Patents

Literature

30results about How to "Reduce bright spots" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

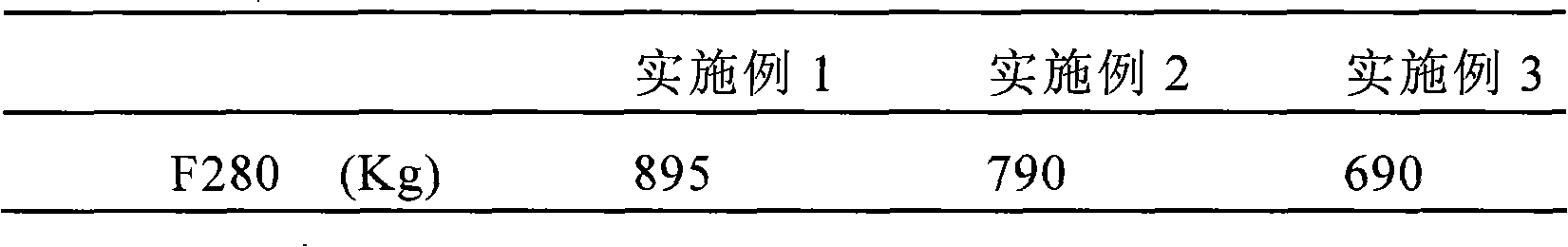

Low-light matt film and preparation thereof

The invention relates to a low-light matt film and a method for preparing the same. The low-light matt film comprises the following components in weight percentage: 40 to 90 weight percent of polypropylene resin, 0 to 30 weight percent of antistatic agent, 0.5 to 30 weight percent of antiblocking agent and 1 to 40 weight percent of matt masterbatch; the components are evenly mixed and measured and undergo physical and chemical reactions through a single screw extrusion machine, longitudinal extension, horizontal extension and traction, and the matt film is obtained after bi-directional extension. Compared with the prior art, the matt film has the characteristics of low luster, high strength, less bright points and good handfeel, etc.

Owner:温州市金田塑业有限公司

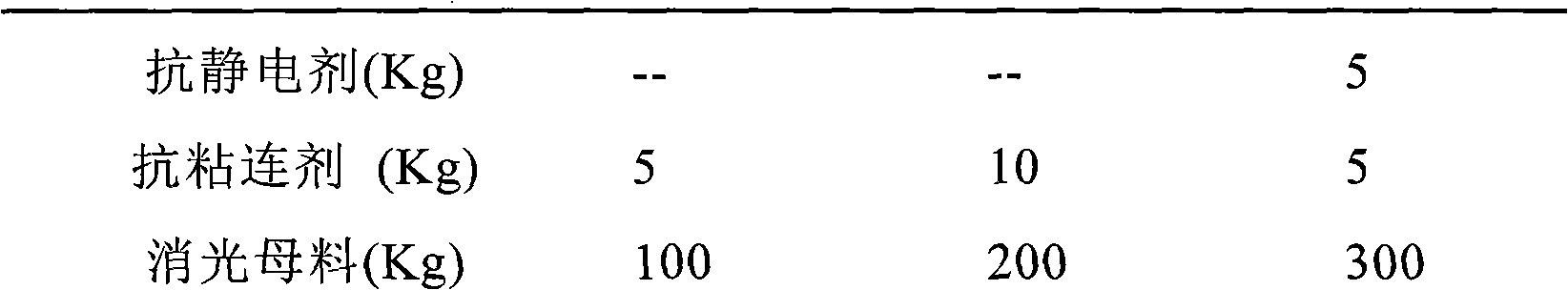

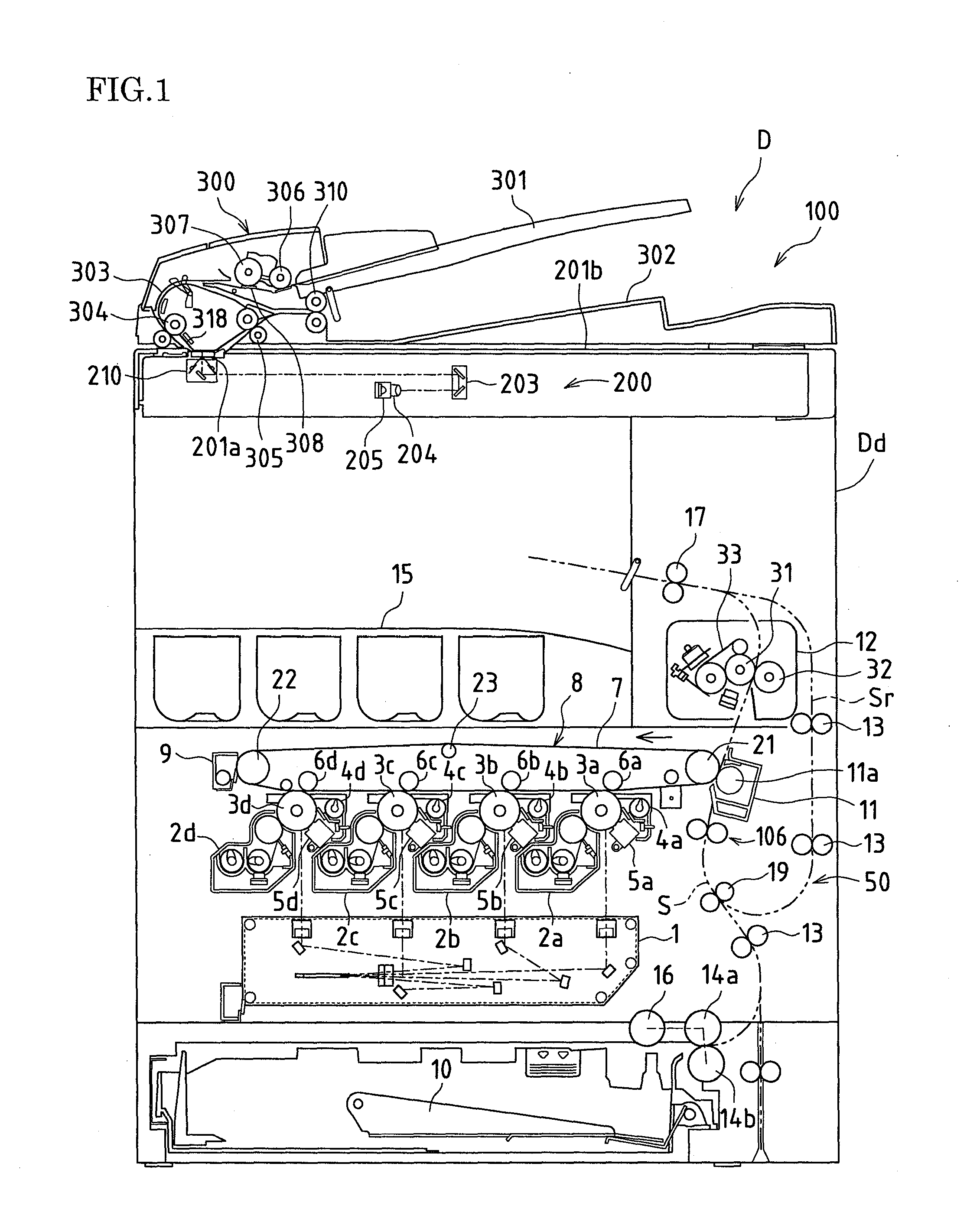

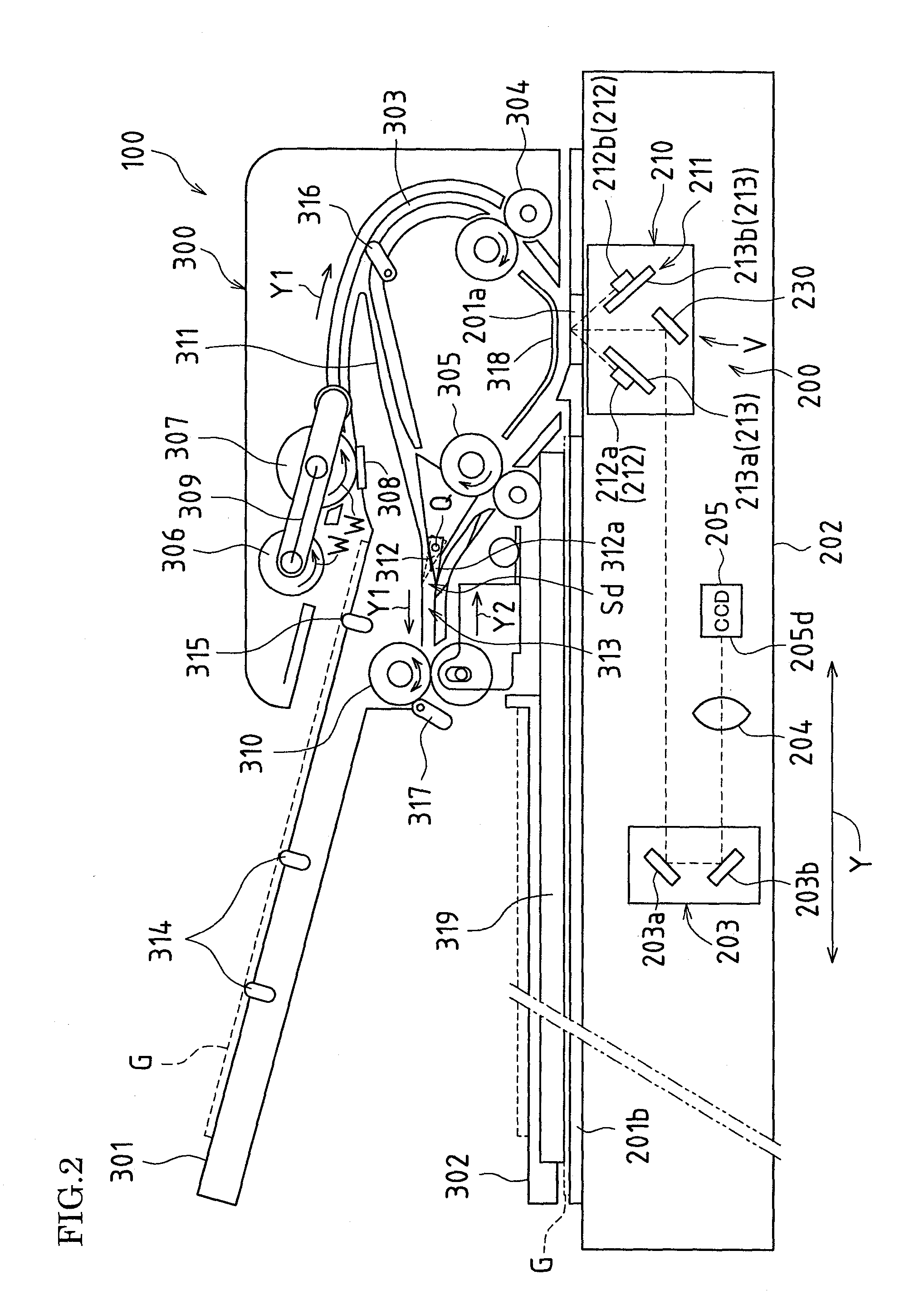

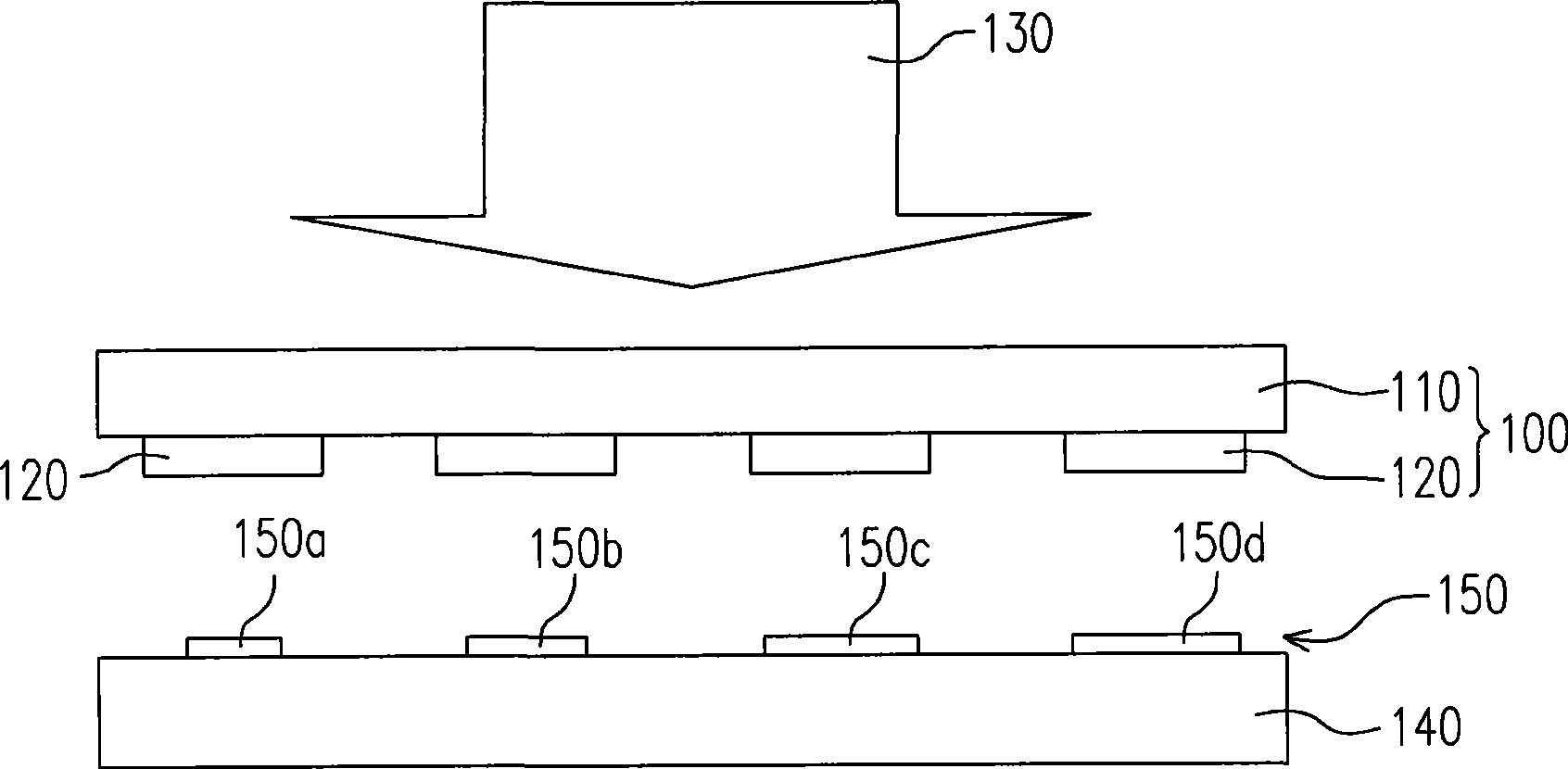

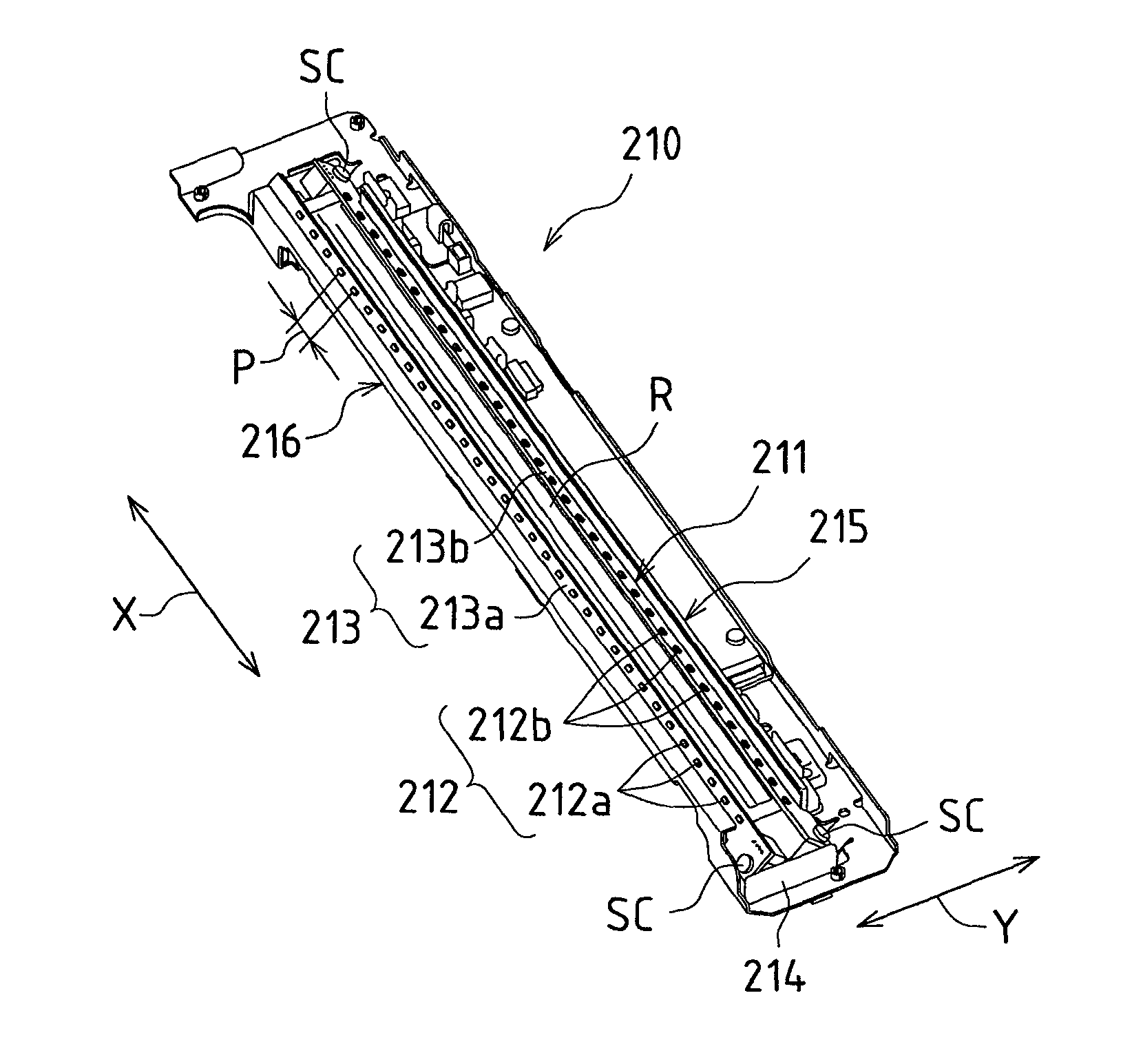

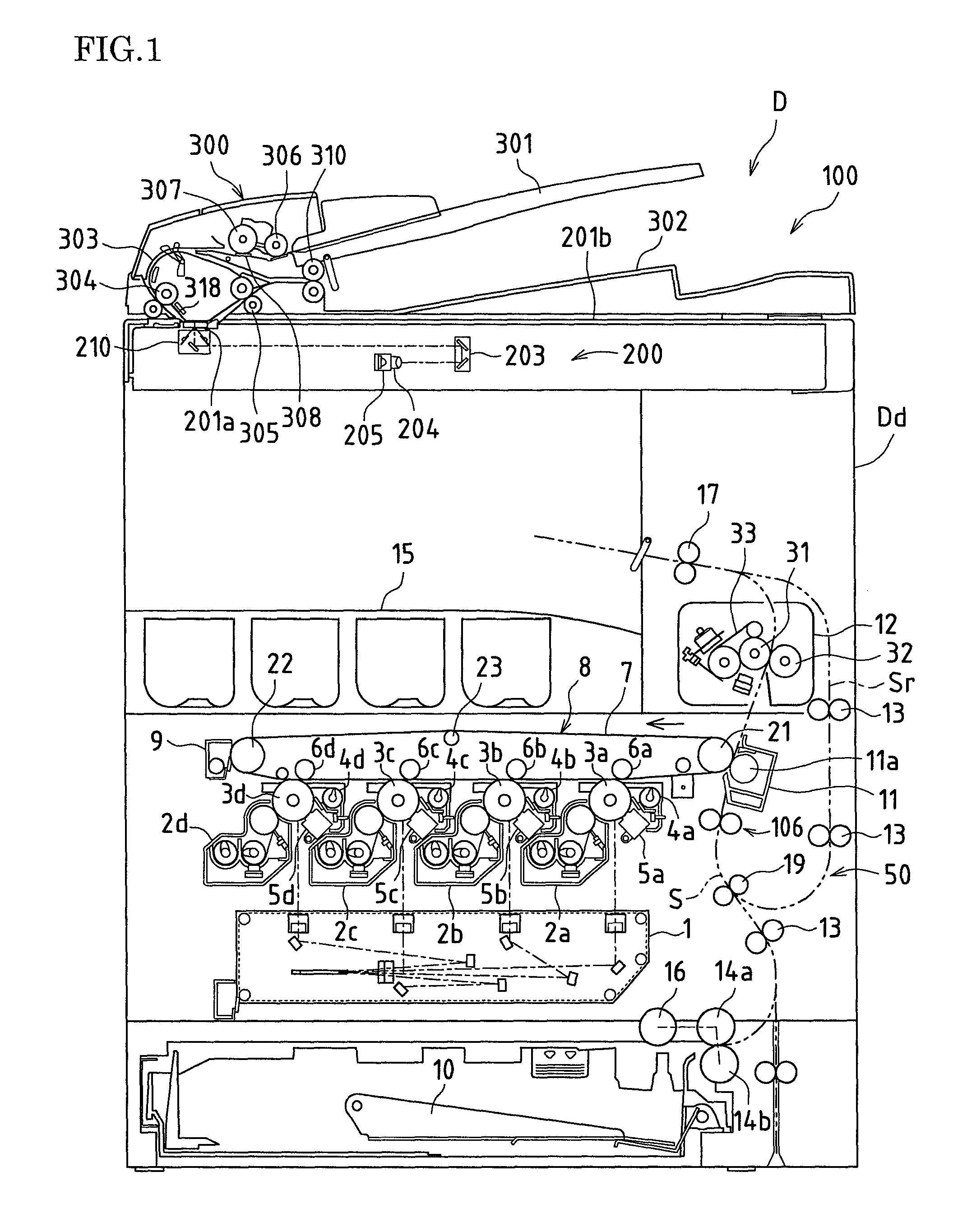

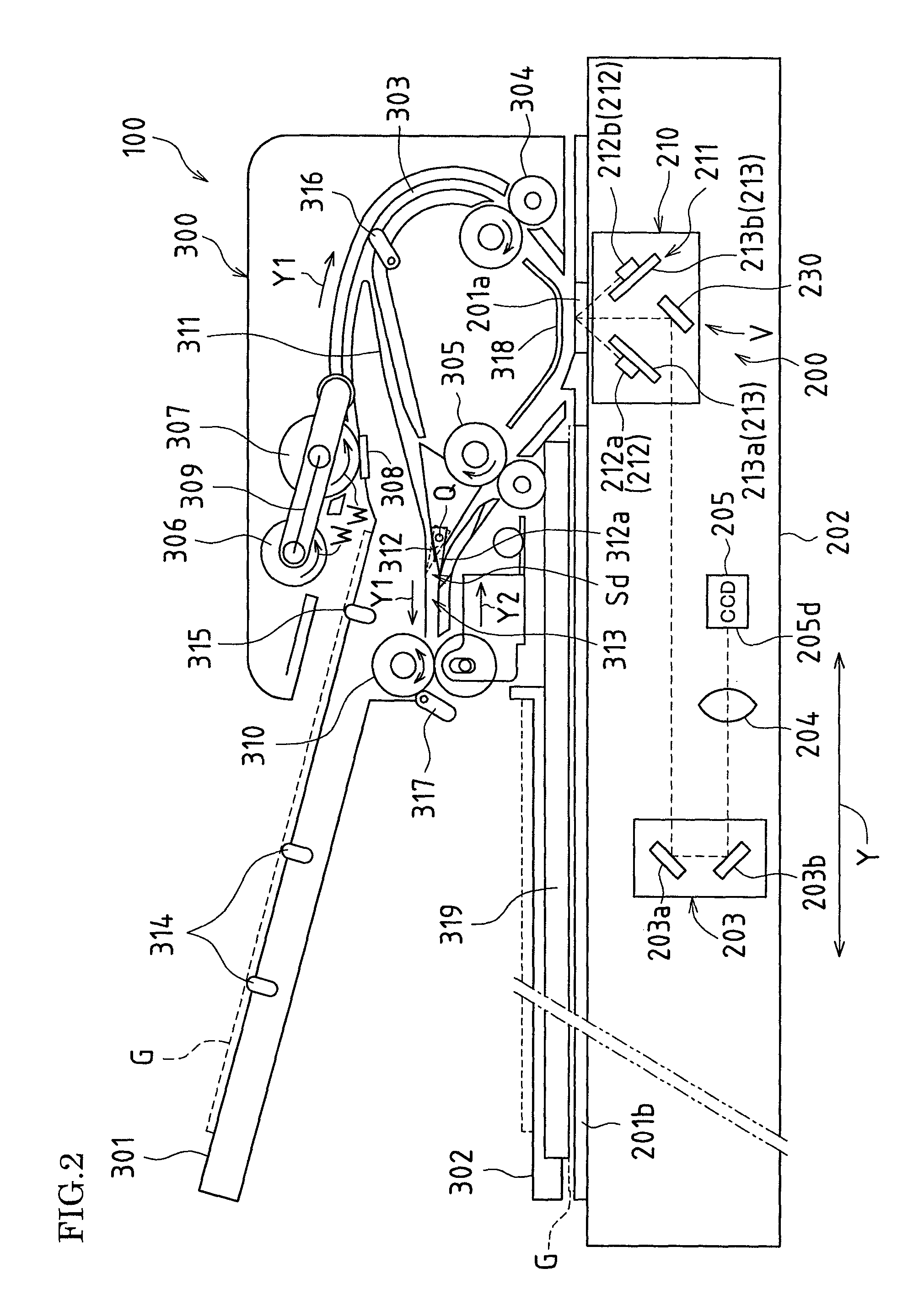

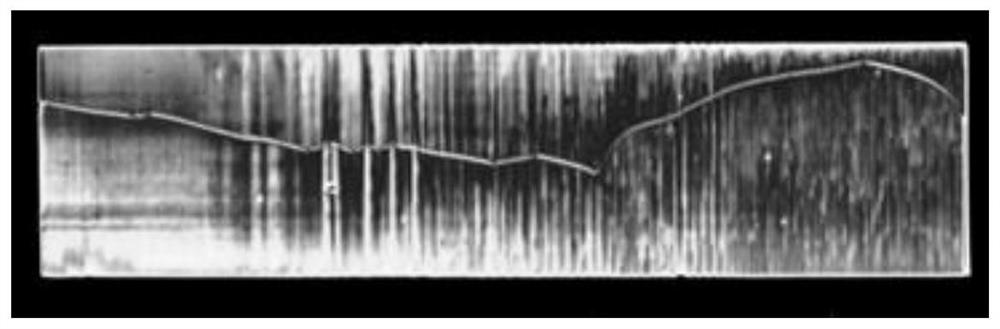

Image reading apparatus and image forming apparatus including the same

ActiveUS20110102863A1Decrease bright spotSuppress uneven illuminanceImage enhancementElectrographic process apparatusLight irradiationImage formation

In one embodiment, an image reading apparatus has a light source configured with a plurality of light-emitting elements disposed in a row in a main scanning direction that irradiate light toward an original, and a photoelectric conversion element that receives light reflected from the original, an output light amount from the light-emitting elements can be adjusted, and a state of bright spots due to repetition of light-dark in the main scanning direction on a light irradiation face of the original due to the plurality of light-emitting elements is determined, and the output light amount from the light-emitting elements is adjusted based on the determination result of the state of the bright spots.

Owner:SHARP KK

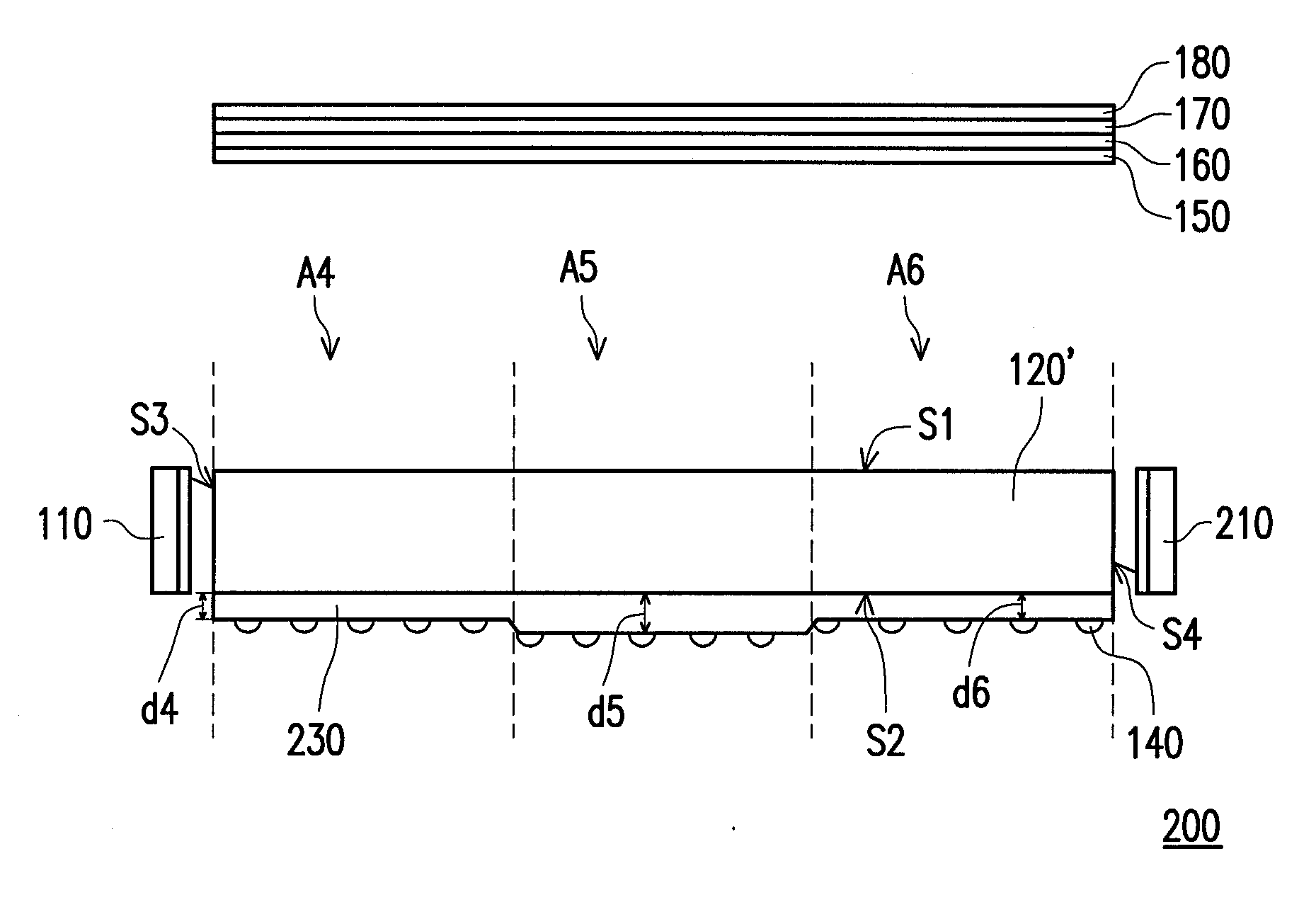

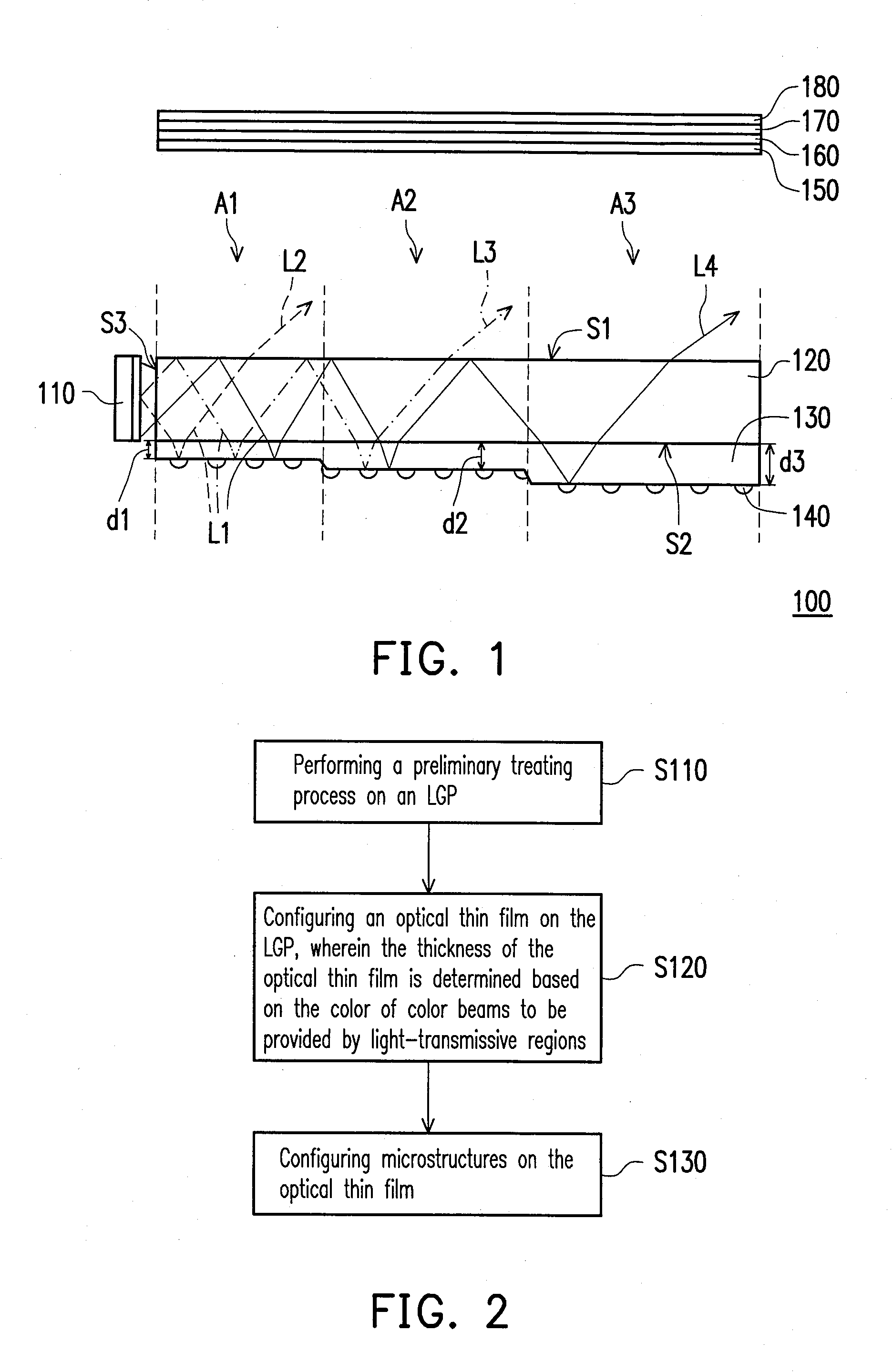

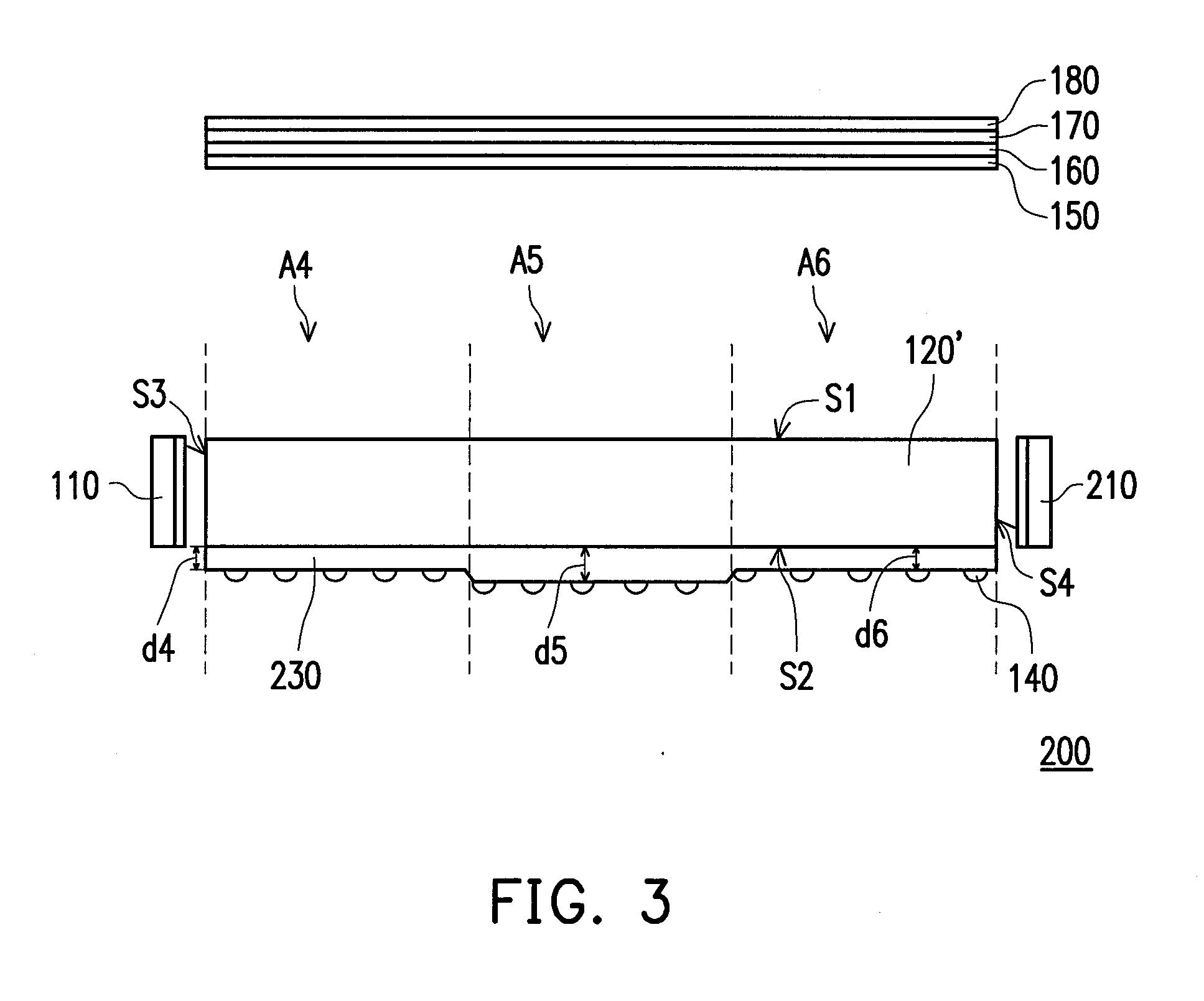

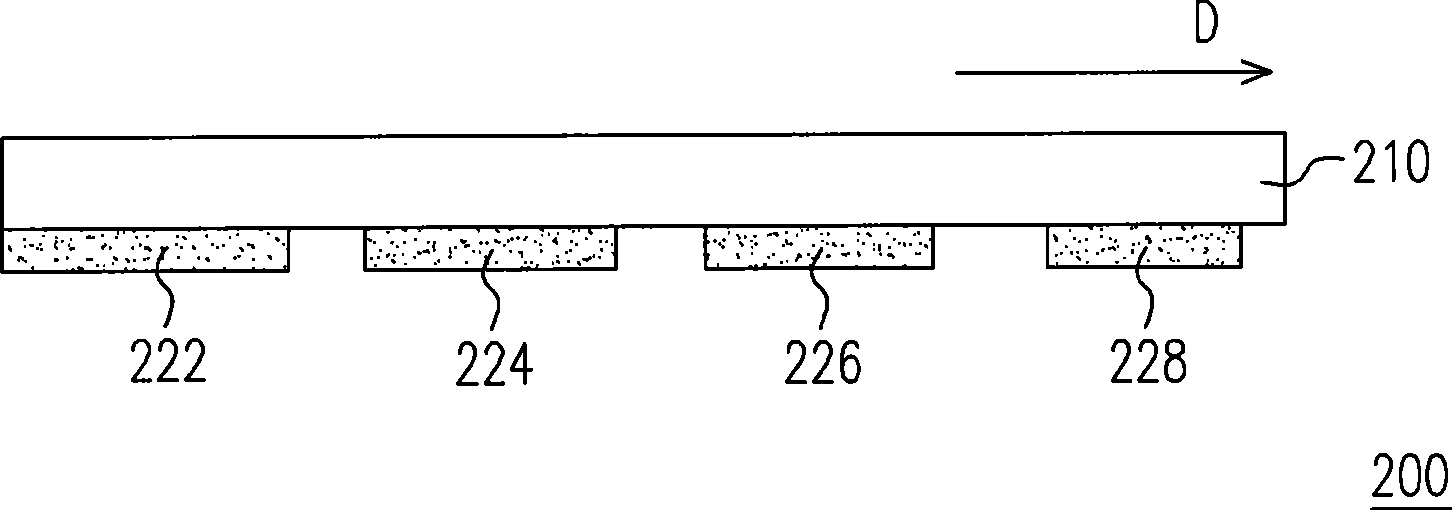

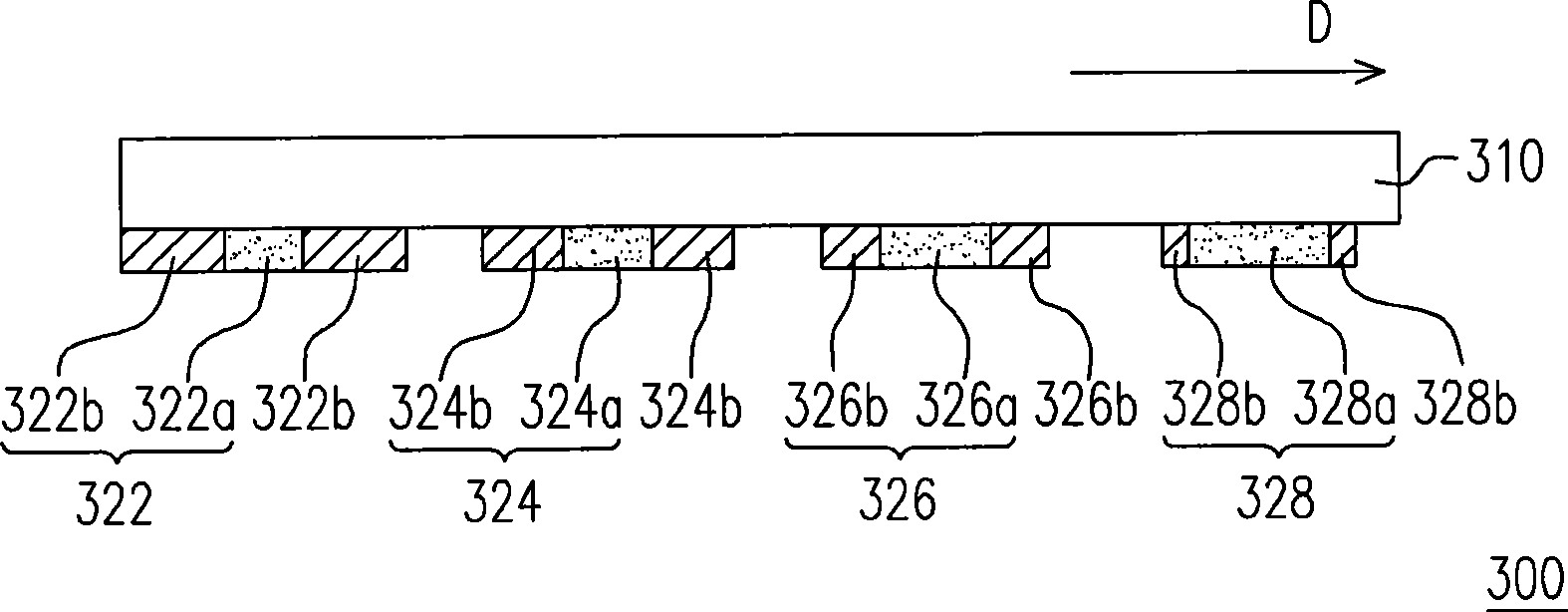

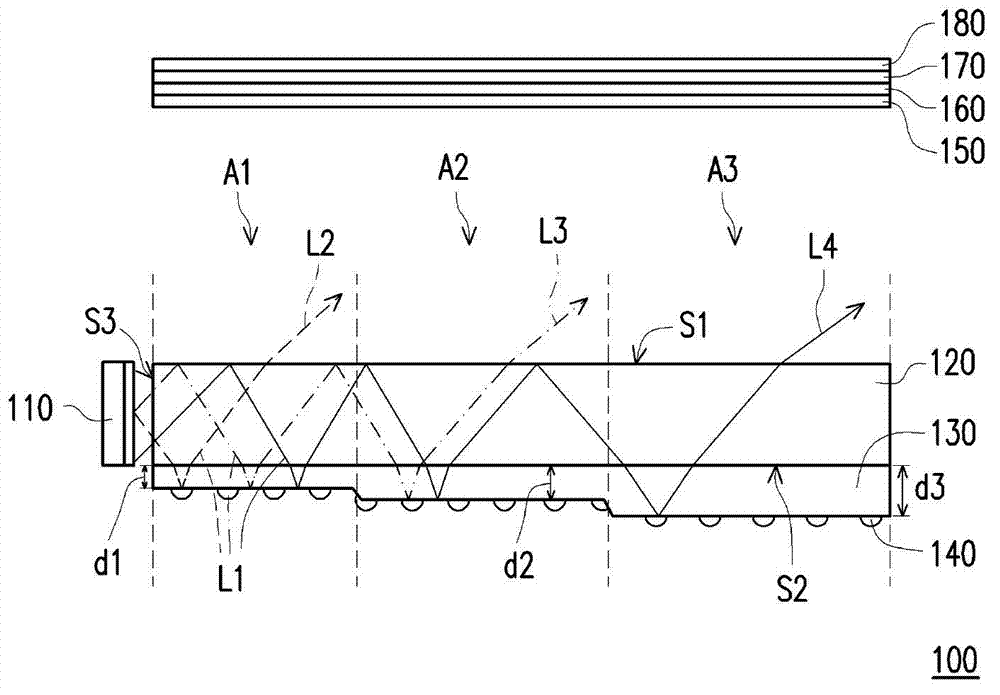

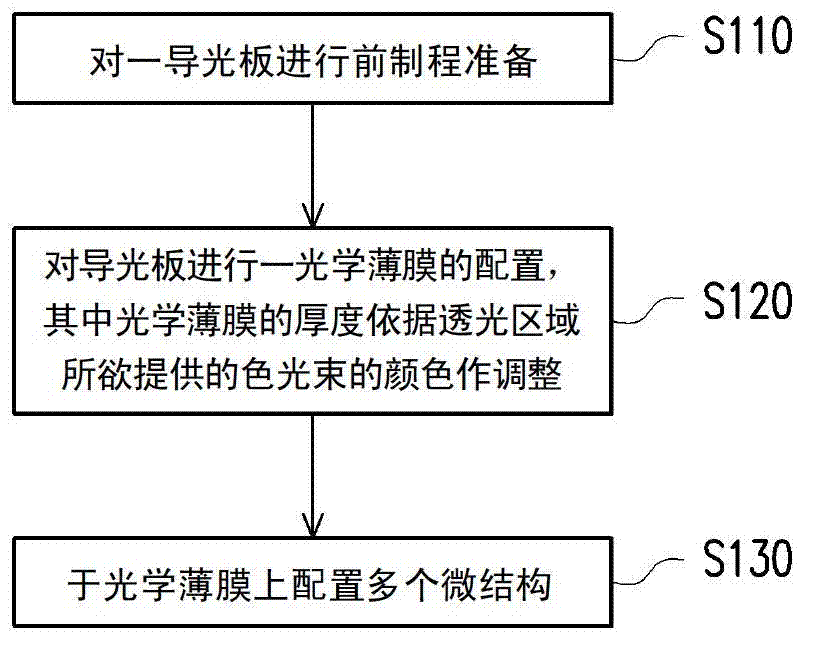

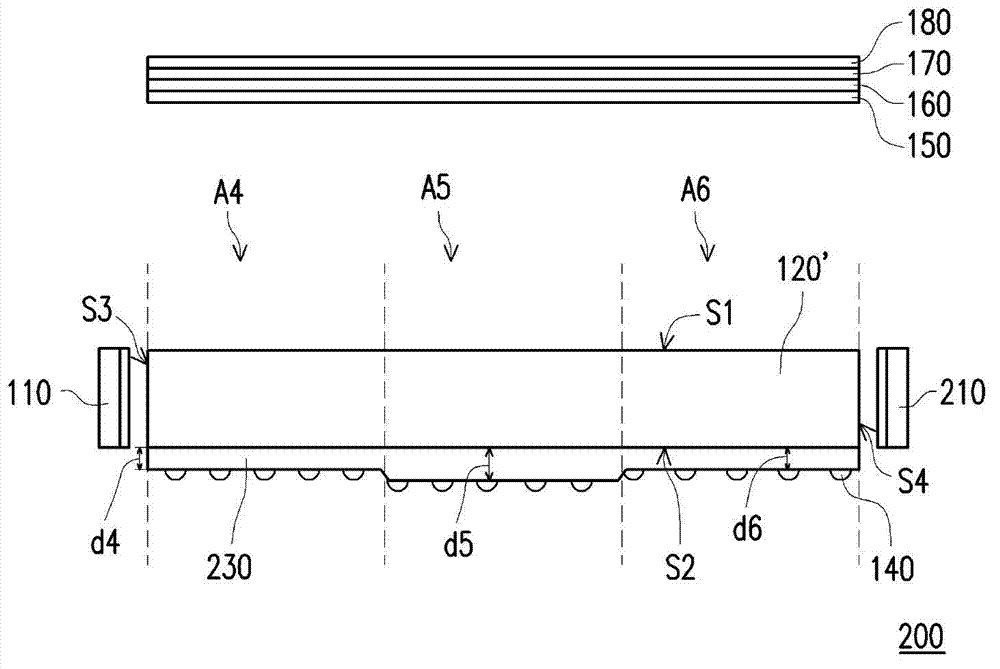

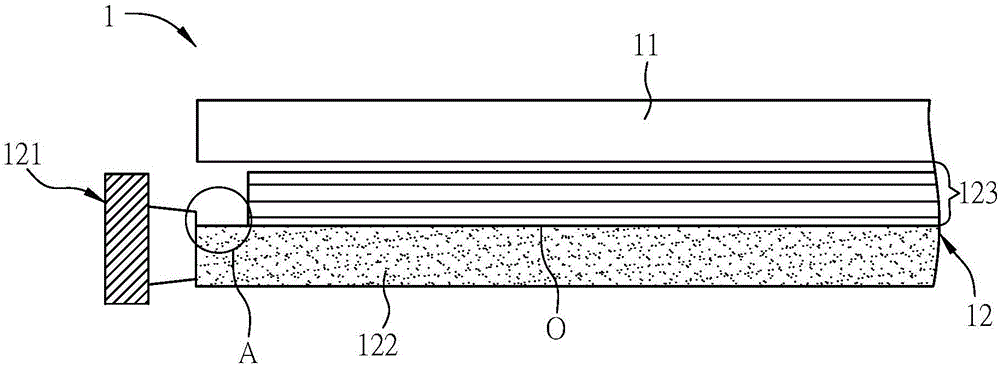

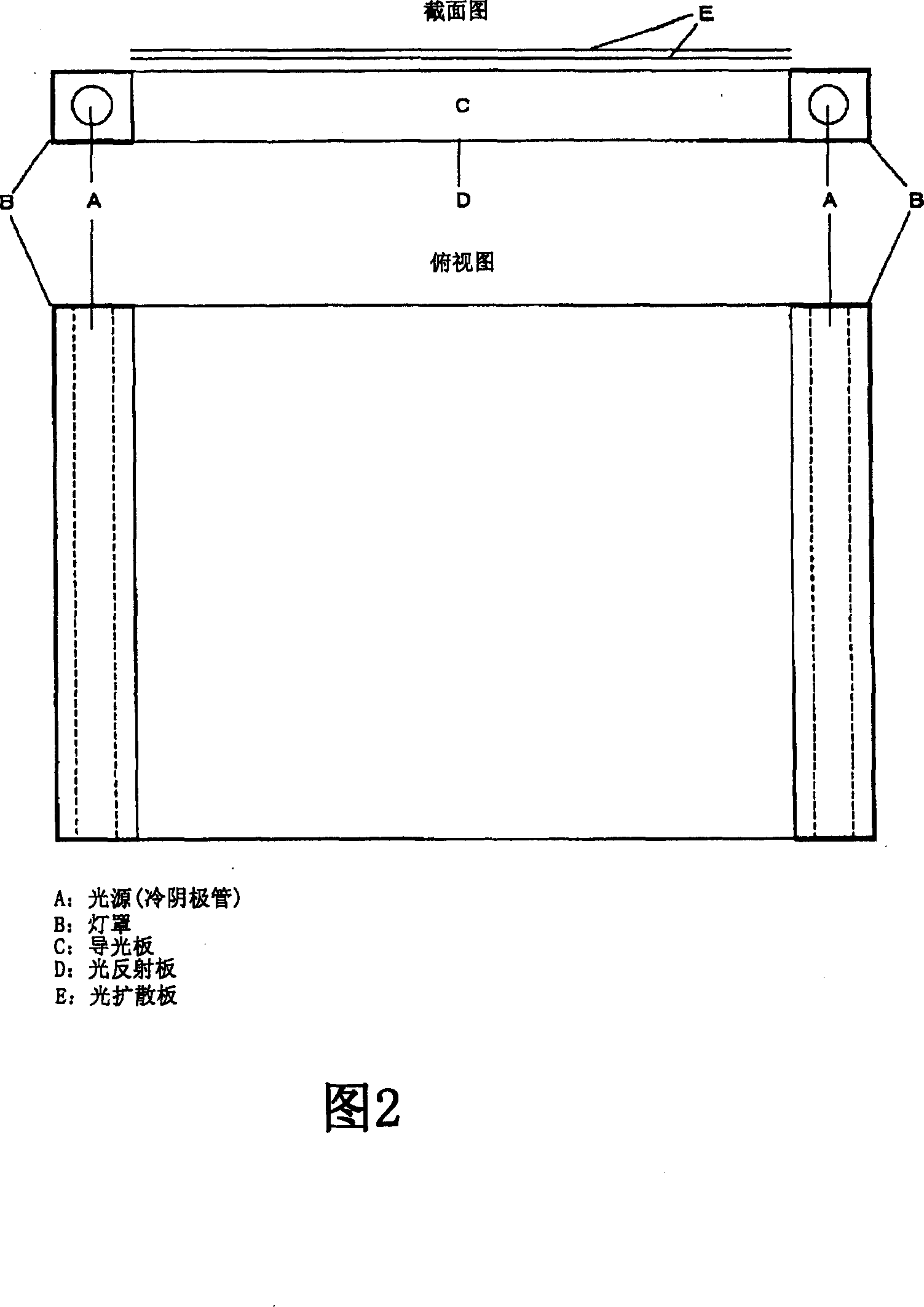

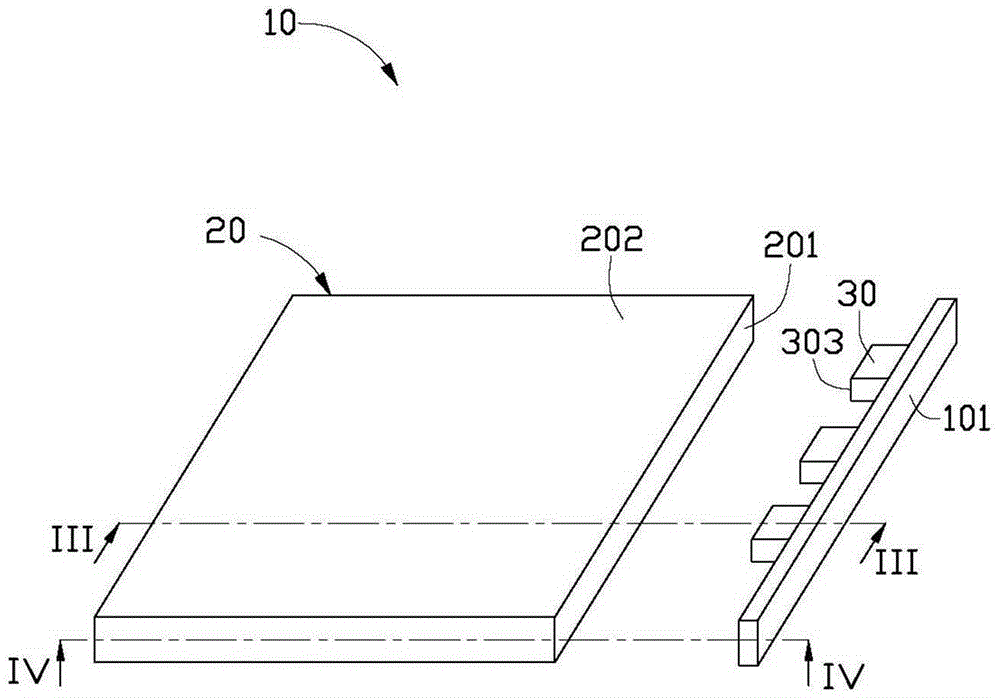

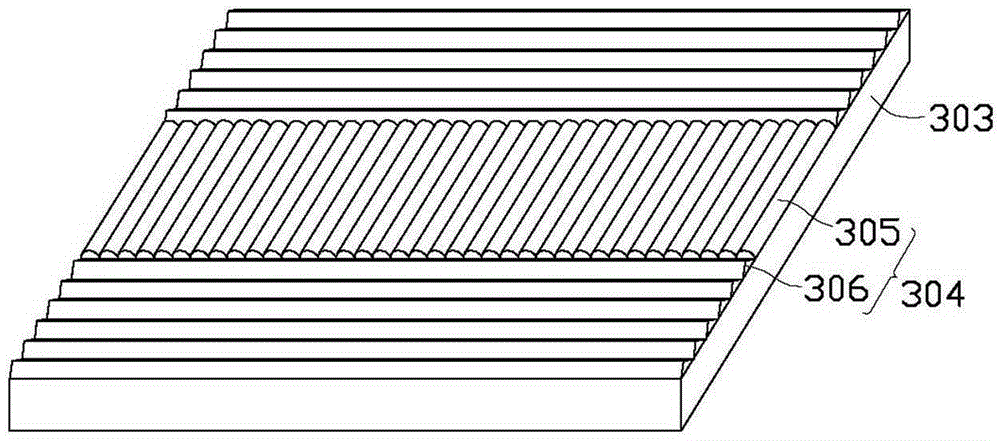

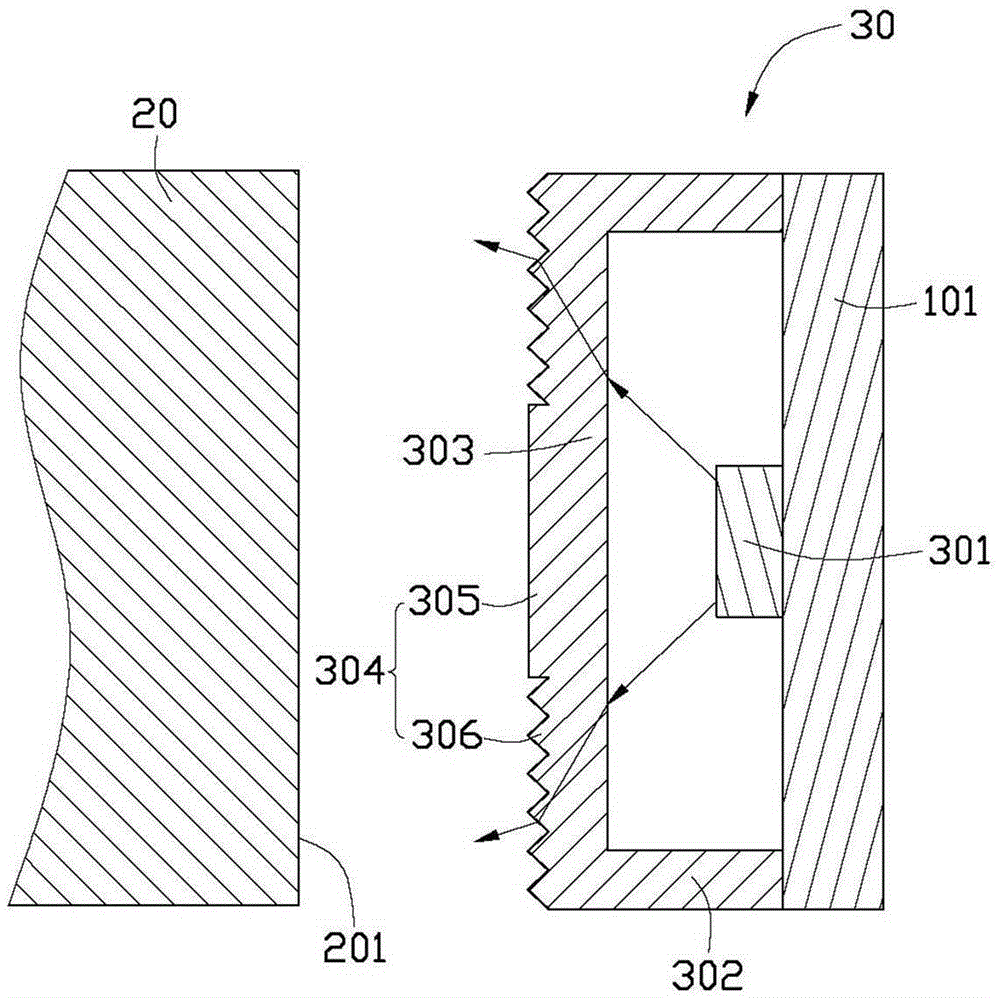

Light source device

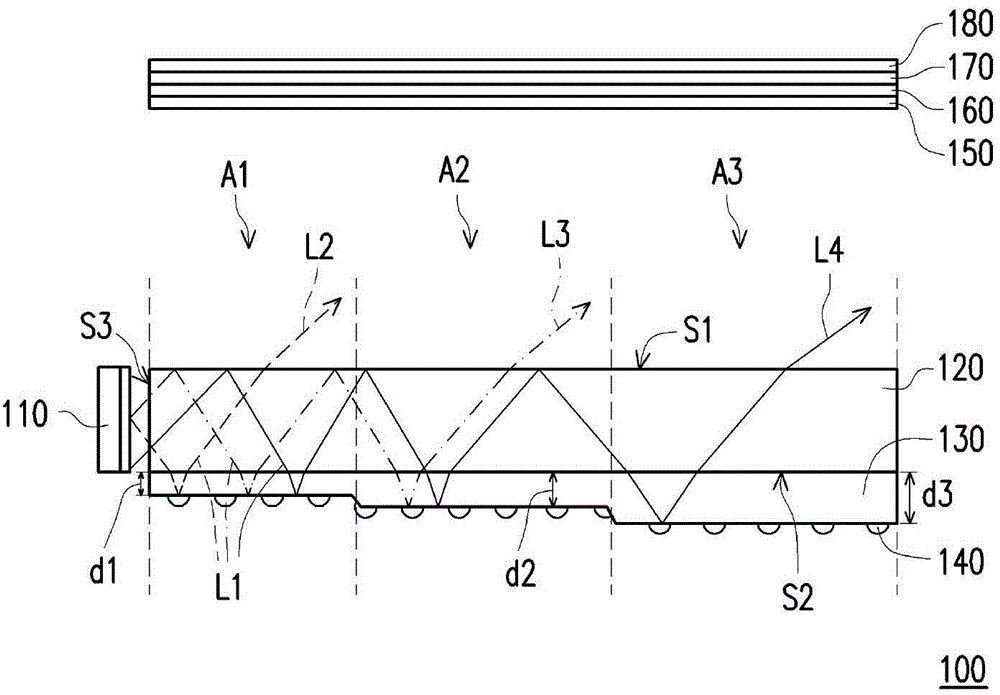

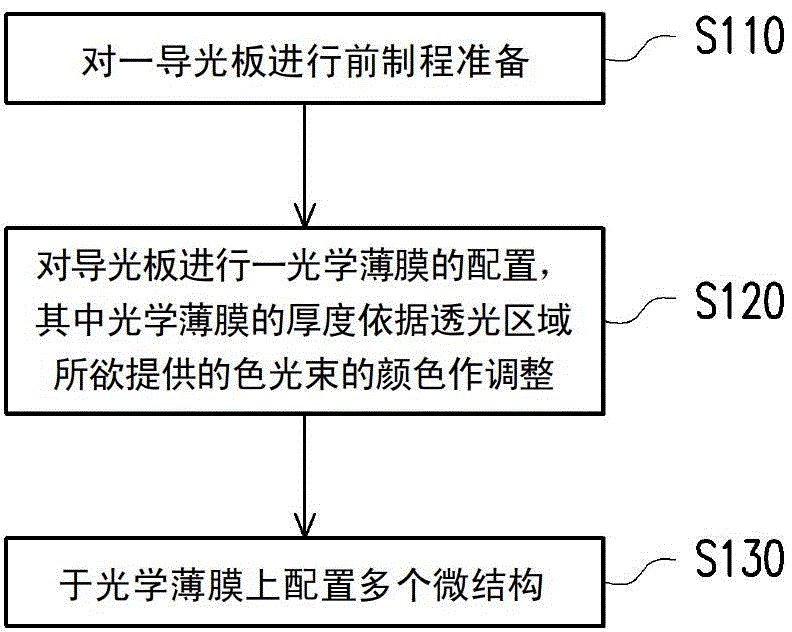

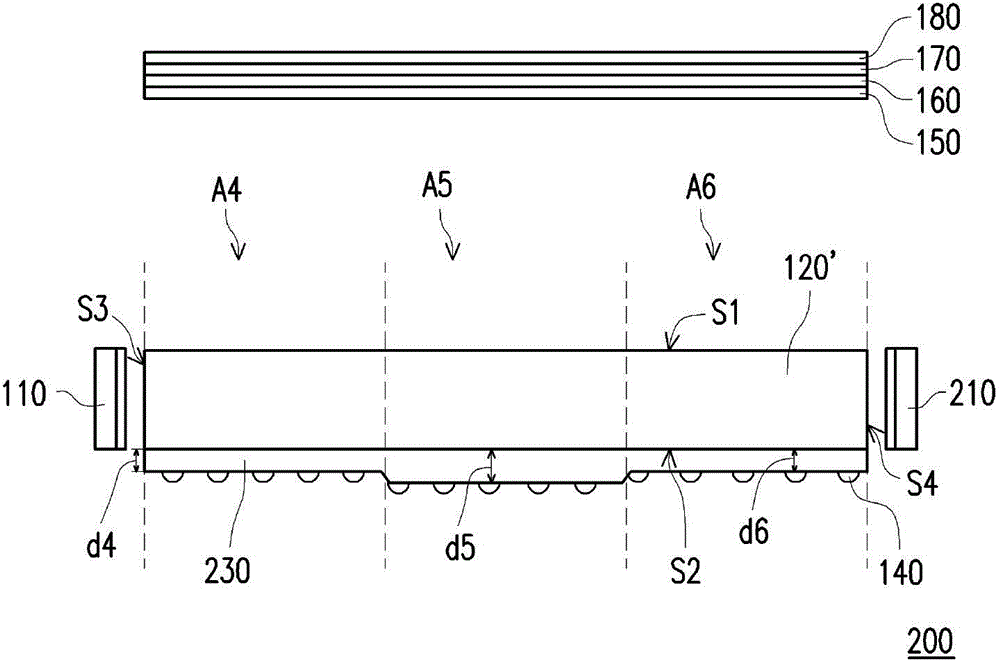

InactiveUS20130051072A1Great thicknessShort wavelengthMechanical apparatusPlanar/plate-like light guidesLight guideLight beam

A light source device includes a first light-emitting element providing illumination beams, a light guide plate (LGP) divided into light-transmissive regions, an optical thin film, and microstructures. The LGP has a first surface, a second surface opposite to the first surface, and a first light-incident surface connecting the first and second surfaces. The first light-emitting element is beside the first light-incident surface. The illumination beams are capable of entering the LGP through the first light-incident surface. The optical thin film is on the second surface of the LGP. The optical thin film has different thicknesses corresponding to at least two of the light-transmissive regions. The microstructures are on the optical thin film. When the illumination beams pass through the light-transmissive regions corresponding to the different thicknesses of the optical thin film and leave the LGP through the first surface, the illumination beams are converted into color beams with different wavelengths.

Owner:CORETRONIC

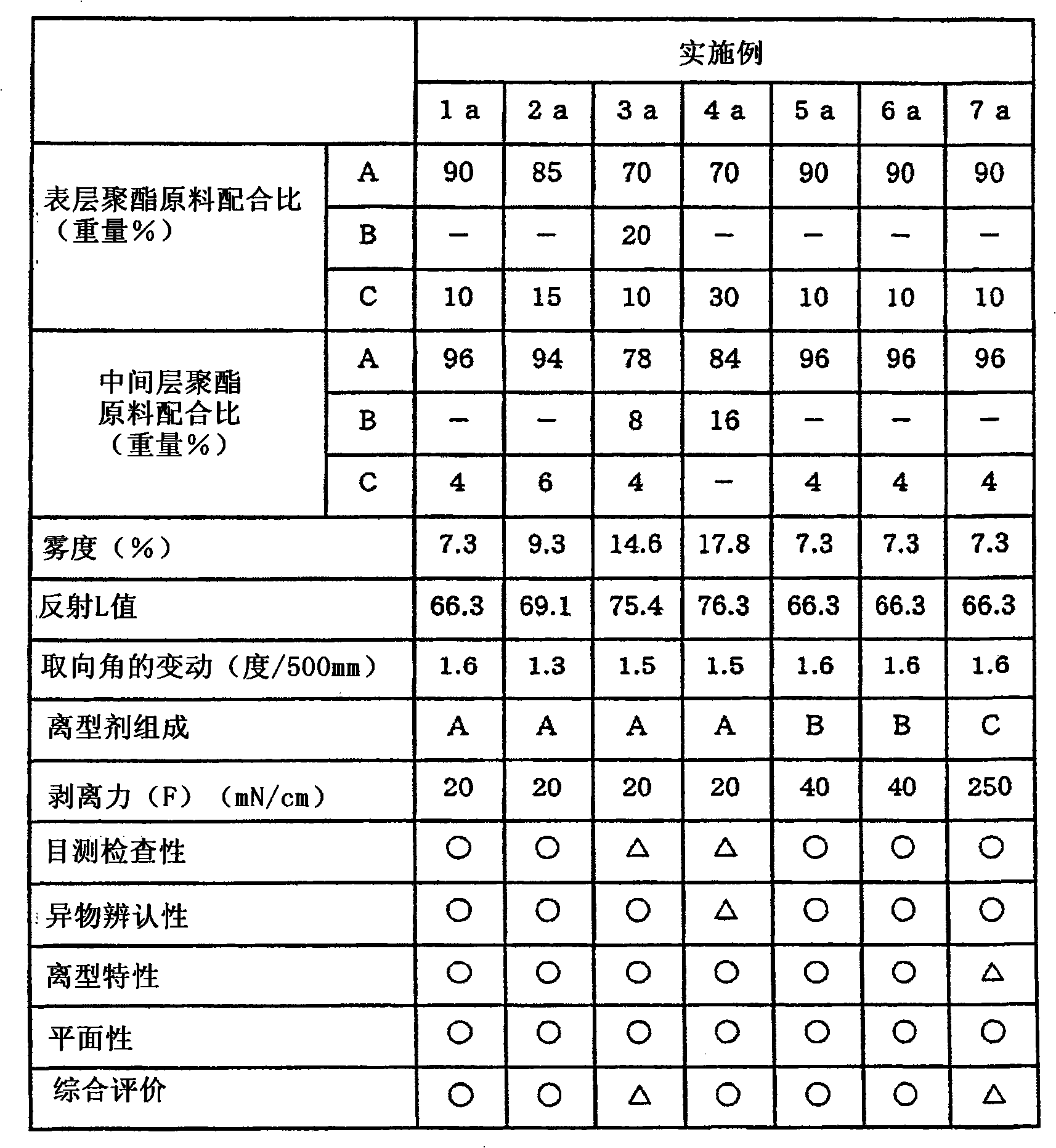

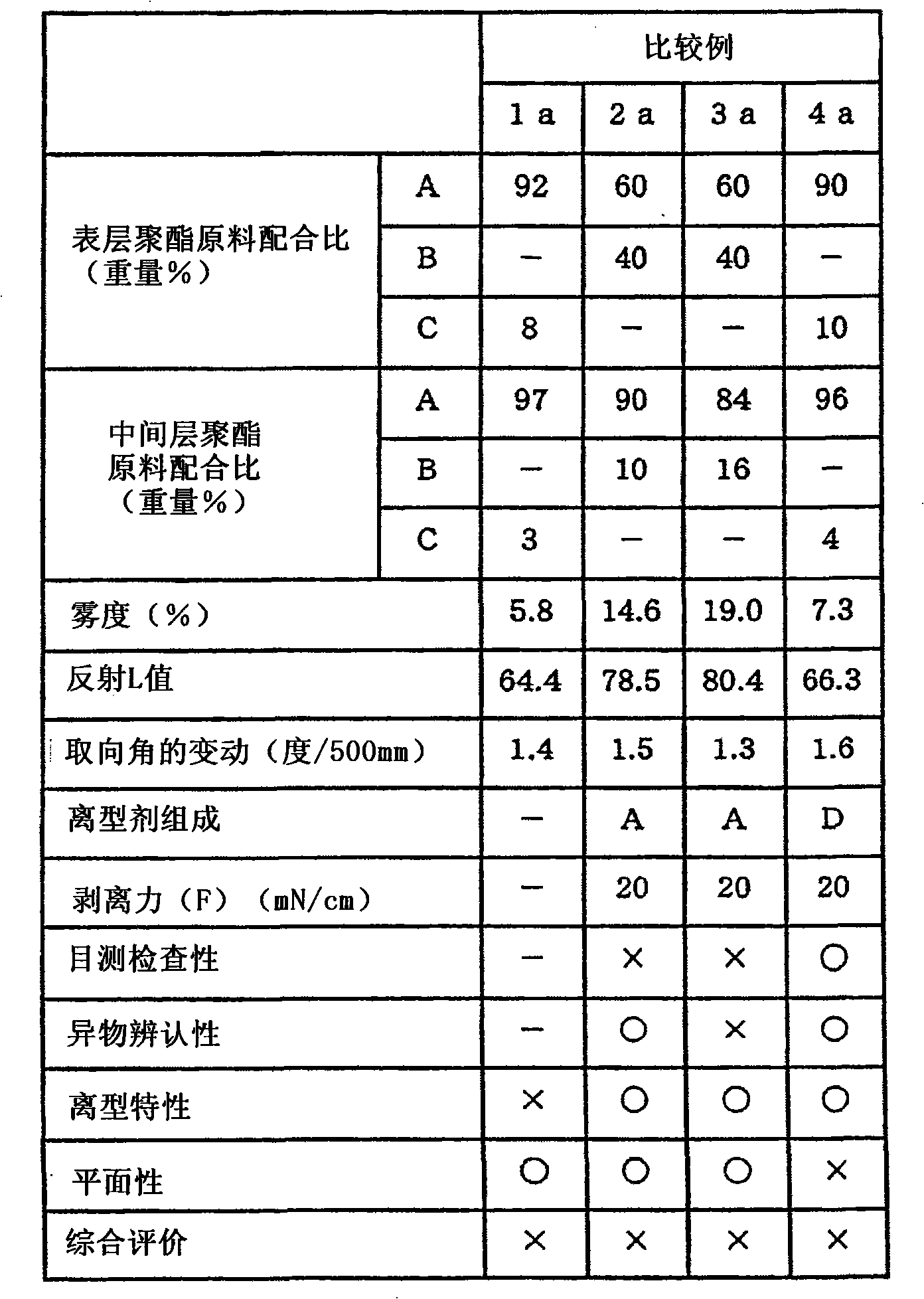

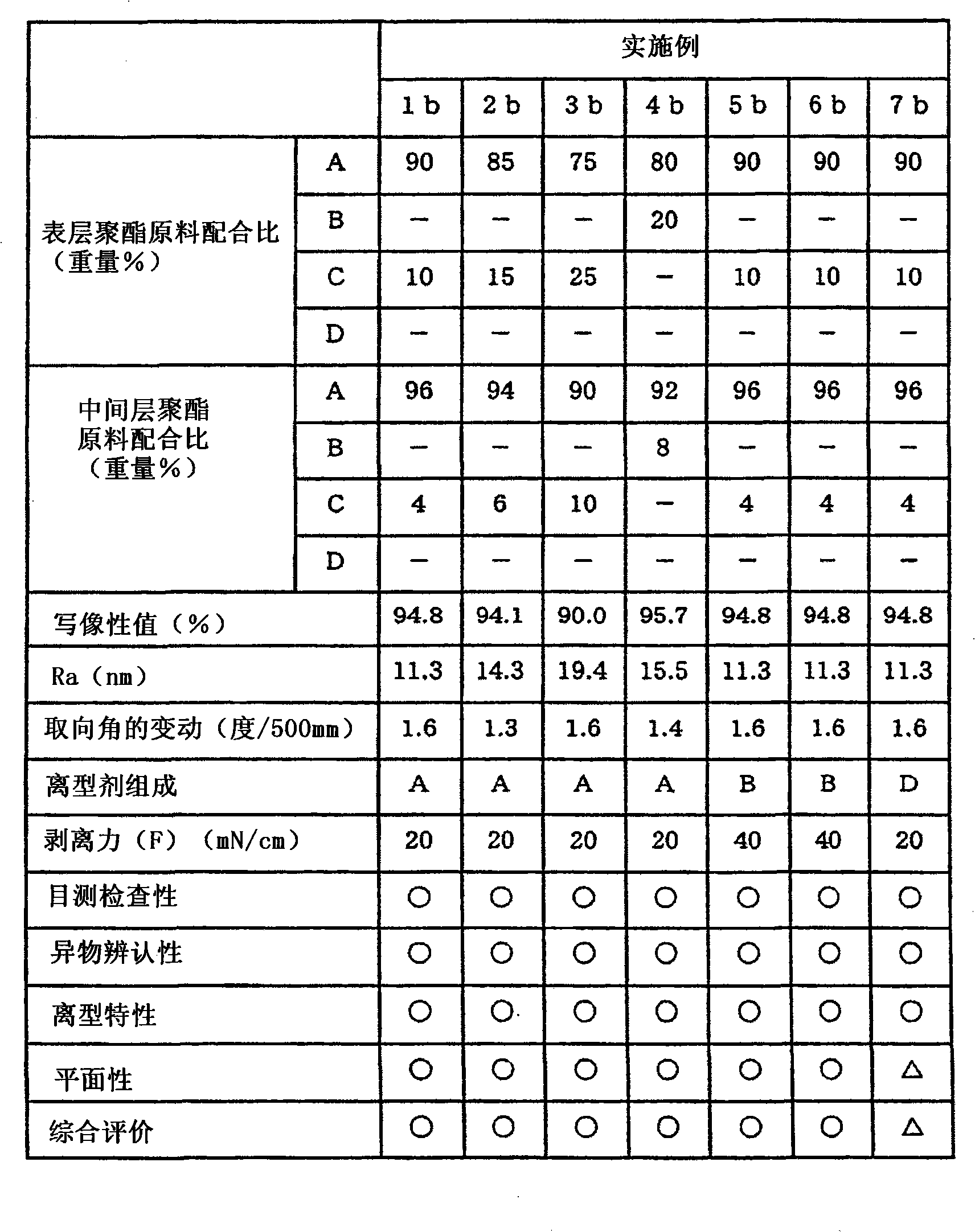

Release film

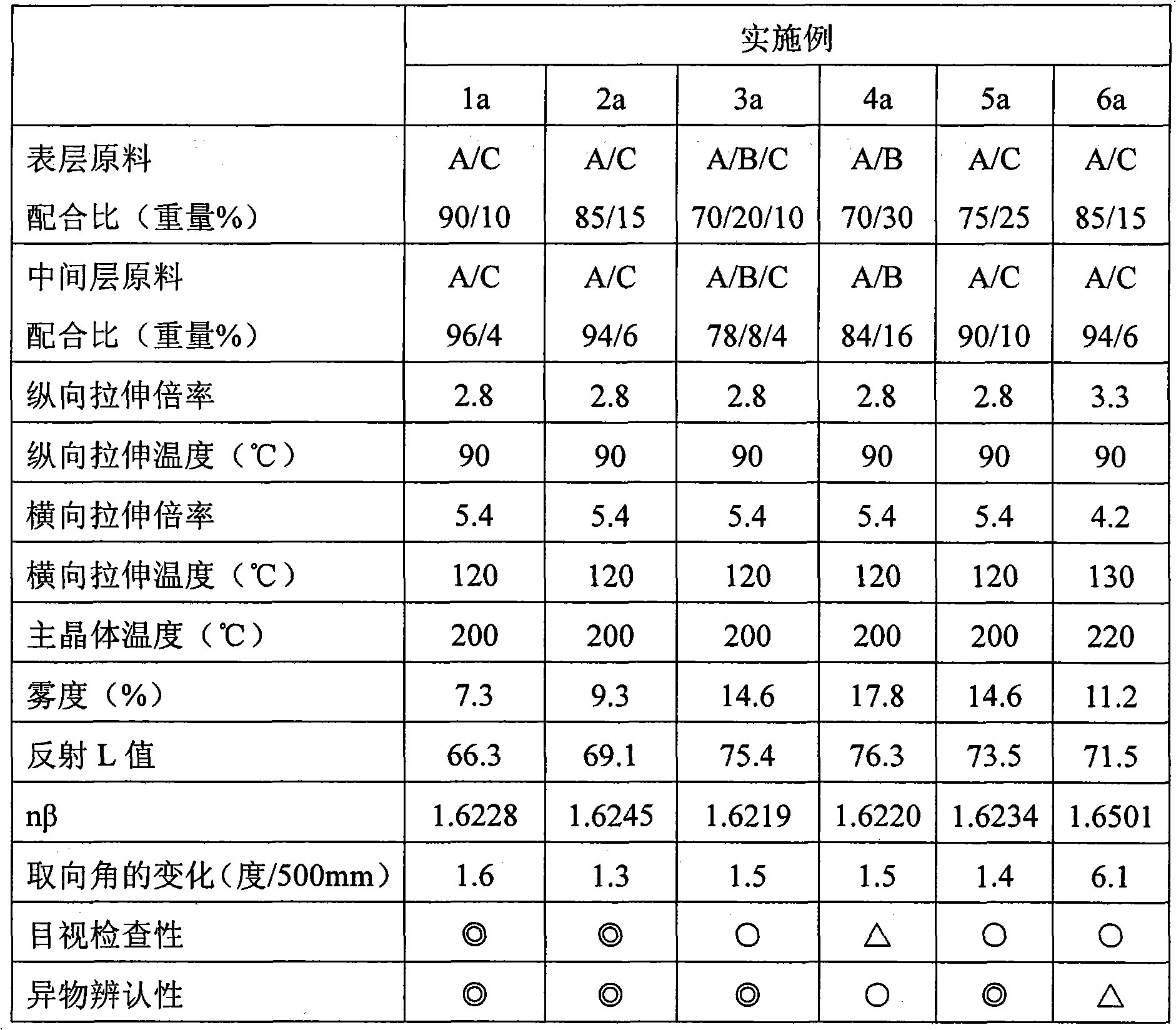

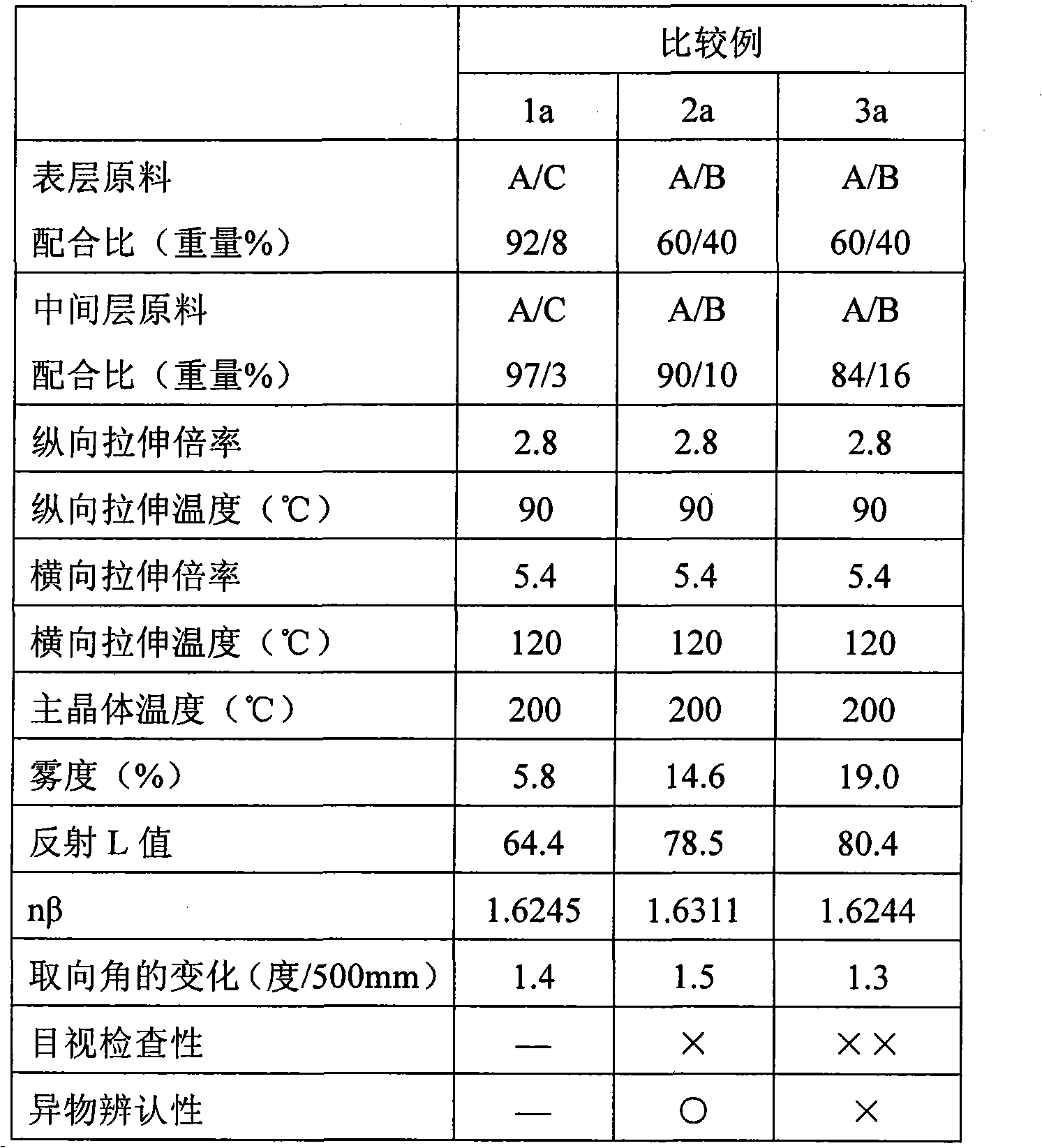

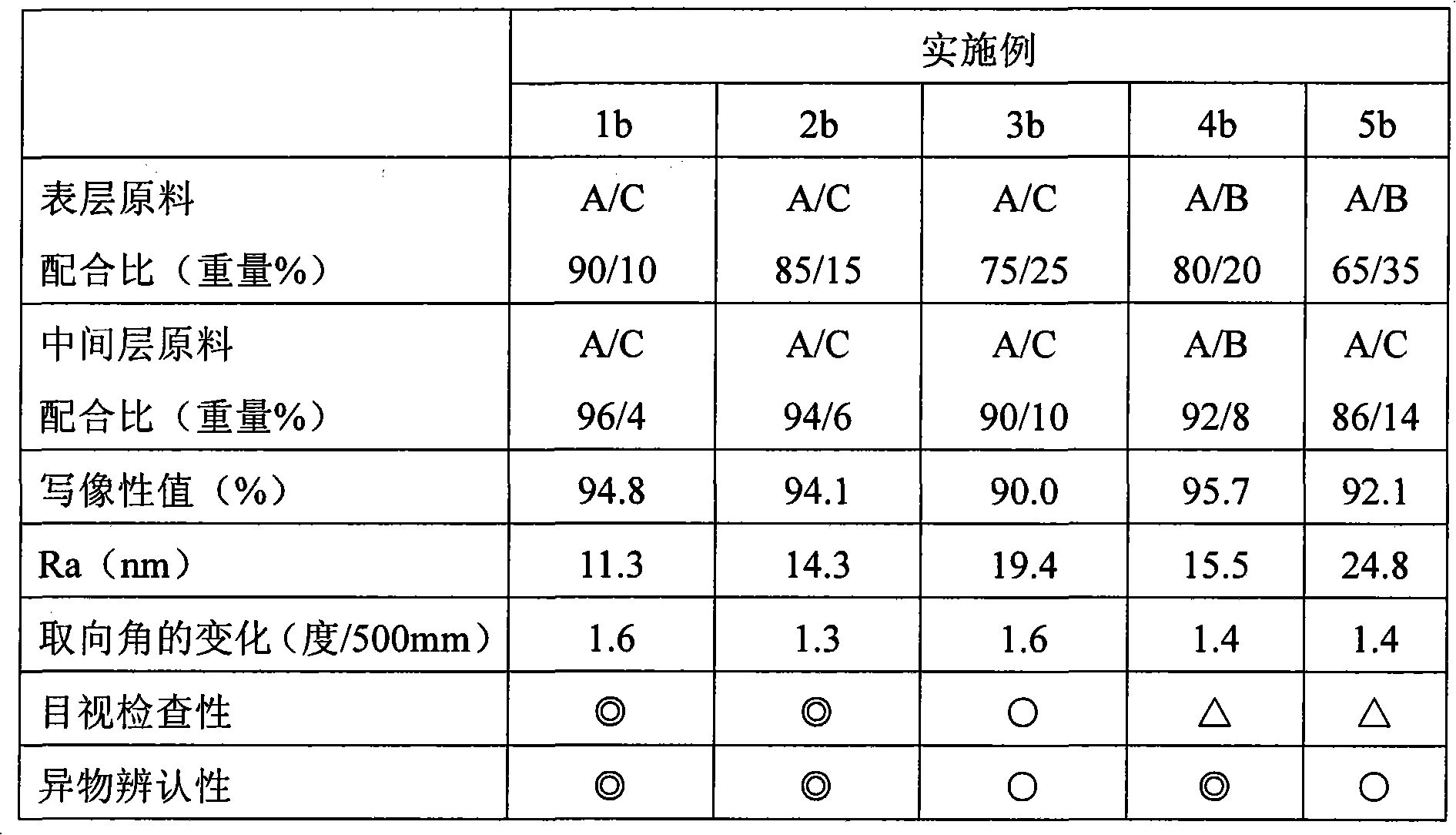

ActiveCN101946196AReduce bright spotsImprove inspection accuracySynthetic resin layered productsPolarising elementsForeign matterPolyester

Disclosed are release films comprising a polyester film that, in inspecting a polarizing plate by a cross Nicol method, can realize a highly accurate inspection without problems that foreign matters or defects cannot be observed without difficulties or are likely to be missed. (i) A release film for a polarizing plate, characterized in that the release film comprises a polyester film provided on one side thereof with a release layer provided by a coat-stretching method and has a film haze of 7 to 18% and an L value of not more than 77 as measured from the release layer surface side by a reflection method. (ii) A release film for a polarizing plate, characterized in that the release film comprises a polyester film provided on one side thereof with a release layer provided by a coat-stretching method and has a film surface roughness (Ra) of 11 to 25 nm and an image clarity value of not less than 90%.

Owner:MITSUBISHI CHEM CORP

Exposure manufacture process, production method of image element structure and semi-modulation type photomask using the same

InactiveCN101369095AUniform sizeSimple processPhotomechanical exposure apparatusMicrolithography exposure apparatusOptoelectronicsMethod of images

The invention discloses a semi-adjustable optical mask, which is applied to the exposal preparing process to form a plurality of photoresistive patterns with even sizes. The semi-adjustable optical mask comprises a transparent baseplate and a plurality of optical mask patterns. The optical mask patterns are arranged on the transparent baseplate along a preset direction, wherein, the size of the optical mask pattern can be gradually changed along the preset direction. Accordingly, though different exposal precision exists in different regions on the large-size baseplate, the photoresistive patterns with even sizes can still be prepared through the gradual compensation way. In addition, the preparing method for utilizing the exposal preparing process and the pixel structure of the semi-adjustable optical mask is also provided.

Owner:CHUNGHWA PICTURE TUBES LTD

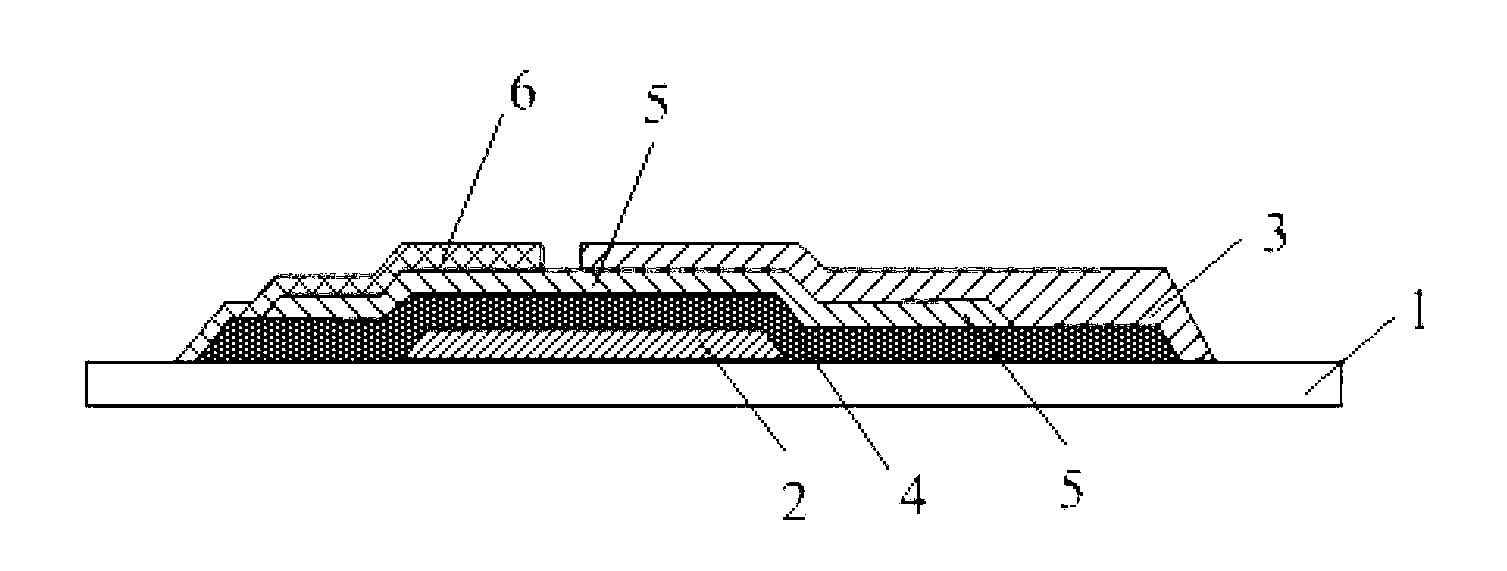

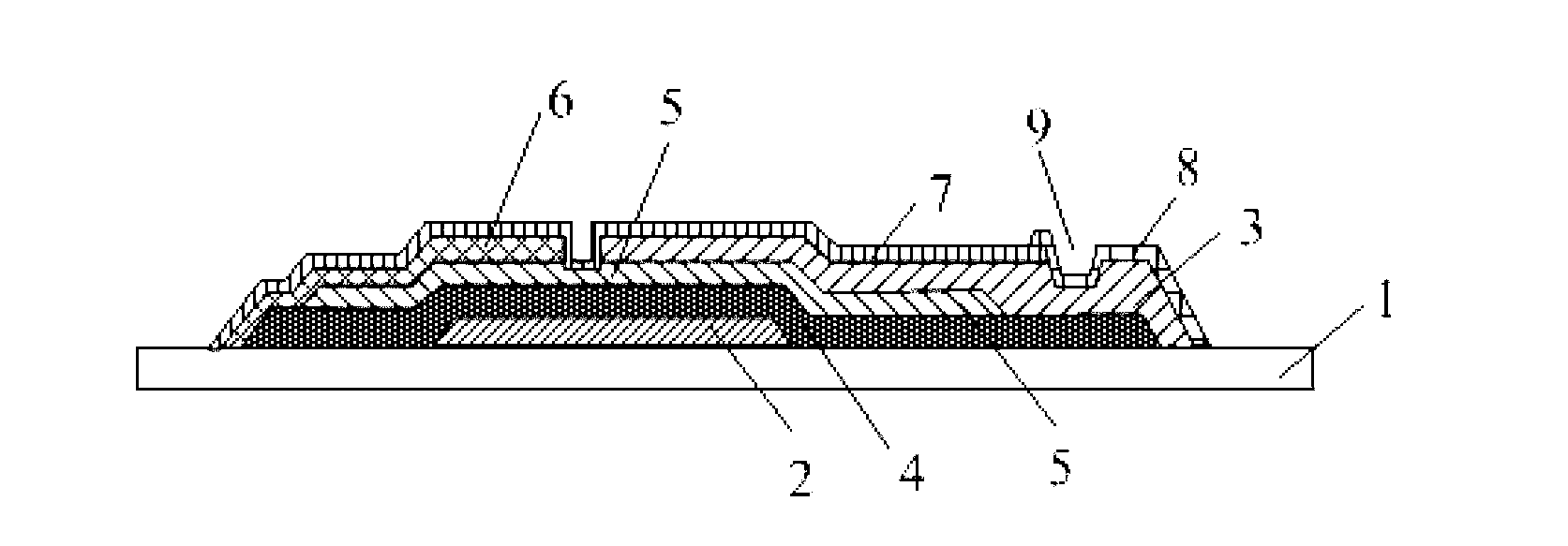

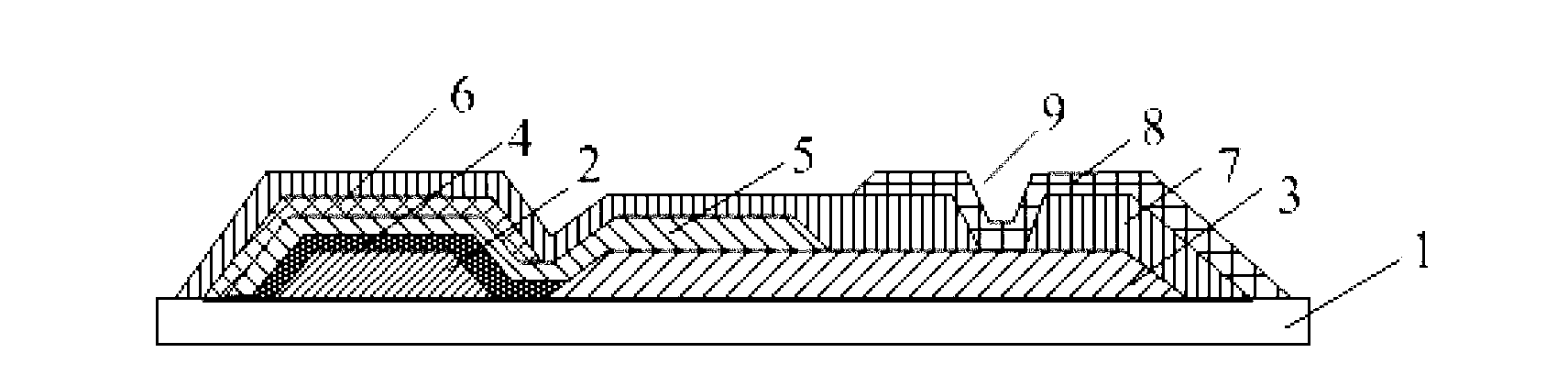

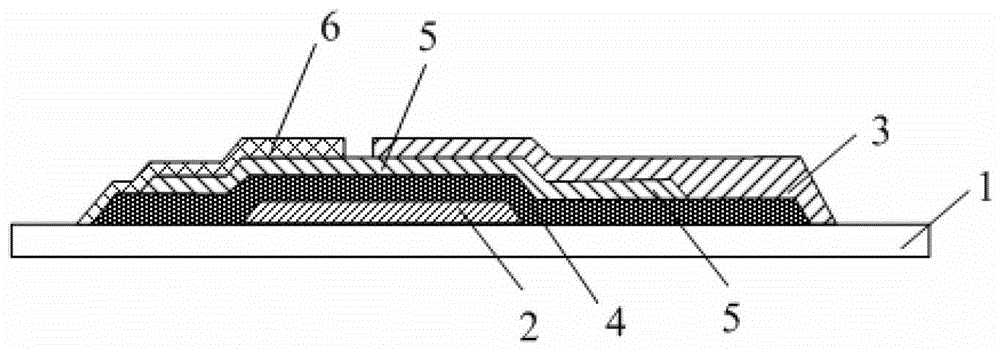

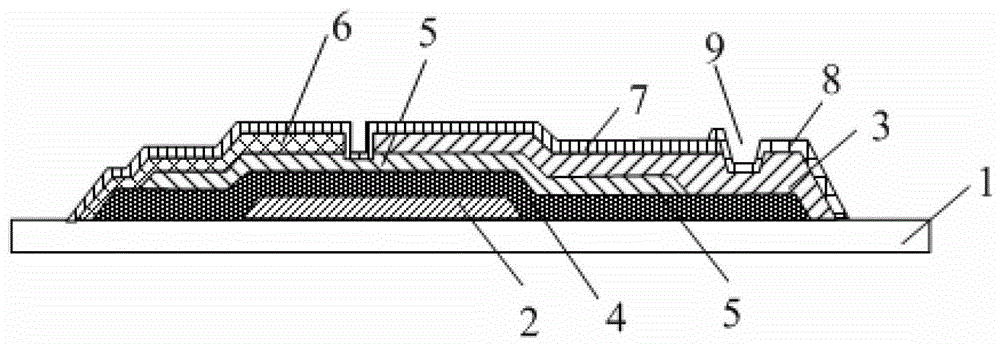

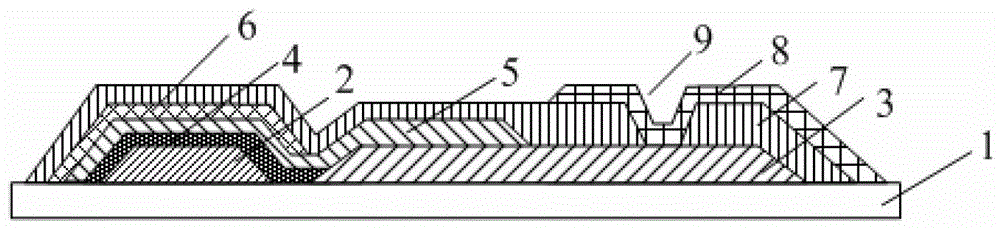

Thin film transistor, array substrate, manufacturing method and display device

ActiveCN103219392APrevent bridgingImprove yieldTransistorSolid-state devicesDisplay deviceOptoelectronics

The invention belongs to the technical field of display, and particularly relates to a thin film transistor, an array substrate, a manufacturing method and a display device. The thin film transistor comprises a substrate and a grid electrode layer, a source electrode layer and a drain electrode layer which are arranged on the substrate. The source electrode layer and the drain electrode layer are arranged on different layers, and the drain electrode layer and the grid electrode layer are arranged on the same layer. The array substrate with the thin film transistor has the advantages that due to the fact that the source electrode layer and the drain electrode layer can be blocked completely, the bridging phenomena cannot occur between the source electrode layer and the drain electrode layer, and product quality of the display device is improved.

Owner:HEFEI BOE OPTOELECTRONICS TECH +1

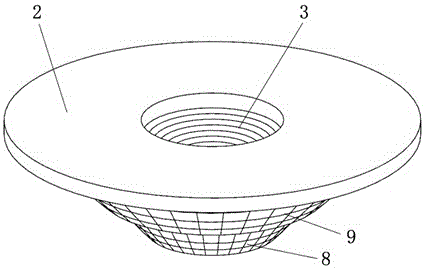

Light distribution lens and lighting device adopting same

InactiveCN105736974AImprove controlSimple designSemiconductor devices for light sourcesRefractorsEffect lightLight beam

Owner:CHENGDU HERCULUX OPTOELECTRONICS TECH CO LTD

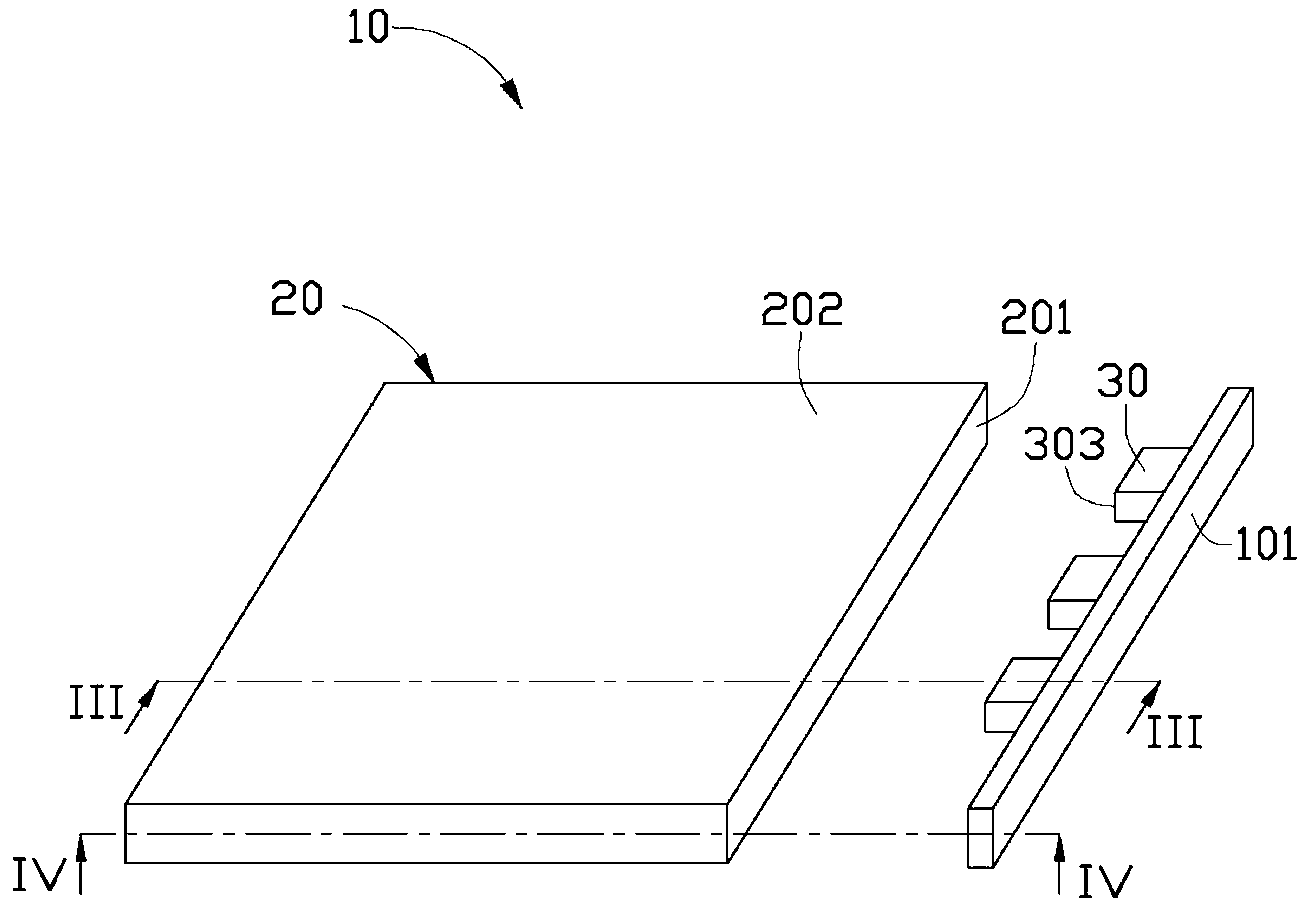

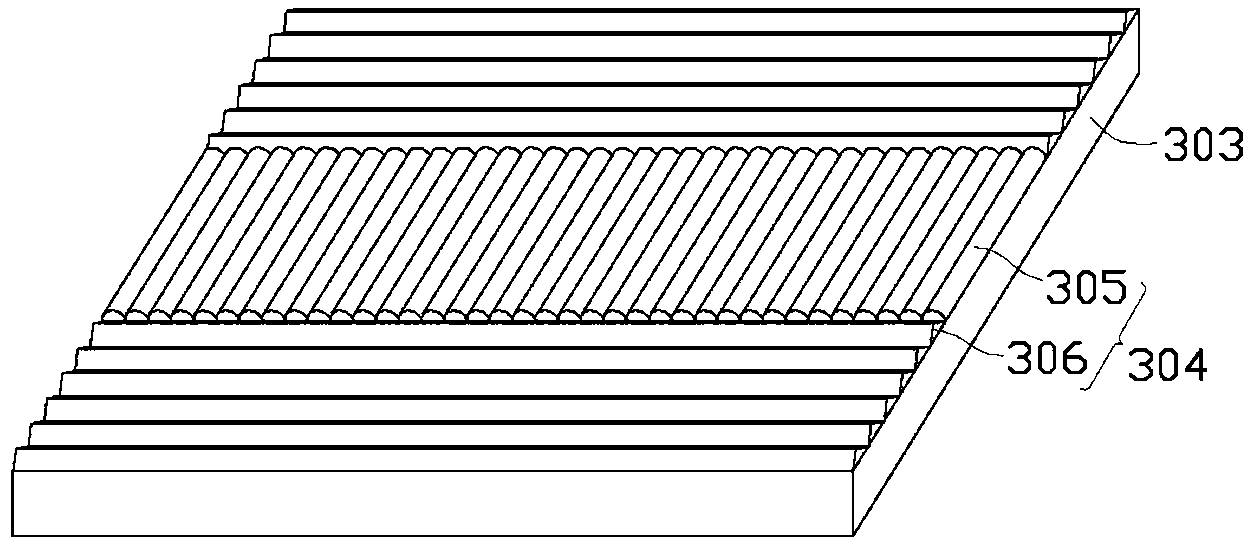

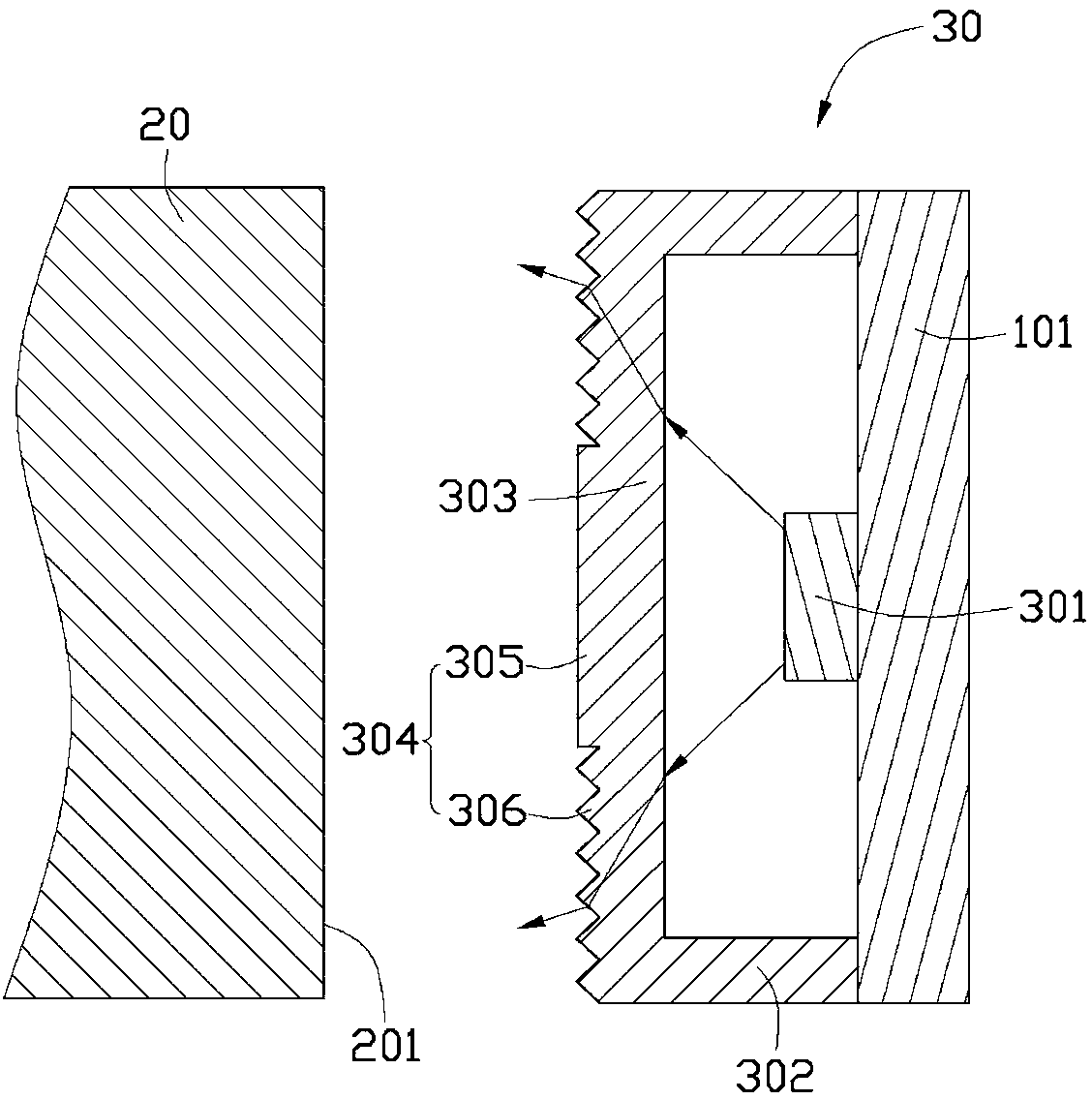

Light source device

InactiveCN102966862AReduce local color castReduce bright spotsElectric lightingPlanar/plate-like light guidesLight guideLight beam

A light source device includes a first light-emitting element providing illumination beams, a light guide plate (LGP) divided into light-transmissive regions, an optical thin film, and microstructures. The LGP has a first surface, a second surface opposite to the first surface, and a first light-incident surface connecting the first and second surfaces. The first light-emitting element is beside the first light-incident surface. The illumination beams are capable of entering the LGP through the first light-incident surface. The optical thin film is on the second surface of the LGP. The optical thin film has different thicknesses corresponding to at least two of the light-transmissive regions. The microstructures are on the optical thin film. When the illumination beams pass through the light-transmissive regions corresponding to the different thicknesses of the optical thin film and leave the LGP through the first surface, the illumination beams are converted into color beams with different wavelengths.

Owner:CORETRONIC

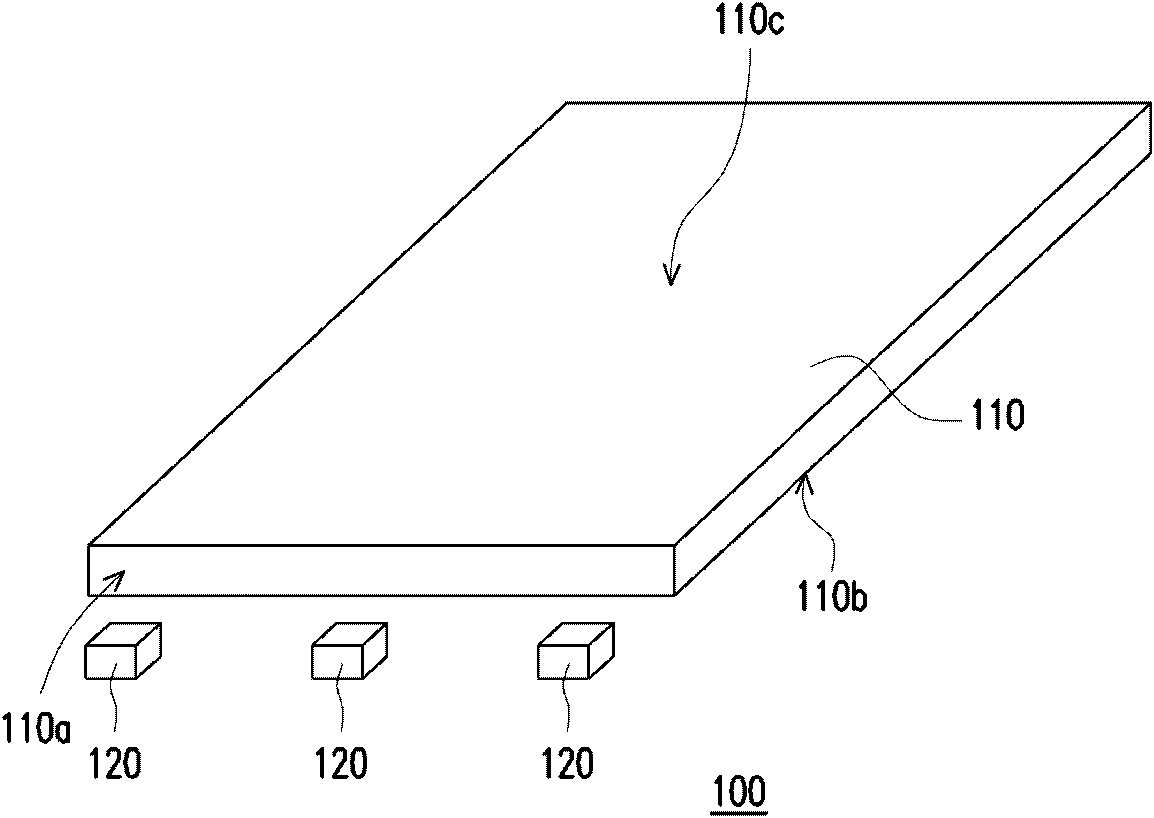

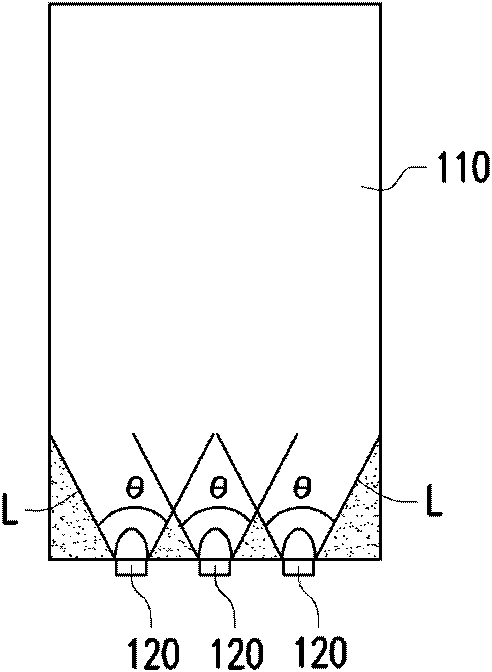

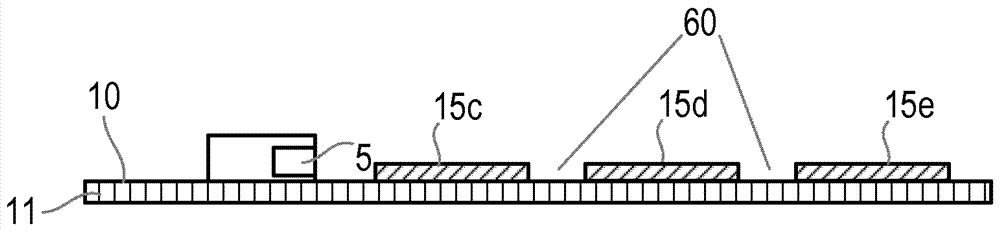

Light guide plate, illuminating device and manufacturing method of light guide plate

InactiveCN102081189AIncrease the light output angle rangeReduce bright spotsPrismsMechanical apparatusLight guideOptoelectronics

The invention relates to a light guide plate, an illuminating device and a manufacturing method of the light guide plate. The light guide plate provided by the invention comprises a plate body, an optical element array and a plurality of optical strip structures, wherein the plate body is provided with a light incident surface, and the light incident surface is provided with an optical difussion region and a fringe region which is adjacent to the optical diffusion region; the optical element array is arranged in the optical diffusion region; and the plurality of optical strip structures are arranged in the fringe region, and are connected to the optical element array and extend in a plurality of directions. The light guide plate, the illuminating device and the manufacturing method of the light guide plate have the beneficial effects that the range of the light emergent angle of a light source can be increased, and the bright speck phenomena can be decreased; the uniform area light source can be provided by the illuminating device provided with the light guide plate; and in addition, according to the manufacturing method of the light guide plate, a cutting tool is adopted for cutting the plate body, and the manufacturing method of the light guide plate has the characteristic of simple manufacturing procedure, and is easy for manufacturing.

Owner:苏州茂立光电科技有限公司

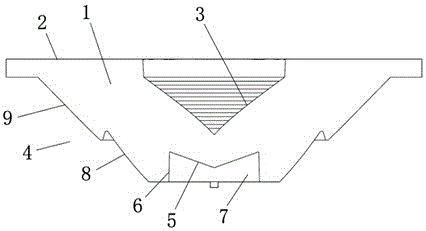

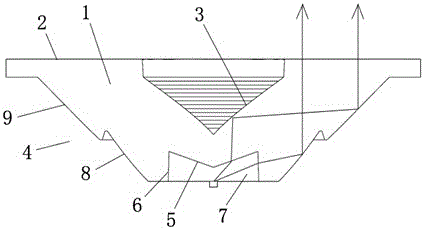

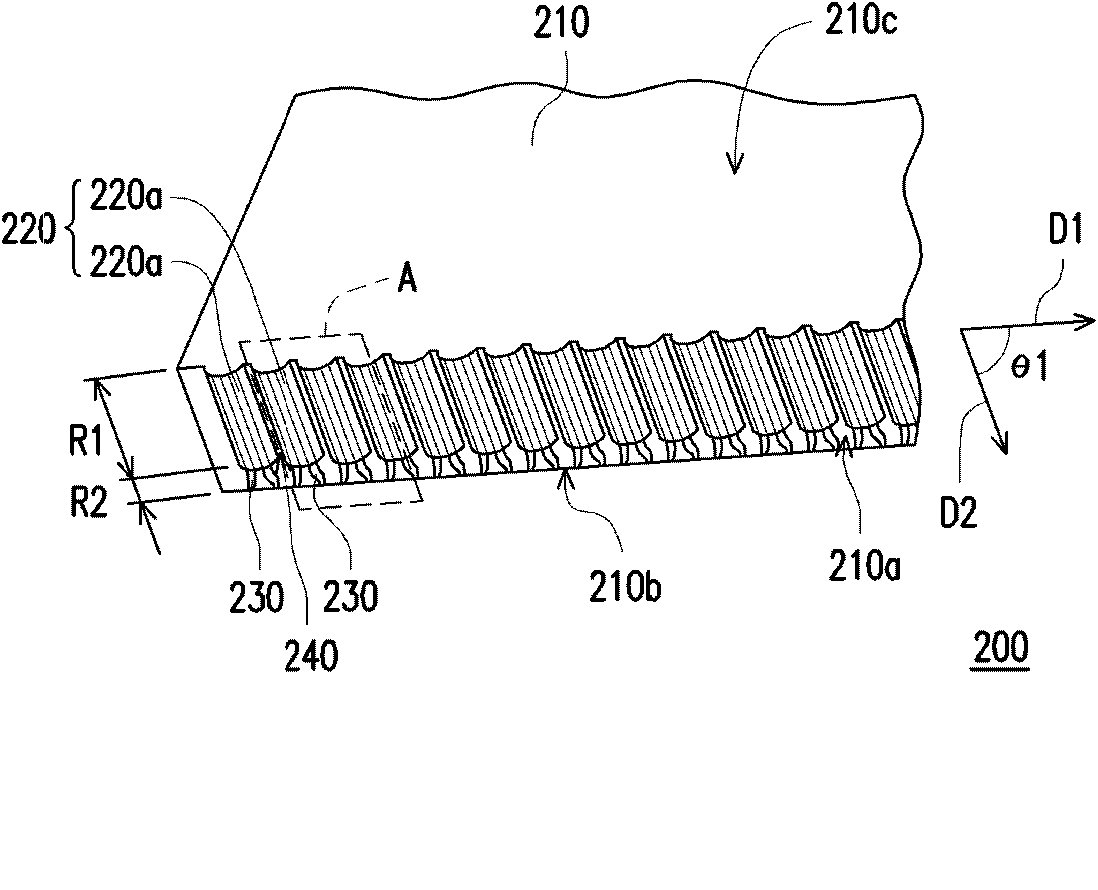

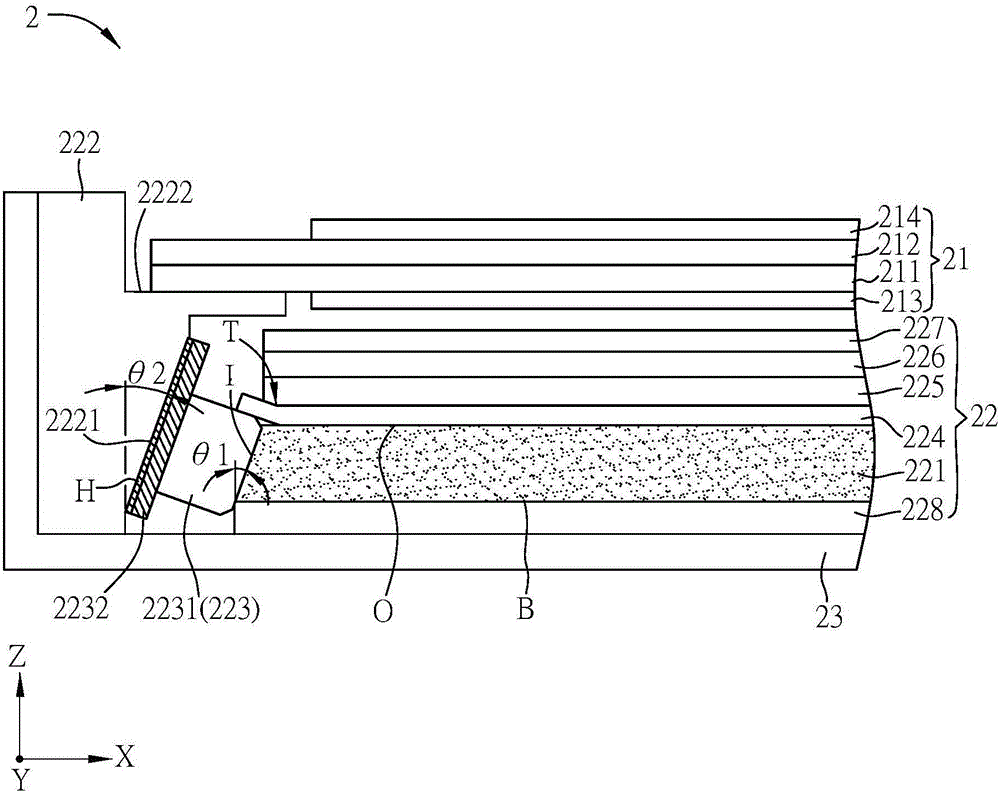

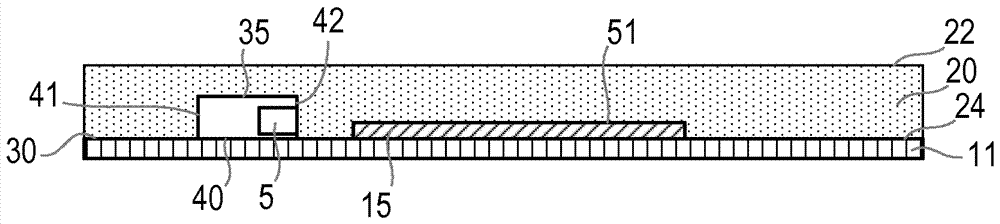

Backlight module and display device

InactiveCN106287577AReduce light leakageReduce bright spotsSpectral modifiersNon-linear opticsLight guideDisplay device

The invention discloses a backlight module and a display device. The backlight module comprises a light guide plate, a carrier, and a light emitting unit, wherein the light guide plate comprises at least one light entering surface and a light exiting surface connected with the light entering surface; the carrier is adjacent to the light guide plate, and comprises a setting surface; the light emitting unit is arranged on the setting surface; light emitted by the light emitting unit enters the light guide plate via the light entering surface, and exits from the light guide plate via the light exiting surface; a first inclined angle is formed between the light entering surface and a direction perpendicular to the light exiting surface; a second inclined angle is formed between the setting surface and the direction perpendicular to the light exiting surface; and the first inclined angle and the second inclined angle are substantially the same as each other.

Owner:HANNSTAR DISPLAY NANJING +1

Polyester film for release film for polarizer and layered product with improved polarizing property

InactiveCN101918477AReduce bright spotsImprove inspection accuracySynthetic resin layered productsPolarising elementsPolyesterForeign matter

A polyester film is provided which is suitable for use as the base film of a release film. When a polarizer having the release film adherent thereto is visually inspected for defects such as a strain and unevenness and for a foreign substance by the crossed Nicol's method, the film can render a high degree of inspection accuracy possible. The polyester film for a release film for use in a polarizer is characterized by having a haze of 7-18% and an L value as determined by the reflection method of 77 or less.

Owner:MITSUBISHI PLASTICS INC

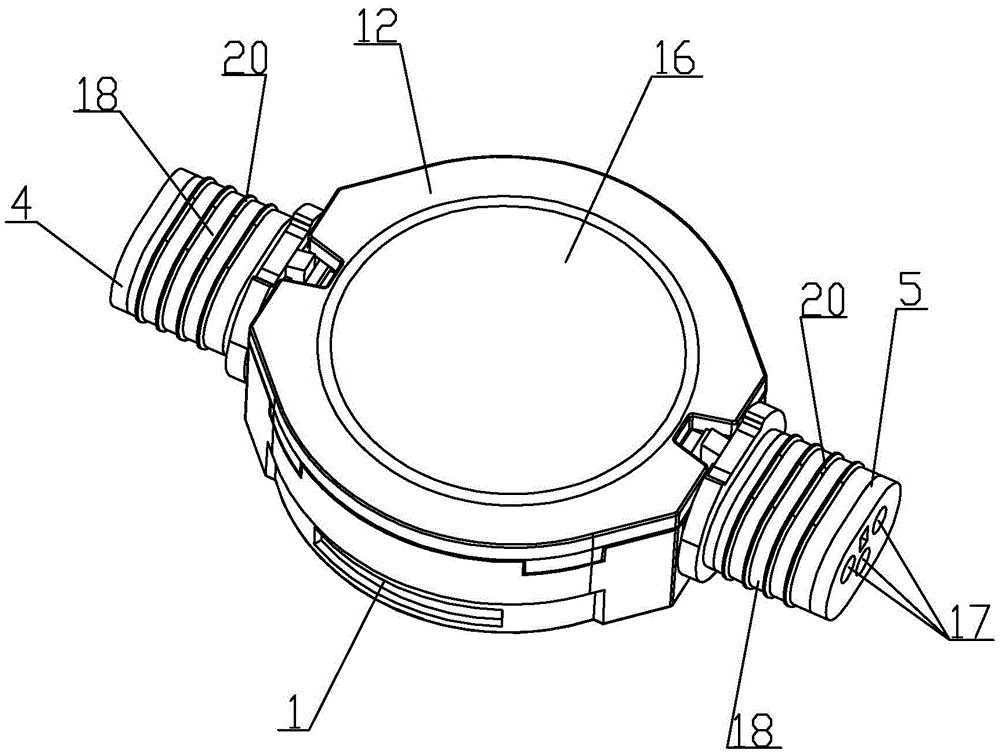

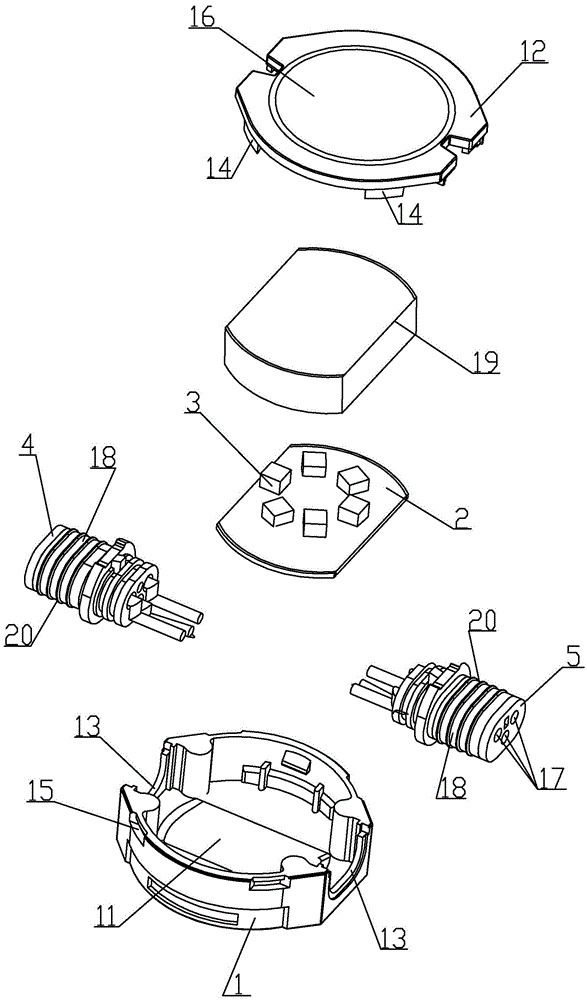

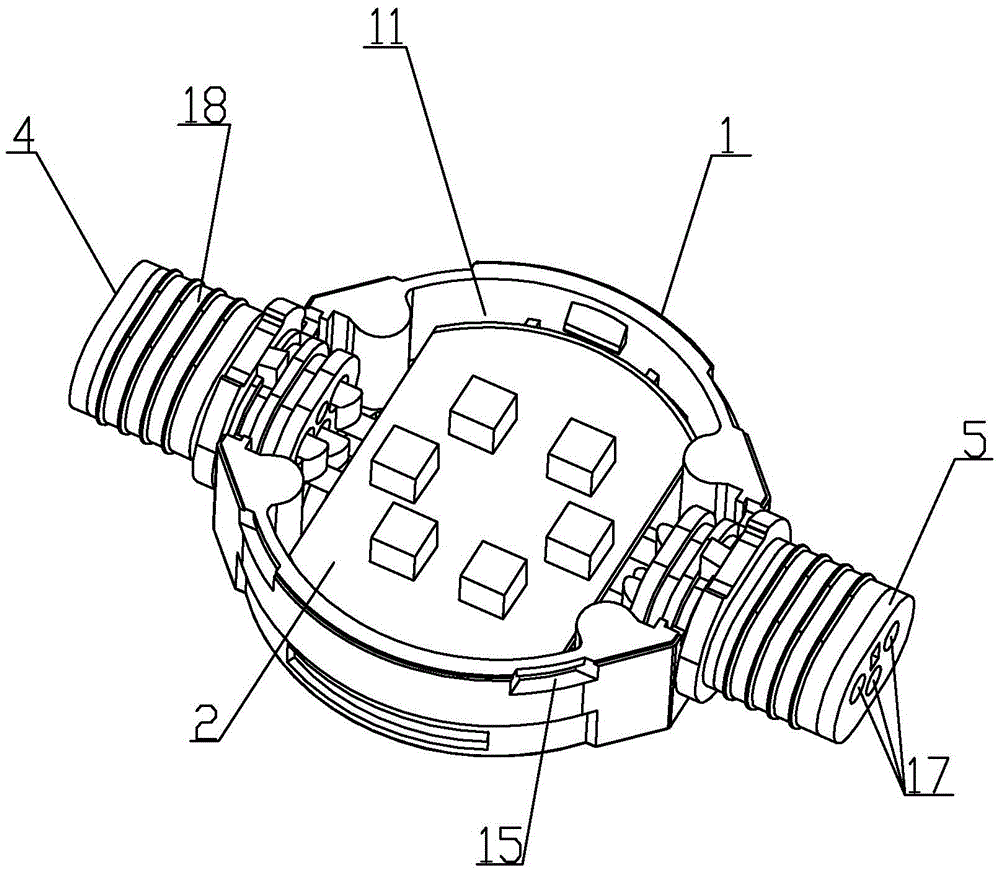

LED (light-emitting diode) point light source

InactiveCN105423156AEasy to useSimple installation processElectric circuit arrangementsProtective devices for lightingEngineeringLED lamp

The invention relates to an LED (light-emitting diode) point light source which comprises a housing, wherein a circuit board is arranged in the housing; and LED lamp beads are arranged on the circuit board. According to the technical scheme, the key point is that the a first connecting plug and a second connecting plug which are electrically connected with the circuit board are respectively arranged on the housing, wherein one end of each of the first connecting lug and the second connecting lug is exposed out of the housing for external connecting. The LED point light source is simple in structure, convenient to dismount, capable of being freely connected, and convenient to replace when a bad product appears after the connecting.

Owner:ZHONGSHAN QIXIN WIRE CONNECTOR CO LTD

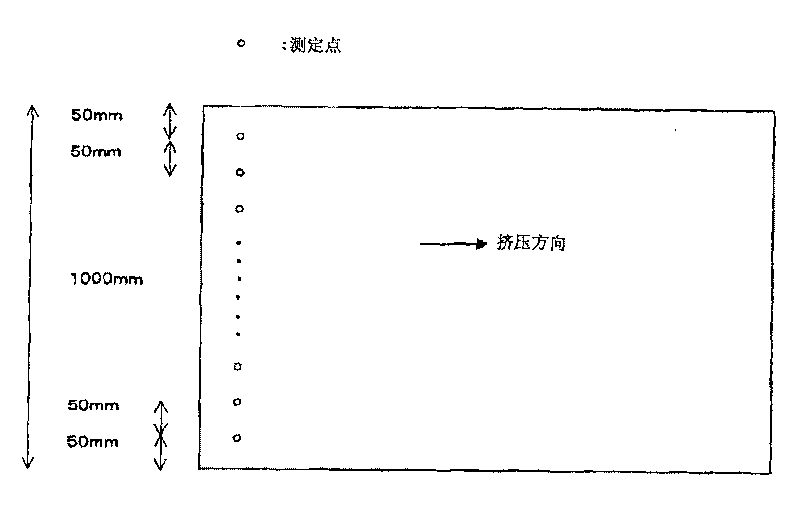

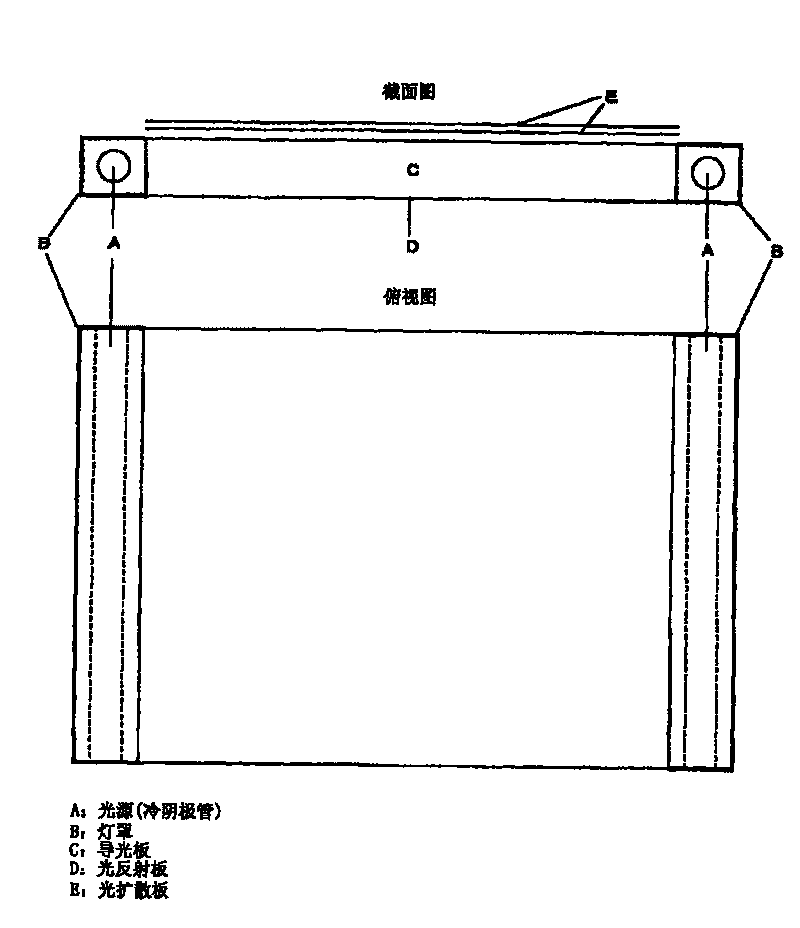

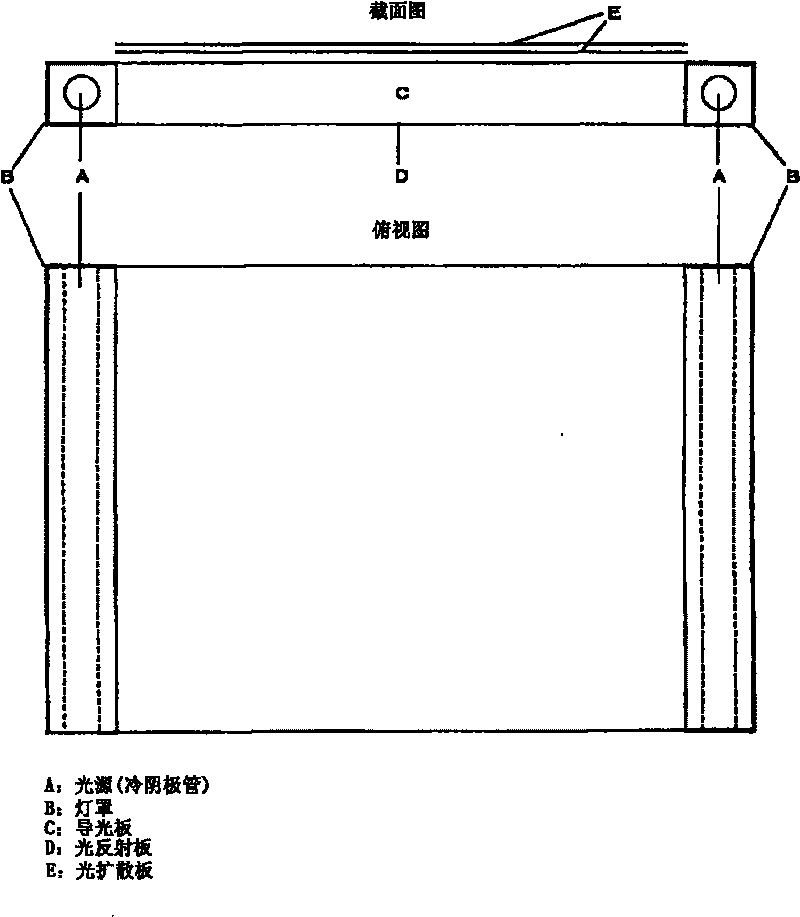

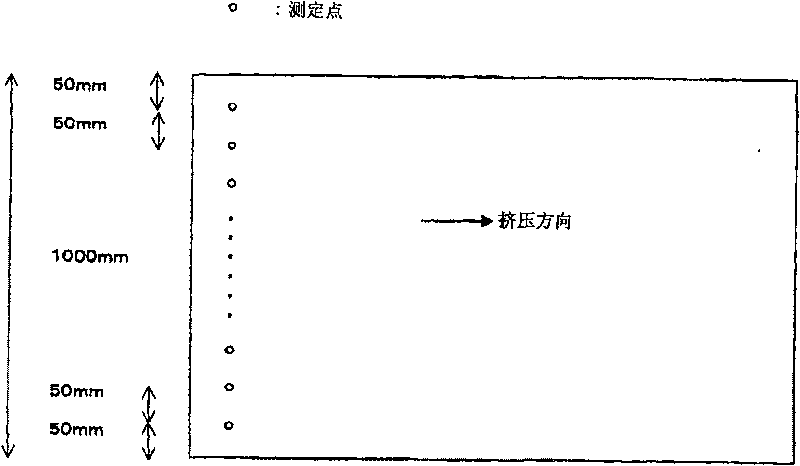

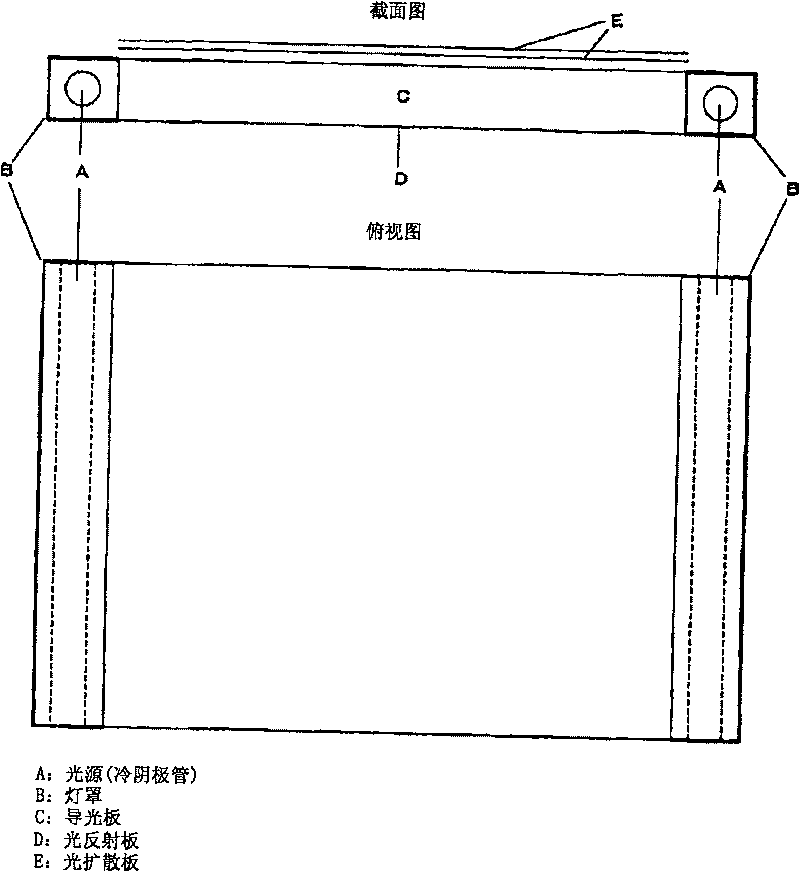

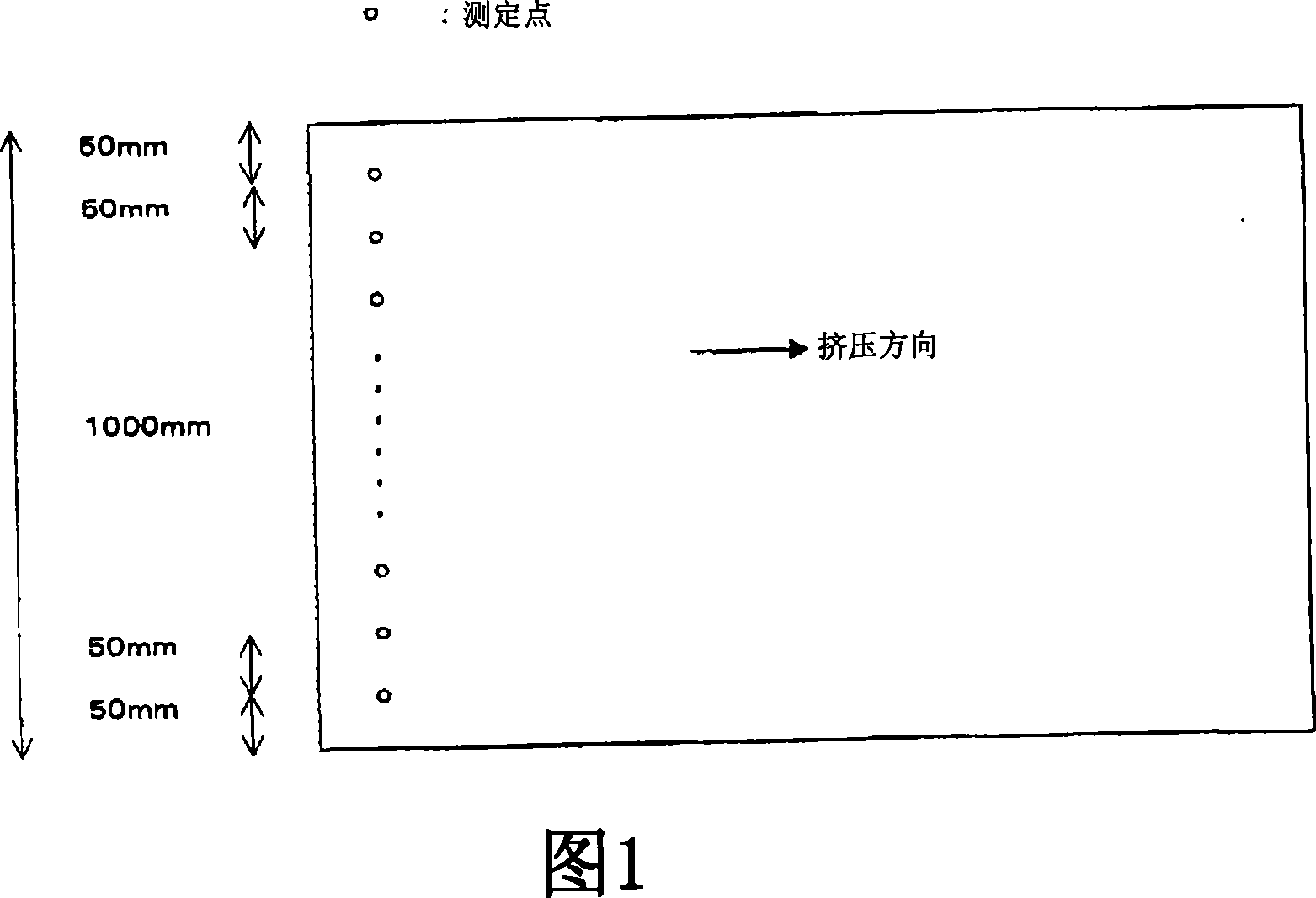

Method for manufacturing optical methacrylic resin extrusion plate

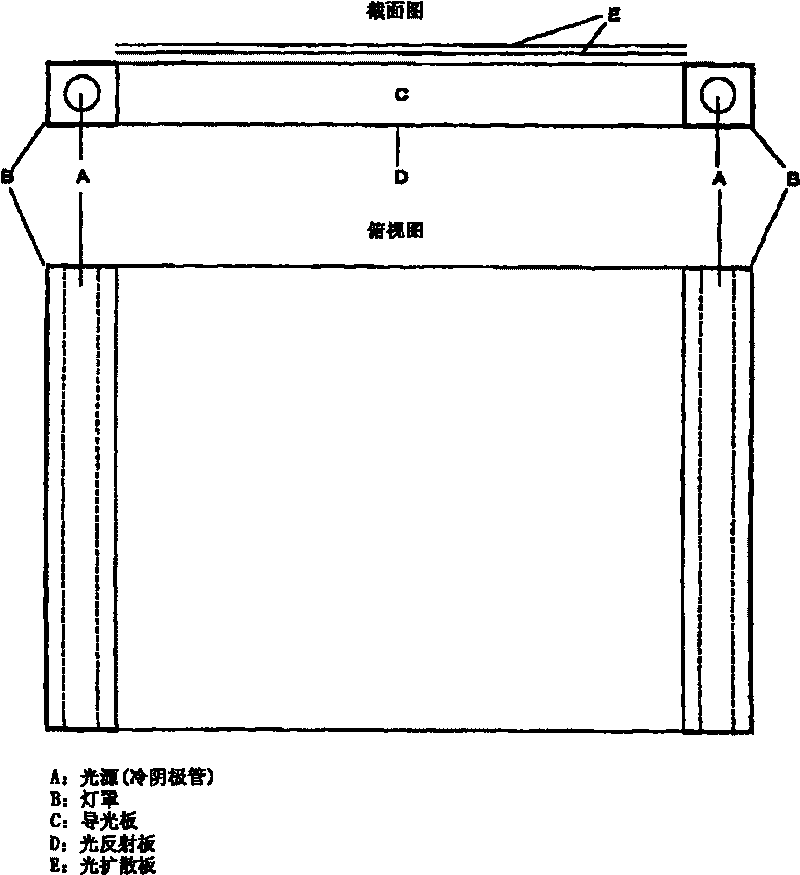

InactiveCN101035665AImprove luminous efficiencyReduce bright spotsFlat articlesOptical light guidesApparent densityLight guide

There is provided a methacrylic resin extrusion plate formed by a mixture having an apparent density of 0.80 g / ml or above prepared by mixing methacrylic resin polymer of a definite shape having an apparent density of 0.63 g / ml to 0.78 g / ml and methacrylic resin polymer of an indefinite shape having an apparent density of 0.55 g / ml to 0.63 g / ml. The plate thickness accuracy in the width direction is controlled to be within +- 1.0% of the average plate thickness. The methacrylic resin extrusion plate for a light guide plate is preferably used for office automation devices such as a personal computer and a word processor, display devices used for various monitors displaying an image signal such as a panel monitor and a television monitor, display devices used for indoor or outdoor illumination devices and sign boards.

Owner:ASAHI KASEI CHEM CORP

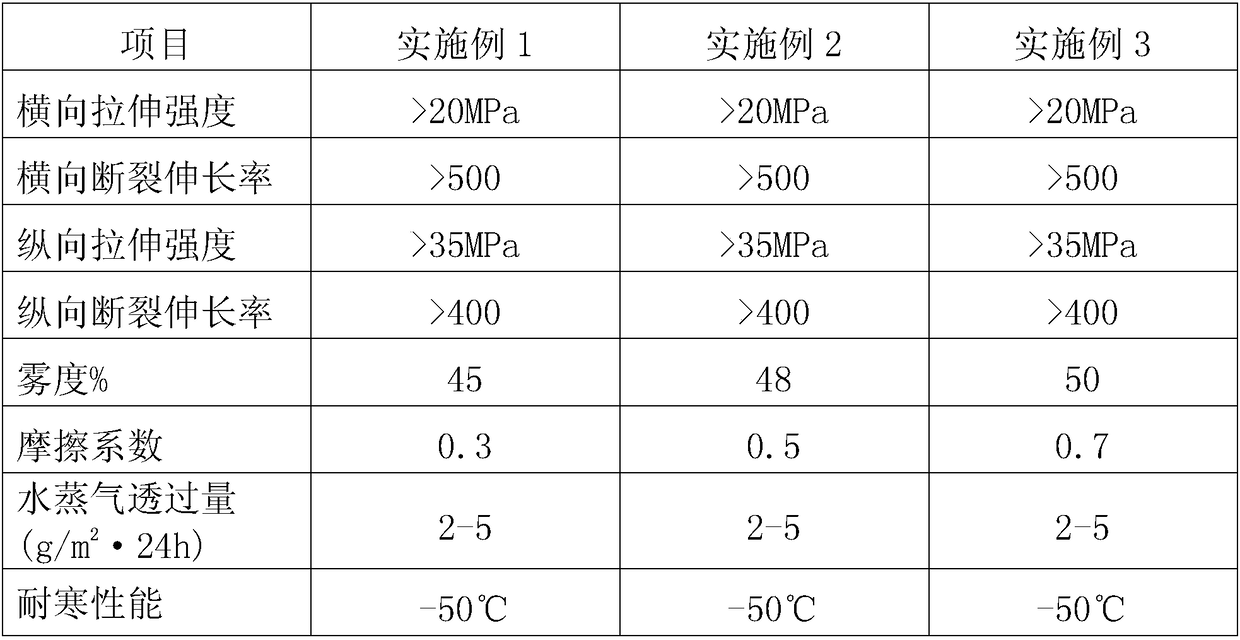

Low-light matt film and preparation thereof

The invention relates to a low-light matt film and a method for preparing the same. The low-light matt film comprises the following components in weight percentage: 40 to 90 weight percent of polypropylene resin, 0 to 30 weight percent of antistatic agent, 0.5 to 30 weight percent of antiblocking agent and 1 to 40 weight percent of matt masterbatch; the components are evenly mixed and measured and undergo physical and chemical reactions through a single screw extrusion machine, longitudinal extension, horizontal extension and traction, and the matt film is obtained after bi-directional extension. Compared with the prior art, the matt film has the characteristics of low luster, high strength, less bright points and good handfeel, etc.

Owner:温州市金田塑业有限公司

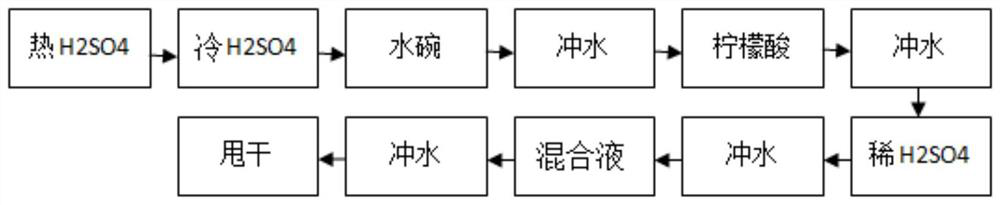

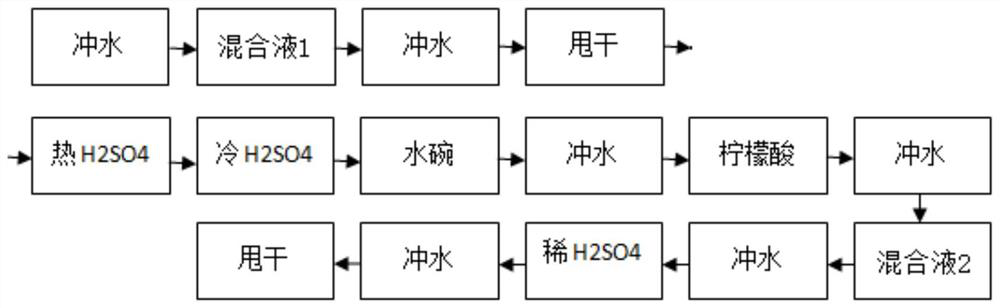

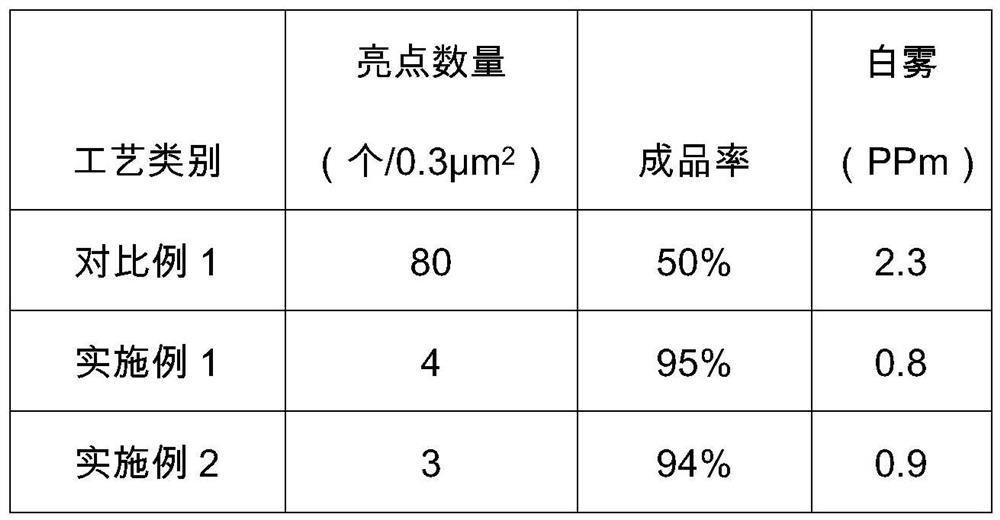

Method for cleaning indium phosphide wafer

PendingCN113035690AReduce bright spotsImprove yieldSemiconductor/solid-state device manufacturingFinal product manufactureIndium phosphideSulfuric acid

The invention discloses a method for cleaning an indium phosphide wafer. The method comprises the following steps of: spin-drying a polished indium phosphide wafer; and sequentially performing hot sulfuric acid soaking, cold sulfuric acid soaking, washing, citric acid aqueous solution soaking, washing, dilute inorganic acid soaking, washing, ammonia water and hydrogen peroxide mixed solution soaking and washing, and spin-drying. Compared with the prior art, the method for cleaning the indium phosphide wafer has the following advantages of obviously reduced bright spots, obviously improved yield, good stability, high safety, and low energy consumption.

Owner:中锗科技有限公司

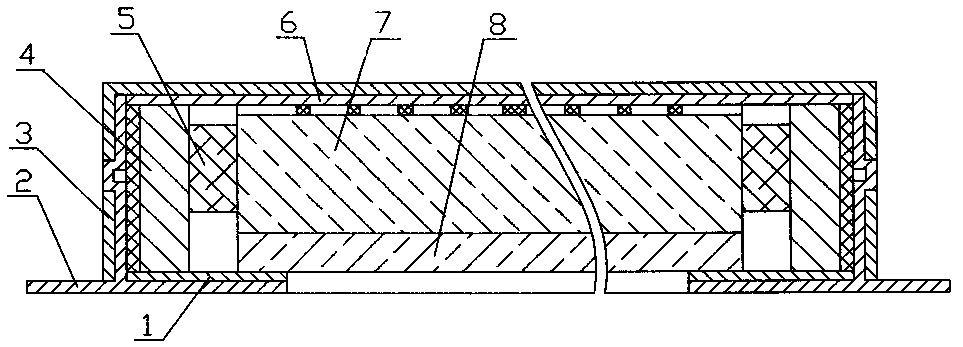

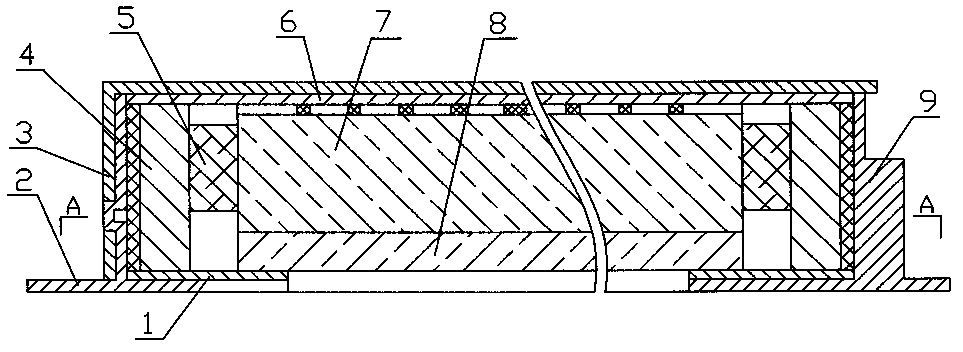

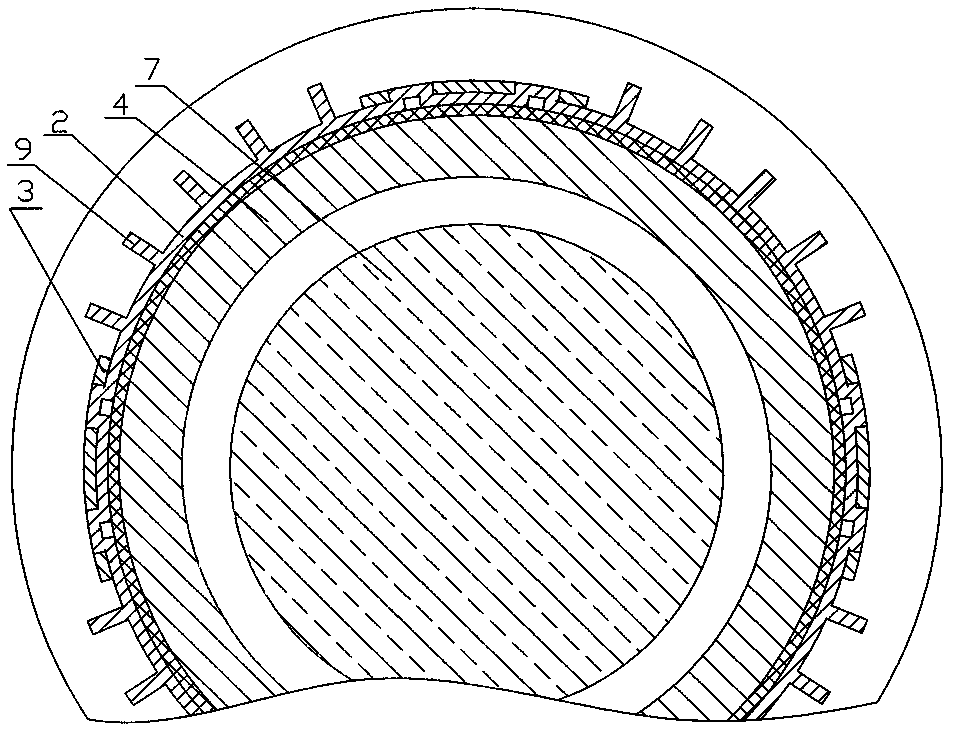

Fastened round LED lamp

InactiveCN102588796ASimple connection structureEasy to manufactureMechanical apparatusPoint-like light sourceLight guideBarrel Shaped

A fastened round LED lamp comprises a lamp frame, an LED lamp panel, a top plate, a top reflecting layer, a light guide plate, a diffusion diaphragm, a circuit board, an outlet lead and a power converter. A plurality of rectangular boss fasteners are evenly distributed on the outer circumferential wall of the annular lamp frame with an inverted 'T'-shaped cross section, the upper plane of a round tube wall of the barrel-shaped top plate with an opening facing down is provided with rectangular holes corresponding to the rectangular boss fasteners, the rectangular holes and the rectangular boss fasteners are fixed in a fastened manner, a corresponding annular disc reflecting layer is arranged on an inner annular disc plate at the bottom of the lamp frame, the circuit board for inserting the LED lamp panel is adhered to the inner circumferential wall of a longitudinal annular plate above the reflecting layer of the lamp frame, white materials with high diffuse reflectivity are coated on the surface of a no-lamp-holder position of the LED lamp panel, or reflective sheets are adhered to the surface of a position except for a lamp holder of the LED lamp panel, the round diffusion diaphragm, the round light guide plate and the round top reflecting layer are sequentially arranged above a reflecting plate in an inner circle of the lamp panel, and the inner circle of the round tube wall of the top plate is sleeved on the outer wall of the longitudinal annular plate of the lamp frame by means of movable fit. The coated materials with the high diffuse reflectivity and the strip-shaped reflecting layers reflect light into the light guide plate, so that the utilization rate of a light source is increased.

Owner:MAXRAY OPTICAL TECH FUJIAN

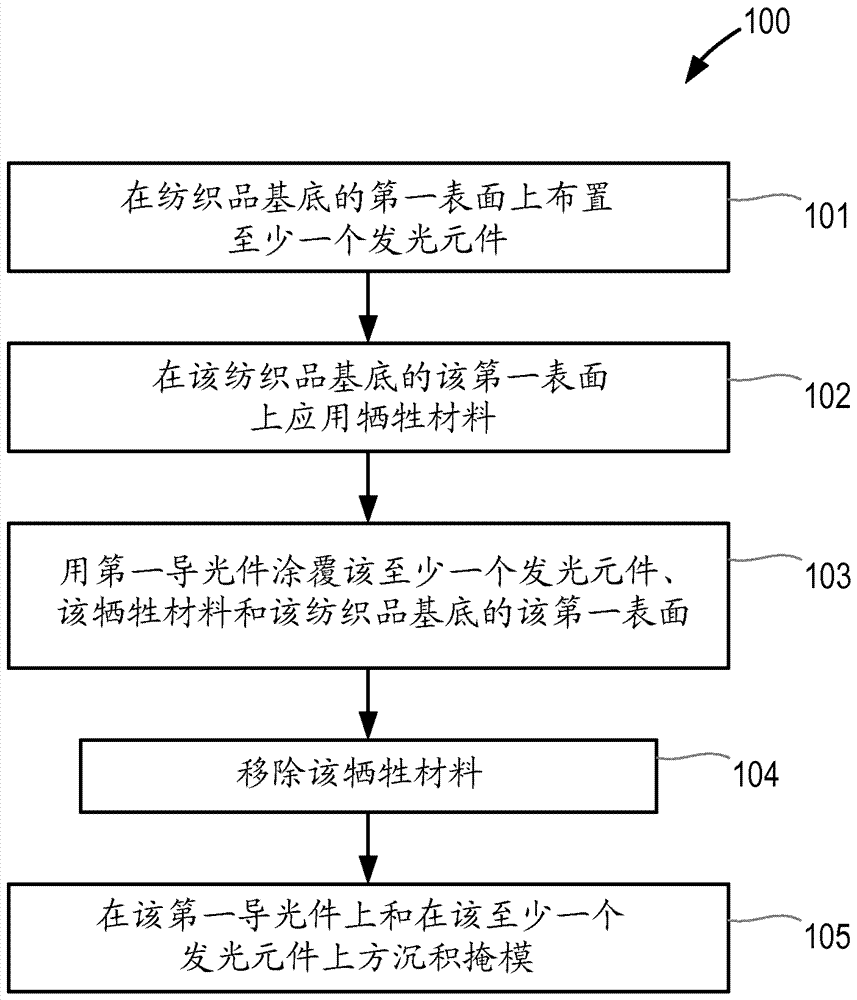

Light spreading in textiles

InactiveCN107407772AReduce bright spotsPlanar/plate-like light guidesLight therapyLight guideLight emitting device

The present invention relates to a light emitting device comprising a light emitting element and a light guide arranged on a textile substrate and wherein one or more air gaps are present in the light guide at the interface with the textile substrate. The method also relates to a method of making the light emitting device and to various uses of the light emitting device.

Owner:SIGNIFY HLDG BV

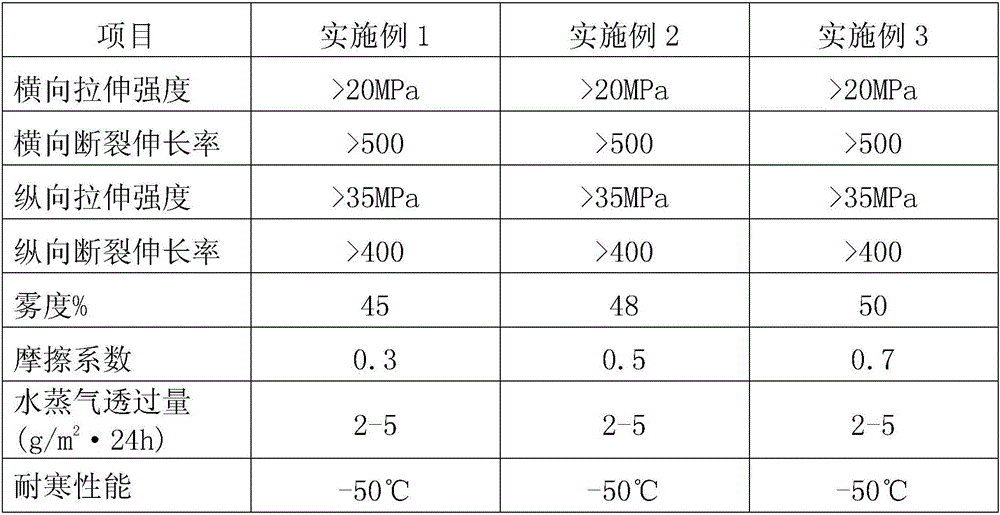

Light extinction silk and satin film and protection process thereof

ActiveCN106364102AImprove barrier propertiesImprove moisture resistanceFlexible coversWrappersElastomerLight extinction

The invention relates to a light extinction silk and satin film and a protection process thereof. The light extinction silk and satin film comprises a layer A, a layer B, a layer C and a layer D which are sequentially compounded. The layer A is prepared from 44 wt% to 46 wt% of homo-polypropylene, 44 wt% to 46 wt% of high density polyethylene and 9 wt% to 11 wt% of block co-polypropylene resin, and the layer B and the layer C are both prepared from 49 wt% to 51 wt% of homo-polypropylene, 44 wt% to 46 wt% of high density polyethylene, 1 wt% to 2 wt% of spherical anti-block agent and 3 wt% to 4 wt% of nanoscale aid, and the layer D is prepared from 85 wt% to 90 wt% of homo-polypropylene and 10 wt% to 15 wt% of polytolefin elastomers. The thickness ratio of the layer A to the layer B to the layer C to the layer D is 60:15:15:10. During production, the main materials of all the layers are added into an extruder, after the main materials are melted, the auxiliary materials of all the layers are added into the extruder for fusion, then melt is extruded to a curtain coating roll, finally, all the layers are compounded into the light extinction silk and satin film, and the both sides of the light extinction silk and satin film are subjected to corona treatment. The light extinction silk and satin film is outstanding in moisture stopping performance, excellent in cold resisting performance, good in heat resisting performance, good in hand feeling and low in gloss, and gives people a noble visual feeling and the effect close to silks and satins.

Owner:永新股份(黄山)包装有限公司

Single crystal wafer and preparation method of crystal bar thereof

InactiveCN112160021AIncrease profitReduce bright spotsPolycrystalline material growthBy pulling from meltWaferingCzochralski method

The invention provides a single crystal wafer and a preparation method of a crystal bar thereof, and belongs to the technical field of crystal growth. A traditional Czochralski method is improved, anempty drawing process is added, the cooling speed is reduced, the cooling time is prolonged, the defects of bright spots, raised grains and the like on the surface of a single crystal wafer with the diameter of 4 inches or above prepared from the obtained single crystal bar are effectively reduced, the percent of pass reaching the low LPD standard is remarkably increased, the crystal bar utilization rate is increased, and the market requirements can be met. The enterprise profits are increased.

Owner:安徽中飞科技有限公司

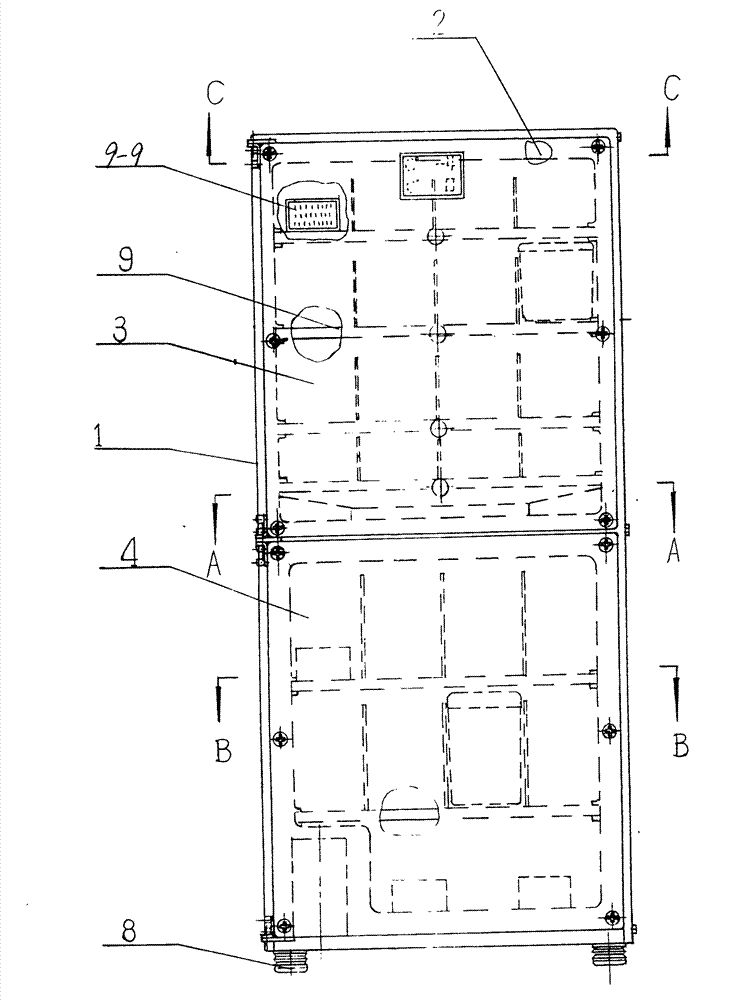

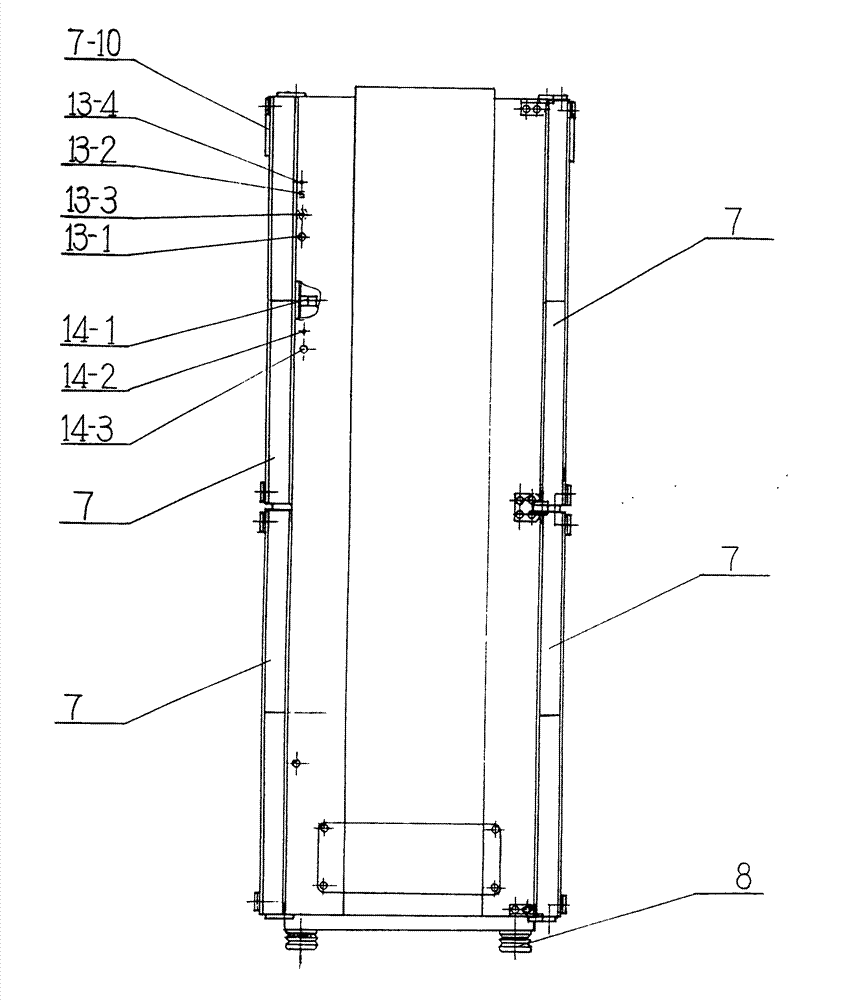

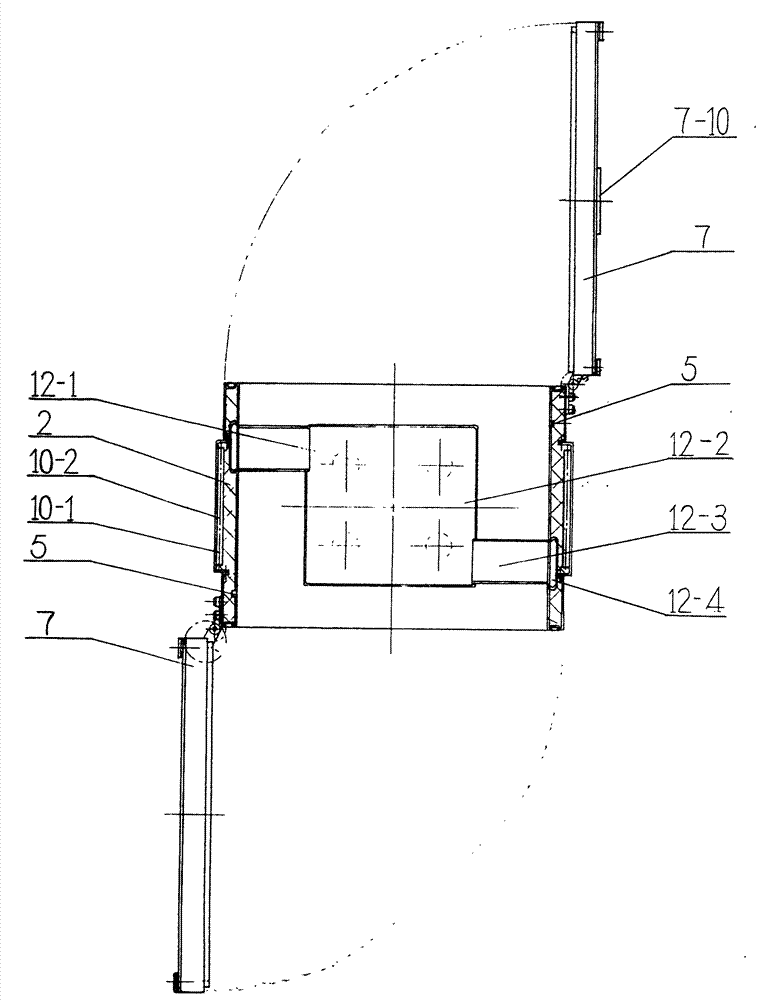

Freezing and refrigeration apparatus

InactiveCN102121778BDoes not affect circulationEasy to useLighting and heating apparatusDomestic refrigeratorsCold chainTemperature control

The invention relates to a freezing and refrigeration apparatus which comprises a box body, an insulating layer, a refrigeration chamber, a freezing chamber, a temperature control device and two refrigeration cycle systems, wherein box door components are arranged on the refrigeration chamber and the freezing chamber respectively; a sealing device is arranged between the box door components and the box body; and shelves and radiating devices are arranged in both of the refrigeration chamber and the freezing chamber; the freezing and refrigeration apparatus is characterized in that: the refrigeration chamber and the freezing chamber are both provided with two box door components which are positioned on the front surface and back surface of the box body; each box door component is of a double-layer vacuum glass structure; a touch screen liquid crystal display panel is mounted at the outer side of each box door component; a conical spring is mounted in each box door component, and a sealing device is mounted at the outer side of the conical spring; and an ultrasonic humidifying system is arranged at the bottom of the refrigeration chamber at the upper part of the box body. Due to thestructure, the freezing and refrigeration apparatus provided by the invention has better functions in energy conservation, isolation, moisture preservation, humidity control, freshness preservation, sterilization, disinfection and intelligent management, and is convenient to operate, reliable to install and the like and particularly suitable for isolating the cold chain processing places and turnover stations.

Owner:张英利

A kind of delustering satin film and its production process

ActiveCN106364102BImprove barrier propertiesImprove moisture resistanceFlexible coversWrappersElastomerPolyolefin

The invention relates to a light extinction silk and satin film and a protection process thereof. The light extinction silk and satin film comprises a layer A, a layer B, a layer C and a layer D which are sequentially compounded. The layer A is prepared from 44 wt% to 46 wt% of homo-polypropylene, 44 wt% to 46 wt% of high density polyethylene and 9 wt% to 11 wt% of block co-polypropylene resin, and the layer B and the layer C are both prepared from 49 wt% to 51 wt% of homo-polypropylene, 44 wt% to 46 wt% of high density polyethylene, 1 wt% to 2 wt% of spherical anti-block agent and 3 wt% to 4 wt% of nanoscale aid, and the layer D is prepared from 85 wt% to 90 wt% of homo-polypropylene and 10 wt% to 15 wt% of polytolefin elastomers. The thickness ratio of the layer A to the layer B to the layer C to the layer D is 60:15:15:10. During production, the main materials of all the layers are added into an extruder, after the main materials are melted, the auxiliary materials of all the layers are added into the extruder for fusion, then melt is extruded to a curtain coating roll, finally, all the layers are compounded into the light extinction silk and satin film, and the both sides of the light extinction silk and satin film are subjected to corona treatment. The light extinction silk and satin film is outstanding in moisture stopping performance, excellent in cold resisting performance, good in heat resisting performance, good in hand feeling and low in gloss, and gives people a noble visual feeling and the effect close to silks and satins.

Owner:永新股份(黄山)包装有限公司

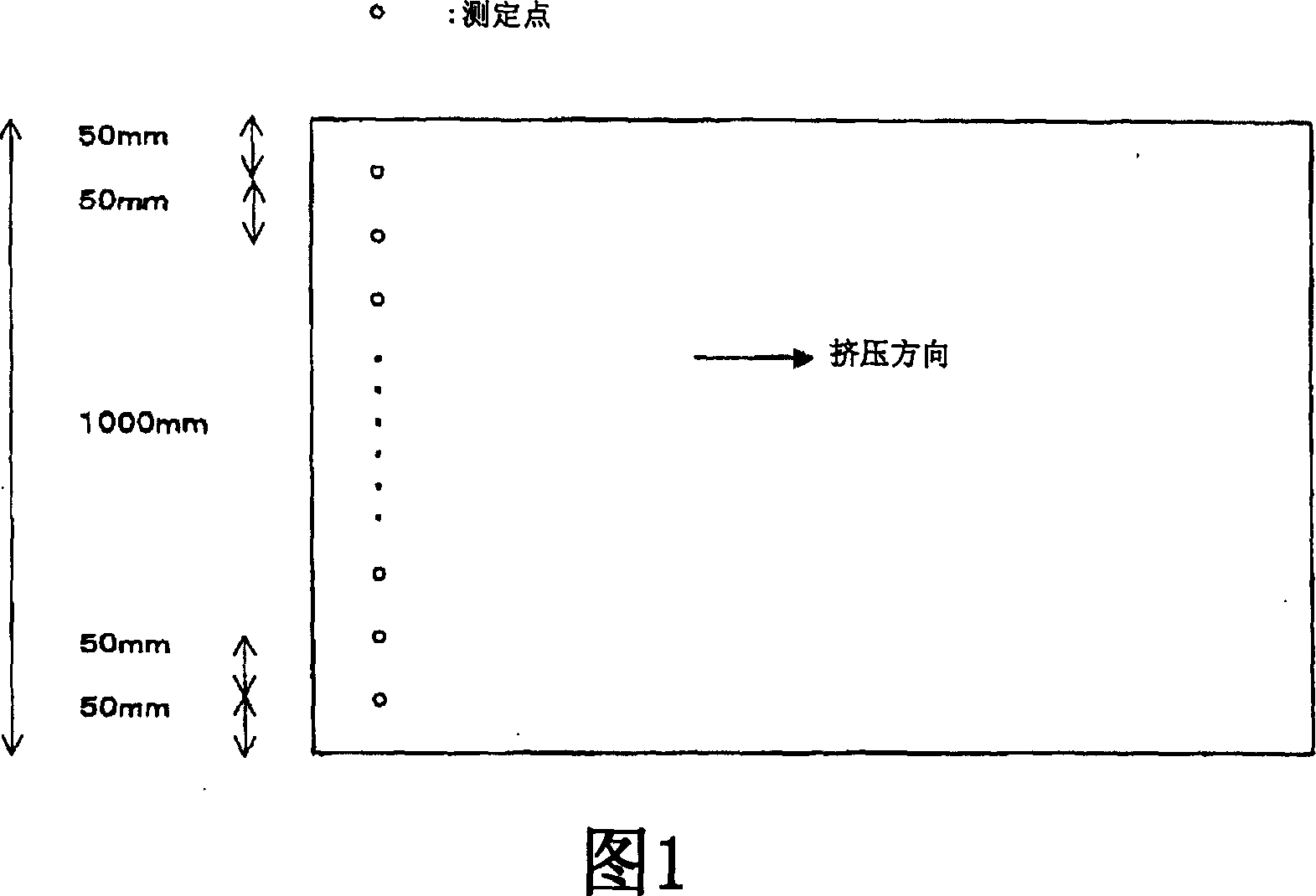

Method for manufacturing optical methacrylic resin extrusion plate

InactiveCN101035665BImprove luminous efficiencyReduce bright spotsFlat articlesOptical light guidesApparent densityLight guide

There is provided a methacrylic resin extrusion plate formed by a mixture having an apparent density of 0.80 g / ml or above prepared by mixing methacrylic resin polymer of a definite shape having an apparent density of 0.63 g / ml to 0.78 g / ml and methacrylic resin polymer of an indefinite shape having an apparent density of 0.55 g / ml to 0.63 g / ml. The plate thickness accuracy in the width directionis controlled to be within +- 1.0% of the average plate thickness. The methacrylic resin extrusion plate for a light guide plate is preferably used for office automation devices such as a personal computer and a word processor, display devices used for various monitors displaying an image signal such as a panel monitor and a television monitor, display devices used for indoor or outdoor illumination devices and sign boards.

Owner:ASAHI KASEI CHEM CORP

Novel methacrylic resin extrusion plate and manufacturing method thereof

InactiveCN101035666BImprove luminous efficiencyReduce bright spotsFlat articlesOptical light guidesDisplay deviceLightness

Extrusion molding is performed by using a methacrylic resin extrusion plate having a plate thickness of 2.0 to 15.0 mm and formed by a mixture having an apparent density of 0.80 g / ml or above preparedby mixing spherical methacrylic resin polymer having an apparent density of 0.70 g / ml to 0.78 g / ml and cylindrical methacrylic resin polymer having an apparent density of 0.63 g / ml to 0.70 g / ml and / or flat methacrylic resin polymer having an apparent density of 0.63 g / ml to 0.70 g / ml. The brightness uniformity is controlled to be 80% or above and the plate thickness accuracy in the width direction is controlled to be within +-1.0% of the average plate thickness. There is provided a methacrylic resin extrusion plate for a light guide plate which can be preferably used for office automation devices such as a personal computer and a word processor, display devices used for various monitors displaying an image signal such as a panel monitor and a television monitor, display devices used for indoor or outdoor illumination devices and sign boards.

Owner:ASAHI KASEI CHEM CORP

Light source module and lighting device

InactiveCN103123051BReduce bright spotsReduce light leakageMechanical apparatusElectric lightingLight guideLight emitting device

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Image reading apparatus and image forming apparatus including the same

ActiveUS8446648B2Low costReduce bright spotsImage enhancementElectrographic process apparatusLight irradiationImage formation

In one embodiment, an image reading apparatus has a light source configured with a plurality of light-emitting elements disposed in a row in a main scanning direction that irradiate light toward an original, and a photoelectric conversion element that receives light reflected from the original, an output light amount from the light-emitting elements can be adjusted, and a state of bright spots due to repetition of light-dark in the main scanning direction on a light irradiation face of the original due to the plurality of light-emitting elements is determined, and the output light amount from the light-emitting elements is adjusted based on the determination result of the state of the bright spots.

Owner:SHARP KK

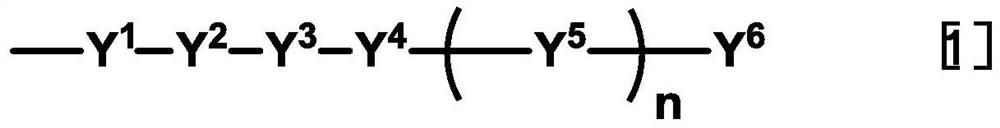

Liquid crystal display element with curved liquid crystal panel and liquid crystal aligning agent used therefor

To provide a liquid crystal display device including a curved liquid crystal panel having no bright spots even when physical friction such as spacer friction occurs. A curved liquid crystal display element including a liquid crystal aligning film containing a polymer having a structure of the following formula [1]. (Y 1 is a single bond, ‑(CH 2 ) a ‑(a is an integer from 1 to 15), ‑O‑, ‑CH 2 O‑,‑COO‑ or OCO‑, Y 2 is a single bond or (CH 2 ) b ‑(b is an integer from 1 to 15), Y 3 is a single bond, ‑(CH 2 ) c ‑(c is an integer from 1 to 15), ‑O‑, ‑CH 2 O‑, ‑COO‑, or OCO‑. Y 4 It is a cyclic group selected from the group consisting of benzene ring, cyclohexane ring and heterocyclic ring (any hydrogen atom on these cyclic groups is optionally replaced by an alkyl group with 1 to 3 carbons, an alkyl group with 1 to 3 carbons alkoxy group, fluorine-containing alkyl group with 1 to 3 carbons, fluorine-containing alkoxy group with 1 to 3 carbons, or fluorine atom substitution.), or selected from organic groups with 12 to 25 carbons having a steroid skeleton The divalent organic group in Y 5 It is a divalent cyclic group selected from the group consisting of benzene ring, cyclohexane ring and heterocycle (any hydrogen atom on these cyclic groups is optionally replaced by an alkyl group with 1 to 3 carbons, 1 ~3 alkoxy, 1-3 carbon fluorine-containing alkyl, 1-3 carbon fluorine-containing alkoxy or fluorine atom substitution.), n in Y 4 When it is a cyclic group selected from the group consisting of benzene ring, cyclohexane ring and heterocycle, it is an integer of 2 to 4, and in Y 4 When it is a divalent organic group selected from organic groups having 12 to 25 carbon atoms having a steroid skeleton, it is an integer of 0 to 4. In addition, when n is greater than 1, multiple Y 5 Each independently has the above-mentioned definition. Y 6 It is an alkyl group having 1 to 18 carbons, a fluorine-containing alkyl group having 1 to 18 carbons, an alkoxy group having 1 to 18 carbons, or a fluorine-containing alkoxy group having 1 to 18 carbons. )

Owner:NISSAN CHEM IND LTD

Thin film transistor, array substrate, manufacturing method and display device

ActiveCN103219392BPrevent bridgingImprove yieldTransistorSolid-state devicesDisplay deviceEngineering

Owner:HEFEI BOE OPTOELECTRONICS TECH +1

Light source module assembly and light-emitting device

InactiveCN103123051AReduce bright spotsReduce light leakageMechanical apparatusElectric lightingLight guideLight emitting device

The invention provides a light source module assembly which includes a shell body and a light source. The shell body is provided with a transparent light-emitting side which is arranged at the position corresponding to the light source. A microstructure is arranged on the outer surface of the transparent light-emitting side away from the light source, and the microstructure includes plural first light-guiding cylinders and plural second light-guiding cylinders which are protruded relatively to the outer surface. The first light-guiding cylinders are arranged in the middle of the outer surface, and the second light-guiding cylinders are arranged on both sides of the first light-guiding cylinders. The first light-guiding cylinders and the second light-guiding cylinders extend along the outer surface and are perpendicular to each other. The first light-guiding cylinders and the section perpendicular to an extension direction are in a semicircular shape, and the second light cylinder and the section perpendicular to the extension direction are in a triangular shape. The invention further discloses a light emitting device which utilizes the light source module.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Novel methacrylic resin extrusion plate and manufacturing method thereof

InactiveCN101035666AImprove luminous efficiencyReduce bright spotsFlat articlesOptical light guidesDisplay deviceLightness

Extrusion molding is performed by using a methacrylic resin extrusion plate having a plate thickness of 2.0 to 15.0 mm and formed by a mixture having an apparent density of 0.80 g / ml or above prepared by mixing spherical methacrylic resin polymer having an apparent density of 0.70 g / ml to 0.78 g / ml and cylindrical methacrylic resin polymer having an apparent density of 0.63 g / ml to 0.70 g / ml and / or flat methacrylic resin polymer having an apparent density of 0.63 g / ml to 0.70 g / ml. The brightness uniformity is controlled to be 80% or above and the plate thickness accuracy in the width direction is controlled to be within +-1.0% of the average plate thickness. There is provided a methacrylic resin extrusion plate for a light guide plate which can be preferably used for office automation devices such as a personal computer and a word processor, display devices used for various monitors displaying an image signal such as a panel monitor and a television monitor, display devices used for indoor or outdoor illumination devices and sign boards.

Owner:ASAHI KASEI CHEM CORP

Light source device

InactiveCN102966862BReduce local color castReduce bright spotsElectric lightingPlanar/plate-like light guidesLight guideLight beam

A light source device includes a first light-emitting element providing illumination beams, a light guide plate (LGP) divided into light-transmissive regions, an optical thin film, and microstructures. The LGP has a first surface, a second surface opposite to the first surface, and a first light-incident surface connecting the first and second surfaces. The first light-emitting element is beside the first light-incident surface. The illumination beams are capable of entering the LGP through the first light-incident surface. The optical thin film is on the second surface of the LGP. The optical thin film has different thicknesses corresponding to at least two of the light-transmissive regions. The microstructures are on the optical thin film. When the illumination beams pass through the light-transmissive regions corresponding to the different thicknesses of the optical thin film and leave the LGP through the first surface, the illumination beams are converted into color beams with different wavelengths.

Owner:CORETRONIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com