Solid electrolyte and preparation method and application thereof

A solid electrolyte, electrolyte salt technology, applied in the field of electrochemistry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

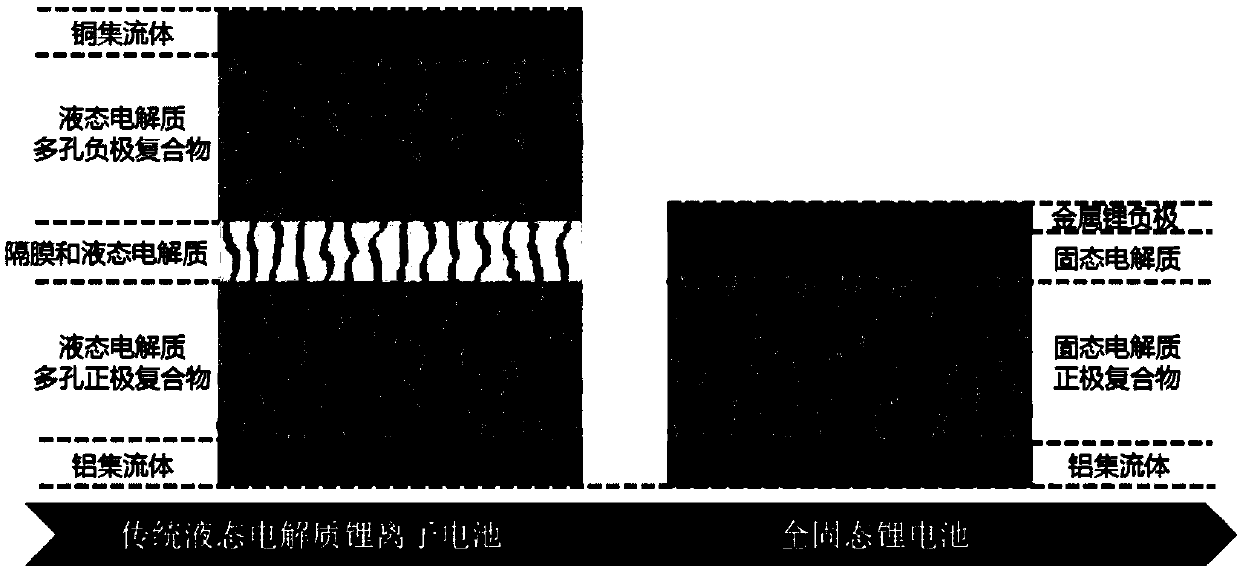

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0166] In some specific embodiments, the polymer solution is sprayed onto a selected receiving surface by electrospinning technology to form (i.e. polymer fibers aggregate to form) a continuous three-dimensional structure, and at the same time, the inorganic particles are sprayed by electrostatic spraying technology. The dispersion liquid is sprayed onto the selected receiving surface to obtain a composite material composed of an organic phase composed of a polymer material and inorganic particles, and then the composite material is subjected to pressure treatment to make it denser, as the For the membrane material, the distance between the electrospinning liquid outlet and the receiving surface may be 5-30 cm, and the electrostatic voltage may be, for example, 5-50 KV. The pressure of the pressure treatment may be 100KPa-20MPa, the time is 1-60 minutes, preferably 1-10 minutes, and the temperature is 25-60°C. As one of the preferred embodiments, the preparation method include...

Embodiment 1-1

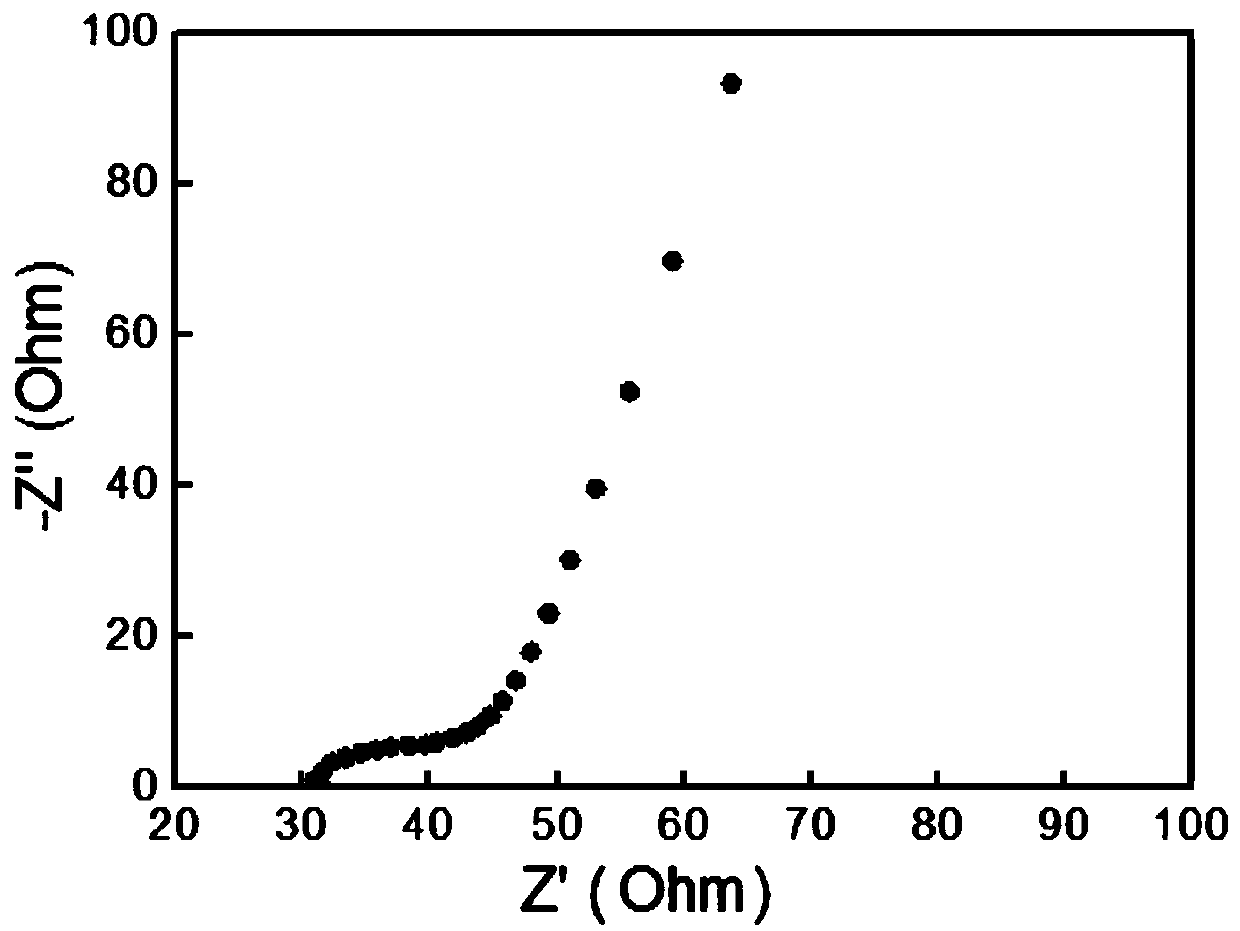

[0295] About 1 g of commercially available polyacrylonitrile (PAN) powder was dissolved in 7 g of N,N-dimethylformamide (DMF) to obtain a polyacrylonitrile solution. Spinning is then carried out under the electrostatic voltage of 15KV, the distance between the nozzle and the roller collector is 15cm, and the flow rate of the polyacrylonitrile solution is 15μl / min. After working like this for about 5 hours, a sheet can be peeled off from the roller device. The flexible polymer film was then rolled at about 2MPa for about 10 minutes, then soaked in 1mol / L lithium perchlorate / ethanol solution for 5 minutes, and then vacuum-dried to remove the solvent therein to obtain a 20μm thick, polymer film. A solid electrolyte with a mass ratio of lithium salt of 2:1, its density is 1.9g / cm 3 .

[0296] Calculate the specific interface area of the solid electrolyte according to the calculation method of the specific interface area described above in the present invention to be about 1.0×1...

Embodiment 1-2

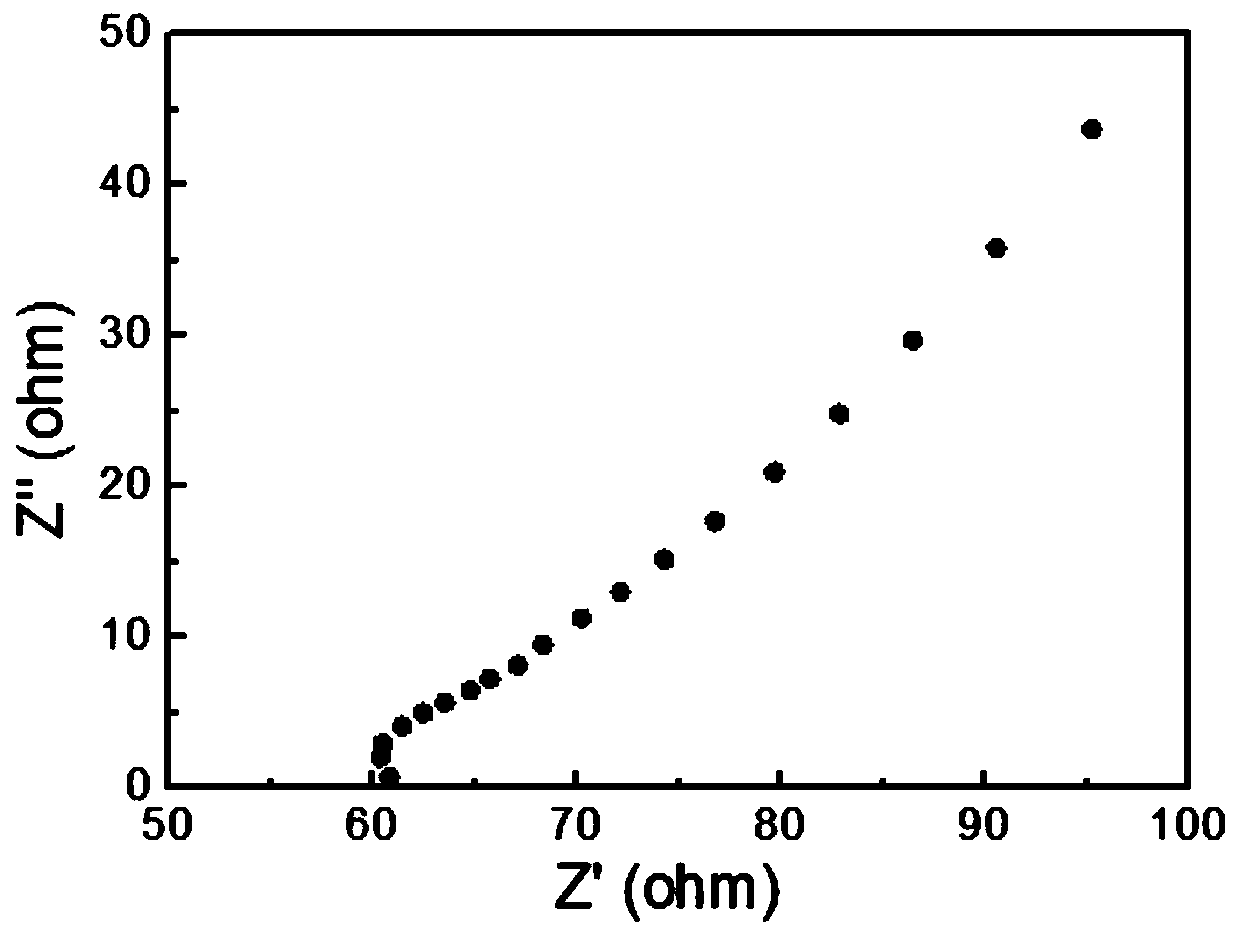

[0301] About 1 g of commercially available polymethyl methacrylate (PMMA) powder was dissolved in 9 g of DMF to obtain a polymethyl methacrylate solution. Spinning is then carried out under the electrostatic voltage of 15KV, the distance between the nozzle and the drum collector is 15cm, and the flow rate of the polymethyl methacrylate solution is 15μl / min. After working like this for about 7 hours, it can be peeled off from the drum device. Next, roll a flexible polymer film at about 2MPa for about 10 minutes, then soak it in 1mol / L lithium hexafluorophosphate / ethanol solution for 5 minutes, and then vacuum dry to remove the solvent in it to obtain a 30μm thick, polymer film. A solid electrolyte with a mass ratio of lithium salt of 4:1, its density is 2.2g / cm 3 .

[0302] Calculate the specific interface area of the solid electrolyte according to the calculation method of the specific interface area described above in the present invention to be about 3.5×10 5 cm 2 / cm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com