High specific energy battery pack internal flame-retardant cooling method

A technology of high specific energy batteries and battery packs, which is applied to battery components, isolation of batteries from their environment, circuits, etc., can solve problems such as impact on battery performance, inability to actively control combustion and explosion, large temperature difference between inside and outside, etc., to achieve high Safety and reliability, elimination of fire hazards, avoidance of installation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with embodiment and accompanying drawing, the present invention is described in further detail, enumerating specific embodiment is the preferred embodiment of the present invention, can not limit the claims of the present invention, the present invention still has multiple other specific implementation modes, All technical solutions formed by equivalent replacement or equivalent transformation fall within the protection scope of the present invention.

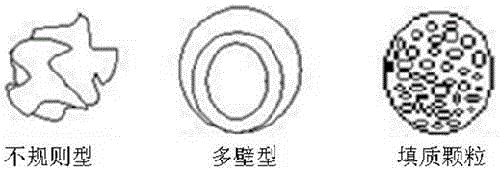

[0014] refer to figure 1 , a method for flame retardant and fire extinguishing inside the battery pack. The method is to microencapsulate the flame retardant and fill it inside the battery pack box. The microcapsule coating of the flammable agent dissolves quickly and releases the flame retardant. By cooling and diluting the inside of the battery pack, the physical way of forming an isolation film and the chemical way of terminating free radicals can eliminate and reduce fire hazards and flame retard...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com