Method for improving energy density of lithium-ion power battery and lithium-ion power battery

A power battery and energy density technology, applied in the field of electrochemistry, can solve the problems of low energy density and achieve the effect of increasing energy density and driving distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] (2) The negative electrode sheet is made of a negative electrode material with a high liquid absorption rate and a high liquid retention rate for the electrolyte, and the negative electrode material is prepared by the following method: calcining the oil-based needle coke raw material at 1300-1800 °C to a pore size 10-15%; the calcined needle coke is mixed with liquid pitch at 100-300°C and 2-10 atmospheres for high-pressure impregnation until the pore size is 3-10%; the impregnated needle coke Coke is graphitized at 3000-3800°C to obtain graphite with a pore size of 0.01-100 μm and a pore size of 50-70%; the above-mentioned graphite is made into graphite particles with D10≥3 μm, D50 of 3-15 μm, and D90≤20 μm ; The above-mentioned graphite particles are coated with furan resin, bakelite resin or hard carbon; the coated graphite particles are subjected to halogenation purification to obtain negative electrode materials;

[0027] (3) adopt the copolymer binding agent with ...

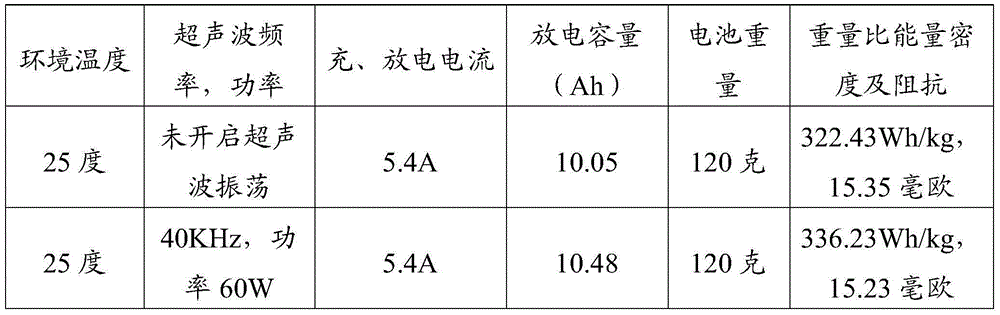

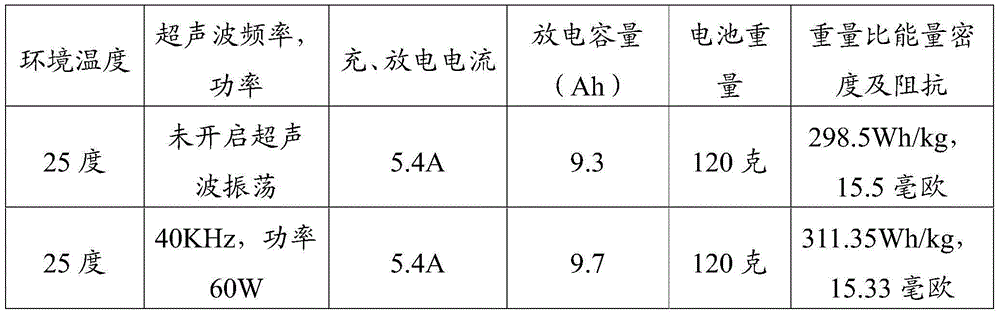

Embodiment 1

[0067] To make a polymer lithium-ion battery with a model number of 0495150 and a capacity of 10.48 ampere hours (Ah), the specific steps are as follows:

[0068] The oil-based needle coke raw material is calcined at 1300 °C, and the temperature of the raw material is about 300 °C, and the gap left after the volatile matter of the raw material is removed after calcination, such high-temperature needle coke is directly put into the vacuum autoclave for high-pressure Dipping, there is asphalt in the autoclave, after feeding such high-temperature needle coke, vacuumize, at a temperature of 100 to 300 degrees and a pressure of 2 to 10 atmospheres, the liquid asphalt penetrates into the pores of the needle coke, thereby To improve the tap density of the product. The porosity dropped from the original 10%-15% to about 3%. The resulting semi-finished product is packaged in a graphite clamp pot and subjected to graphitization treatment at 3000°C. Since the needle coke has been turne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com