Lithium metal cathode coated with solid polymer electrolyte and preparation method thereof

A solid polymer, lithium metal anode technology, applied in solid electrolytes, electrolyte battery manufacturing, electrolytes, etc., can solve problems such as difficult cycling, lithium dendrite growth, thermal runaway, etc., and achieve high room temperature conductivity and cycle performance. Elevate, prepare simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Vinylene carbonate 1g, polyethylene glycol acrylate (molecular weight 1000) 9g, add 0.4g lithium trifluorosulfonate, add azobisisobutyronitrile 0.1g, stir well, inject the mixed liquid into the PTFE mold , Reaction at 70°C for 12h to obtain a solid polymer electrolyte membrane. The conductivity of the electrolyte membrane at room temperature is 5.42×10 -4 S / cm, the electrochemical stability window is 4.8V.

Embodiment 2

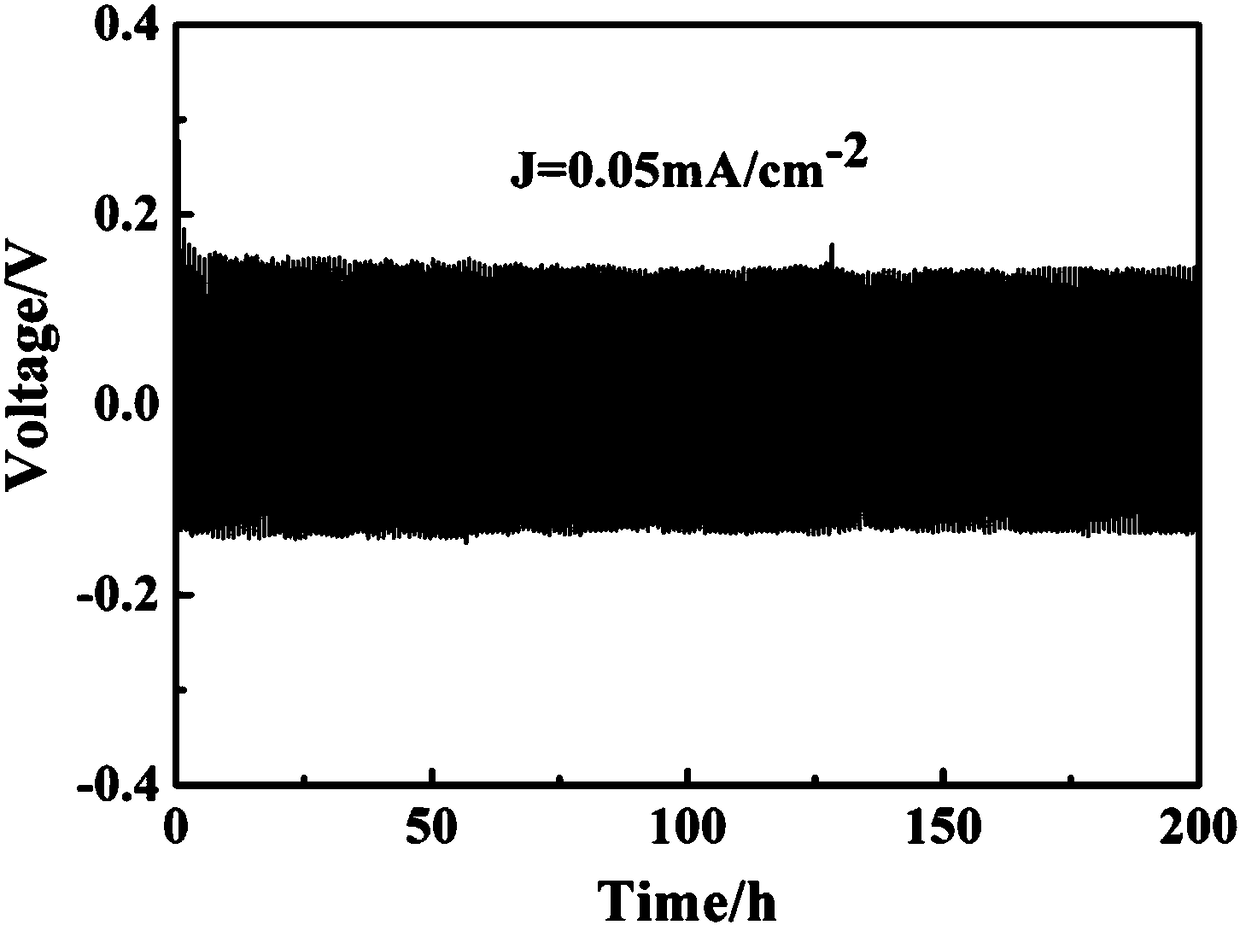

[0029] Vinylene carbonate 1g, polyethylene glycol acrylate (molecular weight 4000) 2g, add 0.4g lithium perchlorate, add azobisisobutyronitrile 0.01g, stir evenly, apply to metal lithium surface, react at 70°C After 12 hours, a lithium negative electrode coated with a solid polymer electrolyte membrane was obtained. Combine it with metal lithium to form a symmetrical battery at 0.05mA / cm -2 Under the current density of 1000000000000000000000000000000000000000000000000000000000000000000000000000000000000000010000000000000000000000001000000000000000000000000000000000000000000 get cyclic test, in 200 hrs, there is no battery short circuit caused by lithium dendrites.

Embodiment 3

[0031] Vinylene carbonate 2g, polyethylene glycol acrylate (molecular weight 200) 1g, methyl methacrylate 1g, add 1g lithium bistrifluoromethanesulfonimide, add benzoyl peroxide 0.01g, stir well , coated on the surface of metallic lithium, and reacted at 80°C for 12 hours to obtain a lithium negative electrode coated with a solid polymer electrolyte membrane. It is combined with sulfur cathode to form a lithium-sulfur battery. The test results show that the Coulombic efficiency can reach 99%, and the cycle life can reach 1000 cycles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity at room temperature | aaaaa | aaaaa |

| Electrochemical stability window | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com