Light source module assembly and light-emitting device

A light source module and light emitting device technology, which is applied in the direction of light source, electric light source, lighting device, etc., can solve the problems of light leakage and brightness reduction of light emitting devices, and achieve the effect of reducing bright spots and light leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

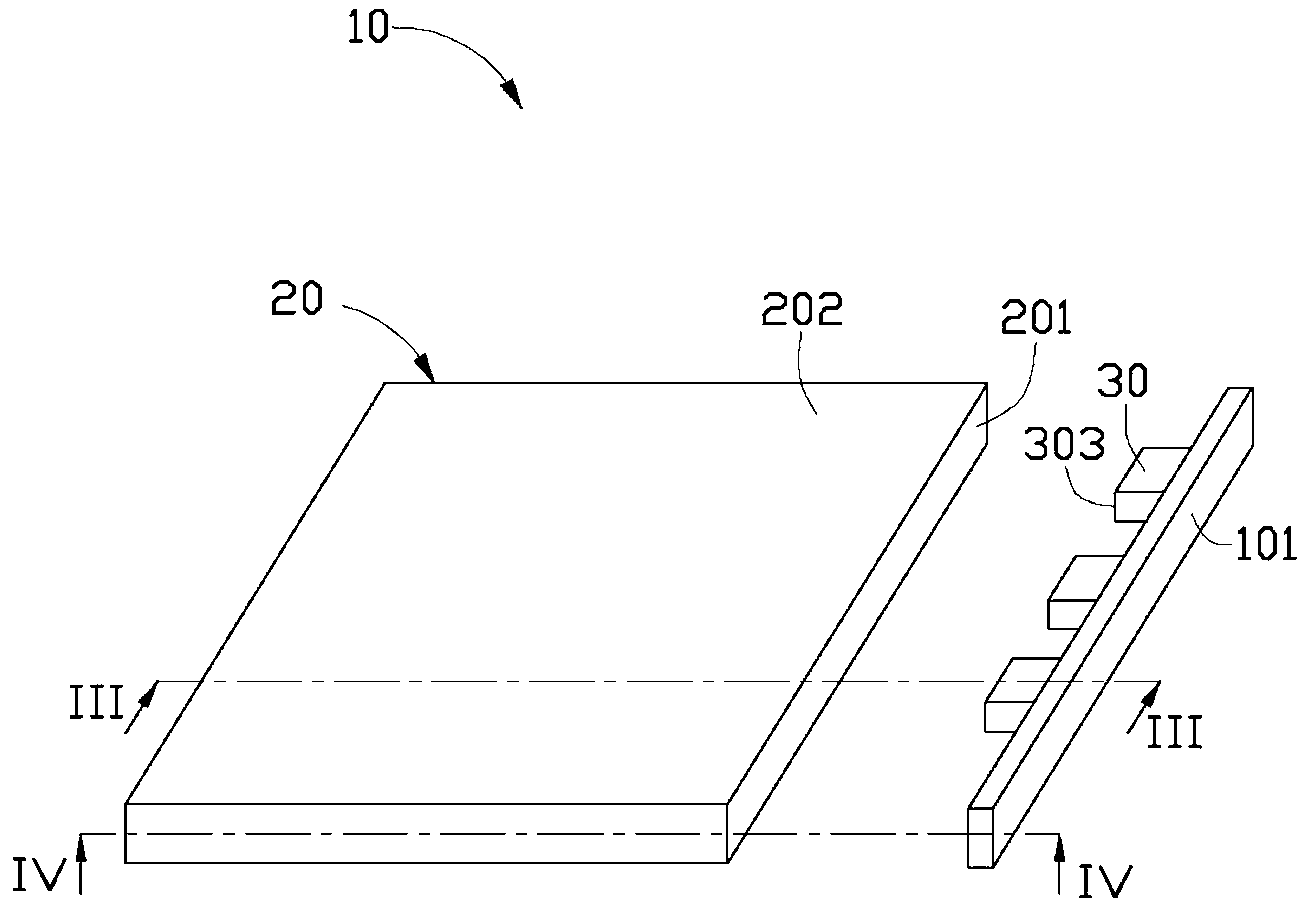

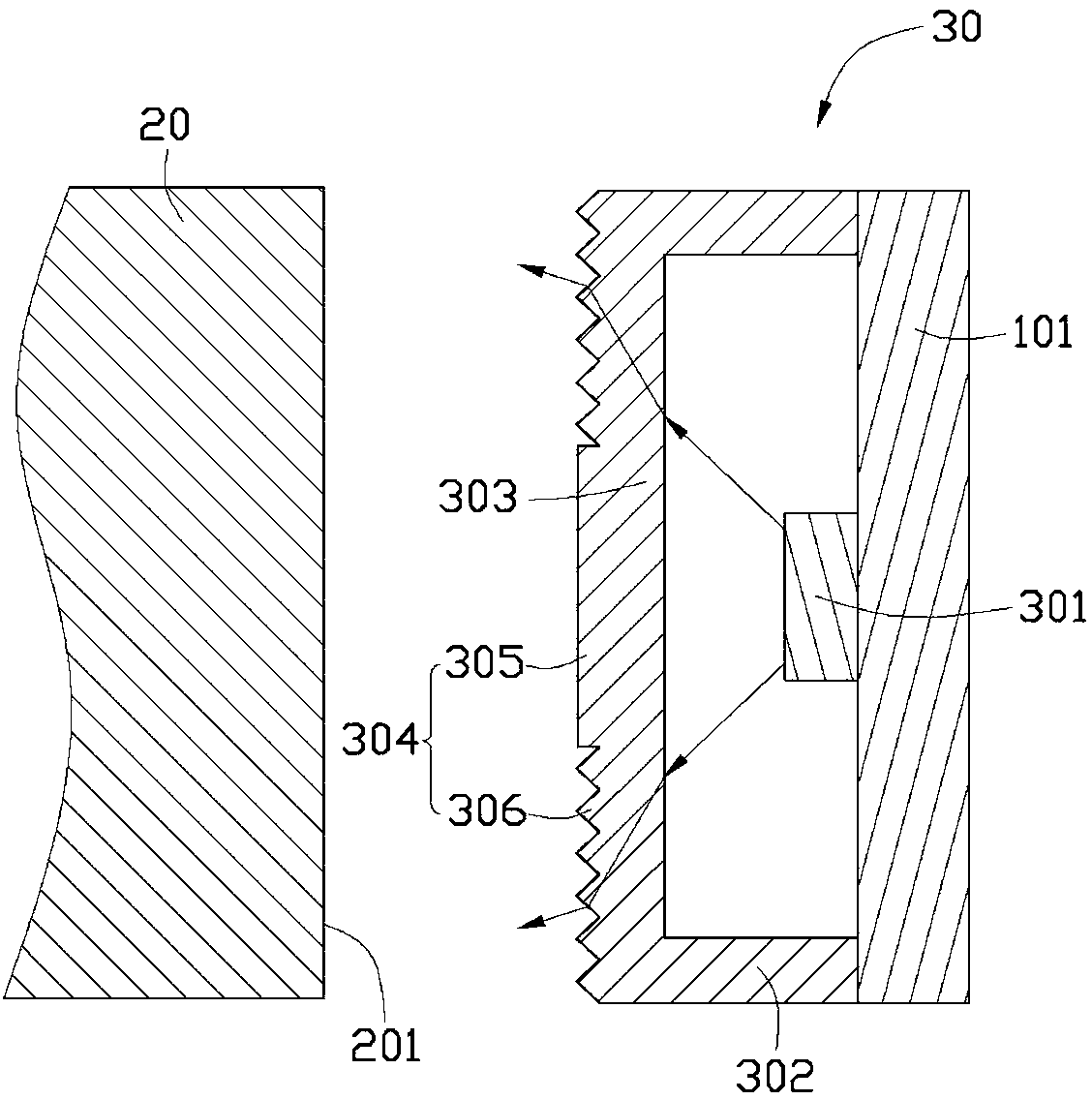

[0016] see figure 1 , the embodiment of the present invention provides a light-emitting device 10, the light-emitting device 10 includes a light guide plate 20, the light guide plate 20 is made of PMMA, PC plastic or other transparent materials, and its refractive index range is 1.47 ~ 1.55, the light guide plate 20 includes a light incident surface 201 and a light exit surface 202. In this embodiment, the light incident surface 201 and the light exit surface 202 intersect perpendicularly. The light incident surface 201 is the side of the light guide plate 20 with a small area. The light emitting surface 202 is a top surface with a larger area of the light guide plate 20 .

[0017] The lighting device 10 also includes a plurality of light source modules 30. In this embodiment, three light source modules are taken as an example. Glossy 201.

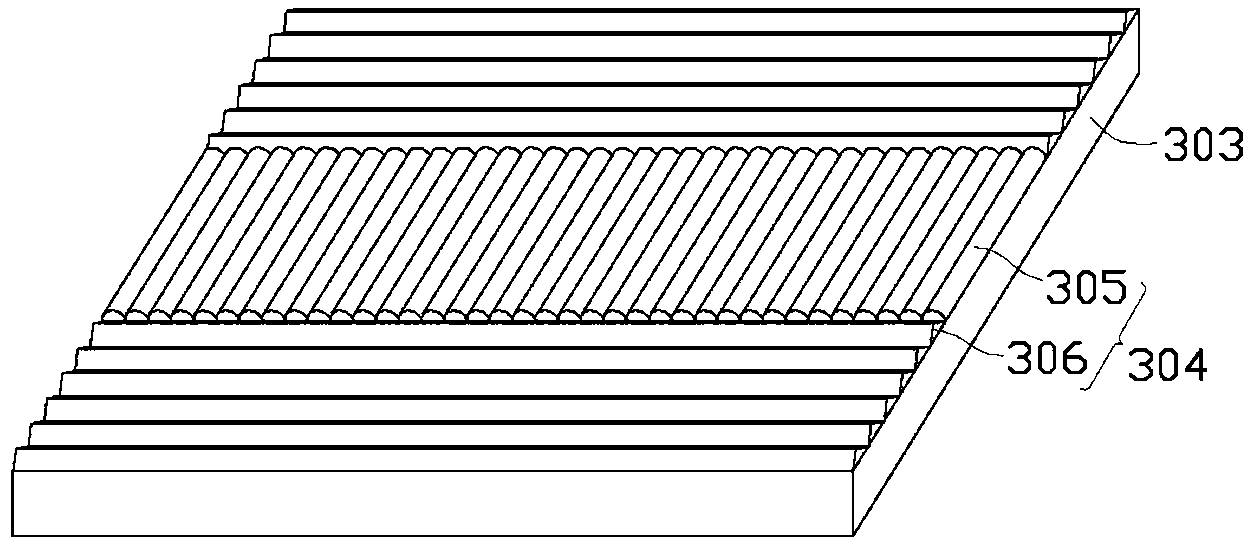

[0018] see Figure 2 to Figure 4 , each light source module 30 includes a light source 301 and a housing 302 , the material of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com