Production for gel polymer electrolyte

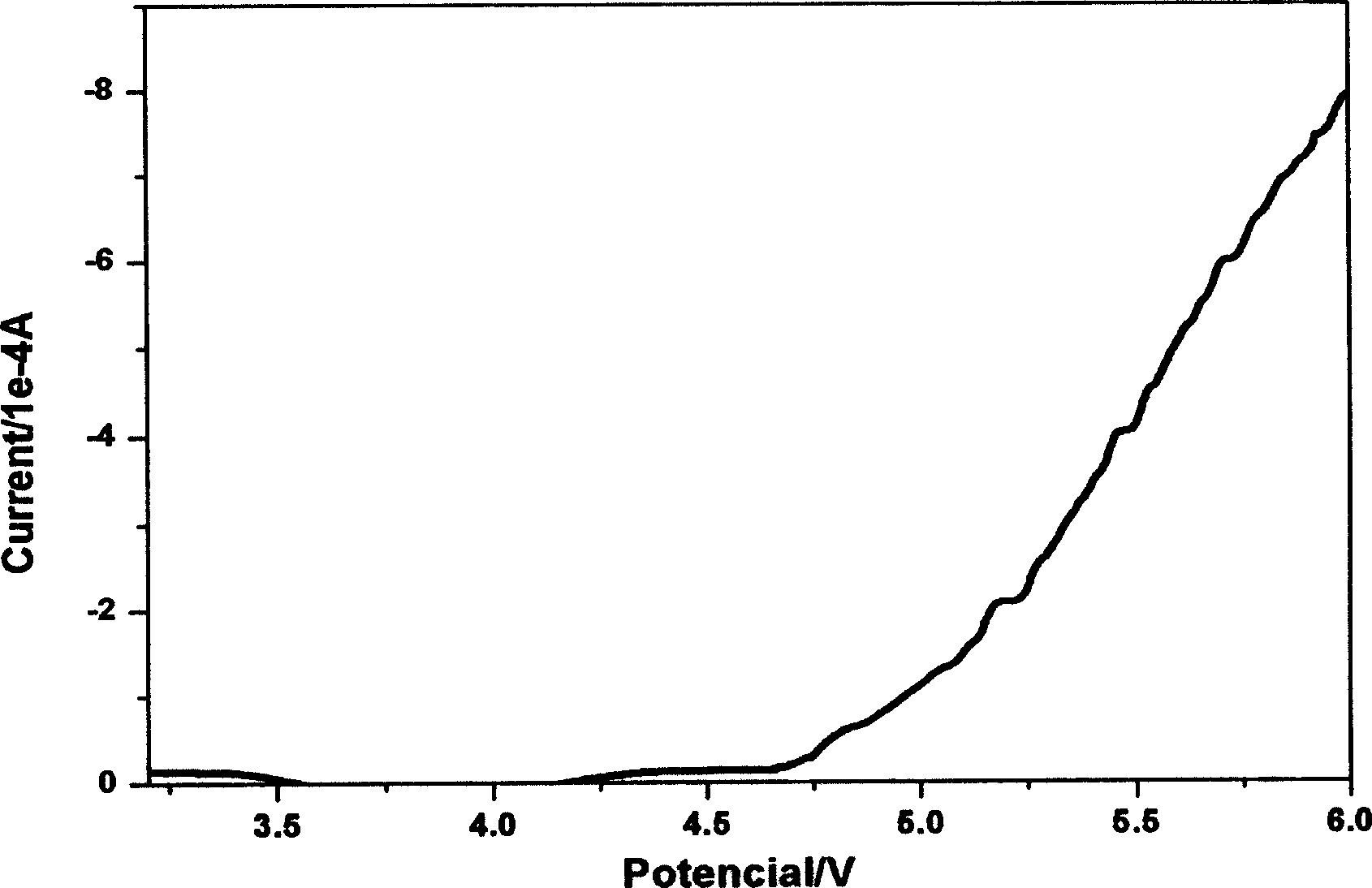

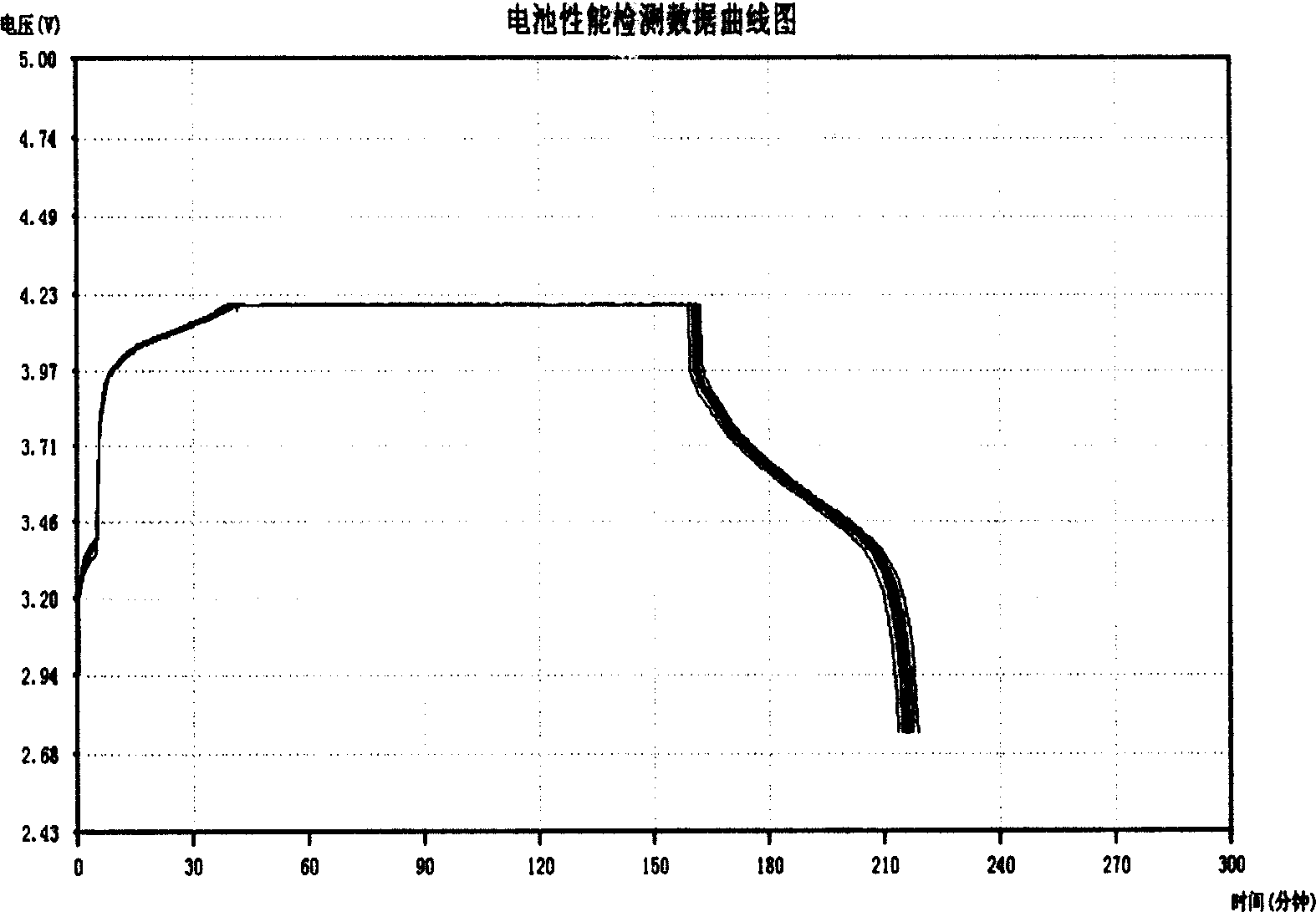

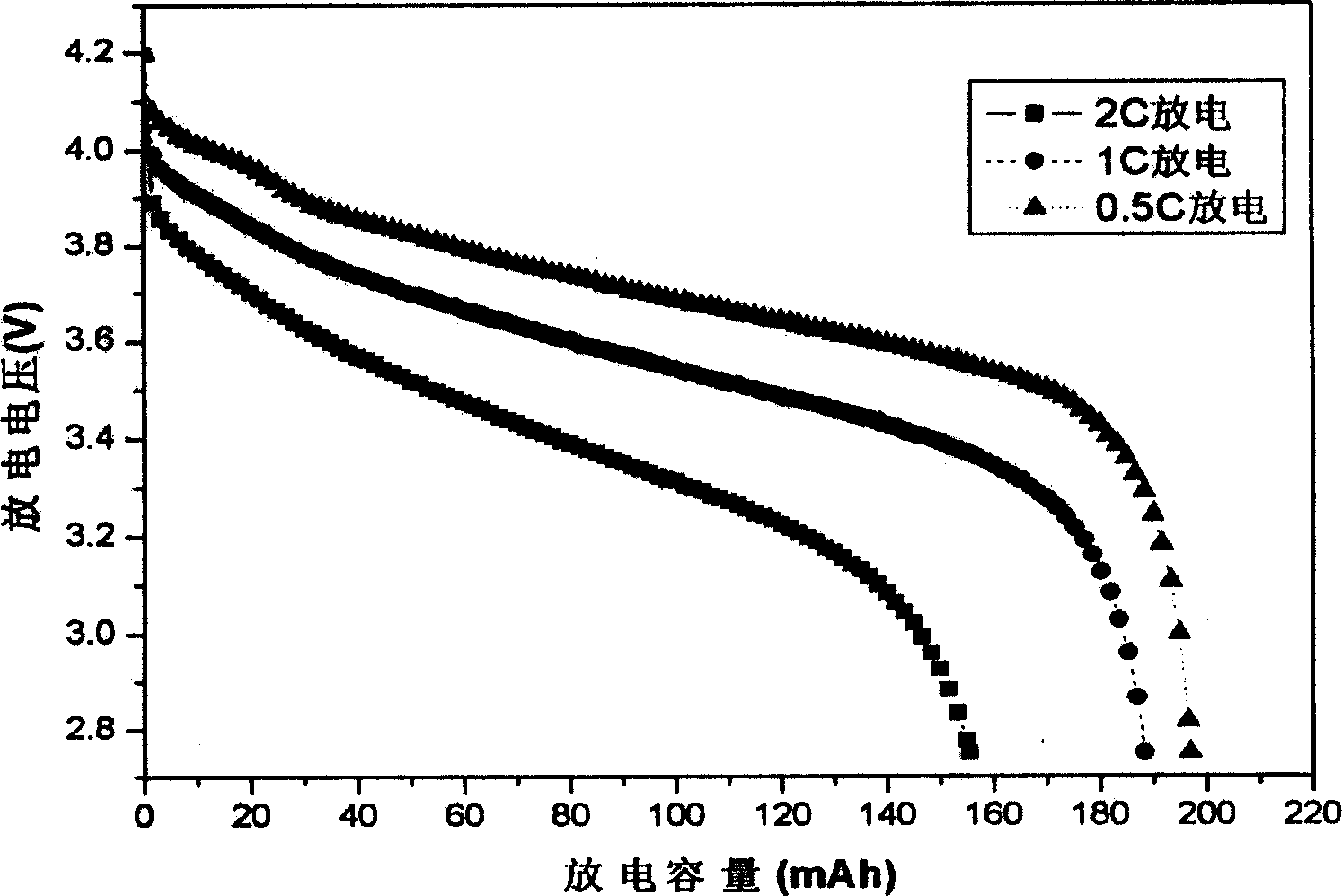

A gel polymer and electrolyte technology, applied in organic electrolyte batteries, non-aqueous electrolyte batteries, circuits, etc., can solve the problems of serious battery charge and discharge cycle attenuation, poor electrochemical stability, and complicated preparation methods, and achieve low cost , good electrochemical stability and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Prepare monomer mixture: mix 0.48g ethylene glycol diacrylate and 0.72g tetraethylene glycol dimethacrylate to prepare monomer mixture;

[0032] (2) Preparation of gel polymer electrolyte precursor: monomer mixture, 0.1g thermal initiator di-o-toluyl peroxide, 18.7g liquid lithium-ion battery electrolyte solution (LiN(CF 3 SO 2 ) 2 (1.0M) / EC:DMC:VC (volume ratio 2:2:1)) mixed evenly;

[0033] (3) Vacuumizing and sealing treatment: use a vacuum liquid injection device to inject the prepared gel polymer electrolyte precursor into the semi-finished battery including the positive and negative electrodes and the insulating resin film with a network structure, and then the semi-finished battery Vacuum and seal inside;

[0034] (4) Thermal polymerization reaction: Put the semi-finished battery into an oven at a constant temperature of 80°C for 60 minutes. After the reaction is finished, the semi-finished battery is cooled to room temperature, and the gel polymer electr...

Embodiment 2

[0039] (1) Prepare monomer mixture: mix 0.5g ethylene glycol dimethacrylate and 0.7g tetraethylene glycol dimethacrylate to prepare monomer mixture;

[0040](2) Preparation of the gel polymer electrolyte precursor: the monomer mixture, 0.1g thermal initiator azobisisobutyronitrile, 18.7g liquid lithium-ion battery electrolyte solution (LiBF 4 (1.0M) / EC:DEC (volume ratio 1:1)) mixed evenly;

[0041] (3) Vacuumizing and sealing treatment: use a vacuum liquid injection device to inject the prepared gel polymer electrolyte precursor into the semi-finished battery including the positive and negative electrodes and the insulating resin film with a network structure, and then the semi-finished battery Vacuum and seal inside;

[0042] (4) Thermal polymerization reaction: Put the semi-finished battery into an oven at a constant temperature of 60°C for 120 minutes. After the reaction is finished, the semi-finished battery is cooled to room temperature, and the gel polymer electrolyte ...

Embodiment 3

[0044] (1) Prepare monomer mixture: mix 0.2g tetraethylene glycol dimethacrylate and 1.8g decaethylene glycol dimethacrylate to prepare monomer mixture;

[0045] (2) Preparation of gel polymer electrolyte precursor: monomer mixture, 0.3g thermal initiator diisopropyl peroxydicarbonate, 17.7g liquid lithium ion electrolyte solution (LiCF 3 SO 3 (1.0M) / EC:EMC:VC (volume ratio 2:2:1)) mixed evenly;

[0046] (3) Vacuumizing and sealing treatment: use a vacuum liquid injection device to inject the prepared gel polymer electrolyte precursor into the semi-finished battery including the positive and negative electrodes and the insulating resin film with a network structure, and then the semi-finished battery Vacuum and seal inside;

[0047] (4) Thermal polymerization reaction: Put the semi-finished battery into an oven at a constant temperature of 100°C for 40 minutes. After the reaction is finished, the semi-finished battery is cooled to room temperature, and the gel polymer elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com