Light distribution lens and lighting device adopting same

A light distribution lens and lens technology, which is applied in the field of optical lenses, can solve the problems of large optical aperture and optical height of the lens structure, weak control ability of light and large-angle light, and difficulty in ensuring lighting effects, etc., to achieve uniform wall thickness and ensure design Lighting effect, effect of good lighting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

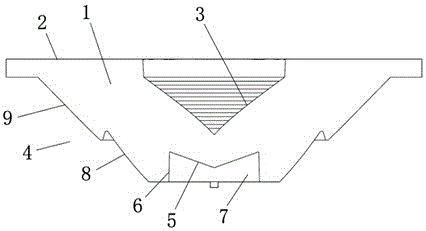

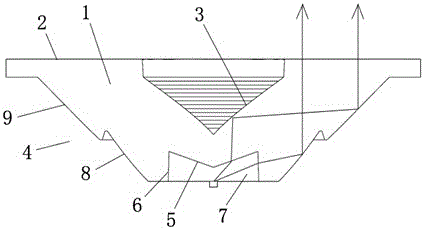

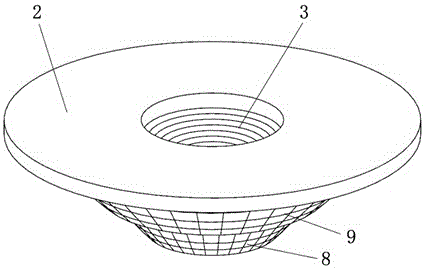

[0041] Embodiment 1: as Figure 1-4 as shown,

[0042] An LED light distribution lens, including a lens body 1, the lens body 1 is provided with an incident area 7 for light entering the interior of the lens, a light exit area 2 for emitting light inside the lens, and a In the reflection area 4 between the areas 2, the lens body 1 is also provided with a central reflection area 3. In the light emitted by the light source, the light in the central part is a small-angle light, and the light in the peripheral part of the light is a large-angle light. The small-angle light is refracted from the incident area 7 into the lens body 1 and then directly irradiates on the central reflection area 3, is reflected by the central reflection area 3 to the reflection area 4, is reflected by the reflection area 4 to the light output area 2, and then refracted Out of the lens body 1, at least a part of the large-angle light is refracted from the incident area 7 into the lens body 1 and directl...

Embodiment 2

[0049] Example 2, such as Figure 1-4 as shown,

[0050] The incident area 7 includes a first incident area 5 and a second incident area 6. The small-angle light rays enter the lens body 1 from the first incident area 5 and then irradiate on the central reflection area 3; the large-angle light rays pass through the second incident area. 6 enters the lens body 1 and irradiates on the reflection area 4 .

[0051] In the above scheme of this embodiment, the incident area 7 is set to include the first incident area 5 and the second incident area 6, the central part of the light emitted by the light source, that is, the small-angle light is irradiated on the first incident area 5, and the large Angled light irradiates on the second incident region 6, and the small-angle and large-angle parts of the light emitted by the light source are refracted into the lens through different regions, which further improves the light control ability of the lens structure of this embodiment.

[0...

Embodiment 3

[0055] Example 3, such as Figure 1-4 as shown,

[0056] The reflective area 4 includes a first reflective area 8 and a second reflective area 9 arranged in a stepped structure, the first reflective area 8 is close to the incident area 7, the second reflective area 9 is close to the light output area 2, and small-angle light rays Reflected from the central reflection area 3 to the second reflection area 9, and then reflected to the exit area by the second reflection area 9; after the large-angle light is refracted from the second incident area 6 into the lens body 1, it is irradiated on the first On the reflective area 8, it is reflected by the first reflective area 8 to the output area.

[0057] In the above solution, the reflective area 4 includes the first reflective area 8 and the second reflective area 9, which control the small-angle light and the large-angle light entering the lens respectively, further improving the control ability of the lens structure on the light, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com