Method for preparing lithium hydroxide and lithium carbonate by utilizing soluble lithium-salt solution

A technology of lithium salt solution and lithium hydroxide, which is applied in the direction of lithium oxide;/hydroxide, lithium carbonate;/acid carbonate, etc., can solve the problem of reducing the operating efficiency of bipolar membrane electrodialyzers and increasing Energy consumption and other issues to achieve the effect of avoiding cumbersome processes and pollution discharge links, saving energy consumption and material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

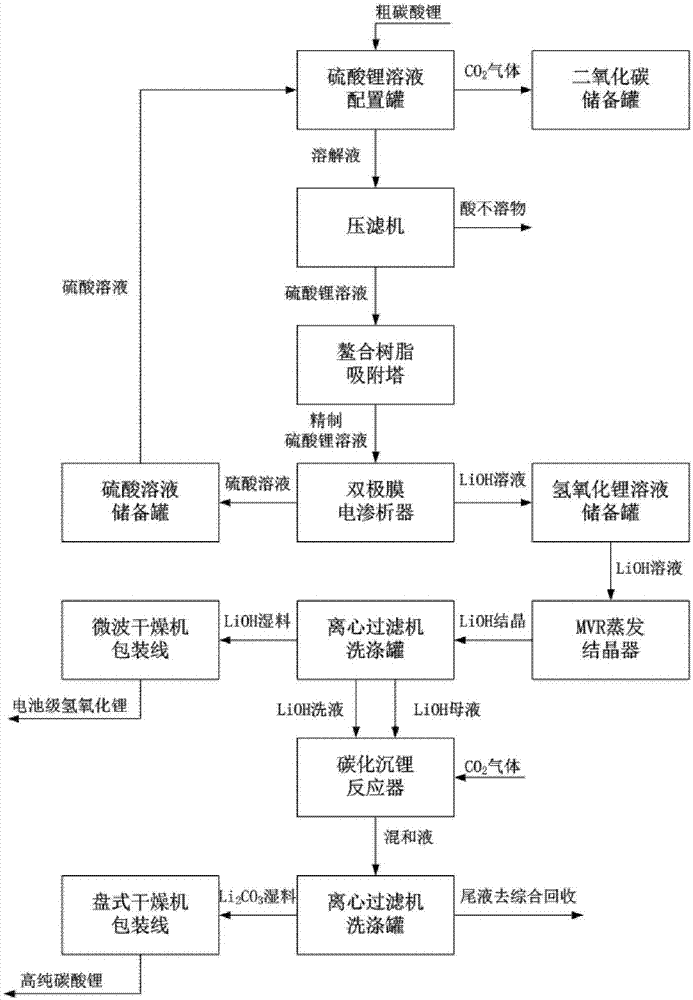

[0095] Use crude lithium carbonate as raw material to prepare battery-grade lithium hydroxide and battery-grade lithium carbonate (see image 3 ).

[0096] 1. Heating ball milling fine washing process of lithium concentrate

[0097] Collect the lithium concentrate (40%-60% crude lithium carbonate) produced by the sun pool of Zhabuye Salt Lake in Tibet, crush it, and then carry out heating ball refining, washing, and centrifugal filtration to form the refined ore (coarse lithium carbonate) and washed liquid. The refined ore enters the lithium sulfate solution configuration process, and the washing liquid enters the comprehensive utilization process.

[0098] Table 1: Zabuye lithium concentrate analysis table (mass percentage content, %)

[0099] project

Li

Ca

Mg

Na

K

Fe 2 o 3

%

10.371

0.372

0.145

16.143

0.996

0.16

project

SO 4 2-

Al

SiO 2

Cl -

CO 3 2-

acid insoluble matter

...

Embodiment 2

[0115] Preparation of battery-grade lithium carbonate from lithium-rich brine.

[0116] Collect intercrystalline brine from Yiliping Salt Lake in Qinghai Province, China, and concentrate through natural evaporation in the salt pan to form potash ore and boron-lithium brine. The ion-selective electrodialysis process is implemented on the boron-lithium brine to form the following lithium-rich brine.

[0117] Table 3: Analysis table of lithium-rich brine (unit: g / l)

[0118] project

Li +

Mg 2+

Ca 2+

Cl -

SO 4 2-

K +

B 3+

Na +

g / l

7.66

5.32

0.05

65.76

0.16

2.16

0.1

5.82

[0119] 1. React lithium-rich brine with lithium lye to causticize magnesium removal

[0120] Mix the lithium-rich brine and the lithium lye prepared by the back-end bipolar membrane electrodialysis process in a heating reactor, control the reaction temperature at 60°C, form magnesium hydroxide sediment, and control the mixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com