Method for improving performance of electrode material LNMO

An electrode material, high-temperature sintering technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of high current performance and unsatisfactory cycle performance of LNMO materials, and achieve high current performance, electrical conductivity, and cycle performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] This example describes a LiNi 0.45 Cr 0.1 mn 1.45 o 4 As the base electrode material, with LiBO 2 ,H 3 BO 3 and NH 4 h 2 PO 4 The reaction yielded LBPO-coated Cr-LNMO. Specific steps are as follows:

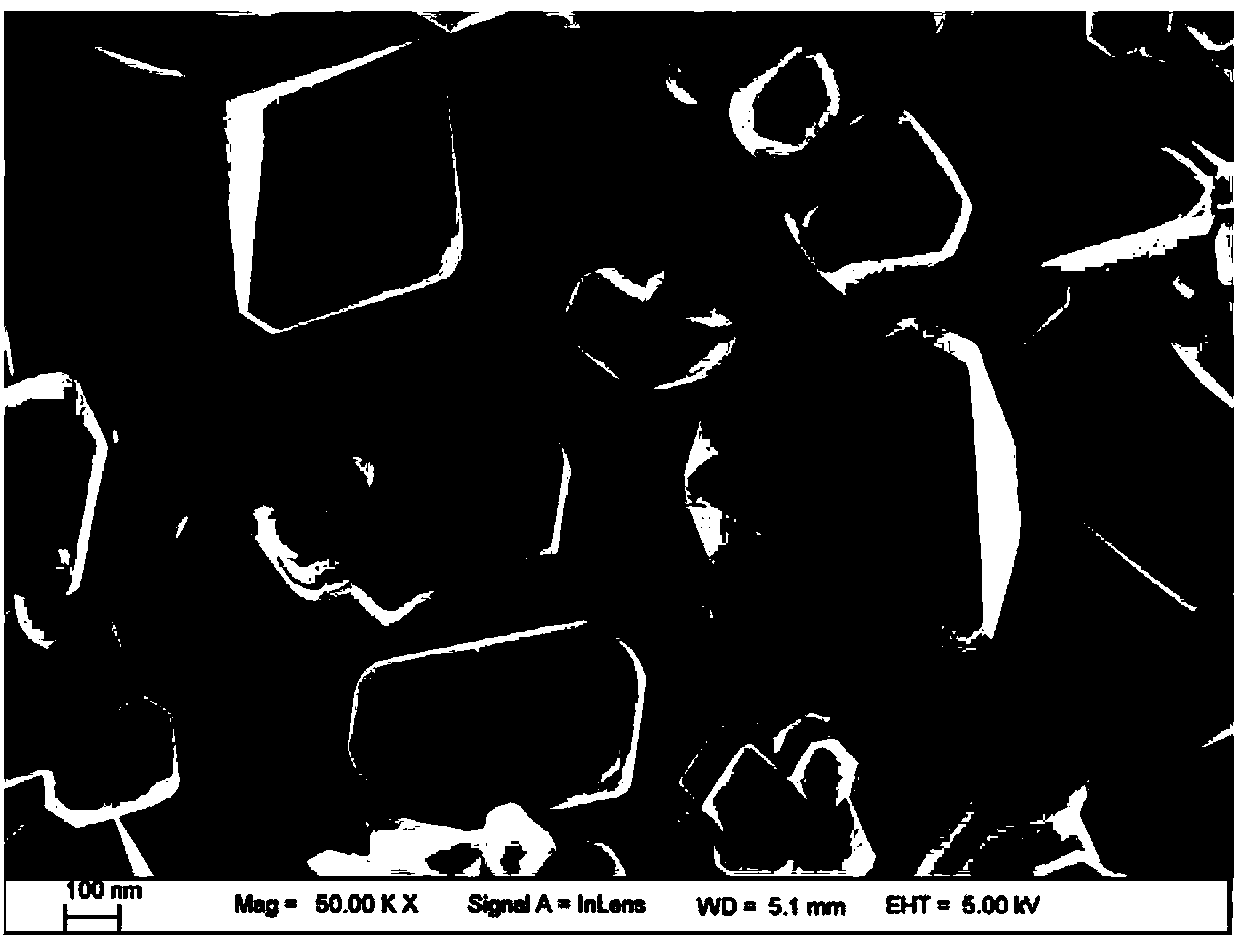

[0018] will LiBO 2 ,H 3 BO 3 and NH 4 h 2 PO 4 Mix according to the molar ratio of Li:B:P=0.1:0.967:1 to obtain the mixture, according to the above mixture and LiNi 0.45 Cr 0.1 mn 1.45 o 4 The mass ratio of the two is 1%, and the two are further mixed evenly, and then sintered in the air at 350 ° C for 7 hours to obtain LBPO-coated Cr-LNMO. It looks like figure 1 shown.

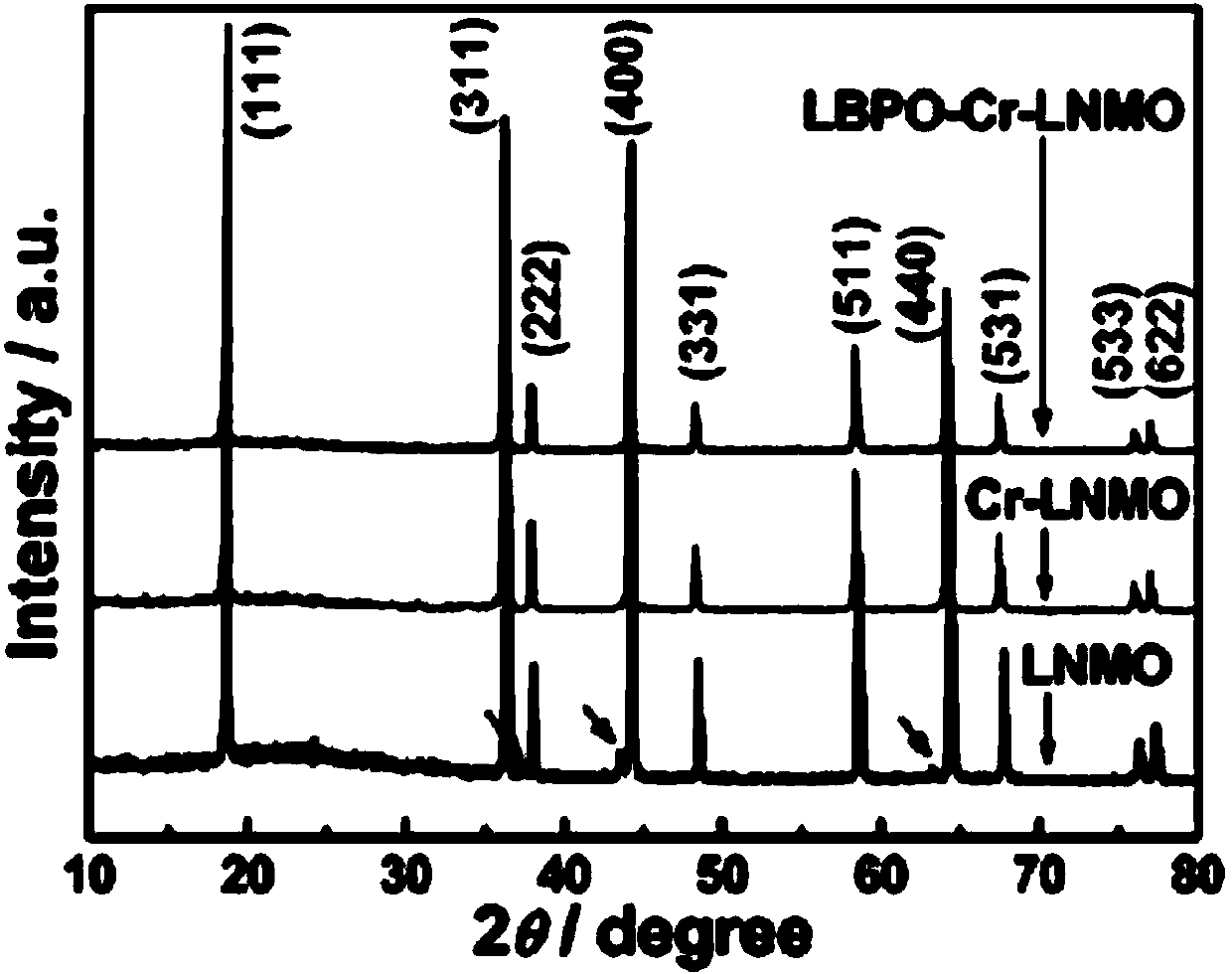

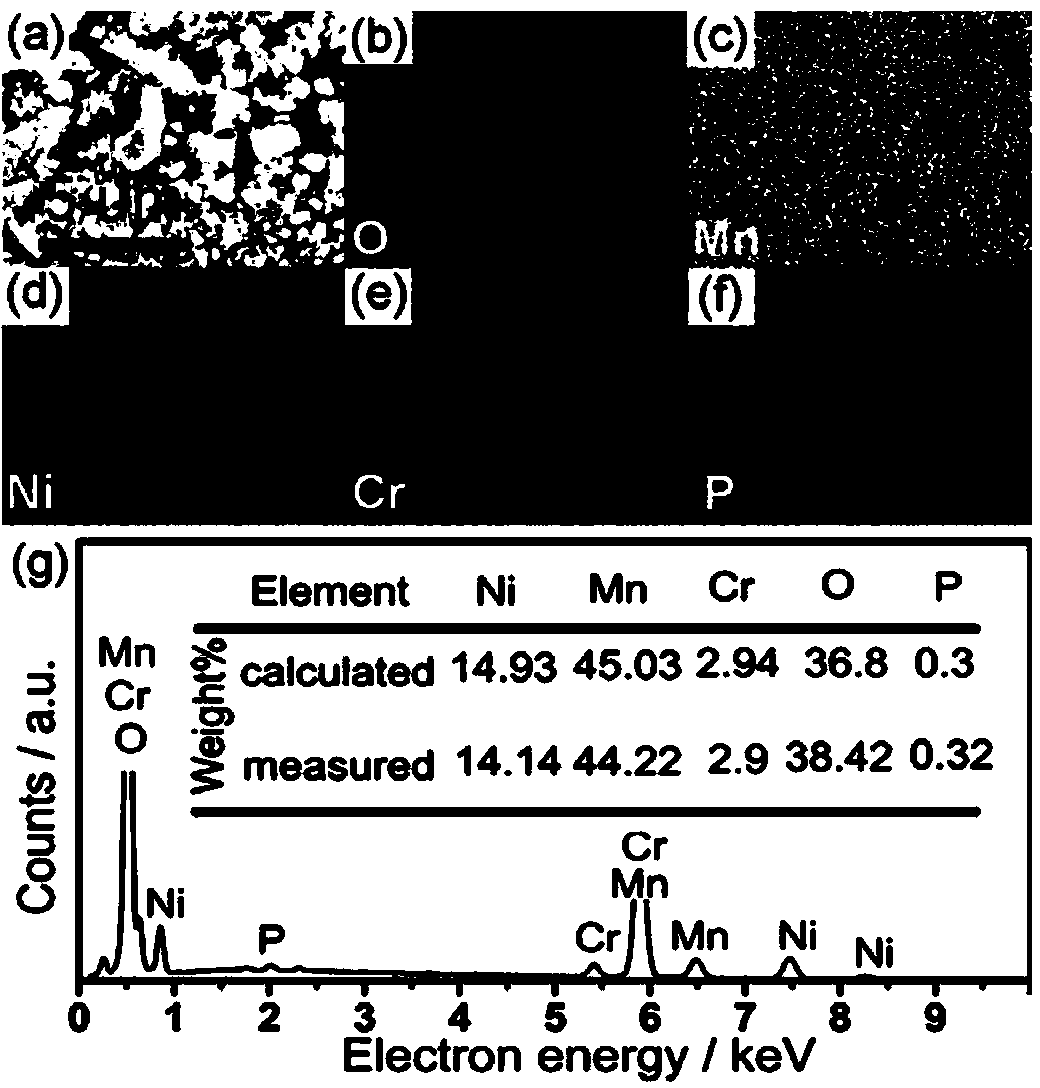

[0019] The XRD contrast of this product with pure LNMO electrode material and Cr-LNMO base electrode material (base electrode material of this embodiment) is as attached figure 2 shown. It can be seen from the figure that the Cr-LNMO material coated with LBPO and the Cr-LNMO material not coated with LBPO have the same XRD, which is different from the XRD of pure LNMO, indicating th...

Embodiment 2

[0025] This example describes a LiNi 0.5 mn 1.5 o 4 As a matrix, react with lithium carbonate, lithium hydroxide, lithium borate, and ammonium dihydrogen phosphate to obtain LBPO-coated LNMO. Specific steps are as follows:

[0026] Lithium carbonate and lithium hydroxide are mixed evenly according to the mass ratio of 1:1, and then mixed evenly with lithium borate and ammonium dihydrogen phosphate according to the molar ratio of Li:B:P=0.1:0.967:1, according to the mass ratio of 0.5%. with LiNi 0.5 mn 1.5 o 4 Further mix evenly, and sinter in air at 800°C for 8 hours to obtain LBPO-coated LNMO.

[0027]The LBPO-coated LNMO obtained above was mixed uniformly with acetylene black and PVDF at a mass ratio of 8:1:1, and coated on an aluminum foil as a positive electrode, and a metal lithium sheet was used as a negative electrode, and a 1M lithium hexafluorophosphate solution (solvent: : Ethylene carbonate, dimethyl carbonate, and ethyl methyl carbonate are mixed according t...

Embodiment 3

[0029] This example describes a Cr-LiNi 0.45 Cr 0.1 mn 1.45 o 4 As a substrate, react with lithium oxide, metaboric acid, and phosphoric acid to obtain LBPO-coated Cr-LNMO. Specific steps are as follows:

[0030] Mix lithium oxide, metaboric acid, and phosphoric acid according to the molar ratio of Li:B:P=0.1:0.967:1 and stir evenly. After the reaction is completed, add sucrose and continue to stir and heat to 150°C. Finally, a brown-black powder is formed. Combined with Cr-LiNi 0.45 Cr 0.1 mn 1.45 o 4 According to 2% mass ratio and further mixed evenly, sintered in the air at 800°C for 8 hours to obtain LBPO-coated Cr-LNMO.

[0031] The LBPO-coated Cr-LNMO obtained above was uniformly mixed with acetylene black and PVDF in a mass ratio of 8:1:1, and coated on an aluminum foil as a positive electrode, with a lithium metal sheet as a negative electrode, and with 1M lithium hexafluorophosphate solution (solvent It is: ethylene carbonate, dimethyl carbonate, and ethyl met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com