Electrode for nonaqueous secondary battery, nonaqueous secondary battery using the same, and method for producing electrode

A non-aqueous secondary battery, manufacturing method technology, applied in battery electrodes, secondary batteries, electrode manufacturing and other directions, can solve problems such as current collector softening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0166] In the ebullating bed reactor, SiO particles (average particle diameter: 5.0 μm) as the negative electrode active material are heated to about 1000°C, and the heated SiO particles are brought into contact with a mixed gas of methane and nitrogen at 25°C. CVD treatment was performed for 60 minutes. In this way, carbon generated by thermal decomposition of the mixed gas (hereinafter also referred to as "CVD carbon") is deposited on SiO particles to form a coating layer, thereby obtaining a negative electrode material.

[0167] The composition of the negative electrode material was calculated from the mass change before and after the coating layer was formed, and it was found that SiO:CVD carbon=85:15 (mass ratio).

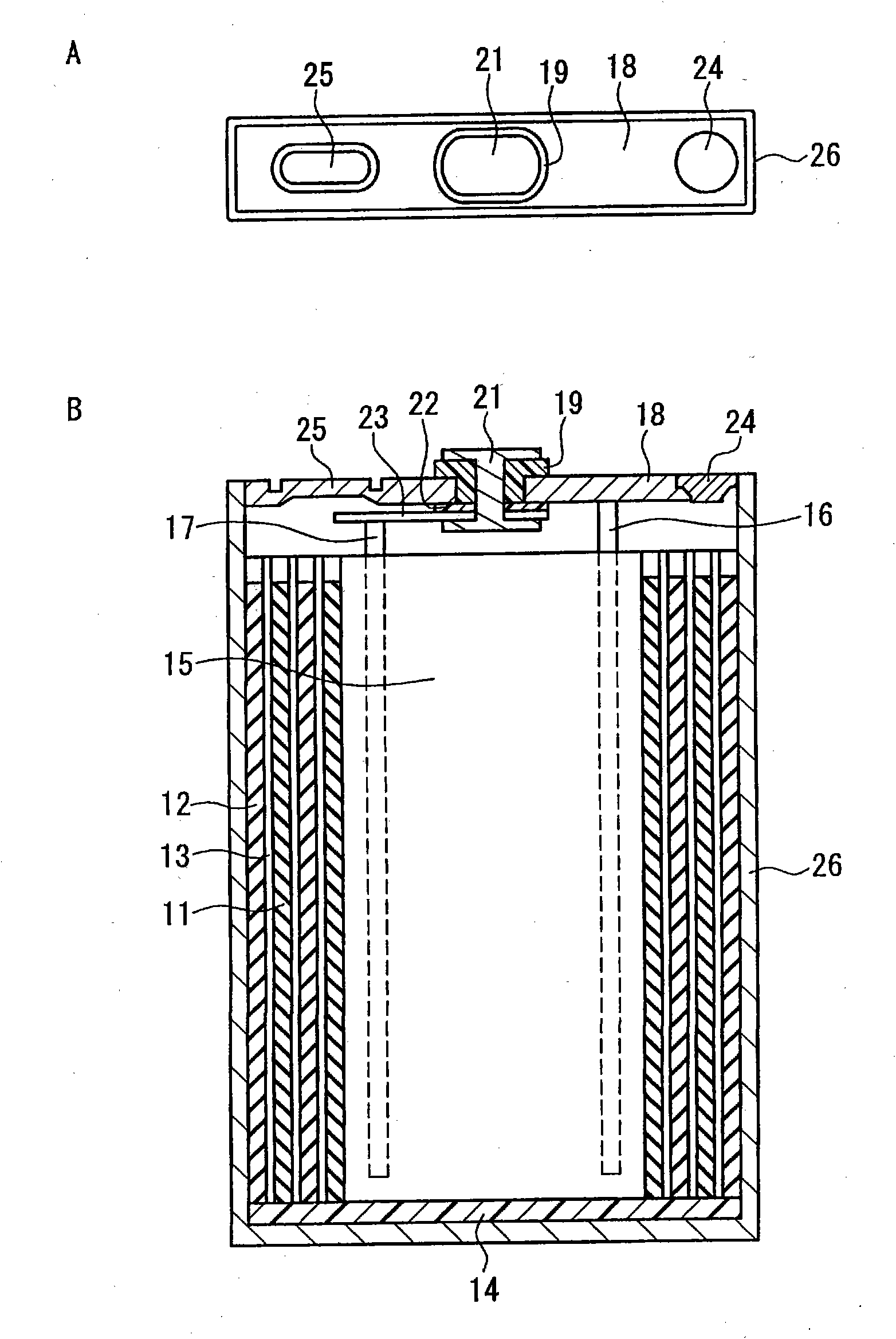

[0168] Next, using the aforementioned negative electrode material, a negative electrode precursor sheet was fabricated. 80% by mass of the aforementioned negative electrode material (mass ratio relative to the total amount of solids in the slurry, the same be...

Embodiment 2

[0174] As an insulating material that does not react with lithium, α-alumina (average particle diameter: 1 μm) 96% by mass (mass ratio relative to the total amount of solid content in the slurry, the same below), polyvinylidene fluoride (PVDF ) 4% by mass and dehydrated NMP were mixed to prepare a coating layer forming slurry.

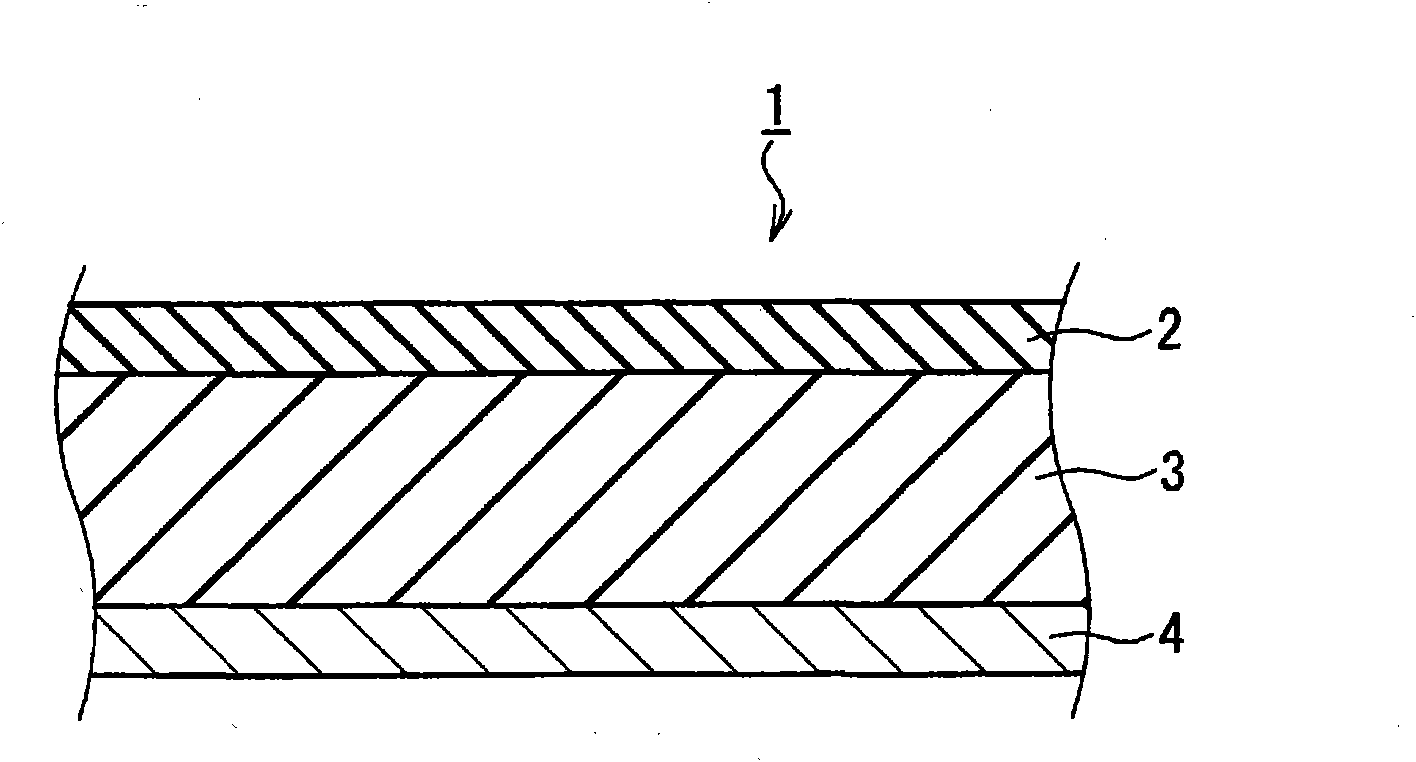

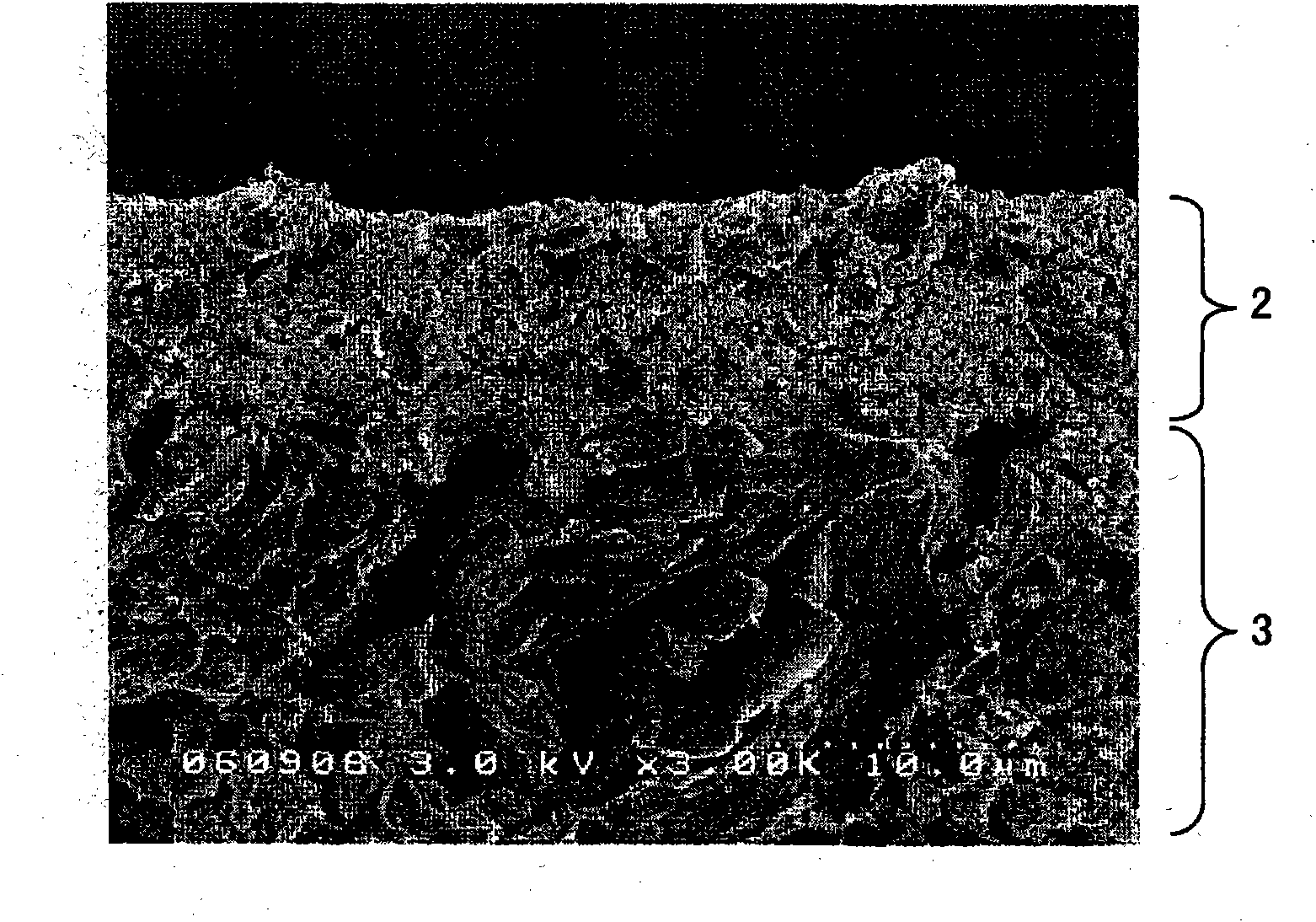

[0175] Using a knife coater, use the slurry containing the negative electrode mixture of the above-mentioned Example 1 as the lower layer, and use the slurry for coating layer formation as the upper layer, and coat them on the current collector composed of copper foil with a thickness of 8 μm. both sides. Next, it was dried at 100° C., and then compression-molded by a roll press to form a laminate of a negative electrode mixture layer with a thickness of 35 μm and a coating layer with a thickness of 5 μm on both sides of the current collector. Next, the current collector on which the laminate was formed was dried in vacuum at 100° C. for 15 hours.

...

Embodiment 3

[0178] Put 200 g of SiO (average particle diameter 1 μm), 60 g of graphite (average particle diameter 3 μm), and 30 g of polyethylene resin particles of the binder into a 4 L stainless steel container, further add stainless steel balls, and perform 3 hours of mixing, crushing, and granulation. As a result, composite particles (composite particles of SiO and graphite) having an average particle diameter of 20 μm were produced. Next, the composite particles were heated to about 950°C in an ebullating bed reactor, the heated composite particles were brought into contact with a 25°C mixed gas of toluene and nitrogen, and CVD treatment was performed at 950°C for 60 minutes. In this way, the carbon generated by thermal decomposition of the aforementioned mixed gas is deposited on the aforementioned composite particles to form a covering layer, thereby obtaining a negative electrode material.

[0179] The composition of the negative electrode material was calculated from the mass ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com