Fastened round LED lamp

A technology of LED circular lamp and LED lamp board, which is applied in lighting and heating equipment, instruments, mechanical equipment, etc., can solve the problems of complicated production of rectangular lamp frame, low coupling efficiency, waste of light source, etc., so as to improve the utilization rate of light source. , The effect of improving the coupling efficiency and simplifying the connection structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

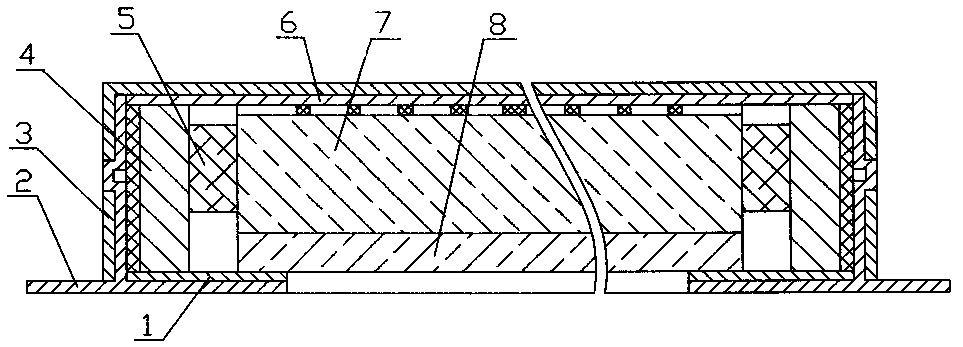

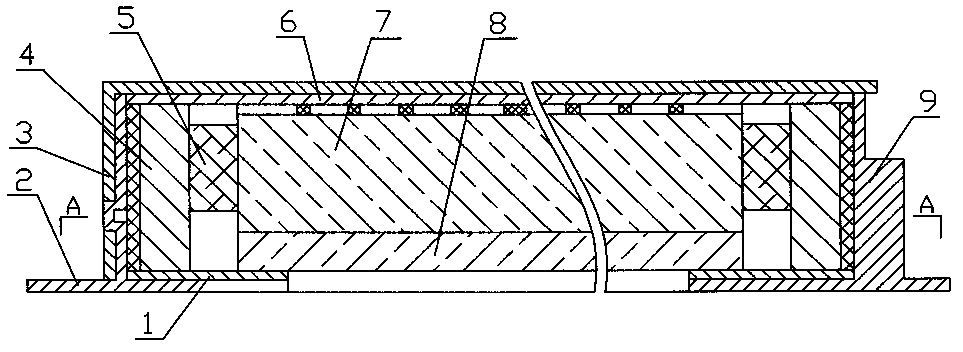

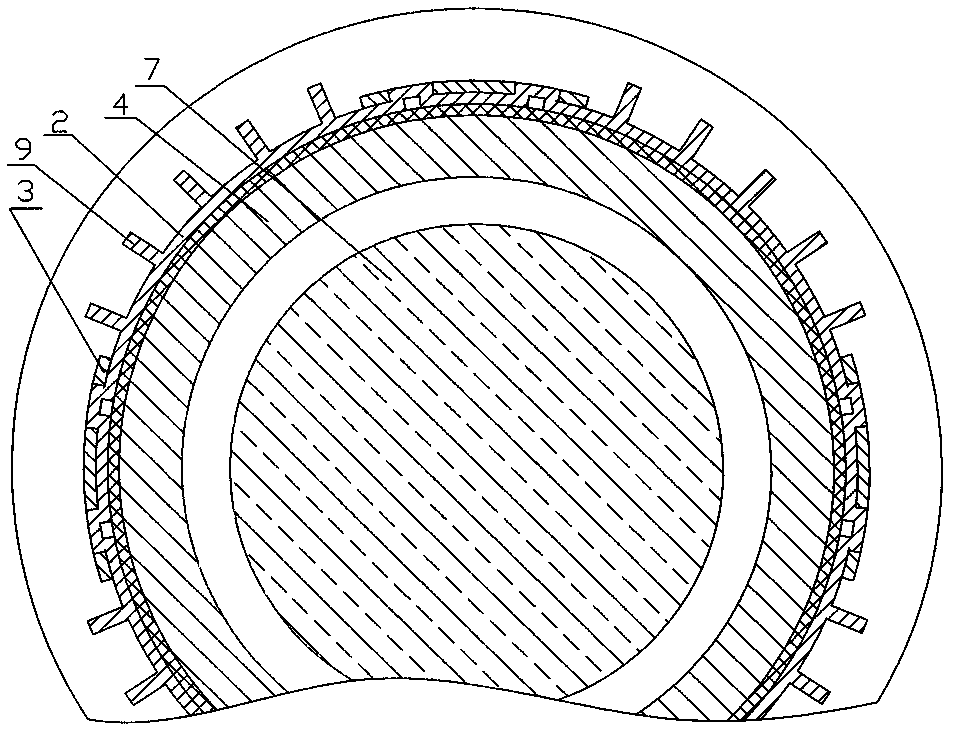

[0013] The structure of the first scheme of the present invention is: comprising a lamp frame 2, an LED lamp board 5, a top board 3, a top reflection layer, a light guide plate 7, a diffusion film 8, a circuit board 4, lead wires, and a power converter, and is characterized in that: Frame 2 is an annular body with an inverted "T" shape in cross-section. Several rectangular boss buckles are evenly distributed on the outer wall of the longitudinal ring plate around the annular body. The top plate 3 is in the shape of a barrel with the opening facing downward. A rectangular hole corresponding to the rectangular boss buckle of the lamp frame 2 is provided on the top; a corresponding circular disk-shaped reflective layer 1 is arranged on the plane of the inner circular disk plate at the bottom of the lamp frame 2, and the circular disk-shaped reflective layer 1 above the lamp frame 2 The inner wall of the longitudinal ring plate is bonded with a circuit board 4; the circuit board 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com