Composite membrane for lithium sulphur battery and preparation method thereof

A lithium-sulfur battery and composite membrane technology, which is applied to battery components, circuits, electrical components, etc., can solve the problems of increasing the battery shuttle effect, improve Coulombic efficiency and cycle life, inhibit the formation of dendrites, Effect of High Coulombic Efficiency and Cycle Life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

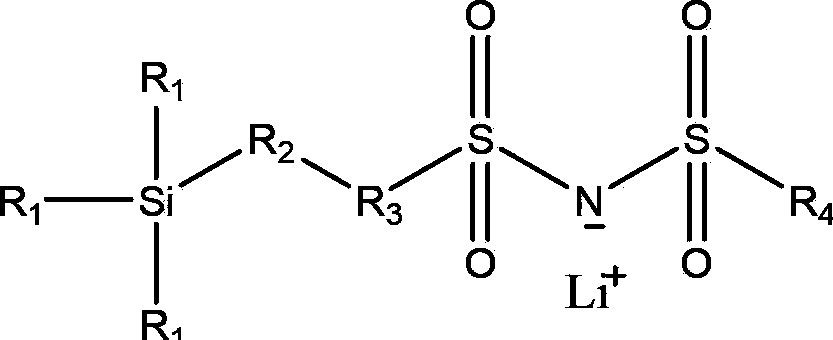

[0053] A commercial polypropylene separator (Celgard 2500) was plasma-modified. The modification conditions are under an oxygen atmosphere, the gas flow rate is 60 sccm, the processing power is 100 W, and the processing time is 1 minute and then taken out. Place the diaphragm in 0.5molL -1 After soaking in the ethanol solution of lithium silane imide (the structural formula is shown in formula 1) for 24 hours, take it out. After repeated rinsing with water and ethanol, place in vacuum-dried at 60°C for 48 hours to remove water and set aside. The modified diaphragm was tested according to the method of Comparative Example 1. The experimental results are shown in Table 1.

Embodiment 2

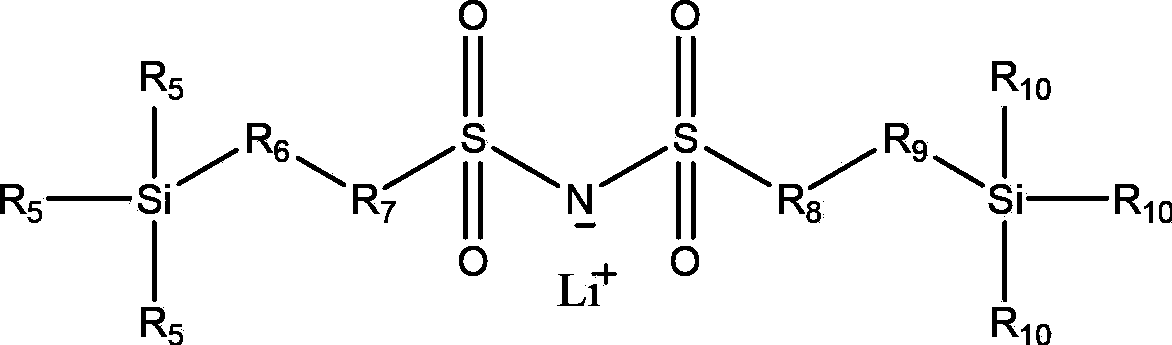

[0055]A commercial polypropylene separator (Celgard 2500) was plasma-modified. The modification conditions are under an oxygen atmosphere, the gas flow rate is 70 sccm, the processing power is 200W, and the processing time is 2 minutes before taking out. Place the diaphragm in 0.7molL -1 The lithium silaneimide (structural formula shown in formula 2) was soaked in methanol solution for 24 hours, and then taken out. After repeated washing with water and methanol, vacuum-dry at 60°C for 48 hours to remove water and set aside. The modified diaphragm was tested according to the method of Comparative Example 1. The experimental results are shown in Table 1.

Embodiment 3

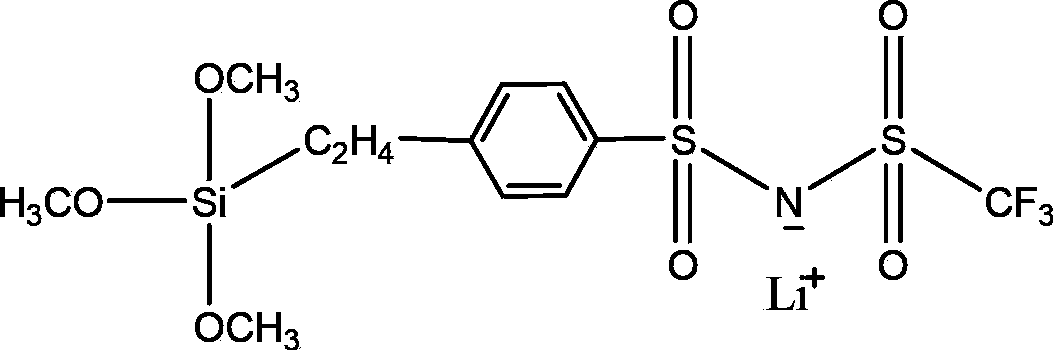

[0057] A commercial polypropylene separator (Celgard 2500) was plasma-modified. The modification conditions are under an argon atmosphere, the gas flow rate is 80 sccm, the processing power is 300 W, and the processing time is 10 minutes before taking out. Place the diaphragm in 1molL -1 Lithium silaneimide (structure formula shown in formula 3) was soaked in toluene solution for 18 hours, and then taken out. After repeated washing with water and isopropanol, vacuum-dry at 60°C for 48 hours to remove water and set aside. The modified diaphragm was tested according to the method of Comparative Example 1. The experimental results are shown in Table 1.

[0058] Table 1

[0059]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com