Chemically-strengthenable glasses for laminates

A technology for glass products and glass compositions, applied in windshields, chemical instruments and methods, glass/slag layered products, etc., can solve problems such as increasing the cost of manufacturing processes, and achieve the effect of increasing compressive stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

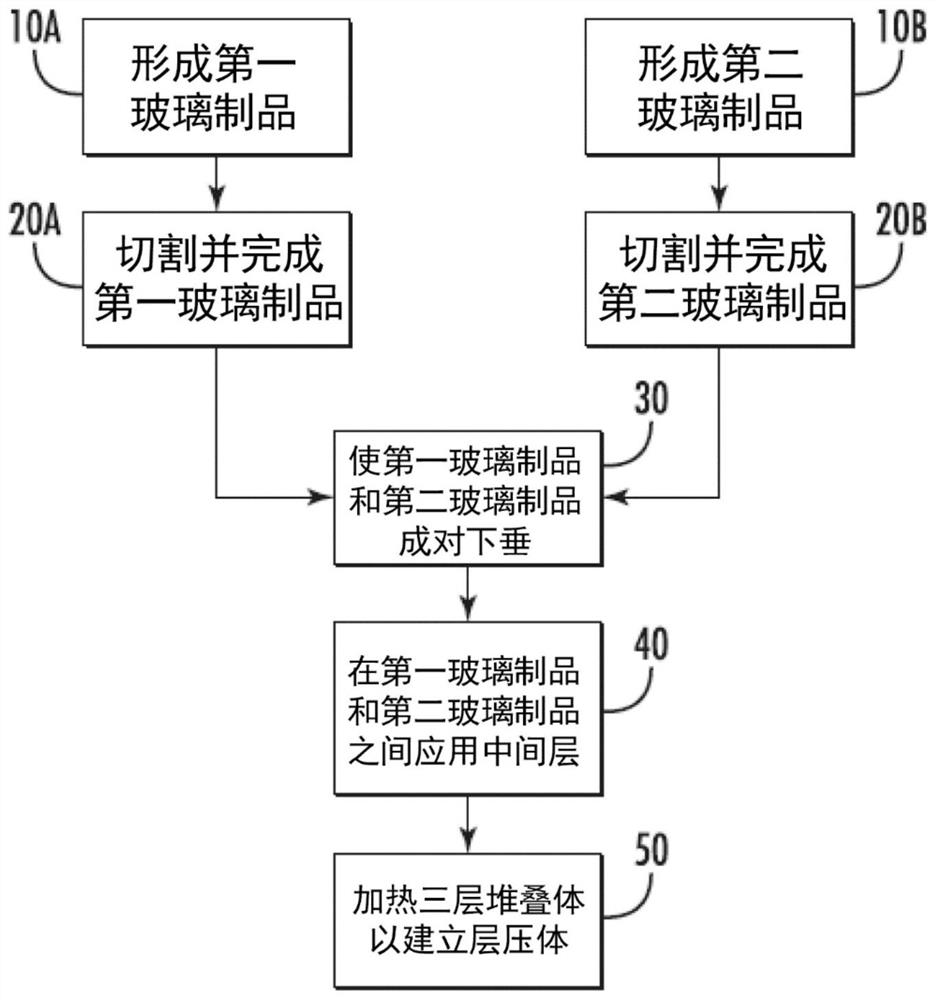

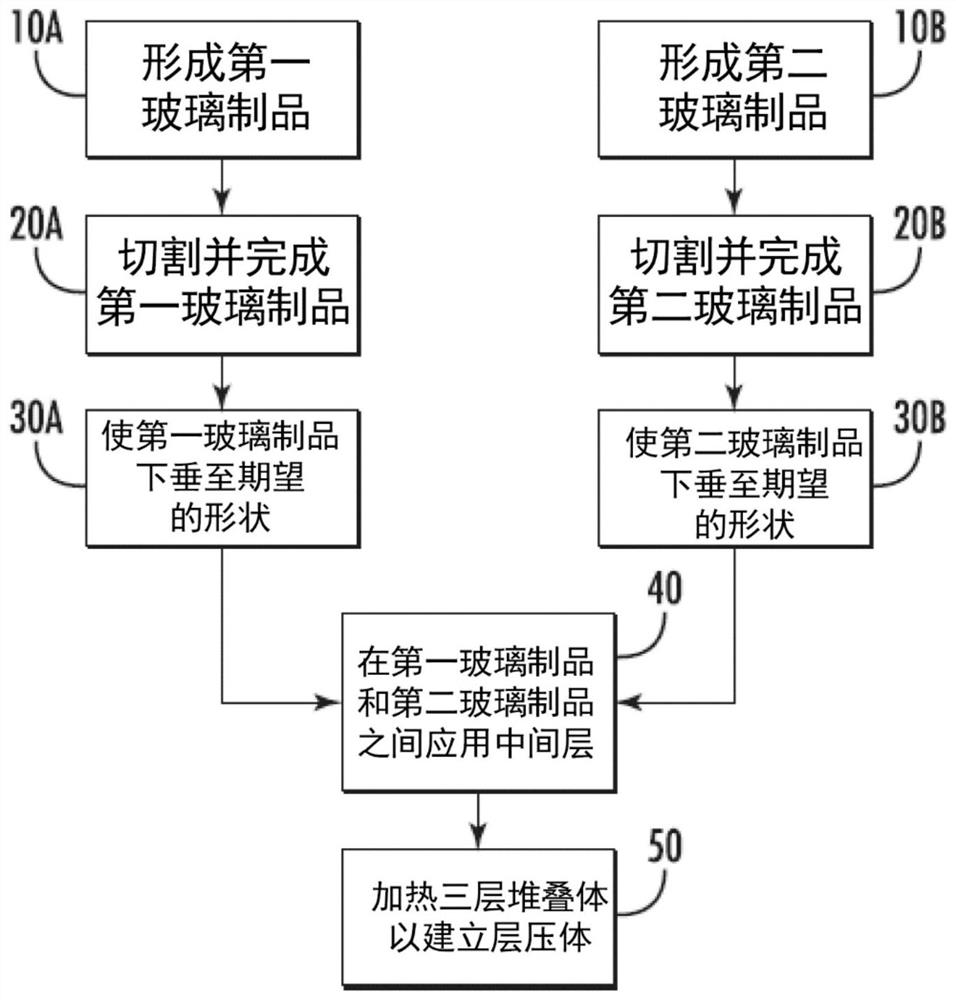

Method used

Image

Examples

Embodiment

[0167] The present disclosure can be further understood by reference to the following examples.

[0168] Table 1, Compositions and Properties of Comparative Examples 1 and 2 and Examples 1 to 5

[0169]

[0170]

[0171] Table 2. Compositions and Properties of Examples 6 to 11

[0172]

[0173]

[0174] Table 3. Compositions and Properties of Examples 12 to 17

[0175]

[0176]

[0177] Table 4. Compositions and Properties of Examples 18 to 21

[0178]

[0179]

[0180] Examples 1-21 are examples of glass compositions made according to the present disclosure. The glass compositions (expressed in mol%) of Examples 1 to 21 are described in Tables 1 to 4. Table 1 also includes information related to strain point temperature (measured by beam bending viscometer), annealing point temperature (measured by beam bending viscometer), softening point temperature (measured by parallel plate), density at 20°C, CTE, refractive index, and stress optic coefficient...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive stress | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com