Ultrasonic rolling recombination laser remelting method for improving fatigue property of welded joint

A technology of laser remelting and welding joints, applied in the field of surface strengthening and material processing, it can solve the problems of low bonding strength between the surface coating and the substrate, the fatigue performance does not play a fundamental role, and the fatigue performance of the material is reduced. Increased stress, improved surface texture, enhanced effect of texture improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

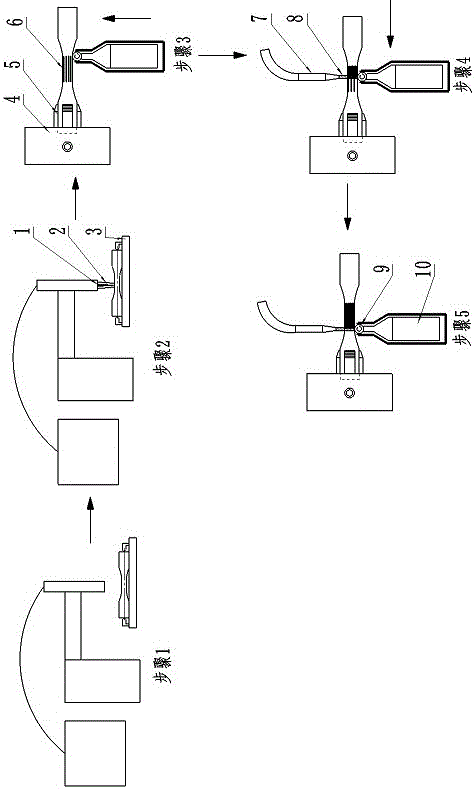

Method used

Image

Examples

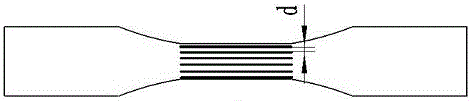

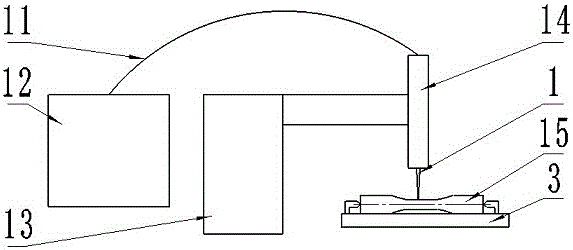

Embodiment 1

[0056] Based on the AZ31B magnesium alloy, ultrasonic rolling combined laser remelting treatment was carried out. AZ31B magnesium alloy size form see Figure 5 , the morphology of the magnesium alloy sample before and after the composite method is as follows Figure 6 shown. Among them, the parameters used in laser processing are: power: 1.1KW; scanning speed: 600mm / min; spot diameter: 3mm; argon gas protection; protection gas flow rate: 15L / min. The processing parameters of ultrasonic rolling are: the impact ball adopts Cr15 steel ball with a diameter of 15 mm; during processing, the magnesium alloy sample is clamped on the chuck 4 of the CNC machine tool, and the ultrasonic rolling device 10 is fixed on the turret of the machine tool instead of the lathe. Knife position, the specific processing parameters are: speed: 250r / min; feed speed: 10mm / min; static pressure: 200N; frequency: 20KHz; processing times: reciprocating three times; coolant: wire cutting cooling milk. The...

Embodiment 2

[0058] The samples before and after strengthening of above-mentioned embodiment 1 are carried out fatigue test, fatigue S-N curve is as follows Figure 8 shown. It can be seen that the fatigue life of the magnesium alloy strengthened by the composite method has been greatly improved, corresponding to 10 7 Under the cycle times, the fatigue performance is improved by more than 20%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com