Composite buffer for crane

A composite, buffer technology, applied in the direction of shock absorbers, shock absorbers, mechanical equipment, etc., can solve the problems of increasing the production cost of the crane, increasing the raw materials of the crane, increasing the volume of the crane, etc., and achieves light weight, low cost, and high production. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

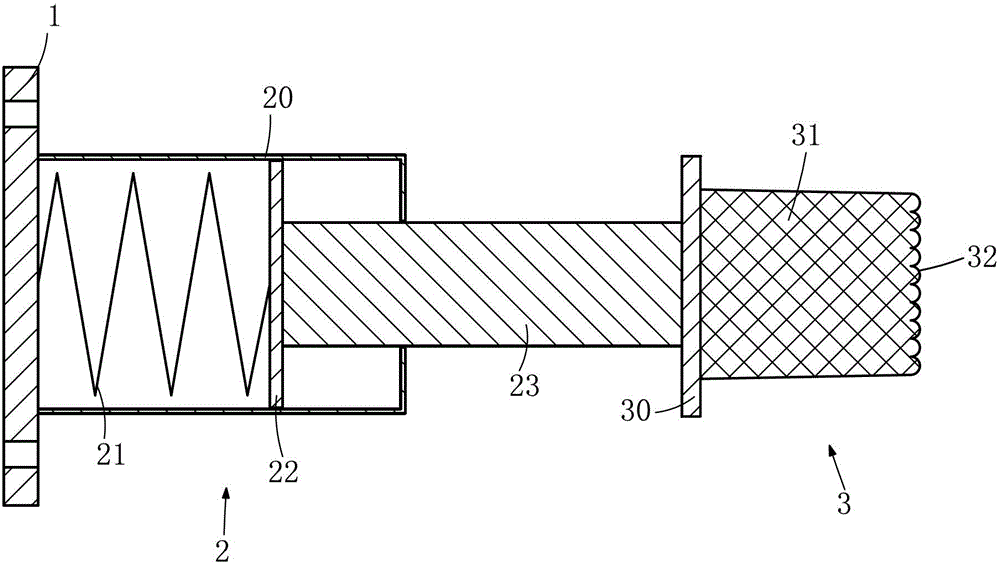

[0017] Such as figure 1 As shown, a composite buffer for a crane includes a base 1, on which a primary buffer device 2 is arranged, and the primary buffer device 2 includes a housing 20 fixed on the base 1, and a spring 21 is arranged in the housing 20 , one end of the spring 21 is fixed on the base 1, the other end of the spring 21 is connected with a piston 22, the other side of the piston 22 is provided with a piston rod 23, and one end of the piston rod 23 passes through the housing 20; the composite buffer also includes The secondary buffer device 3 is connected with the end of the piston rod 23 exposed outside the casing 20 . When a collision occurs, the spring 21 inside the primary buffer device 2 is first compressed to act as a buffer. When the spring 21 is completely compressed and the secondary buffer device 3 is in contact with the housing of the primary buffer device 2, the The first-stage buffer device 3 is compressed to further play a buffering role. The combine...

Embodiment 2

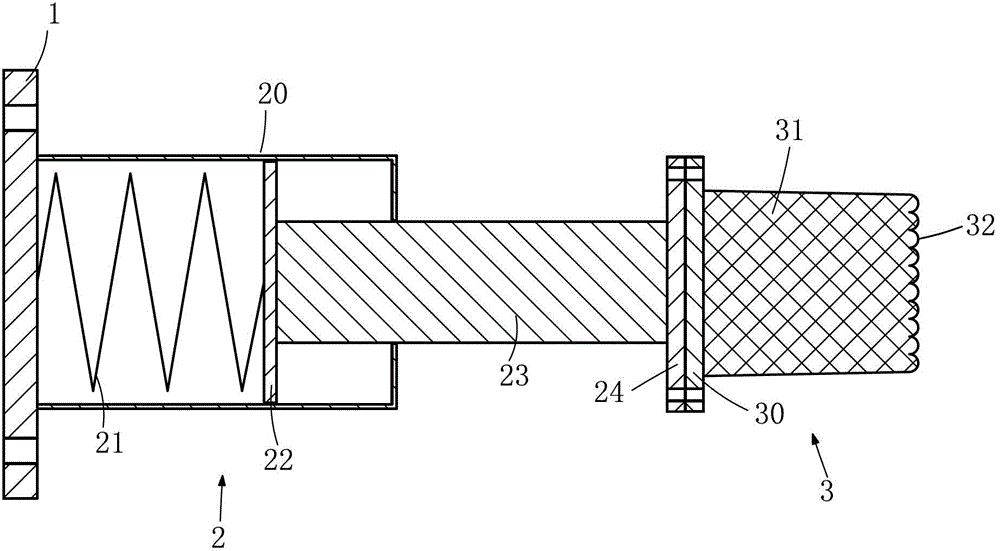

[0021] Such as figure 2 As shown, a composite buffer for a crane has a structure basically the same as that of Embodiment 1, the difference is that a connection plate 24 is provided at the end where the piston rod 23 passes through the housing 20, and the secondary buffer device 3 and the connection plate 24 connections make the installation of the composite buffer more convenient, and it is also very convenient to replace the primary buffer device 2 or the secondary buffer device 3, prolonging the service life of the composite buffer.

[0022] Working principle of the present invention: when a collision occurs, the secondary buffer device 3 is first stressed, and the secondary buffer device 3 transmits the compression force to the piston 22 through the piston rod 23, and the piston 22 compresses the spring 21. When the spring 21 is completely compressed At this time, the connecting bottom plate 30 of the secondary buffer 3 is in contact with the shell of the primary buffer 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com