Lithium ion battery positive plate and manufacture method thereof

A lithium-ion battery, positive electrode technology, applied in electrode manufacturing, battery electrodes, batteries, etc., can solve the problems of energy density loss, long time consumption, rapid expansion of positive electrode and increase in thickness of battery cells, etc. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1. Preparation of positive electrode sheet for lithium-ion battery

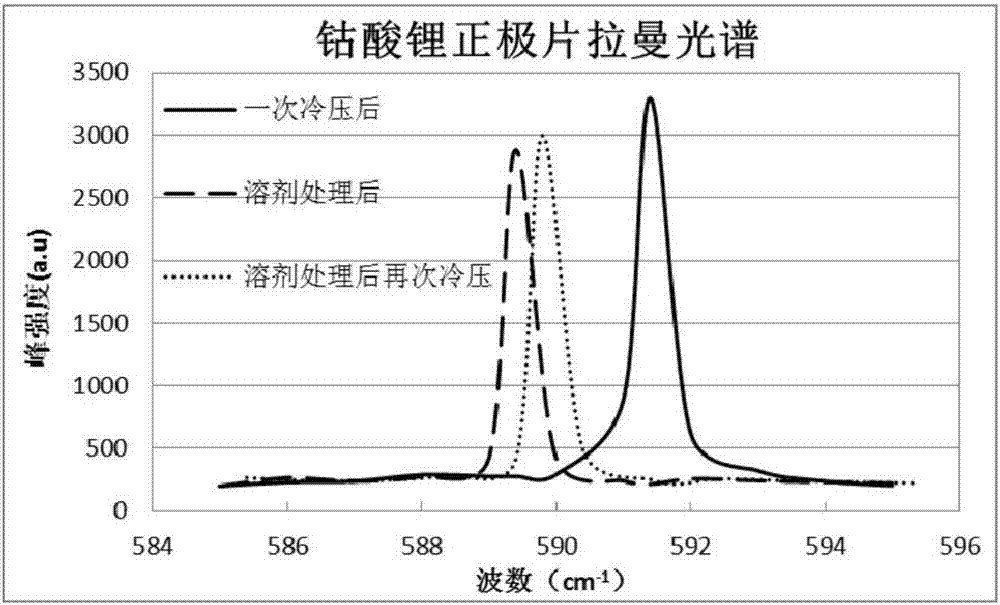

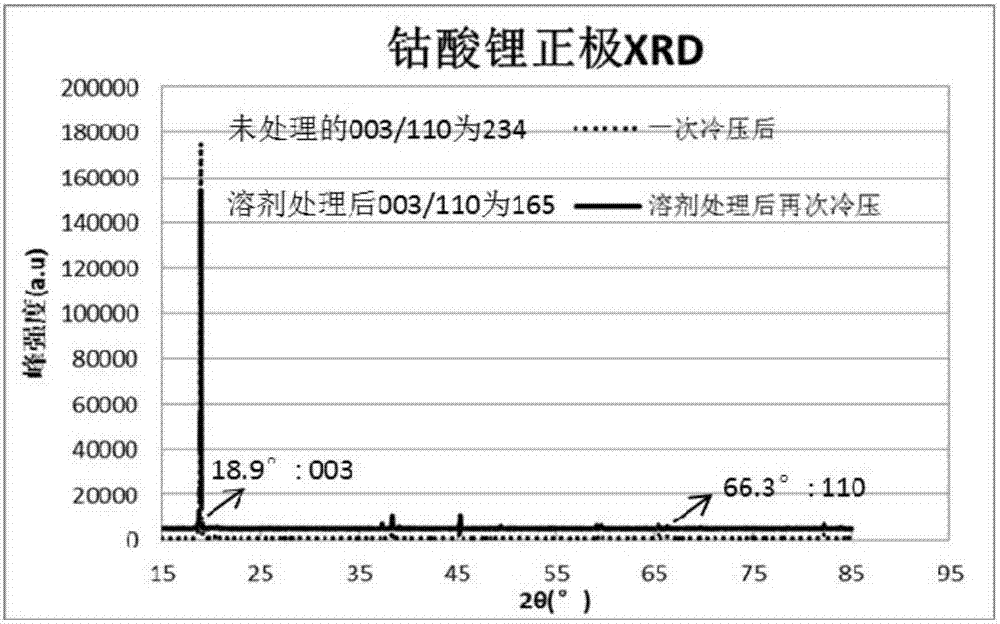

[0036] The cathode active material LiCoO 2 , the conductive agent conductive carbon SP and the binder PVDF are mixed uniformly in the solvent N-methylpyrrolidone at a mass ratio of 95:2:3 to make a positive electrode slurry, and the positive electrode slurry is evenly coated on the positive electrode current collector aluminum foil, and dried The latter cold press to a bulk density of 4.1g / cc, and sliced to obtain positive electrode sheets.

[0037] Ethyl acetate was used as a solvent for infiltration treatment, and ethyl acetate equivalent to 1% of the mass of the positive electrode active material was evenly sprayed on the surface of the positive electrode sheet prepared in the above steps by means of rotary spraying, and then dried and cold pressed twice to obtain the Lithium-ion battery cathode sheets that require bulk density.

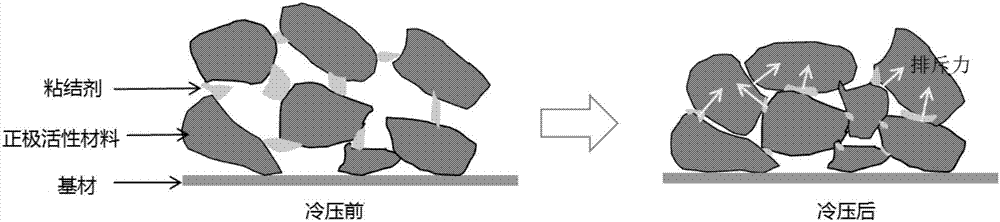

[0038] figure 1 It is a schematic diagram of the distribution of...

Embodiment 2

[0046] The lithium ion battery of Example 2 of the present invention is basically the same as the lithium ion battery of Example 1 of the present invention. The positive electrode sheet surface that step makes.

Embodiment 3

[0048] The lithium ion battery of Example 3 of the present invention is basically the same as the lithium ion battery of Example 1 of the present invention. The positive electrode sheet surface that step makes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com