Self-healing solid polymer electrolyte for lithium battery and preparation method of solid polymer electrolyte

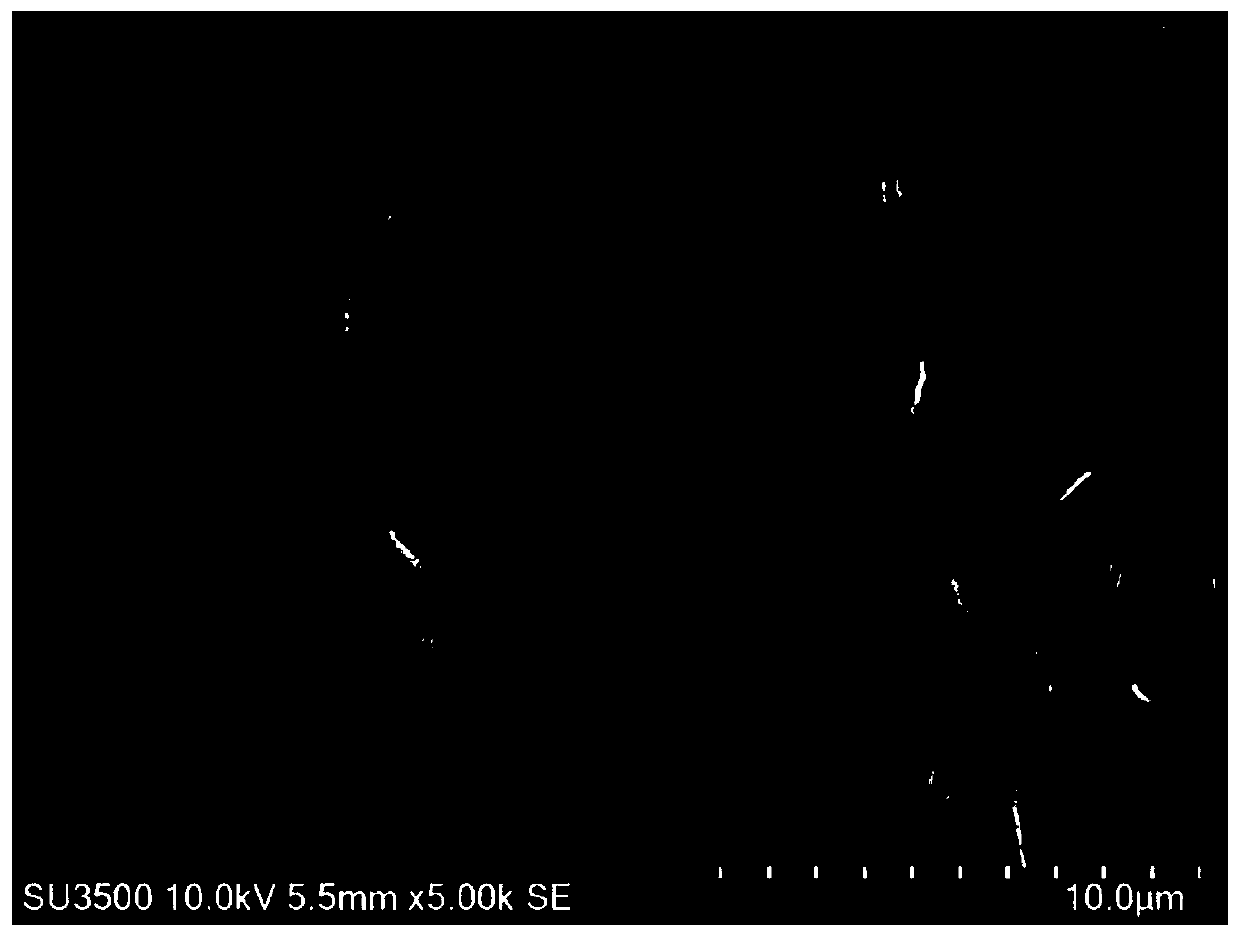

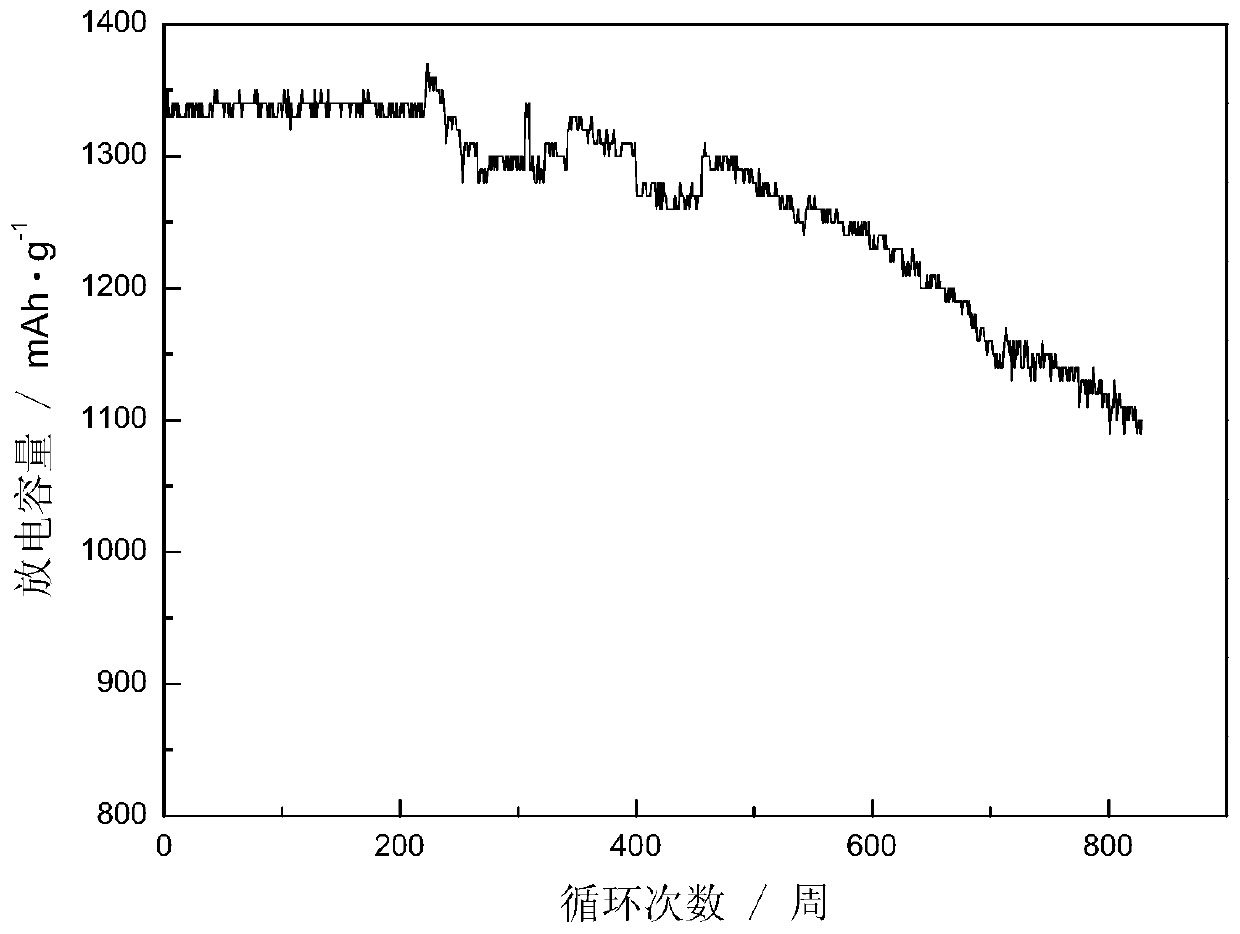

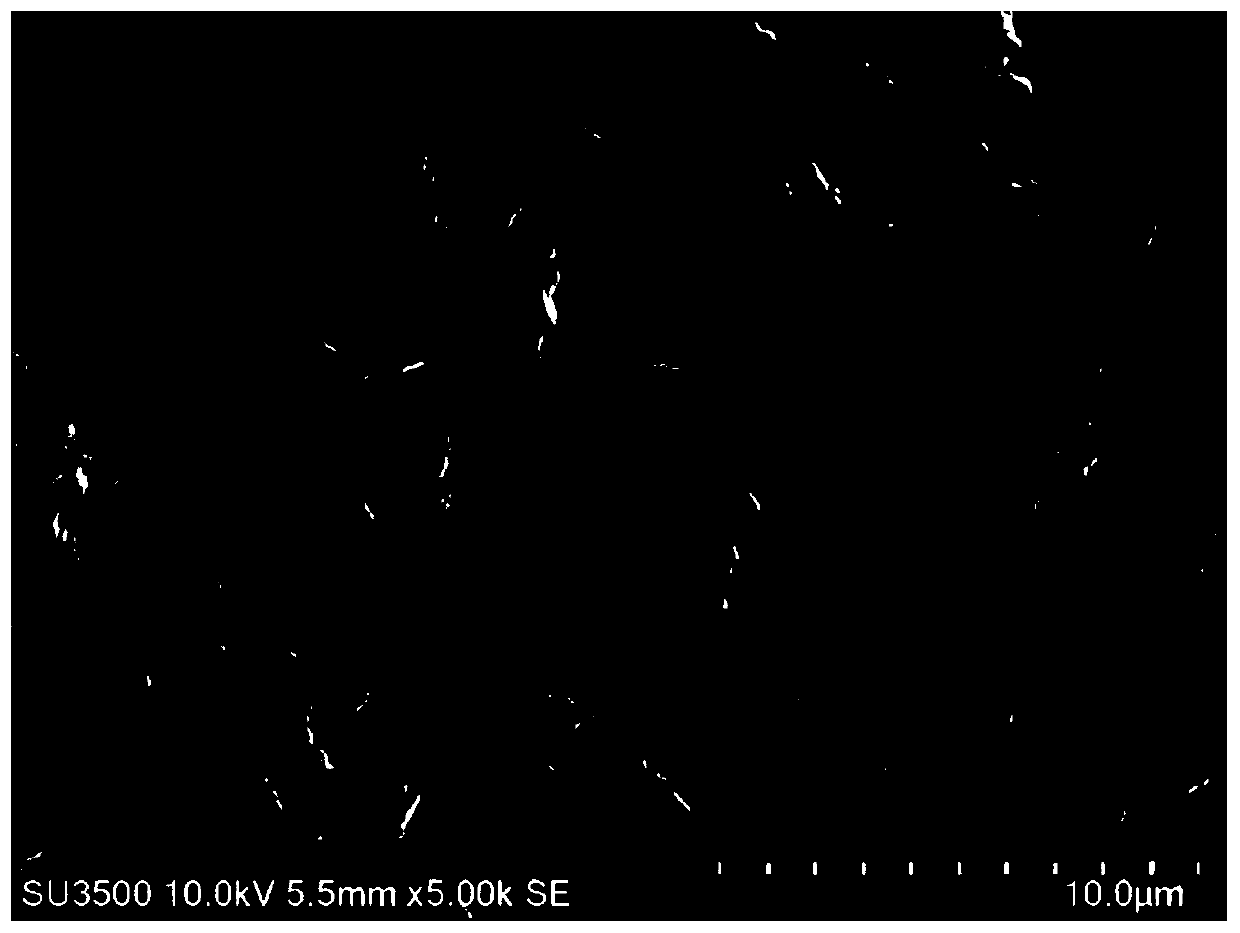

A solid polymer and electrolyte technology, applied in the field of lithium-ion batteries, can solve the problems of low ion conductivity, large interface impedance between solid electrolyte and positive and negative electrodes, etc., and achieve excellent ion conductivity, excellent self-healing performance, pore size evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043]In terms of weight percentage, the composition is: 40g of acetone, 60g of N,N-dimethylformamide, 25g of silyl-terminated polyether (molecular weight is about 10000) (ether bond is about 25 / 58.08=0.43mol), bis Lithium (fluorosulfonyl)imide (0.43 / 10mol) 8.04g, PVDF-HFP 1.25g.

[0044] The preparation process is:

[0045] (1) take by weighing the acetone of 40g;

[0046] (2) Dissolve 8.04 g of lithium bis(fluorosulfonyl)imide in acetone;

[0047] (3) After the lithium bis(fluorosulfonyl)imide is fully dissolved, add 25 g of silyl-terminated polyether, and stir at 35° C. until the polyether is completely dissolved in acetone to form a viscous liquid.

[0048] (4) Weigh 60g of N,N-dimethylformamide;

[0049] (5) Dissolve 1.25g of PVDF-HFP in N,N-dimethylformamide while stirring at 35°C.

[0050] (6) Mix the two solvents, stir at 35°C for 1 hour, ultrasonically disperse for 1 hour, keep at 45°C, and continue stirring until the viscosity is higher than 1000 centipoise.

[...

Embodiment 2

[0055] In terms of weight percentage, the composition is: 40g of acetone, 60g of N,N-dimethylformamide, 50g of silyl-terminated polyether (molecular weight is about 10000) (ether bond is about 50 / 58.08=0.86mol), bis Lithium (fluorosulfonyl)imide (0.86 / 10mol) was 16.1 g, and PVDF-HFP was 10.0 g.

[0056] The preparation process is:

[0057] (1) take by weighing the acetone of 40g;

[0058] (2) Dissolve 16.1 g of lithium bis(fluorosulfonyl)imide in acetone;

[0059] (3) After the lithium bis(fluorosulfonyl)imide is fully dissolved, add 50 g of silyl-terminated polyether, and stir at 35° C. until the polyether is completely dissolved in acetone to form a viscous liquid.

[0060] (4) Weigh 60g of N,N-dimethylformamide;

[0061] (5) Dissolve 10.0 g of PVDF-HFP in N,N-dimethylformamide while stirring at 35°C.

[0062] (6) Mix the two solvents, stir at 35°C for 1 hour, ultrasonically disperse for 1 hour, keep at 45°C, and continue stirring until the viscosity is higher than 1000 ...

Embodiment 3

[0067] In terms of weight percentage, the composition is: 40g of acetone, 60g of N,N-dimethylformamide, 50g of silyl-terminated polyether (molecular weight is about 10000) (ether bond is about 50 / 58.08=0.86mol), bis Lithium (fluorosulfonyl)imide (0.86 / 10mol) 16.1g, PVDF-HFP 2.5g, garnet-type Li 7 La 3 Zr 2 o 12 (LLZO) Nanopowder 1.0 g.

[0068] The preparation process is:

[0069] (1) take by weighing the acetone of 40g;

[0070] (2) Dissolve 16.1 g of lithium bis(fluorosulfonyl)imide in acetone;

[0071] (3) After the lithium bis(fluorosulfonyl)imide is fully dissolved, add 50 g of silyl-terminated polyether, and stir at 35° C. until the polyether is completely dissolved in acetone to form a viscous liquid.

[0072] (4) Weigh 60g of N,N-dimethylformamide;

[0073] (5) Stirring at 35°C, dissolve 2.5g of PVDF-HFP in N,N-dimethylformamide.

[0074] (6) Mix the two solvents, stir at 35°C for 1 hour, then add garnet-type Li to the viscous liquid 7 La 3 Zr 2 o 12 (LLZO)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com