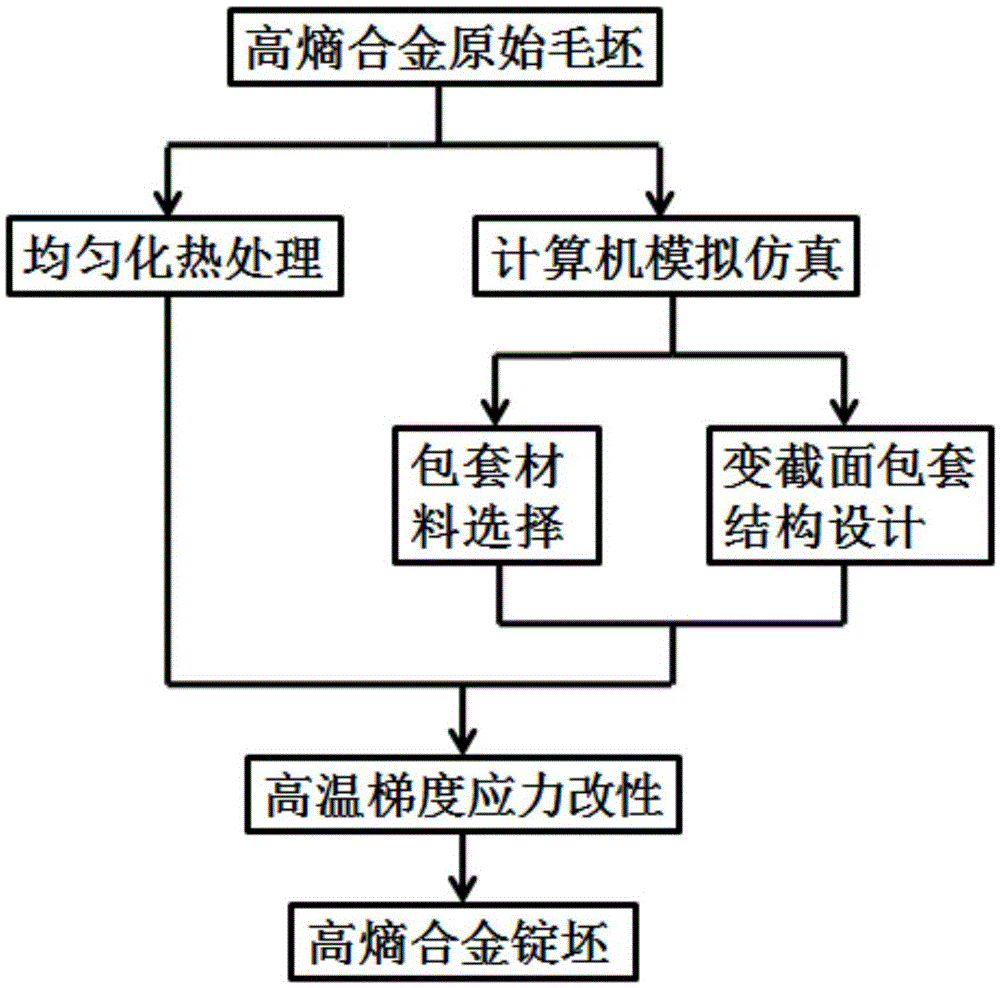

High-entropy alloy gradient stress modification technology

A high-entropy alloy and gradient stress technology, applied in the field of plastic modification, can solve problems such as crystal distortion and easy cracking during plastic processing, and achieve the effect of uniform structure, uniform and excellent structure performance, and convenient and simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Taking AlCoCrFeNiTi as an example, this embodiment is an AlCoCrFeNiTi with uniform structure and significantly improved mechanical properties prepared by high-temperature gradient stress modification technology. 0.5 The method for the high-entropy alloy ingot billet is specifically completed according to the following steps:

[0022] (1) Preparation of high-entropy alloy AlCoCrFeNiTi 0.5 Ingot casting: the selected composition is AlCoCrFeNiTi 0.5 In the ingot of the high-entropy alloy, the molar ratios of the six elements are Al:Co:Cr:Fe:Ni:Ti=1:1:1:1:1:0.5.

[0023] (2) Homogenization heat treatment: AlCoCrFeNiTi selected in step (1) 0.5 The high-entropy alloy ingot is subjected to homogenization heat treatment. The temperature of the homogenization heat treatment is 1000°C-1100°C, and then the heat preservation treatment is carried out according to the thickness of the ingot 0.8-1min / mm. The heat preservation time of the homogenization heat treatment is 12h-100h, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com