Gel film for cleaning mildew and dust on surface of cultural relic

A technology of gel film and mildew spot, applied in the field of gel cleaning agent, to achieve good liquid retention, prevent secondary pollution, and easy storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

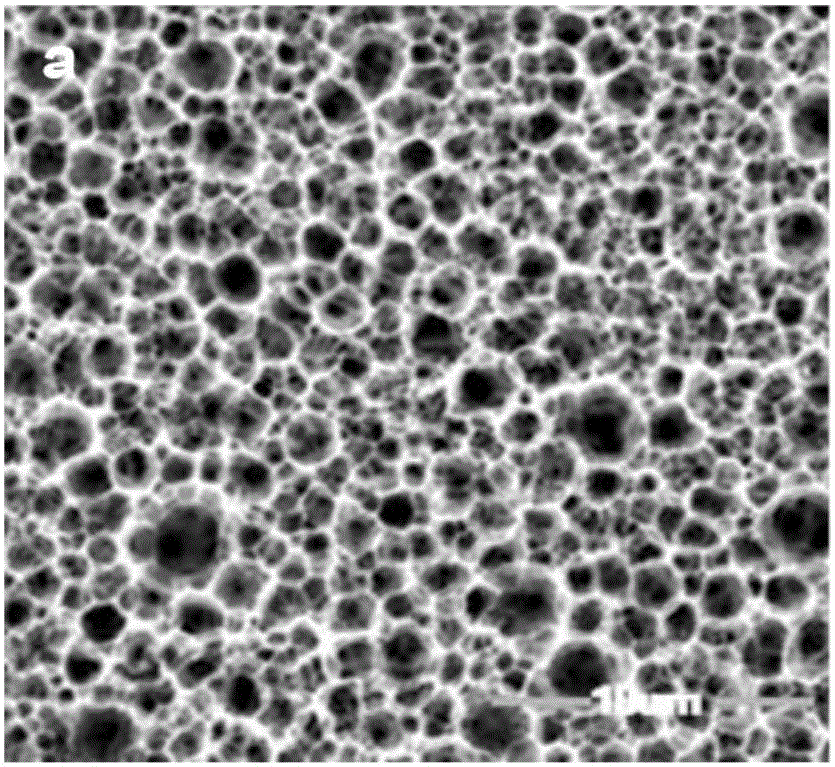

[0029] According to the mass percentage, the composition is: polyvinyl alcohol 7.5%, polyacrylic acid 7.5%, polyethylene glycol 1.5%, glutaraldehyde 0.03%, distilled water 83.47%, add 7.5g polyvinyl alcohol 1799 to 83.26g distilled water, heat to 90 ℃ to completely dissolve polyvinyl alcohol 1799, then add 7.5g of polyacrylic acid with an average molecular weight of 900 and 1.5g of polyethylene glycol with an average molecular weight of 10,000, stir evenly, adjust the pH value to 3 with dilute sulfuric acid, and then stir at room temperature Add 0.24 g of glutaraldehyde aqueous solution with a mass fraction of 12.5% under the condition, stir evenly, pour the obtained solution into a mold, form a film at 45° C. and dry to obtain a gel film with a thickness of 0.09 mm. Depend on figure 1 It can be seen that the obtained gel film has a rich capillary structure, and the pores are 1-3 μm.

Embodiment 2

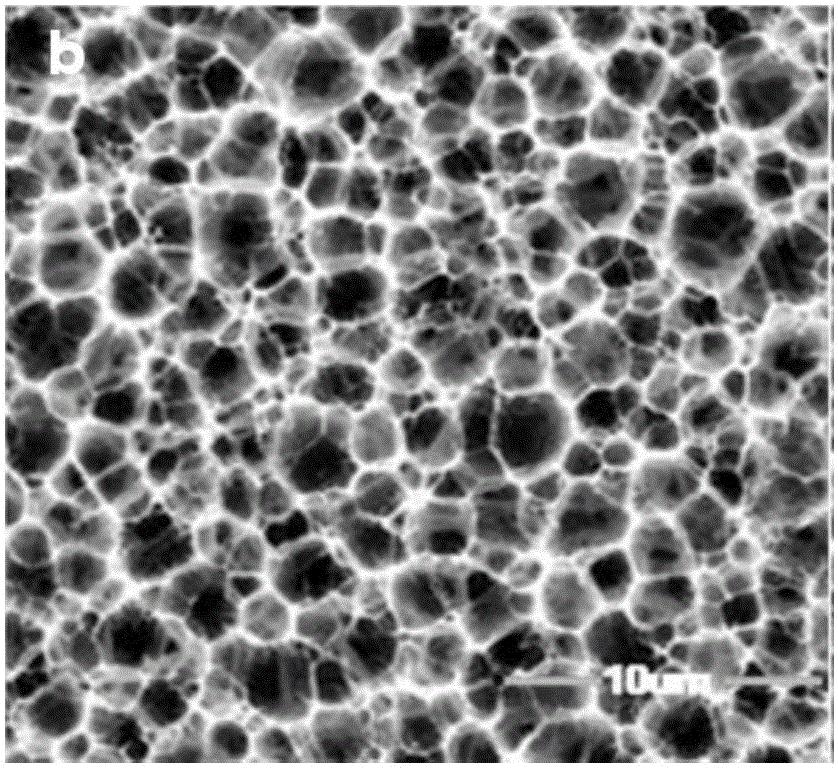

[0031] According to the mass percentage, the composition is: polyvinyl alcohol 7.5%, polyacrylic acid 15%, polyethylene glycol 1.5%, glutaraldehyde 0.03%, distilled water 75.97%, add 7.5g polyvinyl alcohol 1799 to 75.76g distilled water, heat to 90 ℃ to completely dissolve polyvinyl alcohol 1799, then add 15g of polyacrylic acid with an average molecular weight of 900 and 1.5g of polyethylene glycol with an average molecular weight of 10,000, stir evenly, and adjust the pH value to 3. Then add 0.24g of glutaraldehyde aqueous solution with a mass fraction of 12.5% under stirring and normal temperature conditions, stir evenly, pour the resulting solution into a mold, form a film at 45°C and dry to obtain a 0.10mm thick gel film. Depend on figure 2 It can be seen that the obtained gel film has a rich capillary structure, and the pores are 2-3 μm.

Embodiment 3

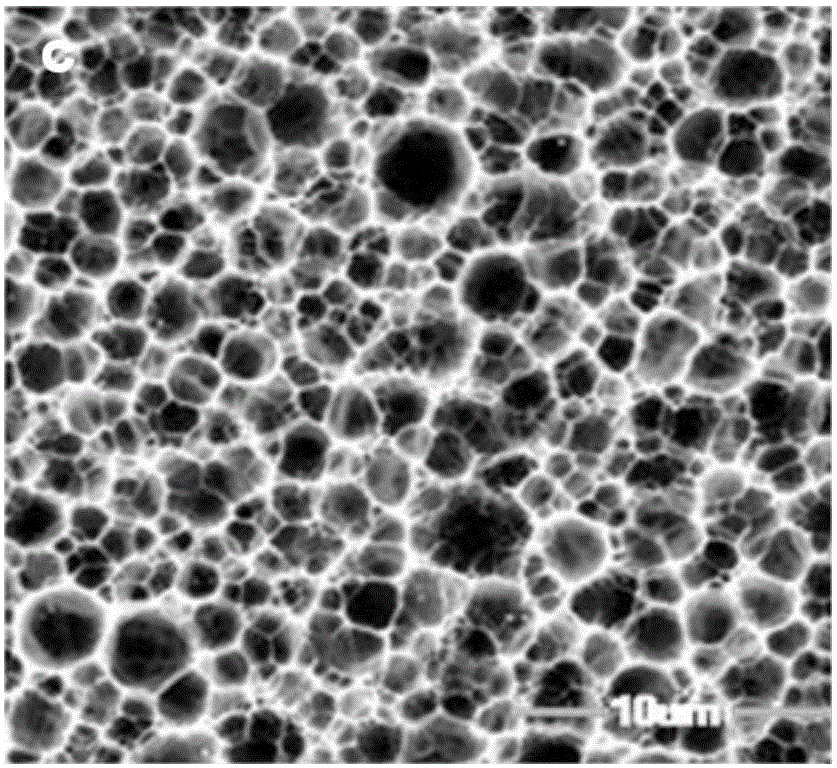

[0033] According to the mass percentage, it is composed of: polyvinyl alcohol 7.5%, polyacrylic acid 22.5%, polyethylene glycol 1.5%, glutaraldehyde 0.03%, distilled water 68.47%, add 7.5g polyvinyl alcohol 1799 to 68.26g distilled water, heat to 90 ℃ to completely dissolve polyvinyl alcohol 1799, then add 22.5g of polyacrylic acid with an average molecular weight of 900 and 1.5g of polyethylene glycol with an average molecular weight of 10,000, stir evenly, and adjust the pH value with a 10% aqueous solution of sodium hydroxide to 3, then add 0.24g of glutaraldehyde aqueous solution with a mass fraction of 12.5% under stirring and normal temperature conditions, stir evenly, pour the resulting solution into a mold, form a film at 45°C and dry to obtain a thickness of 0.13mm gel film. Depend on image 3 It can be seen that the obtained gel film has a rich capillary structure, and the pores are 2-3 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com