Electrolyte and lithium-ion battery using the same

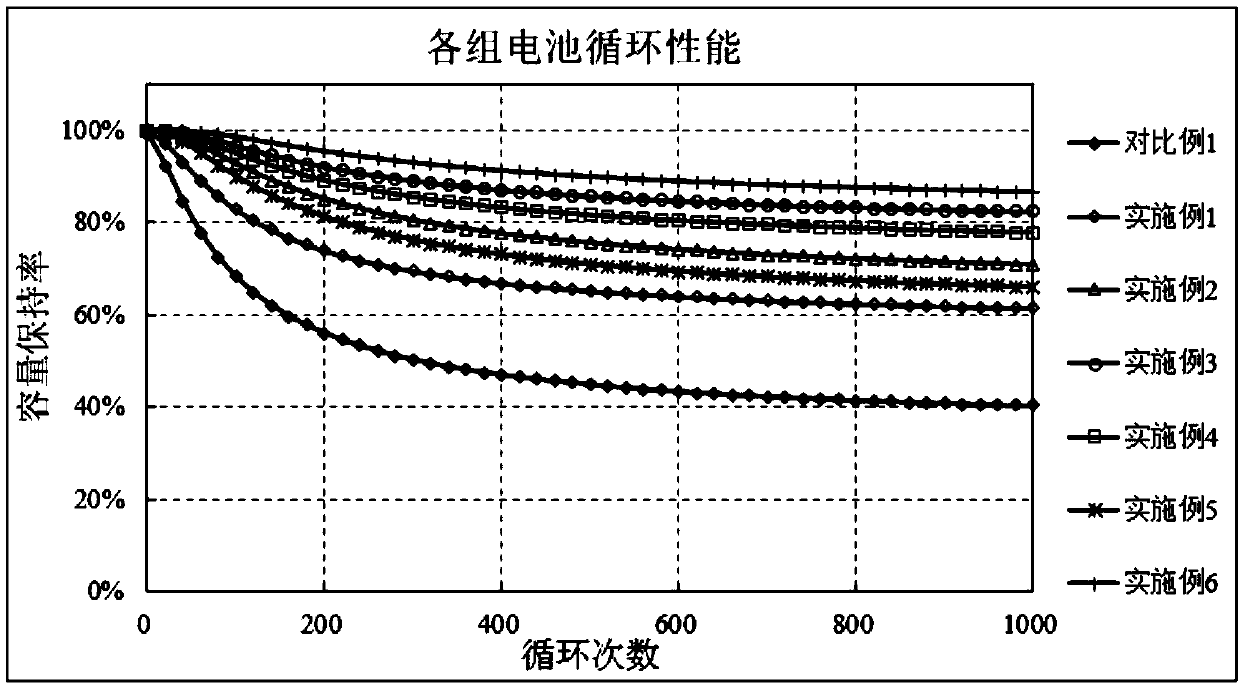

An electrolyte and lithium salt technology, applied in secondary batteries, organic electrolytes, non-aqueous electrolytes, etc., can solve the problems of increased negative electrode surface impedance, structural damage of positive electrode materials, and decreased lattice stability, preventing the reduction reaction. , The effect of improving battery performance and capacity recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

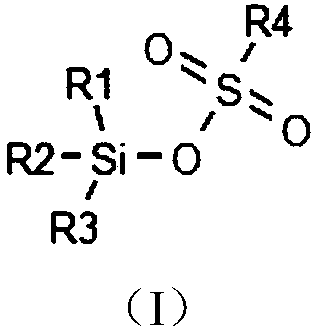

[0041] Preparation of electrolyte

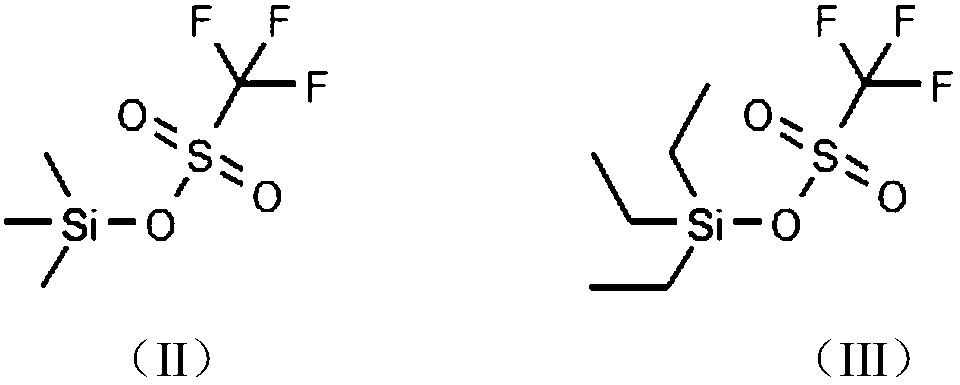

[0042] Mix ethylene carbonate (EC), ethyl methyl carbonate (EMC), and diethyl carbonate (DEC) in a volume ratio of 1:1:1 as a non-aqueous solvent, and dissolve 1 mol / L of LiPF in the non-aqueous solvent 6 As a lithium salt, 1% VC, 1% VEC, 2% FEC, and 0.2% trimethylsilane trifluoromethanesulfonate are added as additives to form lithium ion secondary batteries. Electrolyte. The structure of trimethylsilane trifluoromethanesulfonate is shown in the following formula:

[0043]

[0044] The rest is the same as Comparative Example 1, and will not be repeated here.

Embodiment 2

[0046] Preparation of electrolyte

[0047] Mix ethylene carbonate (EC), ethyl methyl carbonate (EMC), and diethyl carbonate (DEC) in a volume ratio of 1:1:1 as a non-aqueous solvent, and dissolve 1 mol / L of LiPF in the non-aqueous solvent 6 As a lithium salt, 1% VC, 1% VEC, 2% FEC, and 1% trimethylsilane trifluoromethanesulfonate are added as additives to form lithium ion secondary batteries. Electrolyte. The rest is the same as Comparative Example 1, and will not be repeated here.

Embodiment 3

[0049] Preparation of electrolyte

[0050] Mix ethylene carbonate (EC), ethyl methyl carbonate (EMC), and diethyl carbonate (DEC) in a volume ratio of 1:1:1 as a non-aqueous solvent, and dissolve 1 mol / L of LiPF in the non-aqueous solvent 6 As a lithium salt, 1% VC, 1% VEC, 2% FEC, and 3% trimethylsilane trifluoromethanesulfonate are added as additives to form lithium ion secondary batteries. Electrolyte. The rest is the same as Comparative Example 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com