Oil field routing inspection fixed-point data acquisition system and method based on multiple unmanned aerial vehicles

A fixed-point data and multi-drone technology, applied in the direction of location information-based services, specific environment-based services, control/regulation systems, etc., can solve problems such as huge costs, power consumption, and damage to collection or storage equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

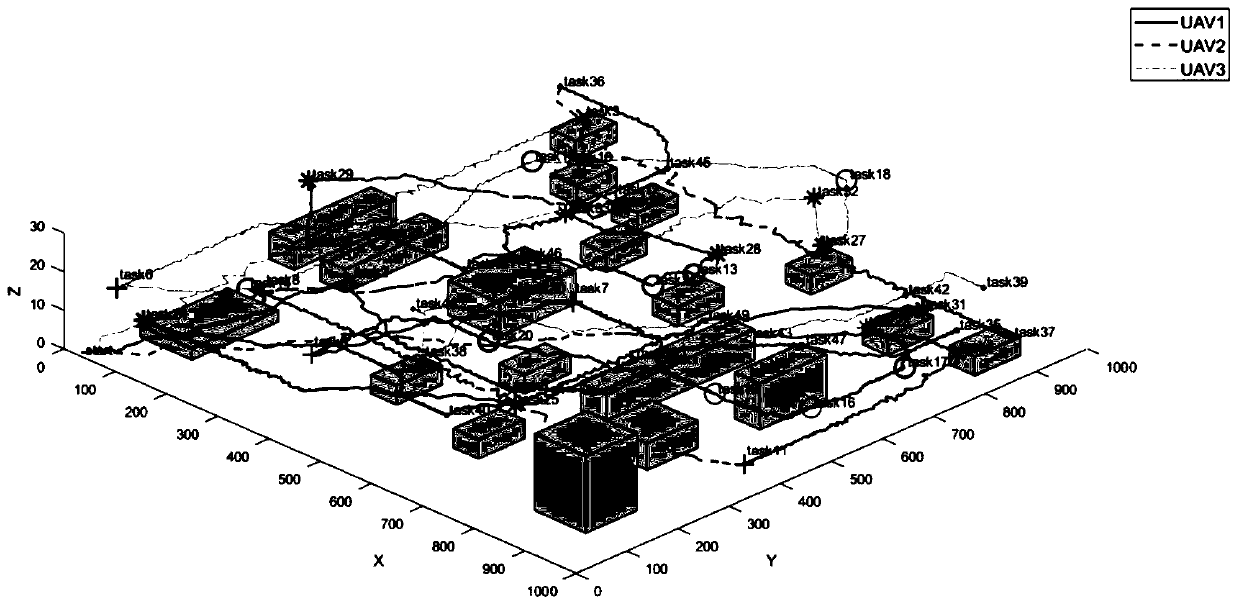

[0049] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

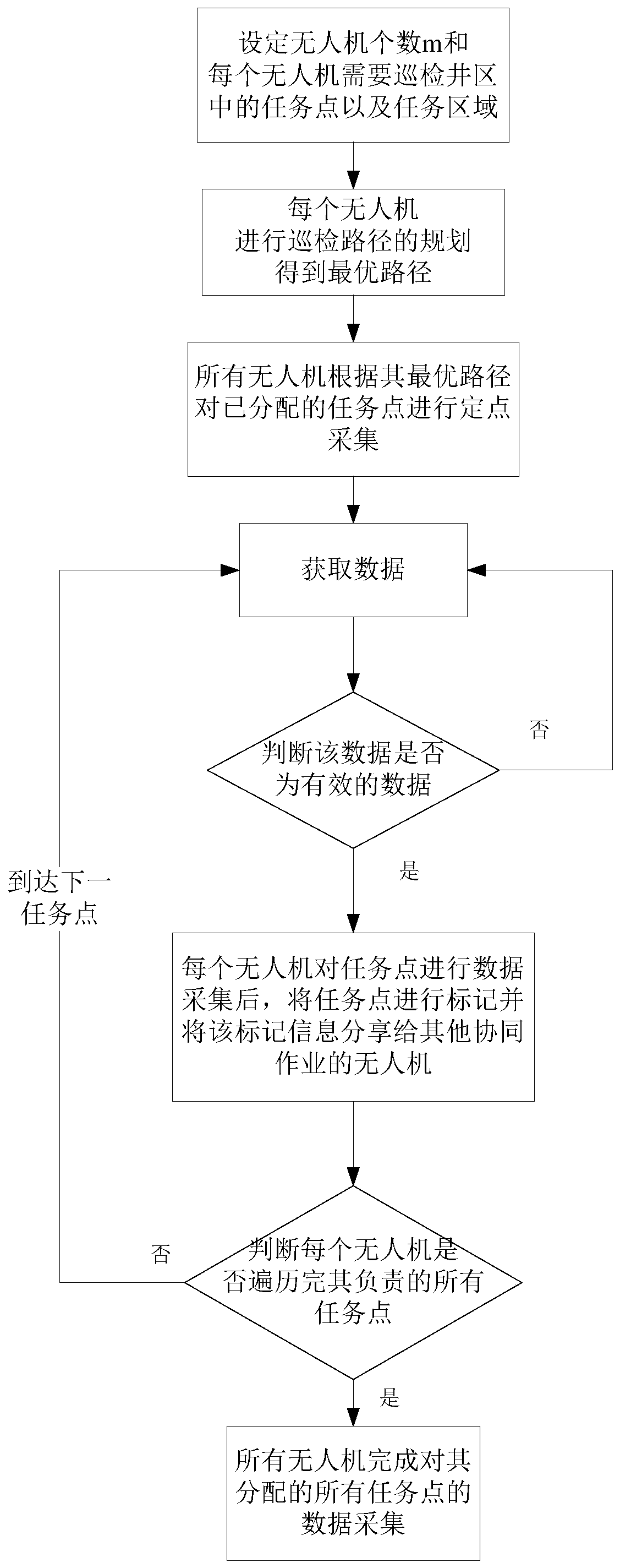

[0050] The method of this example is as follows.

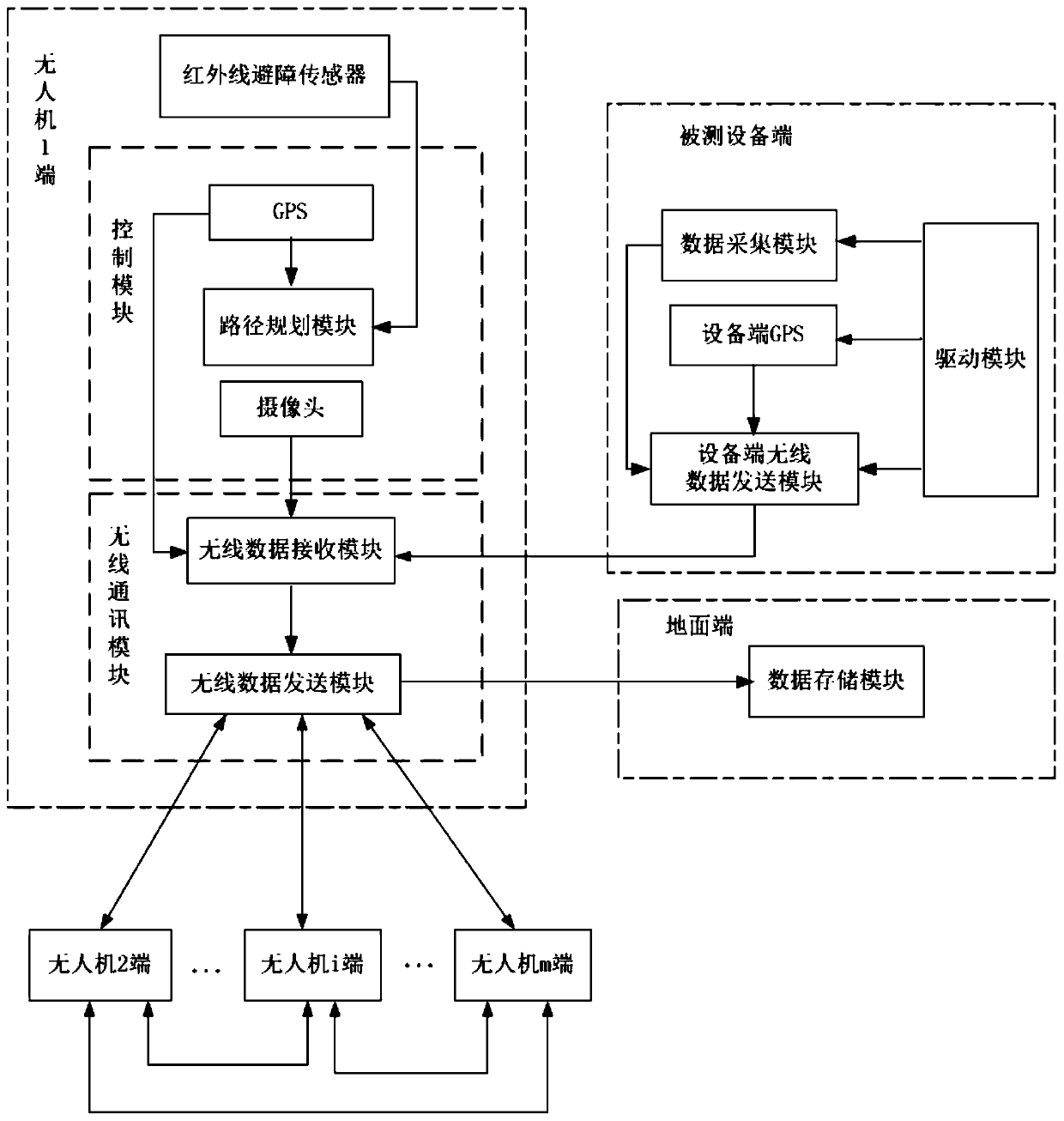

[0051] On the one hand, the present invention provides a fixed-point data acquisition system for oil field inspection based on multiple UAVs, such as figure 1 As shown, including multiple drone terminals, multiple device terminals under test, and ground terminals;

[0052] Each of the unmanned aerial vehicles includes an infrared obstacle avoidance sensor, a control module, and a wireless communication module; the infrared obstacle avoidance sensor is arranged on the unmanned aerial vehicle, and its output terminal is connected with the control module; the control module includes an unmanned drone GPS, path planning modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com