Polymer electrolyte containing lithium imide fluorosulfonate and preparing method of polymer electrolyte

A technology of lithium sulfonimide and polymer is applied in the field of organic polymer functional materials and electrochemistry, which can solve the problems of insufficient mechanical strength and film-forming properties of electrolytes, poor compatibility of electrode materials, and limited application of SPEs, etc. Cycle efficiency and capacity retention, good thermal stability, and the effect of increasing the number of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

[0032] Embodiment 1~6 is the preparation of polymer electrolyte

Embodiment 1

[0033] Example 1: Preparation of a blend electrolyte (electrolyte 1) of (fluorosulfonyl)(trifluoromethylsulfonyl)imide lithium (LiFTFSI) and polyacrylonitrile

[0034] Under ultrasonic conditions, 0.5g (2.1mmol) LiFTFSI was added to 5mL of acetone to obtain a colorless homogeneous liquid, and then 2.2g of LiFTFSI with a molecular weight of 4×10 5 gmol -1 Polyacrylonitrile (its structural unit is acrylonitrile, and the molar ratio of this structure to lithium ions is 20:1) was added to 80 mL of acetone to obtain a colorless viscous liquid (viscosity: 4.3 Pa·s). The polymer solution was added to the lithium salt solution, and ultrasonicated for 2 hours to obtain a mixed solution; then, the obtained mixed solution was uniformly coated on the surface of a flat polytetrafluoroethylene plate by a spin coating method; the final The polytetrafluoroethylene plate was vacuum-dried at 50° C. for 48 hours to obtain a thin film (electrolyte 1) with a smooth surface, a thickness of 120 μm ...

Embodiment 2

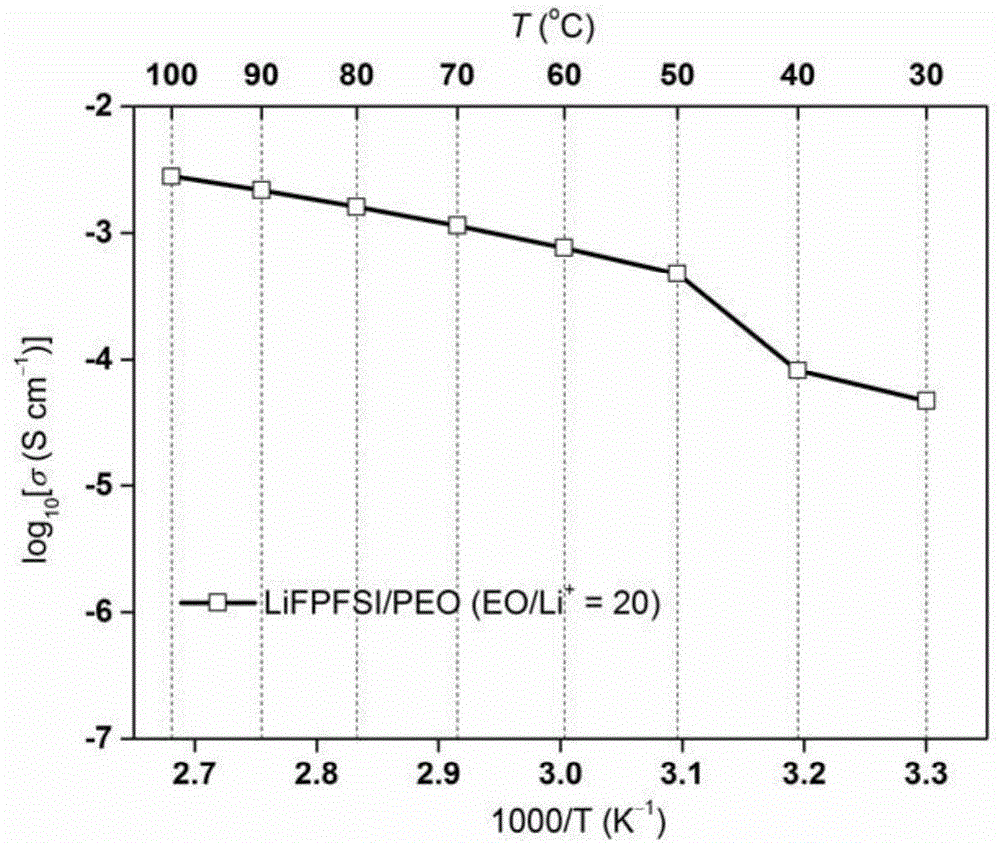

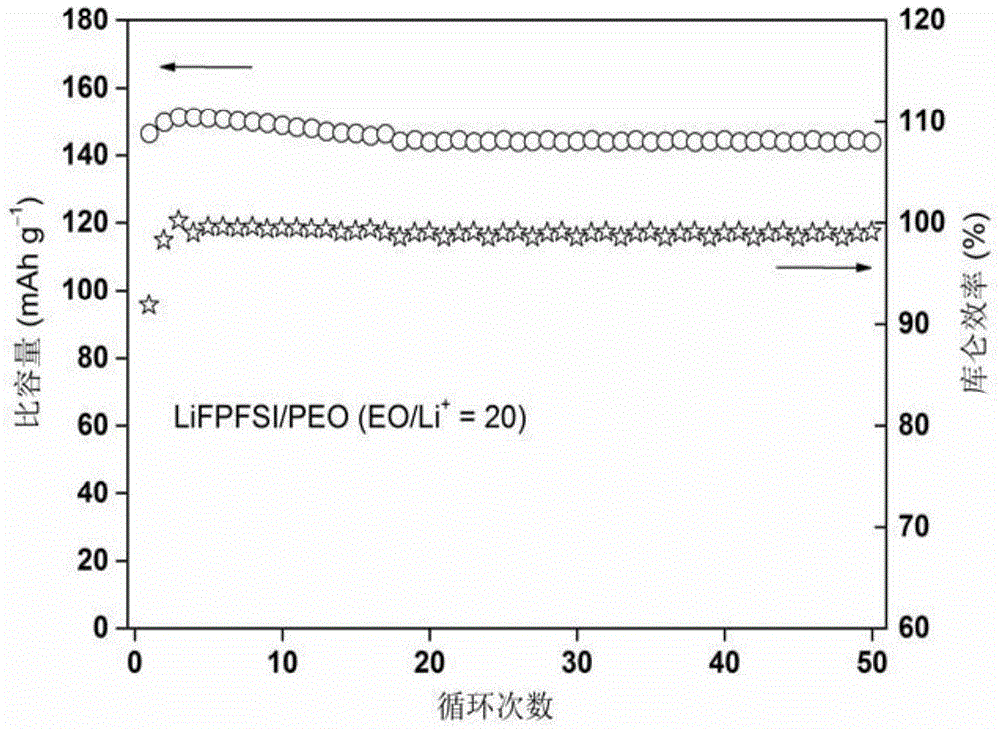

[0035] Example 2: Preparation of a blended electrolyte (electrolyte 2) of lithium (fluorosulfonyl)(pentafluoroethylsulfonyl)imide (LiFPFSI) and polyoxyethylene

[0036] Under ultrasonic conditions, 0.5g (1.7mmol) LiFPFSI was added to 5mL of acetonitrile to obtain a colorless homogeneous liquid, and then 1.5g of LiFPFSI with a molecular weight of 4×10 5 gmol -1 Polyoxyethylene (its structural unit is oxyethylene, and the molar ratio of this structure to lithium ions is 20:1) was added to 50 mL of acetone to obtain a colorless viscous liquid (viscosity: 9.7 Pa·s). The polymer solution was added to the lithium salt solution, and ultrasonicated for 5 hours to obtain a mixed solution; then, the obtained mixed solution was uniformly coated on the surface of a flat polytetrafluoroethylene plate by a spin coating method; the final The polytetrafluoroethylene plate was vacuum-dried at 50°C for 24 hours to obtain a film with a smooth surface, a thickness of 150 μm and a certain mechani...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com