Production method and production equipment of ultrathin lithium belt

A technology for production equipment and production methods, which is applied in the field of production methods and production equipment for ultra-thin lithium strips, can solve problems such as difficulty in producing metal lithium strips, tensile deformation, fracture, etc., and achieve the goal of avoiding discoloration and reliable production of lithium strips Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

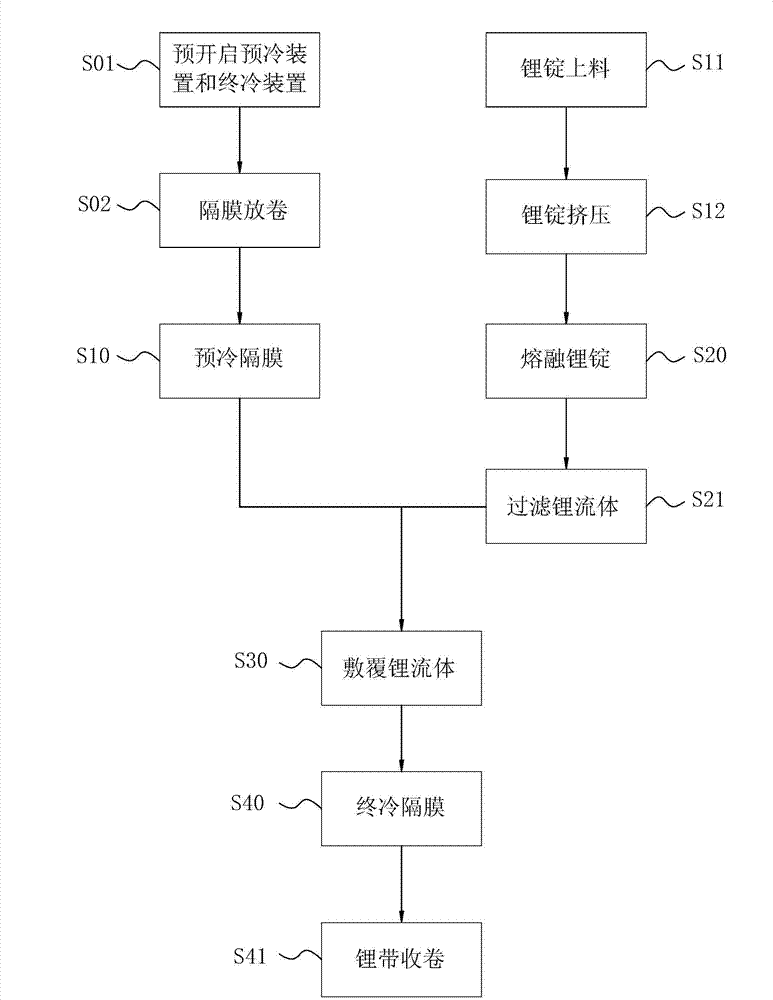

[0058] Such as image 3Shown, a kind of production method of ultra-thin lithium ribbon, comprises the following steps:

[0059] S01, pre-opening the pre-cooling device 17 and the final cooling device 18: opening the pre-cooling device 17 and the final cooling device 18 in advance, so that the pre-cooling device 17 and the final cooling device 18 reach the set temperature required for cooling the battery diaphragm 22;

[0060] S02. Diaphragm unwinding: transport the battery diaphragm 22 into the pre-cooling device 17 that has reached the set temperature.

[0061] S10 , pre-cooling the diaphragm: the temperature of the battery diaphragm 22 is lowered in advance by the pre-cooling device 17 .

[0062] S11. Lithium ingot feeding: put the solid metal lithium ingot into the lithium ingot material cylinder 11;

[0063] S12. Lithium ingot extrusion: Extrude the solid metal lithium ingot into the melting cylinder 12 through the power unit 10 .

[0064] S20. Melting the lithium ingot...

Embodiment 2

[0079] The difference between this embodiment and Embodiment 1 is:

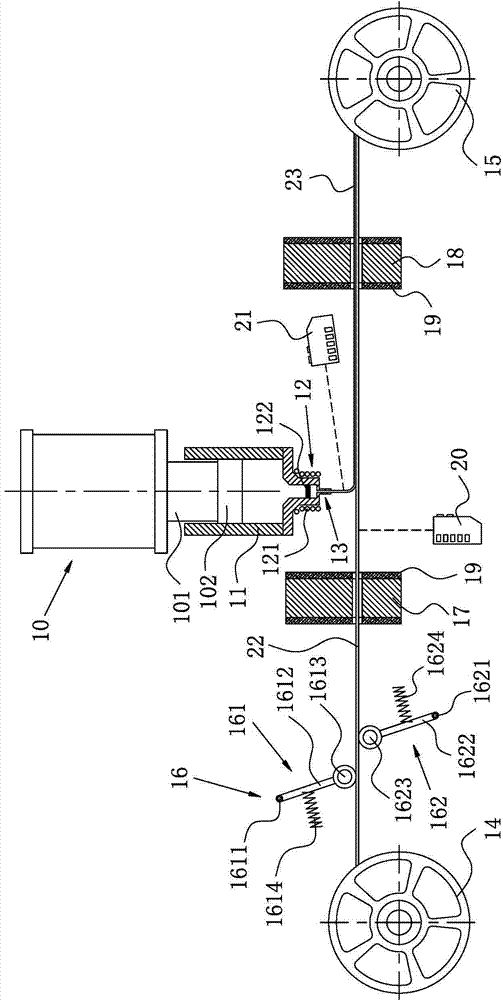

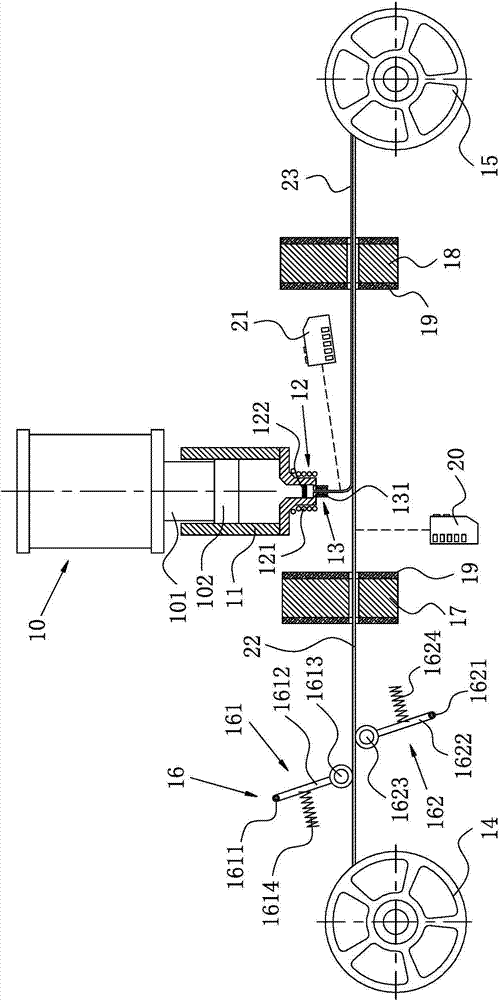

[0080] Such as figure 2 Shown, a kind of production equipment of ultra-thin lithium belt, comprises the lithium ingot material cylinder 11 that is used to store metal lithium ingot, the top of lithium ingot material cylinder 11 is provided with the power unit 10 that is used to extrude described metal lithium ingot, power Device 10 is a pneumatic cylinder.

[0081] The bottom of the melting cylinder 12 is provided with an extrusion head 13 for extruding lithium fluid, and the middle part of the extrusion head 13 is provided with a rectangular discharge through hole, and one end of the discharge through hole communicates with the melting cylinder 12. The other end of the material through hole communicates with the outside and is located above the battery separator 22 . The outer side of the extrusion head 13 is covered with a heat preservation device 131 for keeping the lithium fluid in a molten state. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com