Valve sleeve contact surface gas-solid mixed fluid grinding and polishing device and method

A gas-solid mixing and polishing device technology, which is applied in the direction of grinding/polishing equipment, used abrasive processing devices, abrasives, etc., can solve problems such as incomplete removal of burrs, poor versatility, and large differences in surface roughness. To achieve the effect of improving smoothness, effective processing and reducing roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the drawings.

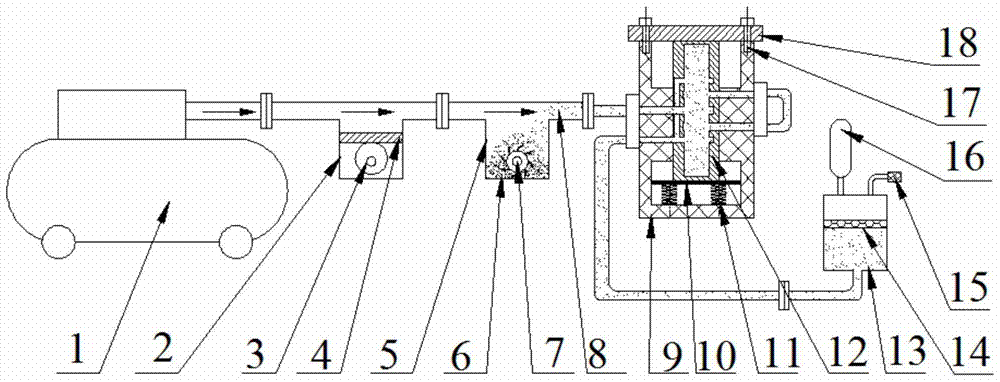

[0024] Such as figure 1 As shown, the gas-solid mixing fluid grinding and polishing device for the valve sleeve contact surface includes an air compressor 1, a gas pressure and flow adjustment assembly, a mixing chamber 5, micro-nano abrasive particles 6, a stirring wheel 7, a grinding chamber 9, and a pressure plate 10. , Spring 11, filter cavity 13, filter device 14, muffler device 15, gas storage cylinder 16, and grinding cavity upper cover 18; the gas pressure and flow adjustment assembly is composed of variable cavity 2, eccentric device 3 and piston 4; The air outlet of the air compressor 1 is communicated with the air inlet of the variable volume cavity 2; the eccentric device 3 and the piston 4 are both arranged in the variable volume cavity 2; the eccentric wheel of the eccentric device 3 is driven by a motor; the piston 4 and the eccentric The wheel end surface constitutes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com