House used for livestock breeding

A livestock and poultry breeding and house technology, applied in poultry cages or houses, animal houses, applications, etc., can solve the problems of various bacteria affecting the healthy growth of livestock and poultry, the inability to establish an immune system, and the lack of vitamins in animals, etc., to achieve It is beneficial to the growth of livestock and poultry, reduces the loss of heat, and has the effect of strong acid resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

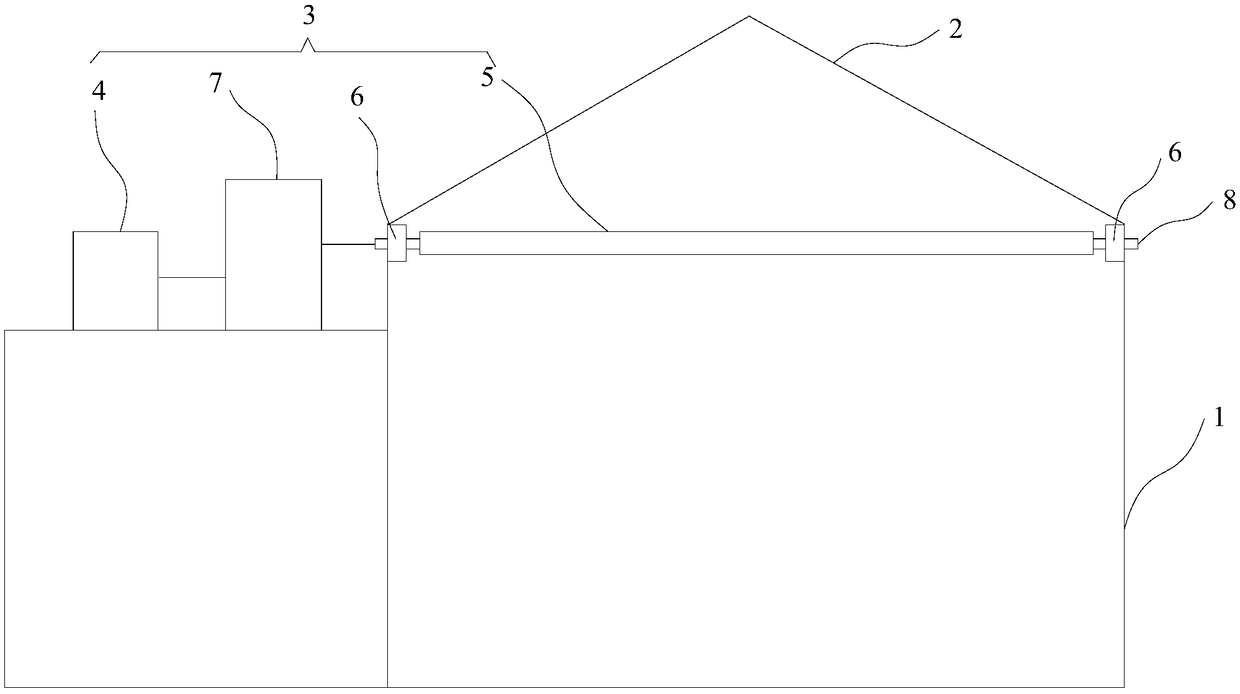

[0025] See figure 1 The embodiment of the present invention provides a house 1 for livestock and poultry breeding. The roof of the house 1 is set as a double-layer roof, the upper roof 2 is set as an inverted V shape, and the lower roof 3 is parallel to the horizontal plane. The upper roof 2 is set as a light-transmitting roof, and the lower roof 3 is set as an opaque heat-insulation roof. The upper roof 2 is made of transparent materials, and the lower roof 3 is set as a reversible light-blocking fence structure. In this embodiment, the reversible light-blocking fence structure includes a controller 4, ten light-blocking fences 5, ten support rods 6 and servo motors 7 equal in number to the ten light-blocking fences. Ten support rods 6 are respectively fixed at the opposite phase ends of the inner side of the upper roof 2 , that is, each end of the inner side of the upper roof 2 is respectively provided with five support rods 6 . The opposite ends of each light-blocking fen...

Embodiment 2

[0029] In this embodiment, except for the parts by weight of the composition of the glass material used to make the upper roof 2, the parts by weight of the composition of the light-absorbing reflective coating provided on the outer surface or inner surface of the light-blocking grille 5 and the diluent are different Except, others are identical with embodiment 1.

[0030] In this embodiment, the upper roof 2 is made of glass material. The glass material includes the following components by weight: 85 parts of quartz sand, 4 parts of calcium oxide, 0.4 part of iron oxide, 0.3 part of titanium dioxide, 0.2 part of bismuth trioxide, 0.2 part of thickener, 0.3 part of aluminum oxide , 4 parts of kaolin, 0.3 parts of vanadium dioxide, 8 parts of soda ash, 0.2 parts of niobium dioxide, 0.2 parts of tellurium dioxide, 0.2 parts of silver chloride, 6 parts of lithium oxide, 6 parts of tungsten carbide, 3 parts of sodium alginate, fluorine 3 parts of sodium silicate and 4 parts of ac...

Embodiment 3

[0033] In this embodiment, except for the parts by weight of the composition of the glass material used to make the upper roof 2, the parts by weight of the composition of the light-absorbing reflective coating provided on the outer surface or inner surface of the light-blocking grille 5 and the diluent are different Except, others are identical with embodiment 1.

[0034] In this embodiment, the upper roof 2 is made of glass material. The glass material includes the following components by weight: 89 parts of quartz sand, 6 parts of calcium oxide, 0.6 part of iron oxide, 0.4 part of titanium dioxide, 0.3 part of bismuth trioxide, 0.3 part of thickener, and 0.4 part of aluminum oxide , 5 parts of kaolin, 0.4 parts of vanadium dioxide, 11 parts of soda ash, 0.3 parts of niobium dioxide, 0.3 parts of tellurium dioxide, 0.3 parts of silver chloride, 7 parts of lithium oxide, 7 parts of tungsten carbide, 4 parts of sodium alginate, fluorine 4 parts of sodium silicate and 5 parts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com