Lithium ion secondary battery and electrolyte thereof

A secondary battery and electrolyte technology, applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problem of cycle performance degradation, achieve the effect of inhibiting oxidation reaction and improving cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

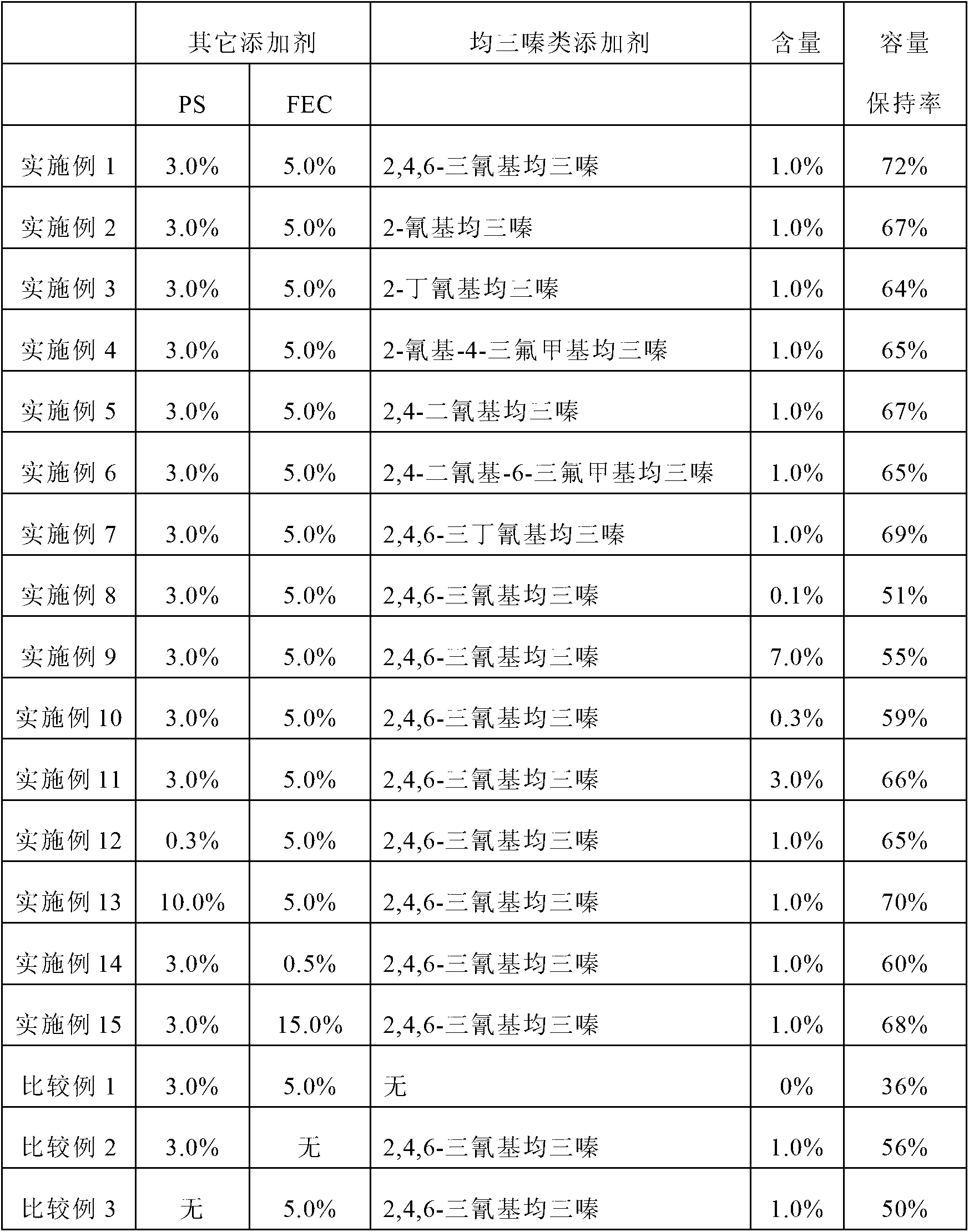

Examples

Embodiment 1

[0036] Preparation of lithium-ion secondary battery positive pole piece: Lithium cobalt oxide, conductive agent SuperP, binder PVDF are mixed with N-methylpyrrolidone (NMP) at a mass ratio of 96:2.0:2.0 to make a lithium-ion secondary battery positive pole Slurry, coated on the current collector aluminum foil, the coating amount is 0.0194g / cm 2; After drying at 85°C, carry out cold pressing; then trim, cut into pieces, and slitting, dry at 85°C for 4 hours under vacuum conditions, weld the tabs, and make positive pole pieces of lithium-ion secondary batteries;

[0037] Preparation of lithium-ion secondary battery negative electrode sheet: mix graphite with conductive agent SuperP, thickener CMC, and binder SBR with pure water at a mass ratio of 96.5:1.0:1.0:1.5 to make a slurry, and coat it on the set Fluid copper foil and dried at 85°C, the coating weight is 0.0089g / cm 2 ; Then trimming, cutting, and slitting, drying under vacuum conditions at 110°C for 4 hours, welding the ...

Embodiment 2

[0041] Preparation of lithium-ion secondary battery positive pole piece: same as Example 1;

[0042] Preparation of lithium-ion secondary battery negative pole piece: same as Example 1;

[0043] Preparation of lithium-ion secondary battery electrolyte: use 2-cyano-s-triazine instead of 2,4,6-tricyano-s-triazine in Example 1, and the rest are the same as in Example 1;

[0044] Preparation of lithium ion secondary battery: same as Example 1.

Embodiment 3

[0046] Preparation of lithium-ion secondary battery positive pole piece: same as Example 1;

[0047] Preparation of lithium-ion secondary battery negative pole piece: same as Example 1;

[0048] Preparation of lithium-ion secondary battery electrolyte: replace 2,4,6-tricyano-s-triazine in Example 1 with 2-butylcyano-s-triazine, and the rest are the same as in Example 1;

[0049] Preparation of lithium ion secondary battery: same as Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com