition for glass, contains 45-66% by weight of SiO 2 , 10‑23% by weight Al 2 o 3 , 0.01‑10% by weight of B 2 o 3 , 0.01‑12% by weight of P 2 o 5 , 10‑19% by weight Na 2 O, 0.01‑5% by weight of K 2 O, 0.01‑5% by weight Li 2 O, 0.01-5% by weight of CaO and 0.01-3% by weight of TiO 2 . The components in the glass composition of the present invention act synergistically to effectively improve the stress relaxation of the prepared glass, and have the advantages of enhanced compressive stress, deep strengthening depth and high impact resistance. It is suitable for protecting display devices, especially for protective covers of display devices, such as touch screen covers.

Owner:DONGXU OPTOELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com