Processing method of liquid smoked abalone

A processing method and technology of liquid cigarettes, applied in the fields of food science, food preservation, application, etc., can solve the problems of polluted products, polluted environment, complexity, etc., and achieve the effects of strong antioxidant capacity, long storage period, and increased stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

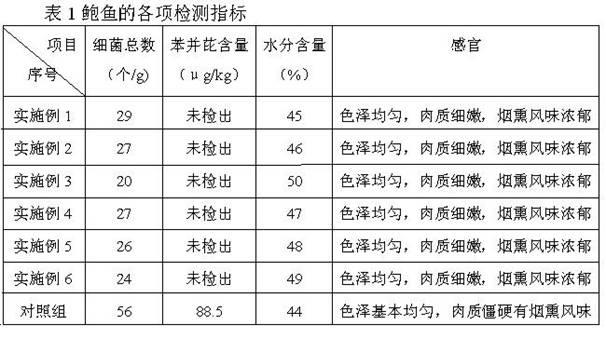

Examples

Embodiment 1

[0036] 1. Preparation of liquid fumigant

[0037] Take 50g of smoked powder, dissolve it in sterile water, fully dissolve, then add 10g of sodium pyrophosphate and 10g of sodium tripolyphosphate into the solution, mix it up to 100kg with sterile water, dissolve it fully, and mix it evenly to obtain a liquid fumigant;

[0038] 2. Pretreatment: shell the fresh abalone, take the meat and clean it;

[0039] 3. Fumigant immersion treatment under vacuum conditions

[0040] Soak abalone in liquid fumigant at room temperature, the mass ratio of abalone to liquid fumigant is 1:6, and soak for 1.5h under the condition of vacuum degree of 0.07MPa;

[0041] 4. Pickling: Take the abalone out of the liquid fumigant, then put it into the seasoning solution and marinate for 1.5 hours. The mass ratio of the abalone to the seasoning solution is 1:6. The seasoning solution is made of the following raw materials in mass percentage Composition: 4% salt, 0.4% monosodium glutamate, 0.5% chili, 1....

Embodiment 2

[0048] 1. Preparation of liquid fumigant

[0049] Take 100g of smoked powder, dissolve it in sterile water, fully dissolve, then add 4g of sodium pyrophosphate and 16g of sodium tripolyphosphate into the solution, mix it up to 100kg with sterile water, dissolve it fully, and mix it evenly to obtain a liquid fumigants;

[0050] 2. Pretreatment: shell the fresh abalone, take the meat and clean it;

[0051] 3. Fumigant immersion treatment under vacuum conditions

[0052] Soak abalone in liquid fumigant at room temperature, the mass ratio of abalone to liquid fumigant is 1:7, and soak for 1.5h under the condition of vacuum degree of 0.085MPa;

[0053] 4. Pickling: Take the abalone out of the liquid fumigant, and then put it into the seasoning solution to marinate for 2 hours. The mass ratio of the abalone to the seasoning solution is 1:7. The seasoning solution is composed of the following raw materials in mass percentage : 5% salt, 0.25% monosodium glutamate, 1.3% chili, 0.7% su...

Embodiment 3

[0059] 1. Preparation of liquid fumigant

[0060] Take 150g of smoked powder, dissolve it in sterile water, fully dissolve it, then add 5g of sodium pyrophosphate and 15g of sodium tripolyphosphate into the solution, prepare 100kg of it with sterile water, dissolve it fully, and mix it evenly to obtain liquid smoke fumigants;

[0061] 2. Pretreatment: shell the fresh abalone, take the meat and clean it;

[0062] 3. Fumigant immersion treatment under vacuum conditions

[0063] Soak abalone in liquid fumigant at room temperature, the mass ratio of abalone to liquid fumigant is 1:7, and soak for 1.5h under the condition of vacuum degree of 0.08MPa;

[0064] 4. Pickling: Take the abalone out of the liquid fumigant, and put it into the seasoning solution to marinate for 1.5 hours. The mass ratio of the abalone to the seasoning solution is 1:7. The seasoning solution is made of the following raw materials in mass percentage Composition: 6% salt, 0.35% monosodium glutamate, 1.0% p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com