Lithium ion battery pole piece and preparation method thereof

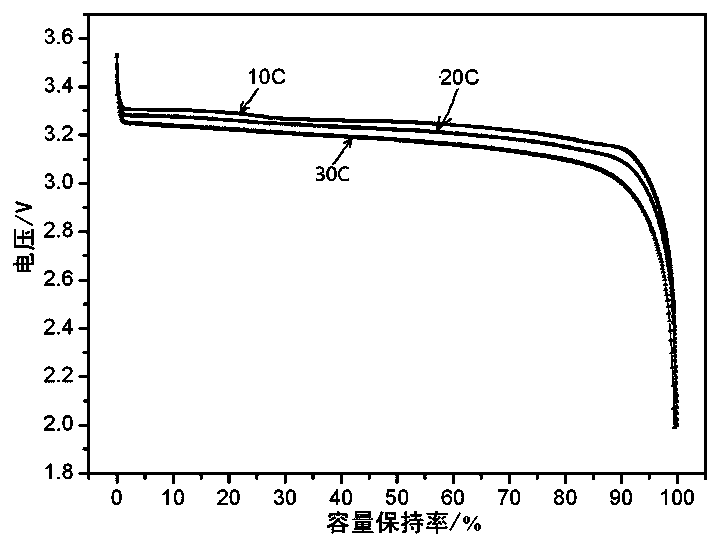

A lithium ion battery and pole piece technology is applied in the field of lithium ion battery pole pieces and their preparation, which can solve the problems of short driving range of electric vehicles, low compaction density of negative electrode pieces, low battery energy density, etc., and can meet the requirements of fast charging and discharging. and service life requirements, changing the charge migration path, improving the rate charge and discharge performance and the effect of cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

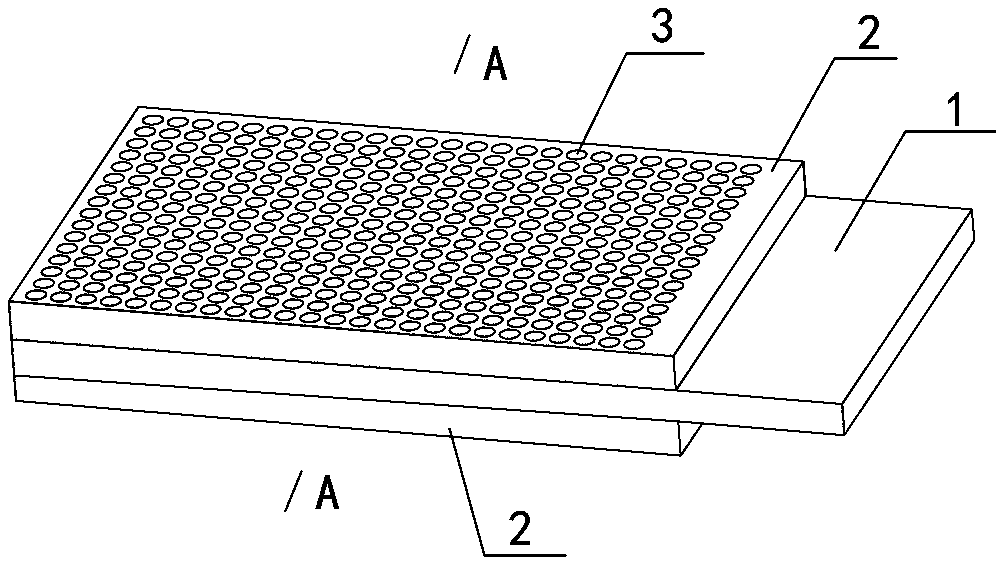

[0033] The preparation method of above-mentioned lithium ion battery pole piece comprises the following steps:

[0034] Step 1, adding the active material, the binder and the conductive agent into the solvent, stirring evenly to obtain a mixture slurry.

[0035] Step 2: Coating the slurry evenly on both sides of the current collector (1), drying and rolling to obtain lithium-ion battery pole pieces.

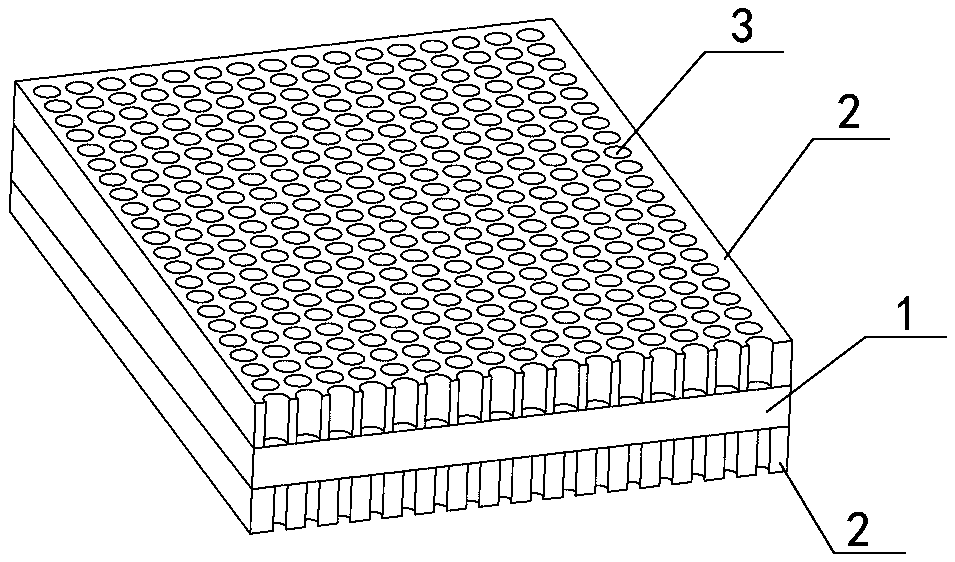

[0036] Step 3: Using mechanical punching or laser punching, uniformly punch micropores (3) on the slurry membrane (2) to obtain a lithium ion battery pole piece with micropores.

[0037] The mechanical punching equipment was purchased from Changsha Lianeng Electronic Technology Co., Ltd., and the equipment model is LE-CK300-50. When the equipment is used for punching, the technical parameters of the control equipment are specifically: the diameter of the mold needle is 0.01-0.1mm, and the length is 5mm or 7mm. Mold hole density is 3-50 holes / mm 2 , the effective punching width...

Embodiment 1

[0040] Add artificial graphite, conductive graphite, sodium carboxymethyl cellulose, and styrene-butadiene rubber into high-purity deionized water and stir evenly to prepare a uniform mixture slurry, and then coat the uniform mixture slurry on the surface of copper foil. Dried in an oven, according to 1.4g / cm 3 The compacted density is rolled to obtain the negative electrode sheet. Then, the negative pole piece is punched, and circular micropores (3) are uniformly punched out on the slurry membrane (2), so as to obtain a lithium ion battery negative pole piece with micropores. The measurement results of the physical parameters of the pole piece are shown in Table 1. Then add lithium iron phosphate, acrylic acid, styrene-butadiene rubber, and conductive graphite into high-purity deionized water and stir evenly to prepare a uniform mixture slurry, and then coat the uniform mixture slurry on the surface of the aluminum foil. Dried in an oven, according to 2.3g / cm 3 The compact...

Embodiment 2

[0042]Add mesophase carbon microspheres, carbon nanotubes, and polyvinylidene fluoride into N-methylpyrrolidone and stir evenly to prepare a uniform mixture slurry, and then coat the uniform mixture slurry on the surface of the three-dimensional copper foil. Dried in an oven, according to 1.6g / cm 3 The compacted density is rolled to obtain the negative electrode sheet. Then, the negative pole piece is punched, and triangular micropores (3) are evenly punched out on the slurry membrane (2), so as to obtain the lithium ion battery negative pole piece with micropores. The measurement results of the physical parameters of the pole piece are shown in Table 1. Then add the ternary material, polyvinylidene fluoride, polyvinylidene fluoride-hexafluoropropylene, and carbon nanotubes into N-methylpyrrolidone and stir evenly to prepare a uniform mixture slurry, and then mix the uniform mixture slurry Coated on the surface of three-dimensional aluminum foil. Dried in an oven, according...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com