Hard alloy drill plate and drill bit

A technology of cemented carbide and brazing chips, which is applied in the direction of drill bits, drilling equipment, earthwork drilling and mining, etc., can solve problems such as uneven internal stress of the brazing chip, asymmetric compressive stress of the alloy brazing chip, production efficiency and benefit impact, etc. Achieve the effects of increasing the lateral compressive stress emission area, preventing splitting, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

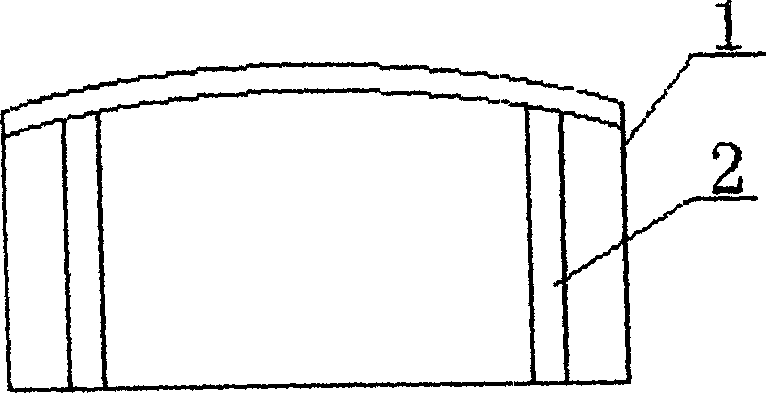

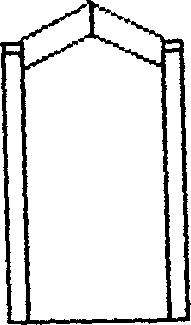

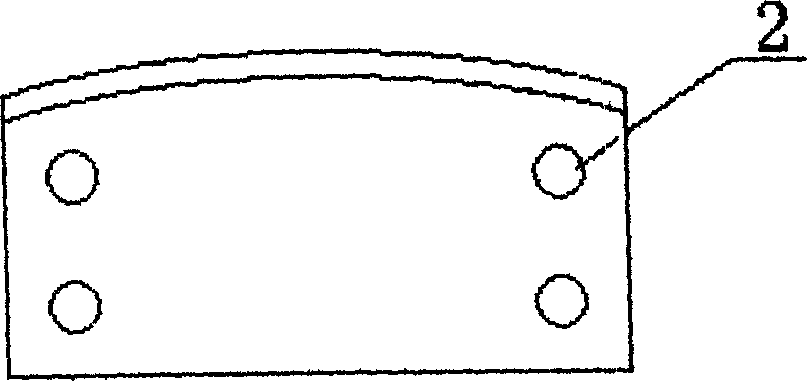

[0025] See figure 1 , figure 2 , The brazing piece of the present invention includes a sheet body 1, on both sides of the sheet body 1 there are positioning blocks 2 with strip-shaped protrusions of the same height, and two positioning blocks are symmetrically distributed on each side. Another kind of structure of brazing piece of the present invention sees image 3 , There are four positioning blocks 2 symmetrically distributed on each side of the brazing chip body. Figure 4 The positioning blocks are shown as three symmetrically distributed.

[0026] See Figure 5 , Image 6 , Figure 7 , The two side surfaces 3 of the brazing chip body 1 of the present invention are arc-shaped symmetrical surfaces concave inward.

[0027] The drill bit of the present invention sees Figure 8 , Figure 9 , the drill bit comprises a trousers body 4, on which there is a brazing chip fixing groove 6, and the brazing chip fixing groove 6 is embedded with the hard alloy brazing chip 1 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com