Single-layer fireproof tempered glass preparation method

A tempered glass, single-layer technology, applied in the direction of glass manufacturing equipment, glass tempering, manufacturing tools, etc., can solve the problems of high installation cost, easy to appear bubbles, poor weather resistance, etc., to achieve improved impact resistance, easy installation, high The effect of weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

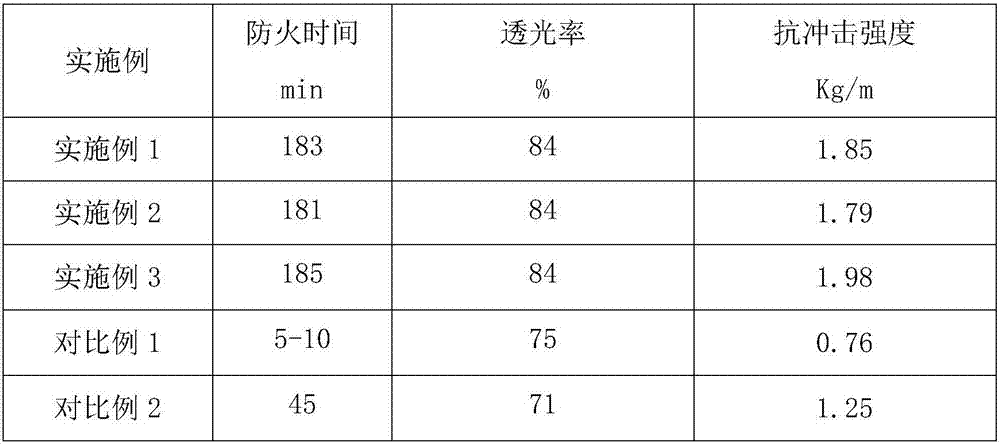

Examples

Embodiment 1

[0023] A method for preparing single-layer fireproof tempered glass, comprising the following steps:

[0024] (1) Pretreatment: Prepare a mixed acid solution with a concentration of 18% nitric acid and a concentration of 10% hydrofluoric acid, wherein the volume ratio of nitric acid and hydrofluoric acid is 1:0.7; use the mixed acid solution to treat the glass surface Acid treatment, then wash and dry the acid-treated glass, preheat to 420°C, and keep it warm for 20 minutes;

[0025] (2) Send the pre-treated glass into a tempering furnace for tempering treatment, the tempering treatment temperature is 650°C, and the tempering treatment time is 1h;

[0026] (3) While tempering and heating the glass, spray the cesium potassium salt solution of a specific composition twice, and perform the second spraying 10 minutes after the first spraying, and the spraying amount of the cesium potassium salt solution is 3g / cm 2 , spray thickness is 3mm; cesium potassium salt solution is compos...

Embodiment 2

[0029] A method for preparing single-layer fireproof tempered glass, comprising the following steps:

[0030] (1) Pretreatment: Prepare a mixed acid solution with a concentration of 18% nitric acid and a concentration of 10% hydrofluoric acid, wherein the volume ratio of nitric acid and hydrofluoric acid is 1:1.4; use the mixed acid solution to treat the glass surface Acid treatment, then wash and dry the acid-treated glass, preheat to 460°C, and keep it warm for 30 minutes;

[0031] (2) Send the pre-treated glass into a tempering furnace for tempering treatment, the tempering treatment temperature is 730°C, and the tempering treatment time is 2h;

[0032] (3) While tempering and heating the glass, spray the cesium potassium salt solution of a specific composition twice, and perform the second spraying 15 minutes after the first spraying, and the spraying amount of the cesium potassium salt solution is 5g / cm 2 , spray thickness is 5mm; cesium potassium salt solution is compos...

Embodiment 3

[0035] A method for preparing single-layer fireproof tempered glass, comprising the following steps:

[0036] (1) Pretreatment: Prepare a mixed acid solution with a concentration of 18% nitric acid and a concentration of 10% hydrofluoric acid, wherein the volume ratio of nitric acid and hydrofluoric acid is 1:1; use the mixed acid solution to treat the glass surface Acid treatment, then wash and dry the acid-treated glass, preheat to 440°C, and keep it warm for 25 minutes;

[0037] (2) Send the pre-treated glass into a tempering furnace for tempering treatment, the tempering treatment temperature is 690°C, and the tempering treatment time is 1.5h;

[0038] (3) While tempering and heating the glass, spray the cesium potassium salt solution of a specific composition twice, and perform the second spraying 13 minutes after the first spraying, and the spraying amount of the cesium potassium salt solution is 4g / cm 2 , the spray thickness is 4mm; the cesium potassium salt solution i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com