Additive manufacturing method, method and equipment for preparing gradient film materials

A thin film material and additive manufacturing technology, applied in the field of additive manufacturing, can solve the problems of uneven bonding area bonding force, low production efficiency, poor mechanical strength, etc., to reduce deposition defects, improve production efficiency, and reduce surface roughness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

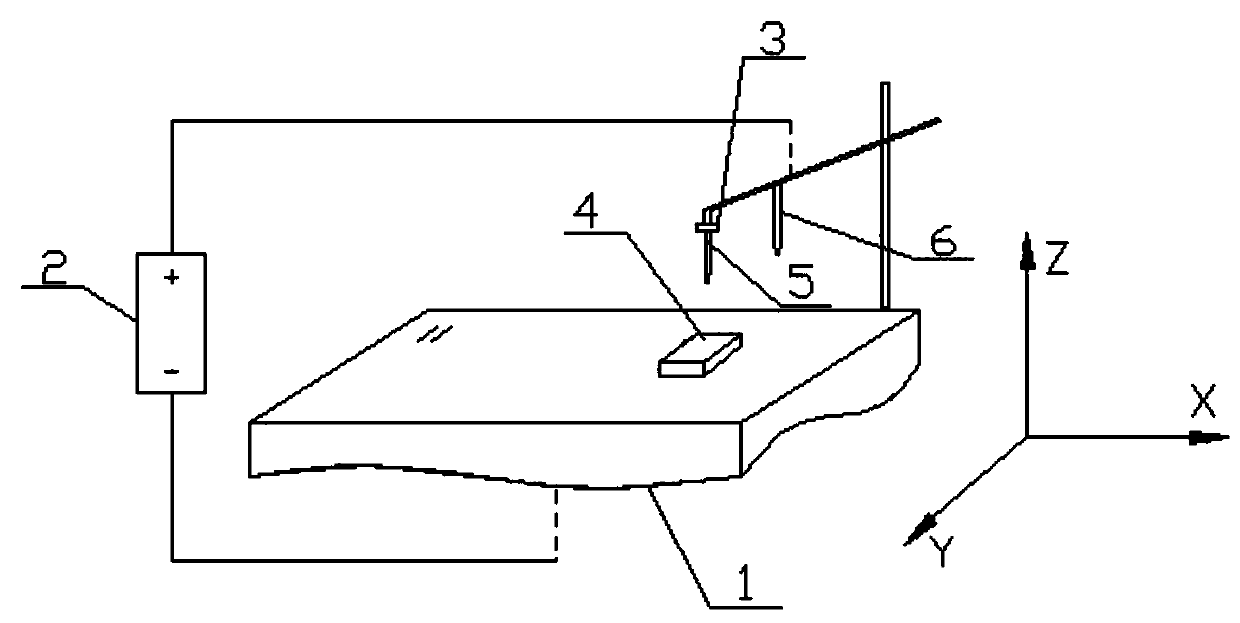

[0046] The matrix 4 of the gradient film material of this embodiment is a 301L alloy steel plate, the first tissue layer and the second tissue layer are both ferrite, wherein the thickness of the matrix 4 is 5 mm, and the first tissue layer The grain size of the second tissue layer is 20nm, and the thickness is 40μm. The grain size of the second tissue layer is 10nm, and the thickness is 40μm. The deposition materials 5 that constitute the first tissue layer and the second tissue layer are all diameter 0.9mm low carbon steel.

[0047] The preparation process of the gradient film material is as follows:

[0048] 1) Place the 301L alloy steel plate on the workbench 1 and connect it to the cathode of the power supply 2, and then clamp the low carbon steel with the electrode clamping part 3 connected to the anode of the power supply 2 , and then control the movement route of the low-carbon steel through the first control mechanism, so that the low-carbon steel is deposited on the...

Embodiment 2

[0053] The matrix 4 of the gradient film material in this embodiment is a 301L alloy steel plate, the first tissue layer and the second tissue layer are both austenite, wherein the thickness of the matrix 4 is 5 mm, and the first tissue layer The grain size of the second tissue layer is 35 nm, and the thickness is 70 μm. The grain size of the second tissue layer is 20 nm, and the thickness is 60 μm. 0.9mm 301 stainless steel.

[0054] The preparation process of the gradient film material is as follows:

[0055] 1) Place the 301L alloy steel plate on the workbench 1 and connect it to the cathode of the power supply 2, and then clamp the 301 stainless steel with the electrode clamping part 3 connected to the anode of the power supply 2, Then, the movement route of the 301 stainless steel is controlled by the first control mechanism, so that the 301 stainless steel is deposited on the surface of the 301L alloy steel plate and forms the first layer of tissue layer, wherein the vo...

Embodiment 3

[0060] The substrate 4 of the gradient film material in this embodiment is a 301L alloy steel plate, the first layer of structure is ferrite, its grain size is 25nm, and its thickness is 50 μm. The deposition material 5 that constitutes the first layer of structure is a diameter It is 0.9mm low-carbon steel, the second structure layer is austenite, its grain size is 15nm, and its thickness is 45 μm, and the deposition material 5 constituting the second structure layer is 301 stainless steel with a diameter of 0.9mm, The thickness of the base body 4 is 5 mm.

[0061] The preparation process of the gradient film material is as follows:

[0062] 1) Place the 301L alloy steel plate on the workbench 1 and connect it to the cathode of the power supply 2, and then clamp the low carbon steel with the electrode clamping part 3 connected to the anode of the power supply 2 , and then control the movement route of the low-carbon steel through the first control mechanism, so that the low-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com