Microswitch

An electrical switch and reed technology, applied in the field of micro switches, can solve the problems of high design cost of switch design scheme, weakened switch function, increased production cost, etc., and achieve the effect of favorable design scheme, improved durable performance and simple cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

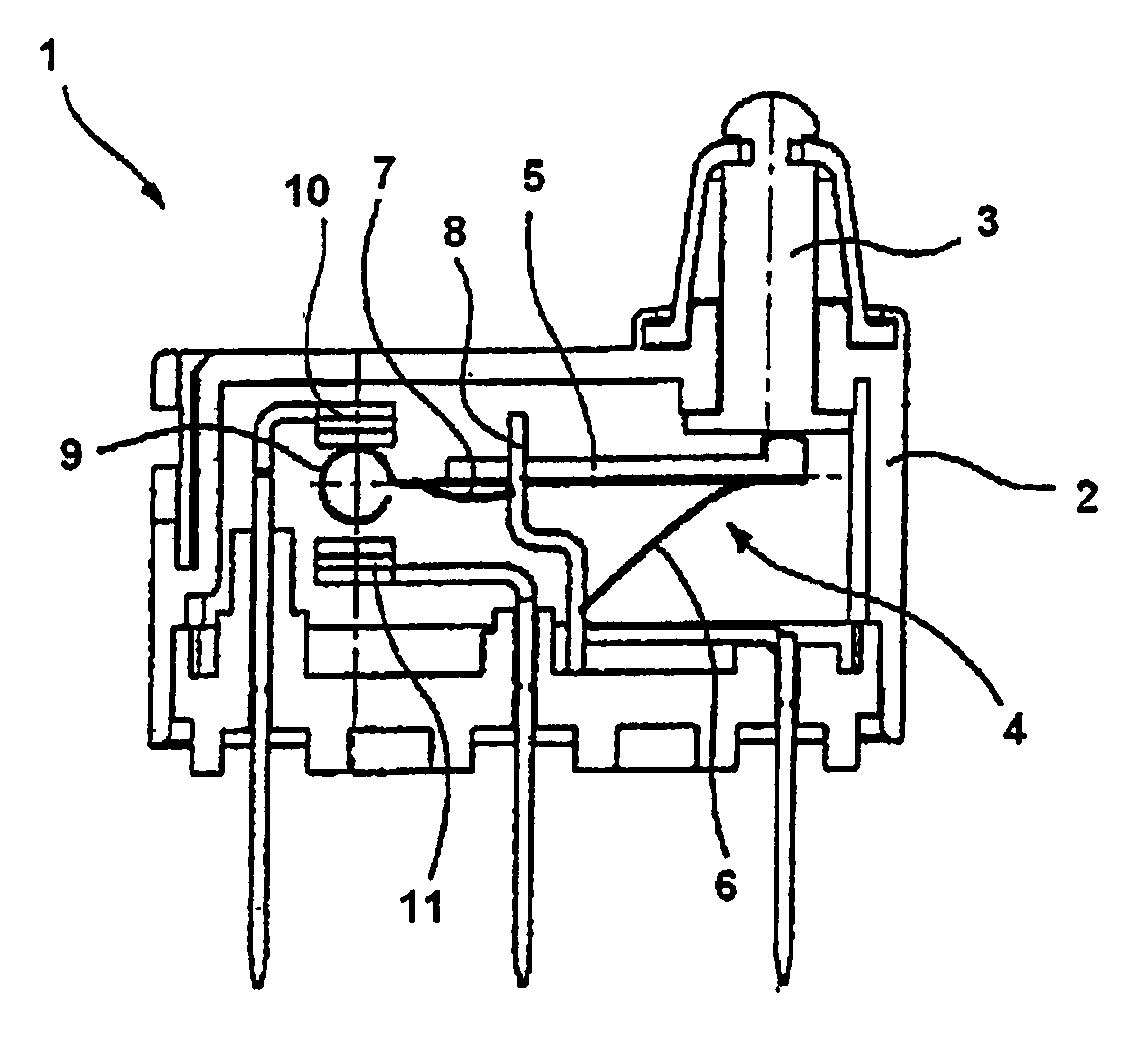

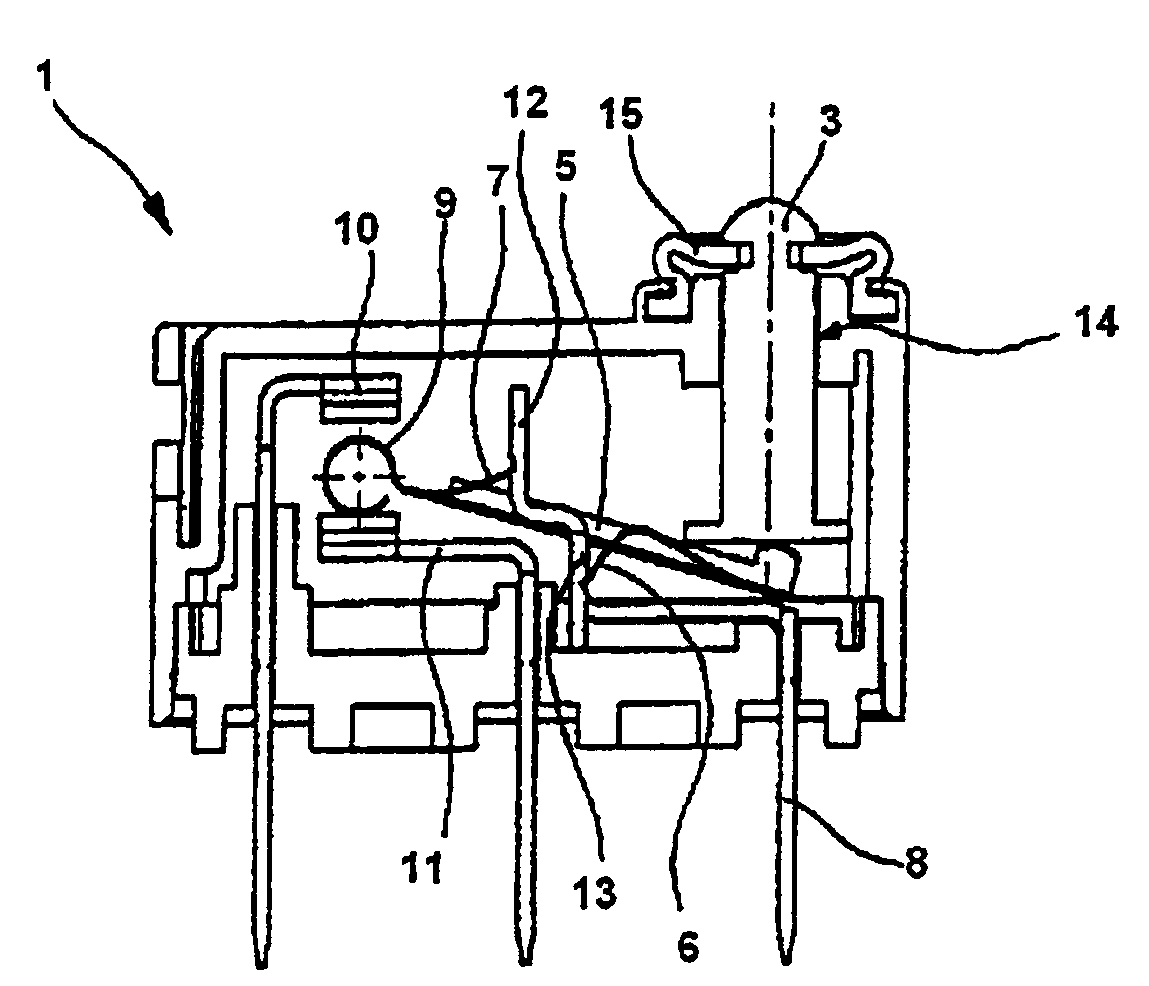

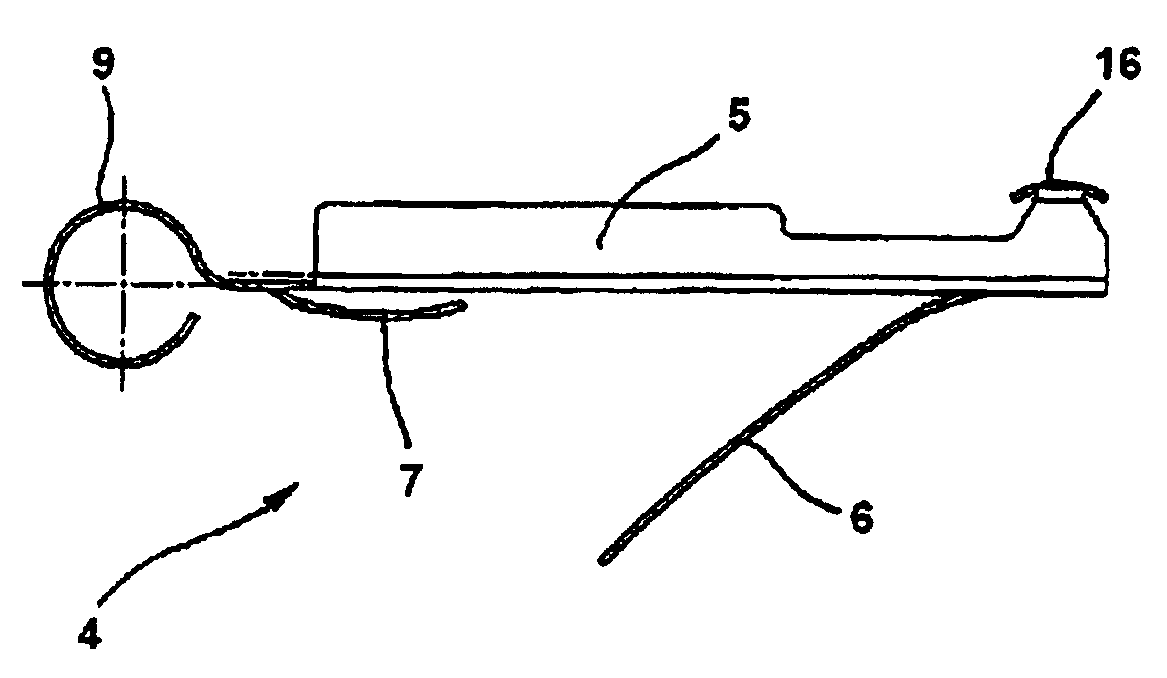

[0021] use figure 1 A microswitch is shown, which has at least one housing 2 and an actuating element 3 protruding into the housing, which in turn contacts a contact spring 4 which can be jumped over to different switching positions. bump. The contact spring 4 has a closed spring frame 5 on which two spring tongues 6 , 7 extending approximately in opposite directions are arranged in a flexible manner. The reed tongues 6 , 7 are preferably formed in one piece with the spring frame 5 and are supported on both sides on a carrier 8 designed as an electrical contact. In this case, the first reed tongue 6 is a longitudinally bent spring leaf which is loaded with compressive stress at least in its longitudinal direction, and which additionally serves as a return device for the actuator 3 . The second reed tongue 7 preferably controls the switching function of a contact area 9 formed on the contact spring 4 which can be switched back and forth between the upper contact 10 and the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com