Composite lithium battery diaphragm and preparation method thereof

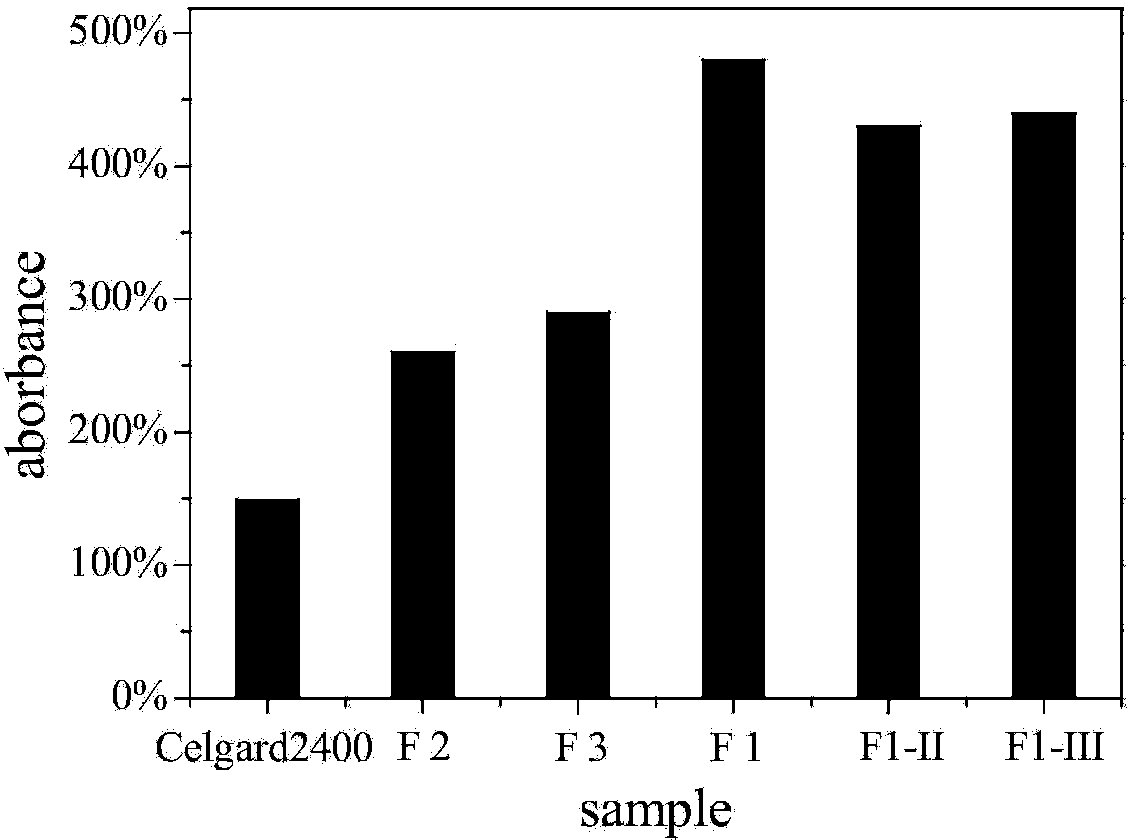

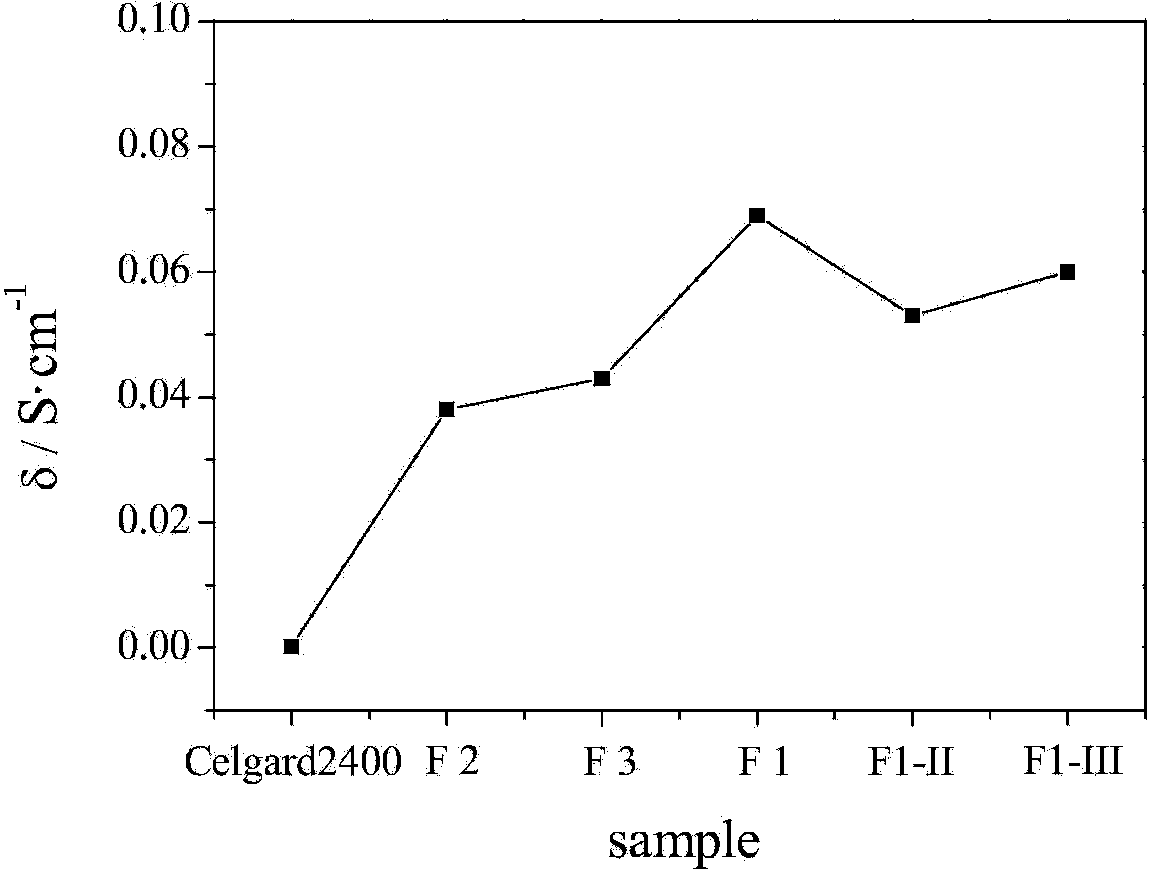

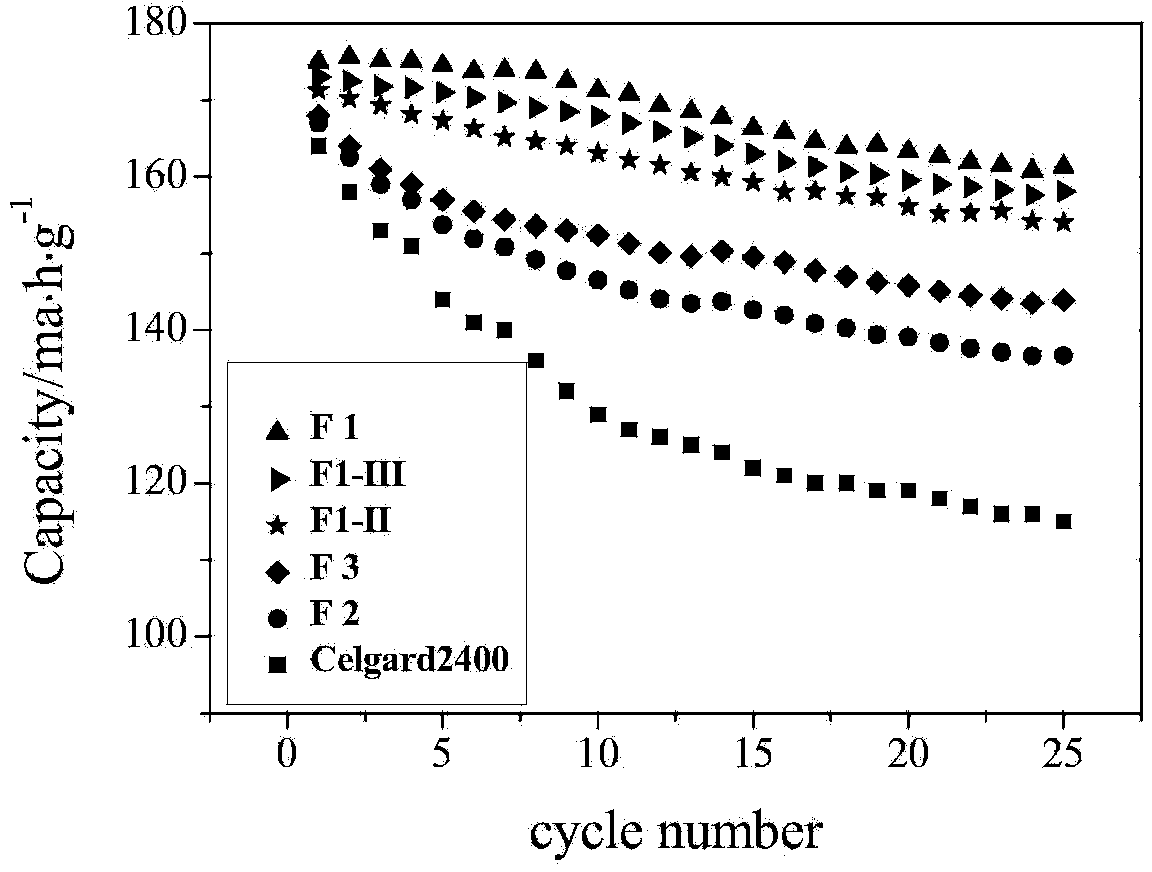

A technology of battery diaphragm and composite diaphragm, which is applied to battery components, separators/films/diaphragms/spacers, circuits, etc., which can solve the problem of low liquid absorption rate, poor wettability of electrolyte, and affecting battery cycle performance and other problems, to achieve the effect of improving room temperature conductivity and good cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Preparation of Composite Separator F1:

[0032] ①The chemical synthesis steps of sulfonated polyimide are:

[0033] Add 1.5510 g (5 mmol) of diphenyl ether tetracarboxylic dianhydride and 0.8006 g of 2,2'-bistrifluoromethyl-4,4'-diaminobiphenyl ( 2.5mmol) and 2,2'-disulfonic acid group-4,4'-diaminobiphenyl 0.8609g (2.5mmol), add 30mL m-cresol (m-cresol) solvent and 0.73mL triethylamine (Triethylamine) , and then add 5 drops of isoquinoline (Isoquinoline) as a catalyst, raise the temperature of the reaction system to 120°C for 2h, then raise the temperature to 190°C for 8h, cool to 80°C, pour the polymer solution into 400mL of ethanol, pump The white fibrous precipitate was obtained by filtration, washed twice with ethanol, the precipitate was acidified with dilute sulfuric acid, and dried under vacuum at 100°C to obtain sulfonated polyimide SPI-50.

[0034] ②The preparation method of the composite lithium battery separator is as follows:

[0035] Take 1.0000g polyeth...

Embodiment 2

[0037] Preparation of composite separator F1-II:

[0038] ① "The chemical synthesis steps of sulfonated polyimide are:

[0039] Add 1.8613 g (6 mmol) of diphenyl ether tetracarboxylic dianhydride and 0.9607 g of 2,2'-bistrifluoromethyl-4,4'-diaminobiphenyl ( 3mmol) and 1.0331g (3mmol) of 2,2'-disulfonic acid-4,4'-diaminobiphenyl, add 30mL m-cresol (m-cresol) solvent and 0.75mL triethylamine (Triethylamine), and then Add 6 drops of isoquinoline (Isoquinoline) as a catalyst, raise the temperature of the reaction system to 130°C for 2 hours, then raise the temperature to 200°C for 8 hours, cool to 90°C, pour the polymer solution into 400mL of ethanol, and filter with suction to obtain The white fibrous precipitate was washed twice with ethanol. The precipitate was acidified with dilute sulfuric acid and dried in vacuum at 100°C to obtain the sulfonated polyimide SPI-50-II.

[0040] ②The preparation method of the composite lithium battery separator is as follows:

[0041] Take ...

Embodiment 3

[0043] Preparation of composite separator F1-III:

[0044] ① "The chemical synthesis steps of sulfonated polyimide are:

[0045] Add 1.5510 g (5 mmol) of diphenyl ether tetracarboxylic dianhydride and 0.8006 g of 2,2'-bistrifluoromethyl-4,4'-diaminobiphenyl ( 2.5mmol) and 2,2'-disulfonic acid group-4,4'-diaminobiphenyl 0.8609g (2.5mmol), add 30mL m-cresol (m-cresol) solvent and 0.75mL triethylamine (Triethylamine) , and then add 6 drops of isoquinoline (Isoquinoline) as a catalyst, raise the temperature of the reaction system to 110°C for 2h, then raise the temperature to 190°C for 12h, cool to 70°C, pour the polymer solution into 400mL of ethanol, pump The white fibrous precipitate was obtained by filtration, washed twice with ethanol, the precipitate was acidified with dilute sulfuric acid, and dried under vacuum at 100°C to obtain the sulfonated polyimide SPI-50-III.

[0046] ②The preparation method of the composite lithium battery separator is as follows:

[0047] Take 1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com