High Density Lithium Cobalt Oxide for Rechargeable Batteries

a lithium cobalt oxide, rechargeable battery technology, applied in the direction of cell components, conductors, cellulosic plastic layered products, etc., can solve the problems of high tap density, fire or explosion of batteries, and obtained electrode density not correspondingly high, so as to improve increase capacity and rate capability of cells with certain volume, and increase the effect of energy density and rate capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

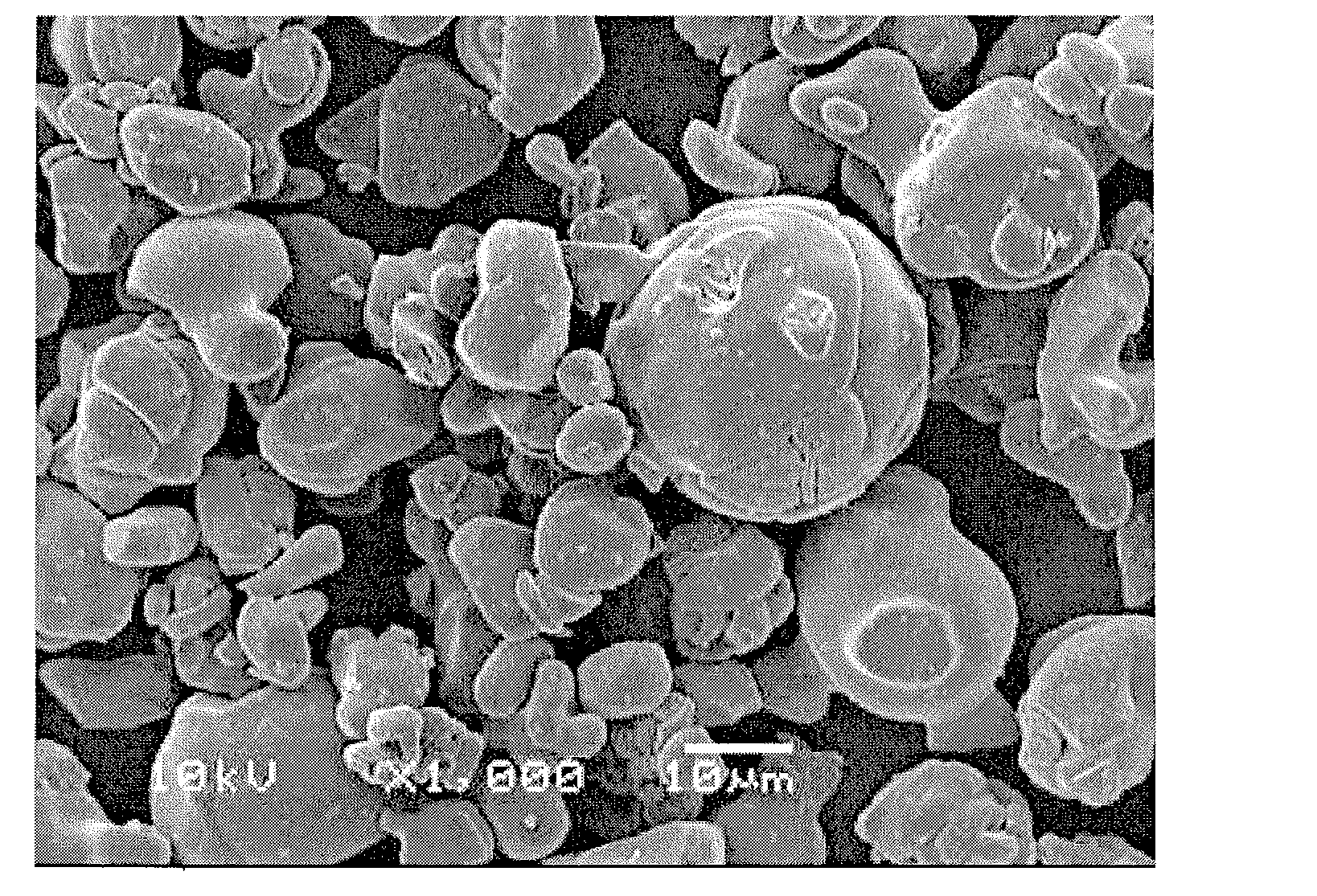

[0055]A mixture is made with aggregated Co(OH)2 with a d50 of 19.3 μm and Li2CO3 with a Li to Co (atomic) blending ratio of 1.05. The mixed powder is fired in air at 980° C. for 12 hours. After cooling, the obtained material is milled and screened with a 270 mesh screen.

example 2

[0056]Same as example 1, except that the firing temperature is 970° C.

example 3

[0057]A mixture is made with aggregated Co(OH)2 with a d50 of 19.3 μm and Li2CO3 with a Li to Co blending ratio of 1.04. The mixed powder is fired in air at 990° C. for 10 hours. After cooling, the obtained material is milled and screened with a 270 mesh screen.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| working voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com