High-conductivity polymer electrolyte and preparation method thereof

A high-conductivity, polymer technology, applied in solid electrolytes, non-aqueous electrolytes, circuits, etc., can solve problems such as limited applications, low ionic conductivity, no conductivity, electrochemical stability and interface stability, and achieve Simple preparation method, high room temperature conductivity, good electrochemical and interface stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

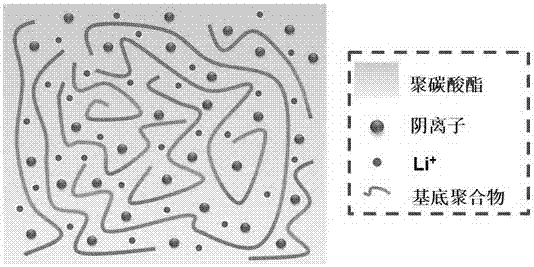

[0026] Add 2.7g polyvinyl carbonate and 100g N-methylpyrrolidone into a 250 ml reagent bottle and stir at room temperature for 6 h to obtain a uniform solution, add 1.8g lithium bistrifluoromethanesulfonimide to the above solution, and stir at room temperature After 6 h, add 0.5g of polyvinylidene fluoride after complete dissolution, stir to obtain a uniform mixed solution, inject the mixed solution into a polytetrafluoroethylene (PTFE) mold to dry to form a film, and vacuum dry to obtain a solid polymer electrolyte membrane .

Embodiment 2

[0028] Add 0.5 g of polyvinyl carbonate and 100 g of dimethyl sulfite to a 250 ml reagent bottle and stir at room temperature for 6 h to obtain a uniform solution. Add 4.5 g of lithium bisfluorosulfonyl imide to the above solution and stir at room temperature for 6 h. h, after complete dissolution, add 1.25g poly(vinylidene fluoride-hexafluoropropylene), stir to obtain a uniform mixed solution, pour the mixed solution into a polytetrafluoroethylene (PTFE) mold to dry to form a film, and vacuum dry to obtain Solid polymer electrolyte membrane.

Embodiment 3

[0030] Add 3g of polypropylene carbonate and 100g of acetonitrile into a 100ml reagent bottle and stir at room temperature for 6 hours to obtain a homogeneous solution. Add 3g of lithium perchlorate to the above solution and stir for 6 hours at room temperature. After completely dissolving, add 6g of polyethylene Alcohol, stirring to obtain a uniform mixed solution, injecting the mixed solution into a polytetrafluoroethylene (PTFE) mold to dry to form a film, and vacuum drying to obtain a solid polymer electrolyte membrane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com