Steam-water stirring flue-eliminating and dust-removing apparatus

A technology for smoke and dust removal and soda water, which is applied in combination devices, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of polluting the atmosphere, large emissions, and the inability of smoke and dust removal devices to achieve the purpose of purification, and achieve a thorough treatment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

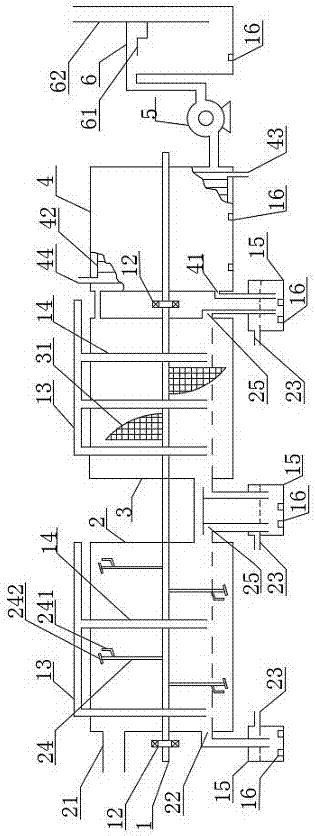

[0011] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes a flue gas inlet 21, which is characterized in that: the flue gas inlet 21 is arranged on the tooth mixer 2, the tooth mixer 2 is connected to the screw mixer 3, and the screw mixer 3 is connected to the water pipe cooler 4; The tooth mixer 2 and the top of the spiral mixer 3 are equipped with a purification liquid supply pipe 13, and the purification liquid supply pipe 13 is provided with several downward purification liquid spray pipes 14, which extend into the tooth mixer 2 and the spiral mixer 3. Inside; the upper side of the tooth mixer 2 is provided with a flue gas inlet 21, and the bottom is provided with a purified liquid overflow port I22, and a purified liquid sedimentation tank 15 is provided under the purified liquid overflow port I22, and the purified liquid sedimentation tank 15 is provided with cleaning dust 16 mouths and purification liquid overflow p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com