Novel methacrylic resin extrusion plate and manufacturing method thereof

A technology of methacrylic acid and shape methacrylic acid, which is applied in the field of methacrylic resin extruded plates for light guide plates, which can solve the problems of small changes in plate thickness, lack of high brightness, and poor brightness uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

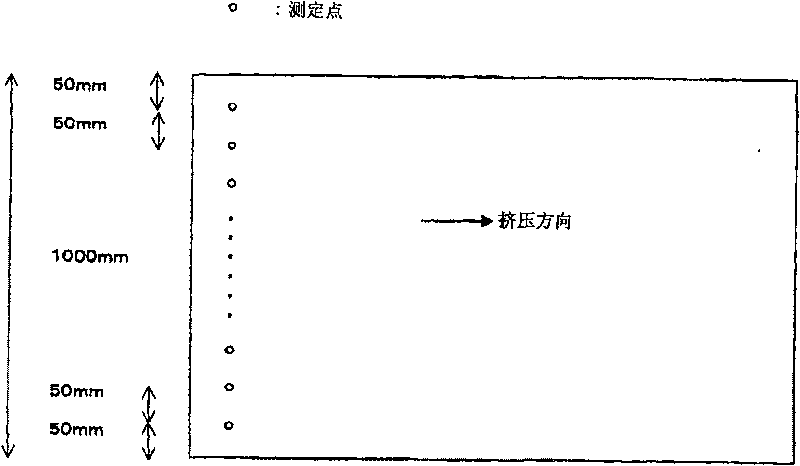

[0082] Using a 150mmΦ single-screw extruder (barrel temperature: 200°C-210°C-210°C-260°C-260°C-240°C from the supply side) with a T-die for plates (die temperature: 250°C), 3 polishing rolls (roller temperature: 80 ℃) that are adjusted temperature, and the extruded plate forming machine that traction device is formed, with the mixture of the polymer-A of 50 weight parts and the polymer-C of 50 weight parts (table The apparent density is 0.88g / ml) and extruded with an extrusion rate of 600Kg / hr to obtain a methacrylic resin extruded sheet (extruded sheet-A) with a width of 1000mm and a thickness of 6mm. right figure 1 The indicated thickness measurement points were measured, and the plate thickness accuracy was calculated. The results are shown in Table 1.

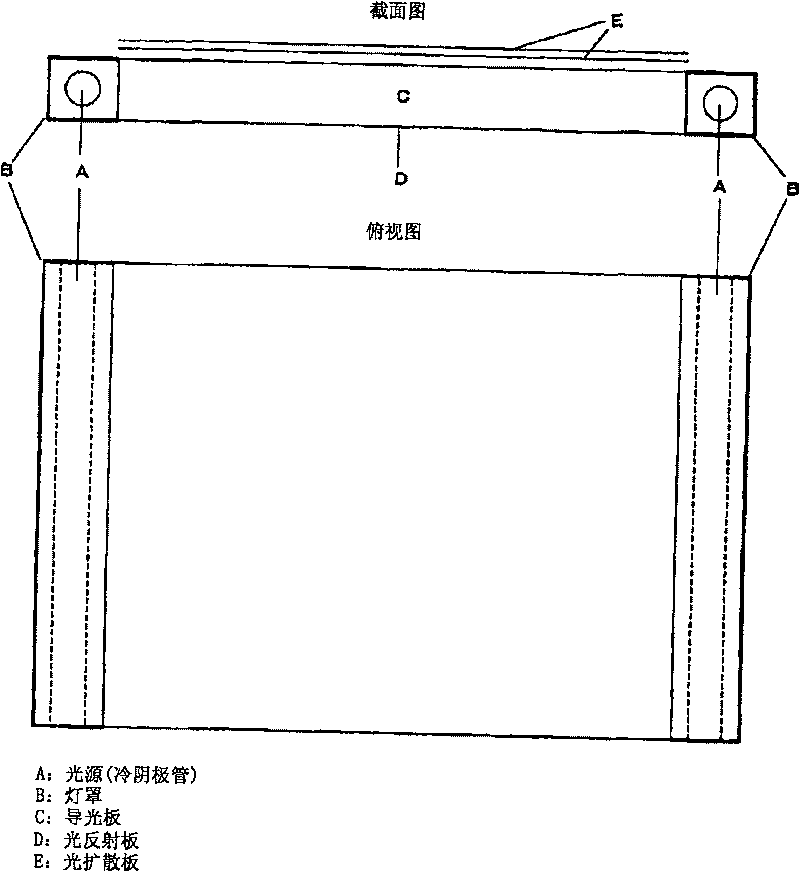

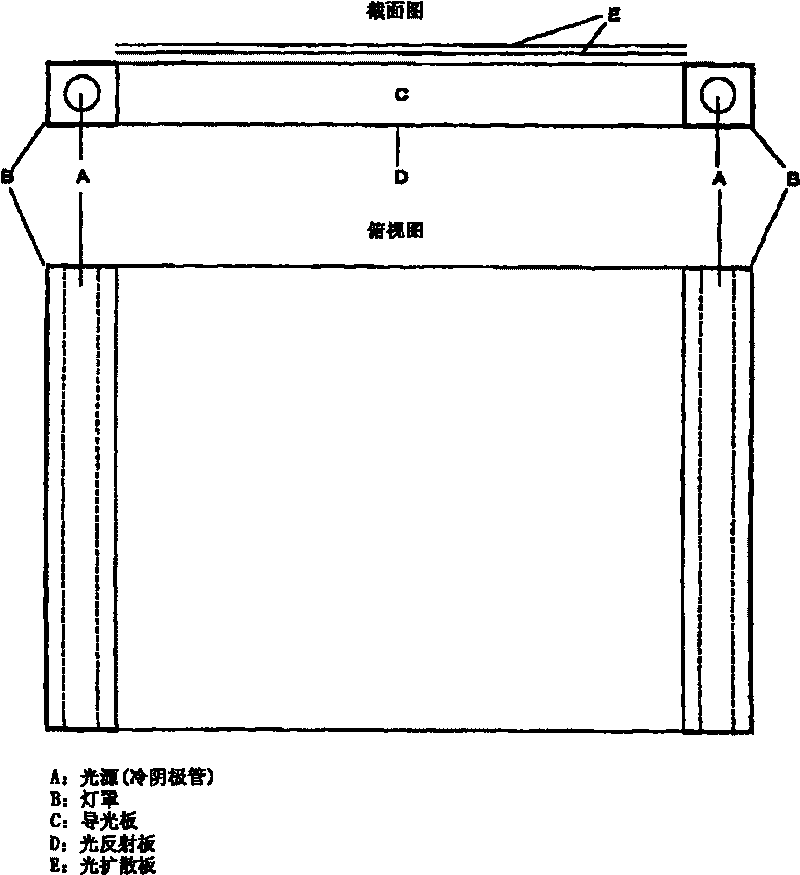

[0083] Next, the obtained extruded board was cut into a size with a width of 241 mm and a length of 319 mm with a circular saw, and then the cut surface of the cut board was ground with a precision grinder (PLA-BEAUTY: man...

Embodiment 2

[0087] Except that the mixing amount of the polymer used is 80 parts by weight of the polymer-A and the mixture of the polymer-C of 20 parts by weight (the apparent density is 0.82g / ml), operate in the same way as in Example 1 to obtain extrusion Board-D. The same measurement as in Example 1 was performed, and the results are shown in Table 1.

Embodiment 3

[0089] Except that the mixing amount of the polymer used is 20 parts by weight of the polymer-A and the mixture of the polymer-C of 80 parts by weight (the apparent density is 0.81g / ml), operate in the same way as in Example 1 to obtain extrusion Board-E. The same measurement as in Example 1 was performed, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com