Determination method of volation organic metter in air

A technology of volatile organic compounds and air, applied in the direction of color/spectral characteristic measurement, measuring devices, instruments, etc., can solve the problems of complex instrument structure and high cost, and achieve high sensitivity, low temperature, and good hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation of the sampling tube in the method of the present invention is described.

[0032] 1) Treatment of adsorbent:

[0033] Put poly-2,6-diphenyl-p-phenylene ether, 60-80 mesh, into a U-shaped glass tube, under the protection of deoxidized high-purity nitrogen with a flow rate of 100-300 ml / min, aging treatment, temperature program It is: the initial temperature is 50°C, and the temperature rises to 350°C at a rate of 0.5°C / min.

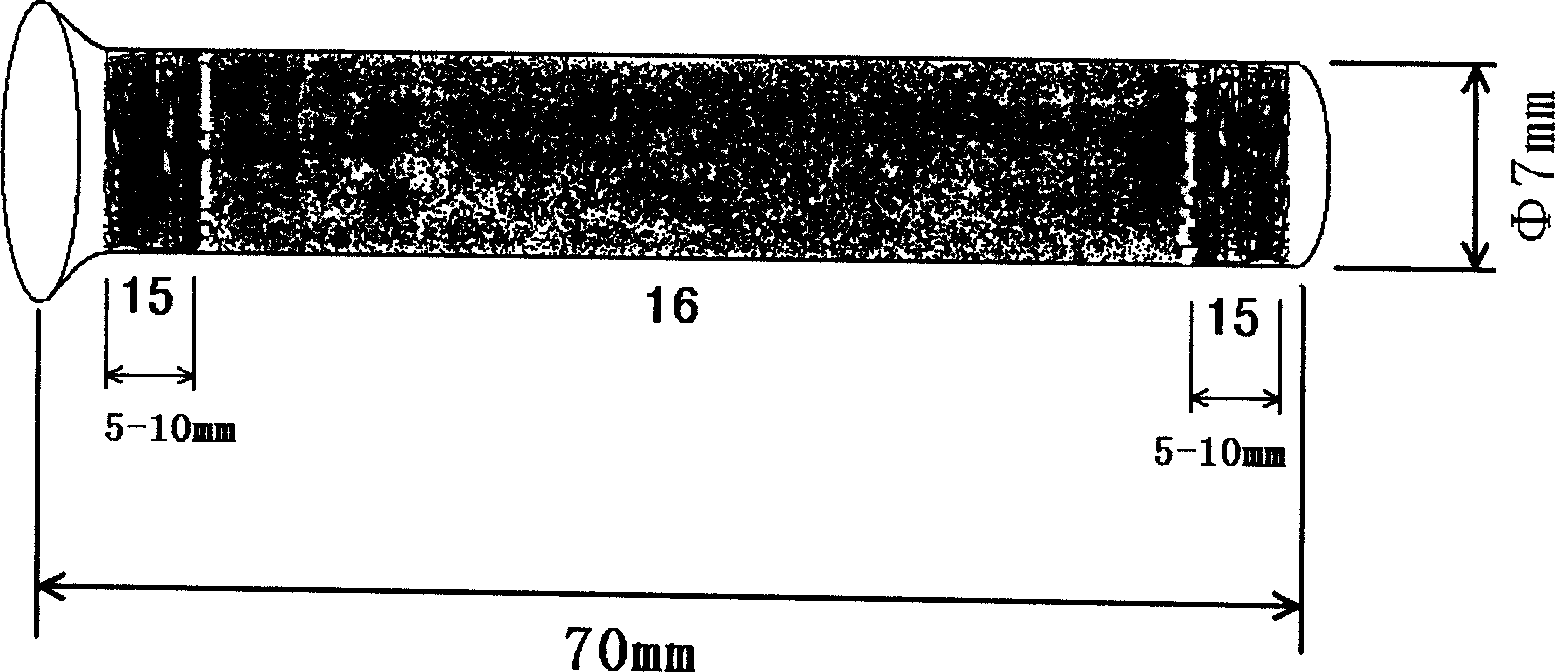

[0034] 2) Sampling tube specifications and filling of poly-2,6-diphenyl-p-phenylene ether:

[0035] The sampling tube is a glass or stainless steel tube with a specification of 70mm×Φ7mm (outer diameter). One end is straight (lower end), and the other end has a bell mouth (upper end). The design of the mouth end and bell mouth is conducive to its installation and disassembly in the desorption furnace.

[0036] Fill the tube with 0.3 g of poly-2,6-diphenyl-p-phenylene ether treated in step 1), and fill the two ends with 6 mm quart...

Embodiment 2

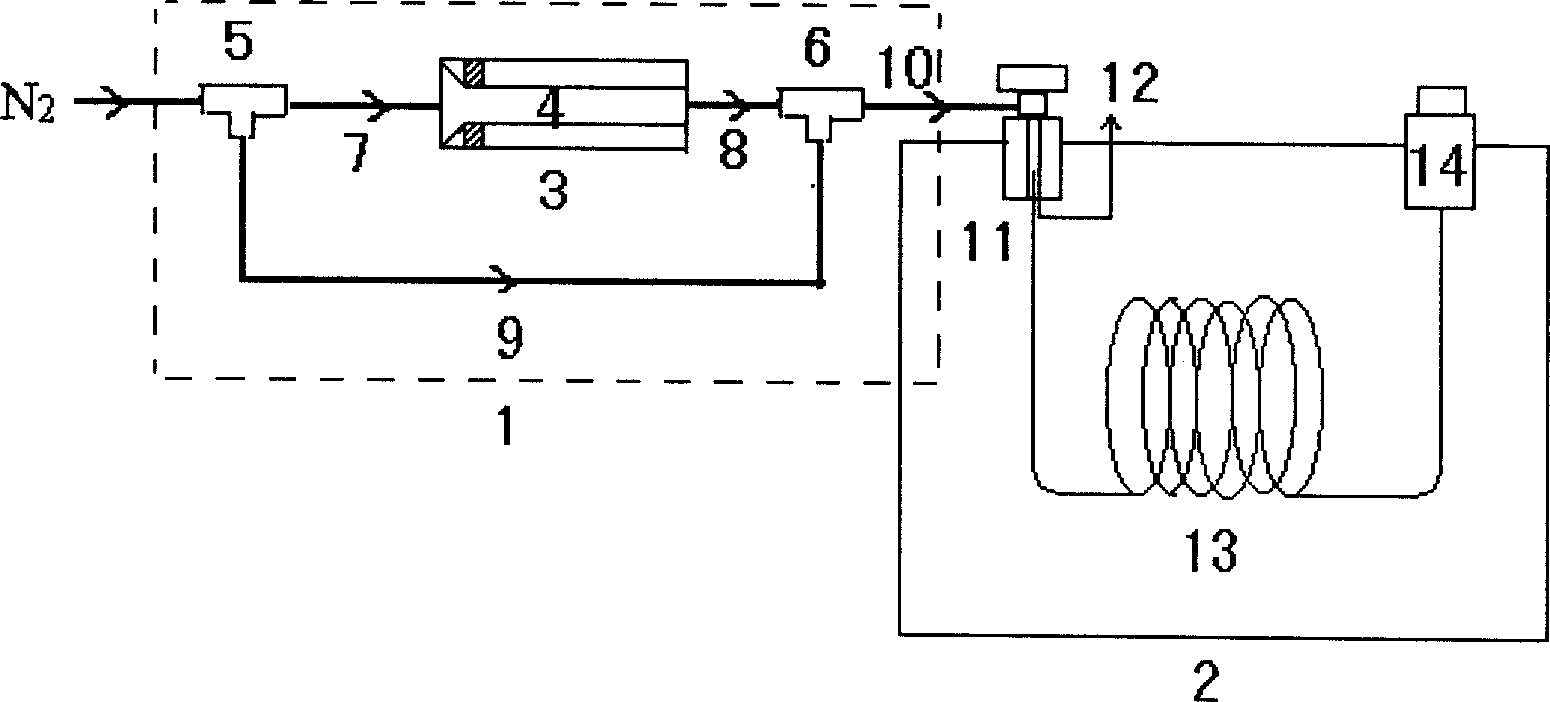

[0040] The online combined use of thermal desorption instrument and chromatograph in the method of the present invention is described. figure 1 It is a schematic diagram of the on-line combination of the primary thermal desorption instrument and the gas chromatograph in the method of the present invention.

[0041]In the experiment, a gas chromatograph equipped with a split capillary inlet and an FID detector was used for analysis, and a methylpolysiloxane elastic quartz capillary column with a specification of 50 meters × 0.32 mm inner diameter × 1.0 micron (film thickness) was selected. Temperature operating conditions: 50°C (hold for 10 minutes), temperature rises to 250°C at a rate of 5°C / min, other operating conditions are: vaporization chamber temperature: 250°C; detector (FID) temperature: 260°C, FID hydrogen flow: 38 ml / min, FID air flow: 320 ml / min, FID makeup gas (N 2 ) flow: 28 ml / min, pre-column pressure: 0.1 MPa, split ratio: 1:15, sample volume: 1 microliter for...

Embodiment 3

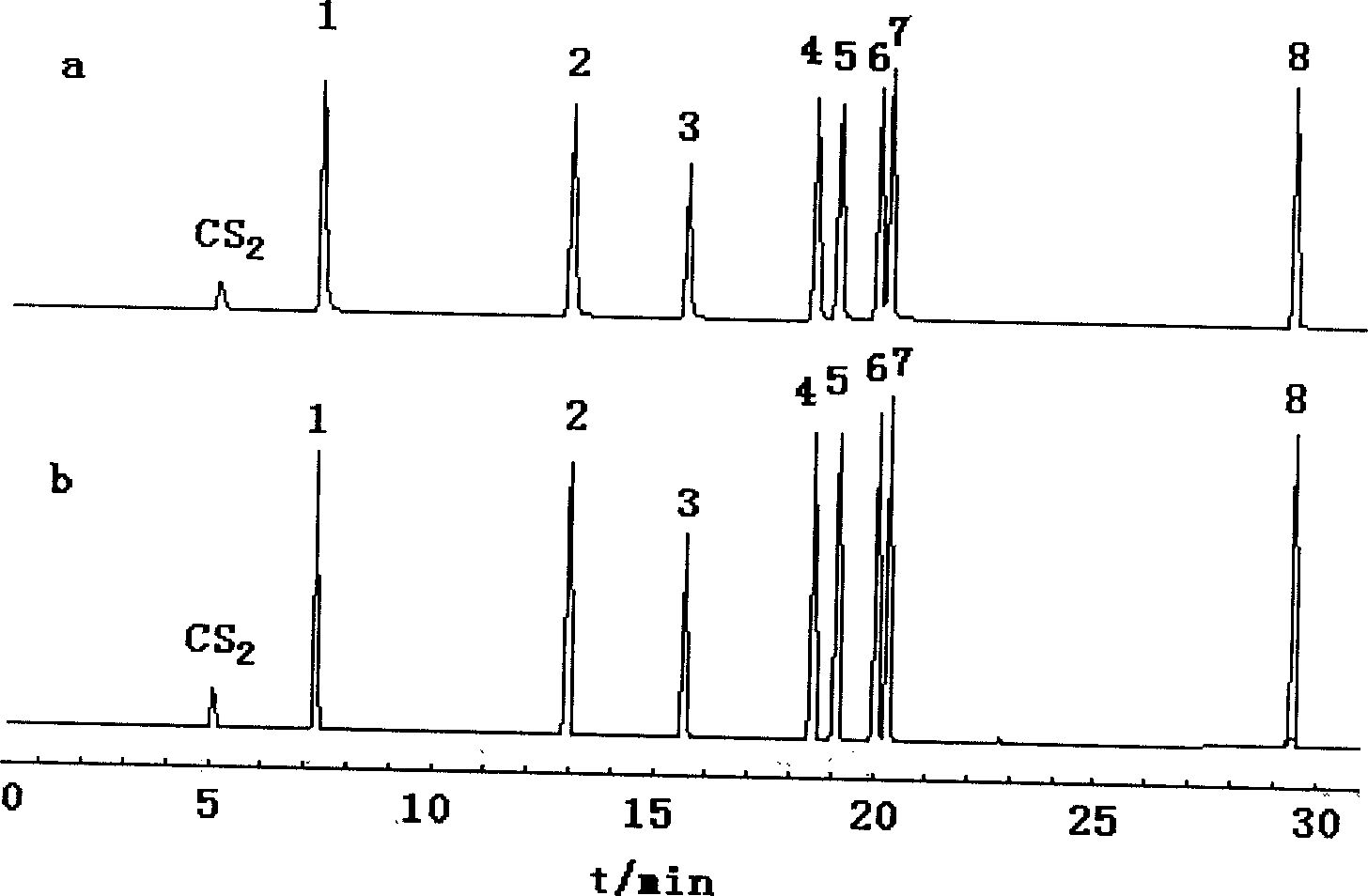

[0045] The online performance of the first-stage thermal desorption instrument and gas chromatograph is described.

[0046] Benzene, toluene, n-butyl acetate, ethylbenzene, p-xylene, styrene, o-xylene and n-undecane are the most representative compounds in air pollution. Get containing each compound concentration and be 0.1 mg / ml, solvent is 1 microliter of the mixed standard solution of carbon disulfide, analyze by the conditions described in example 2 respectively with thermal desorption sample injection and direct sample injection two modes, obtain two chromatograms . Contrast attached image 3 From the two spectral lines in a and b, it can be seen that the first-stage desorption sampling can make the capillary chromatographic column maintain a high separation (resolution) ability for the peaks, without causing the peaks to broaden, and achieve the effect of a secondary structure with a cold trap , the peak shape is consistent with direct injection. Peaks 1 to 8 are in o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com