Patents

Literature

32 results about "Tribometer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A tribometer is an instrument that measures tribological quantities, such as coefficient of friction, friction force, and wear volume, between two surfaces in contact. A tribotester is the general name given to a machine or device used to perform tests and simulations of wear, friction and lubrication which are the subject of the study of tribology. Often tribotesters are extremely specific in their function and are fabricated by manufacturers who desire to test and analyze the long-term performance of their products. An example is that of orthopedic implant manufacturers who have spent considerable sums of money to develop tribotesters that accurately reproduce the motions and forces that occur in human hip joints so that they can perform accelerated wear tests of their products.

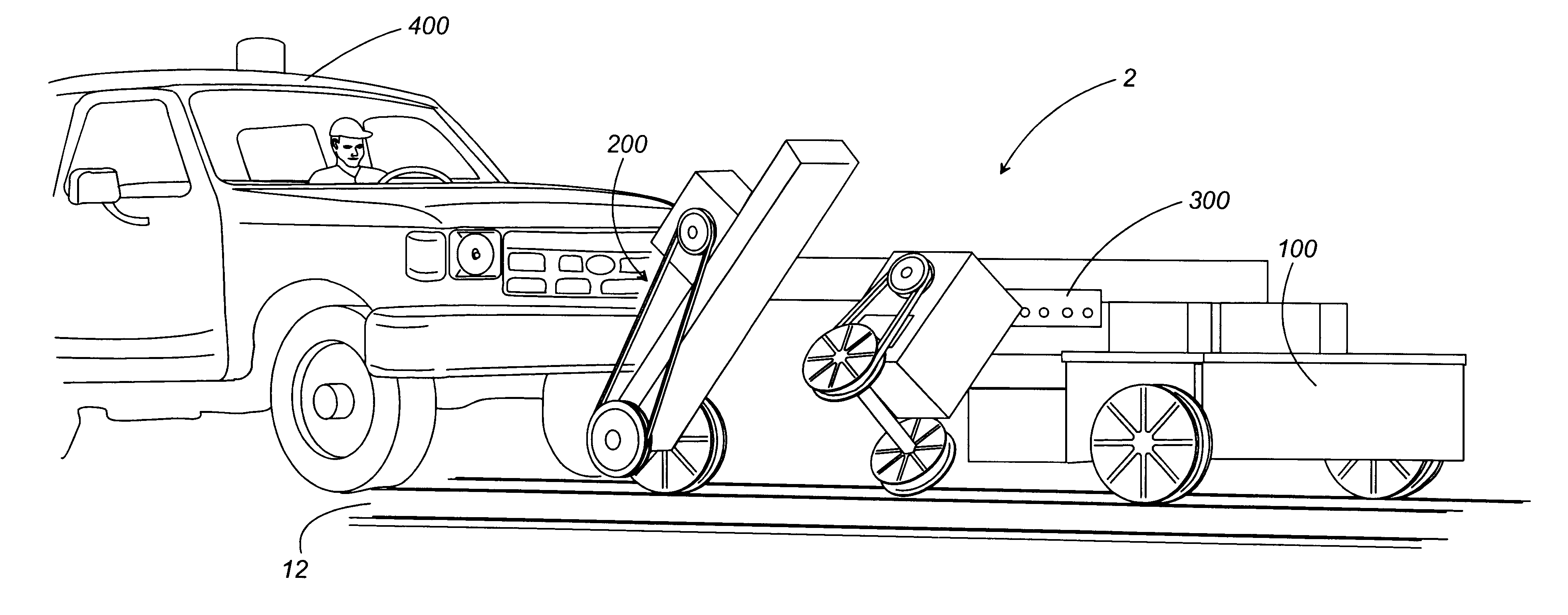

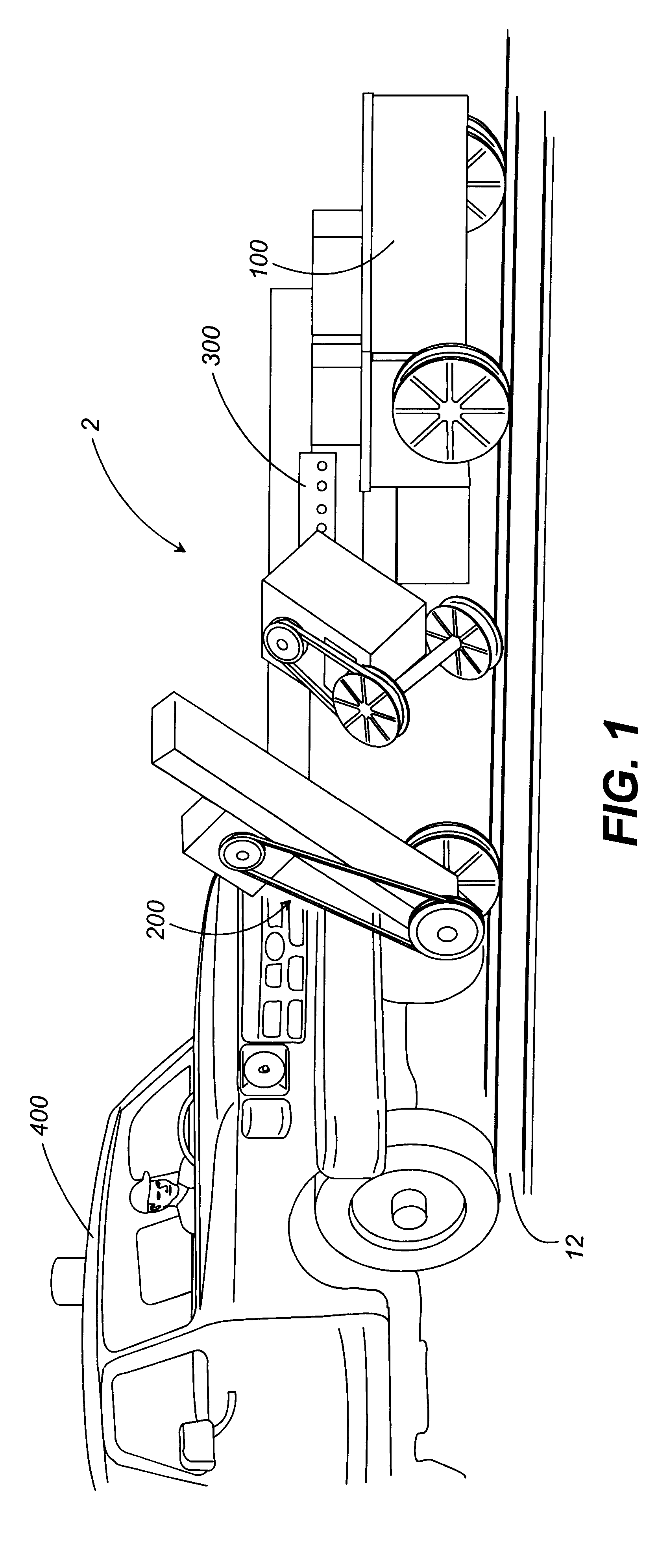

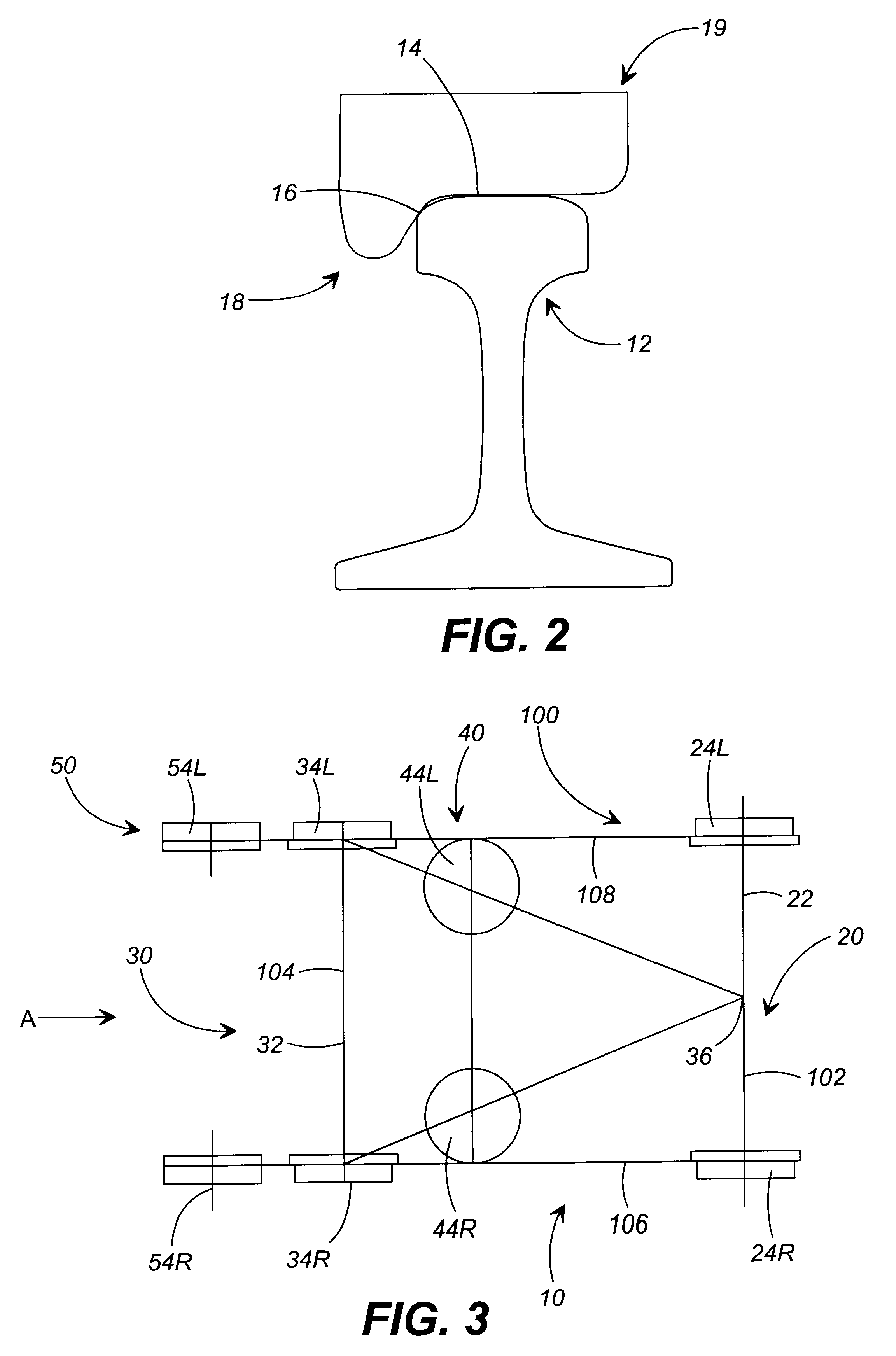

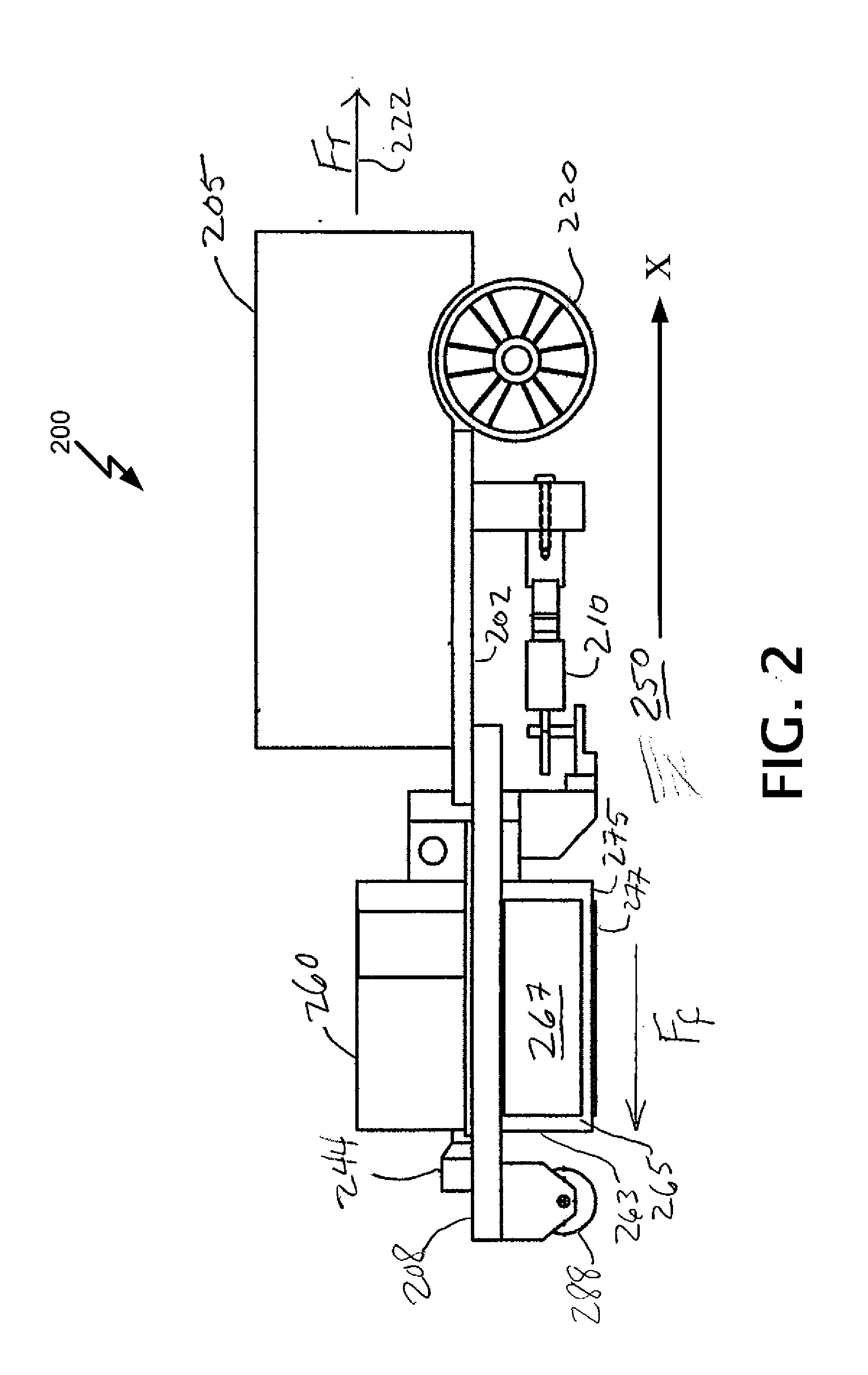

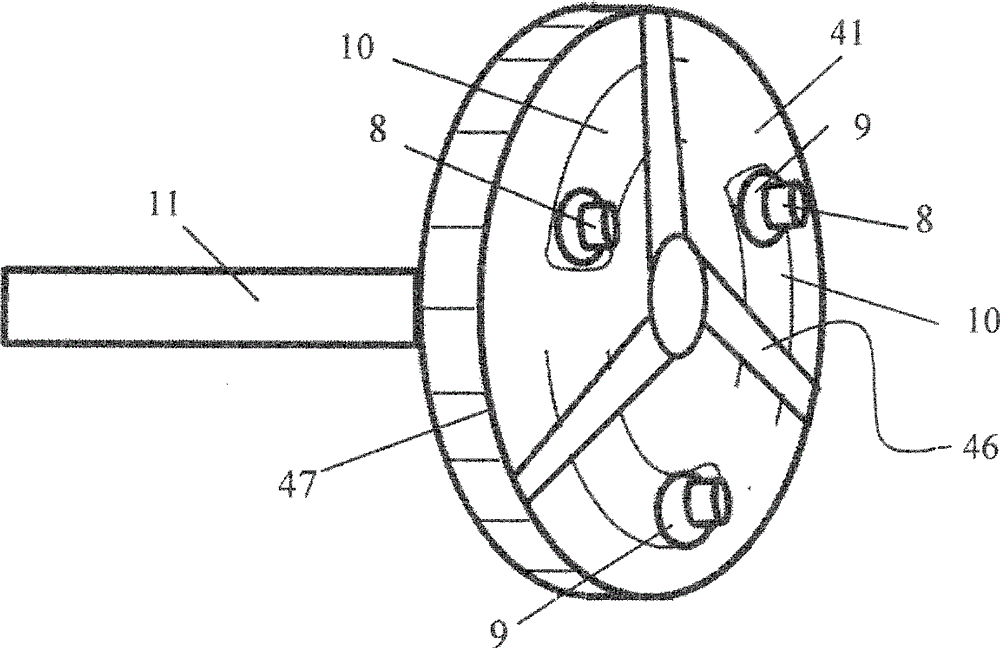

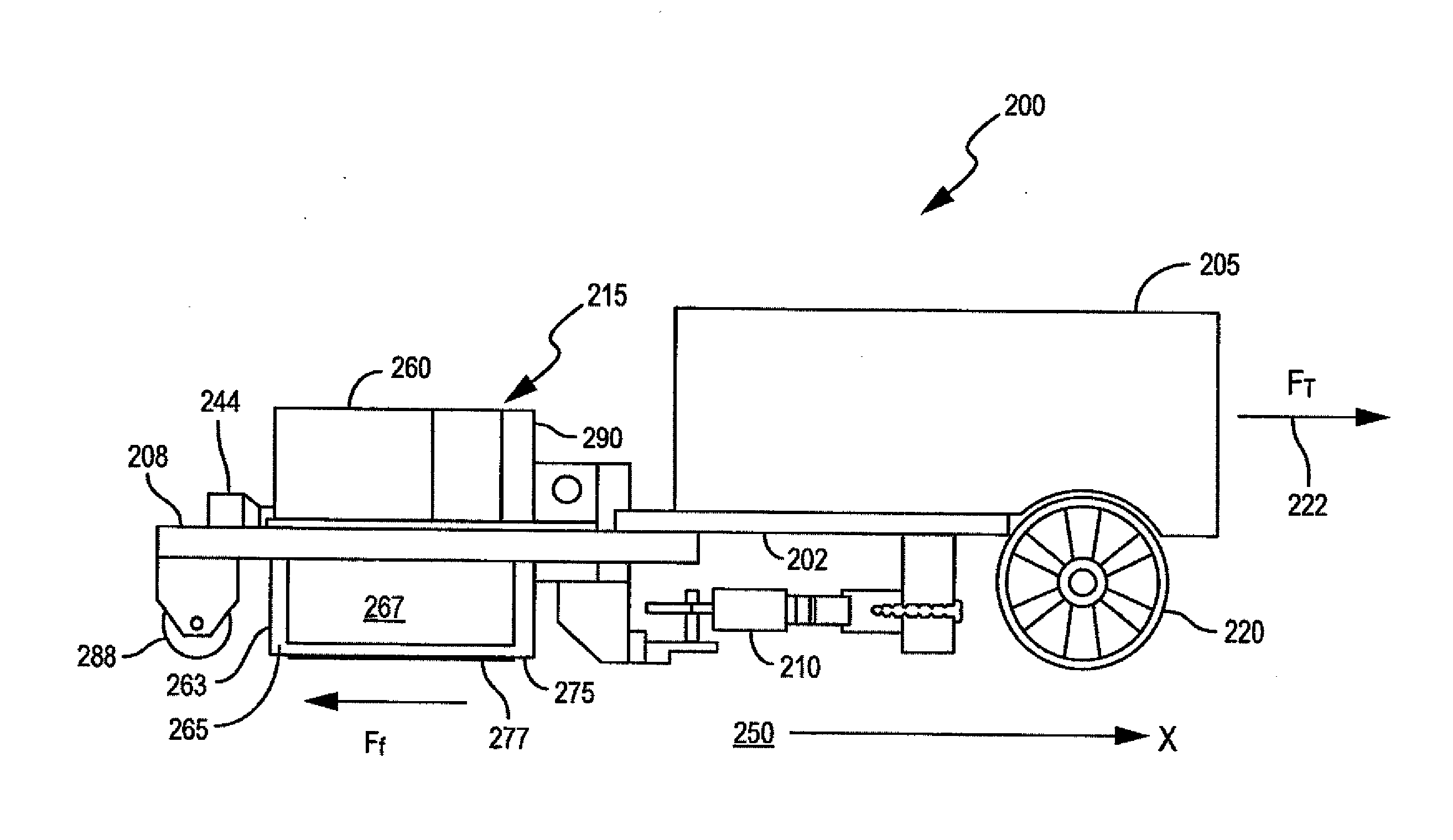

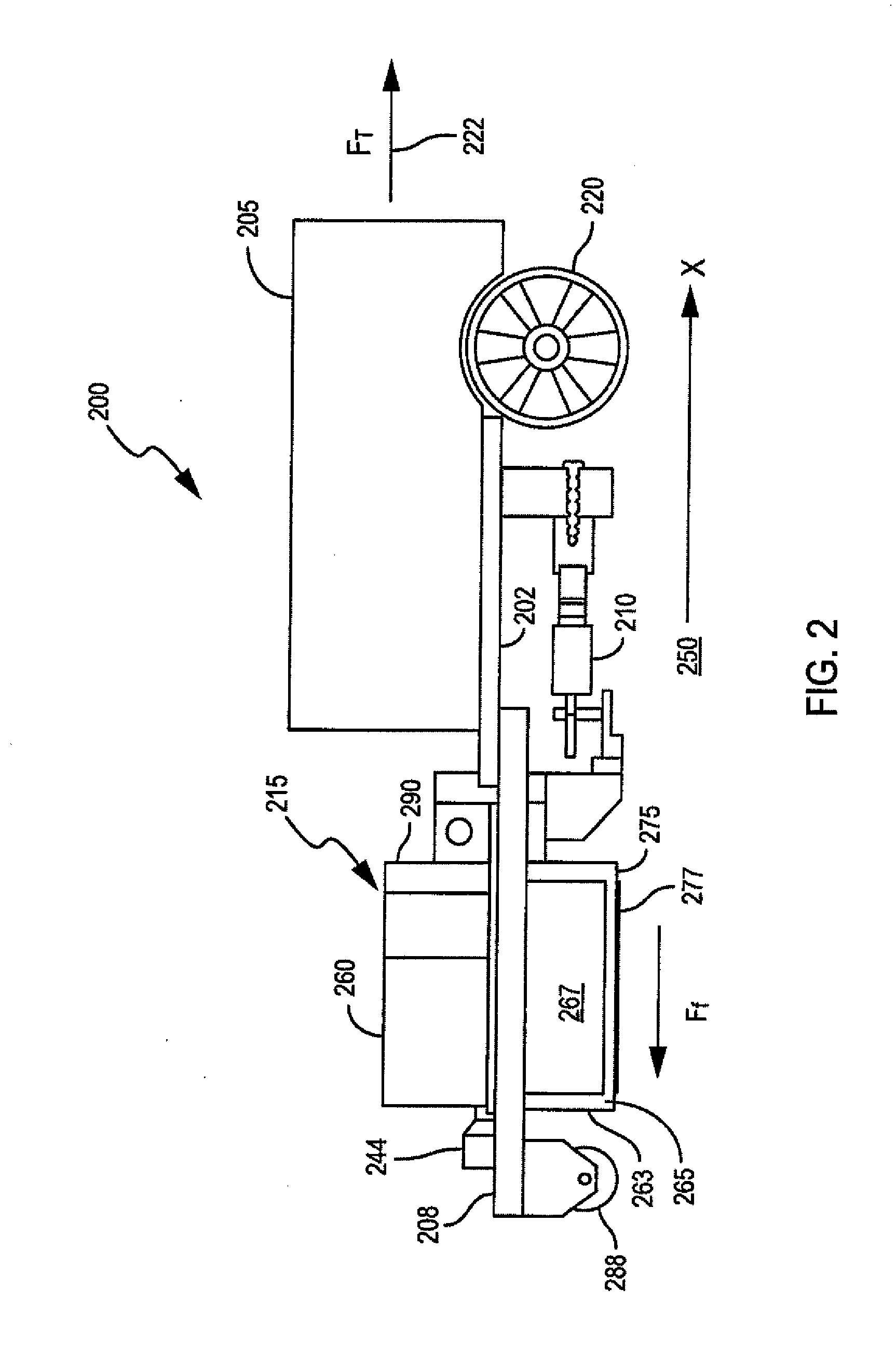

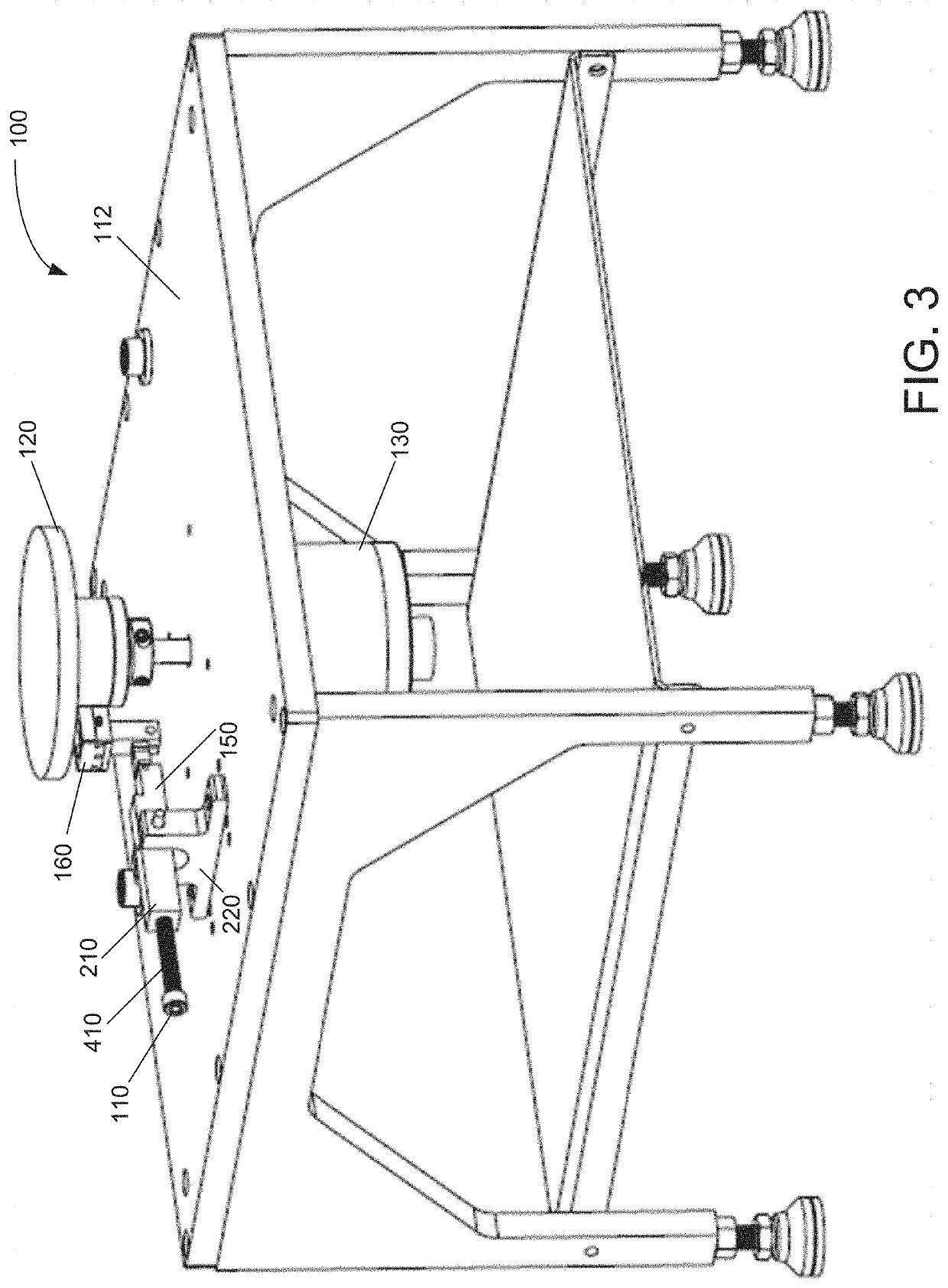

Tribometer for testing the efficiency of lubrication upon a railroad track surface

InactiveUS6192736B1Reduce capacityReduce frictionMeasurement/indication equipmentsRailway auxillary equipmentMechanical engineeringLubrication

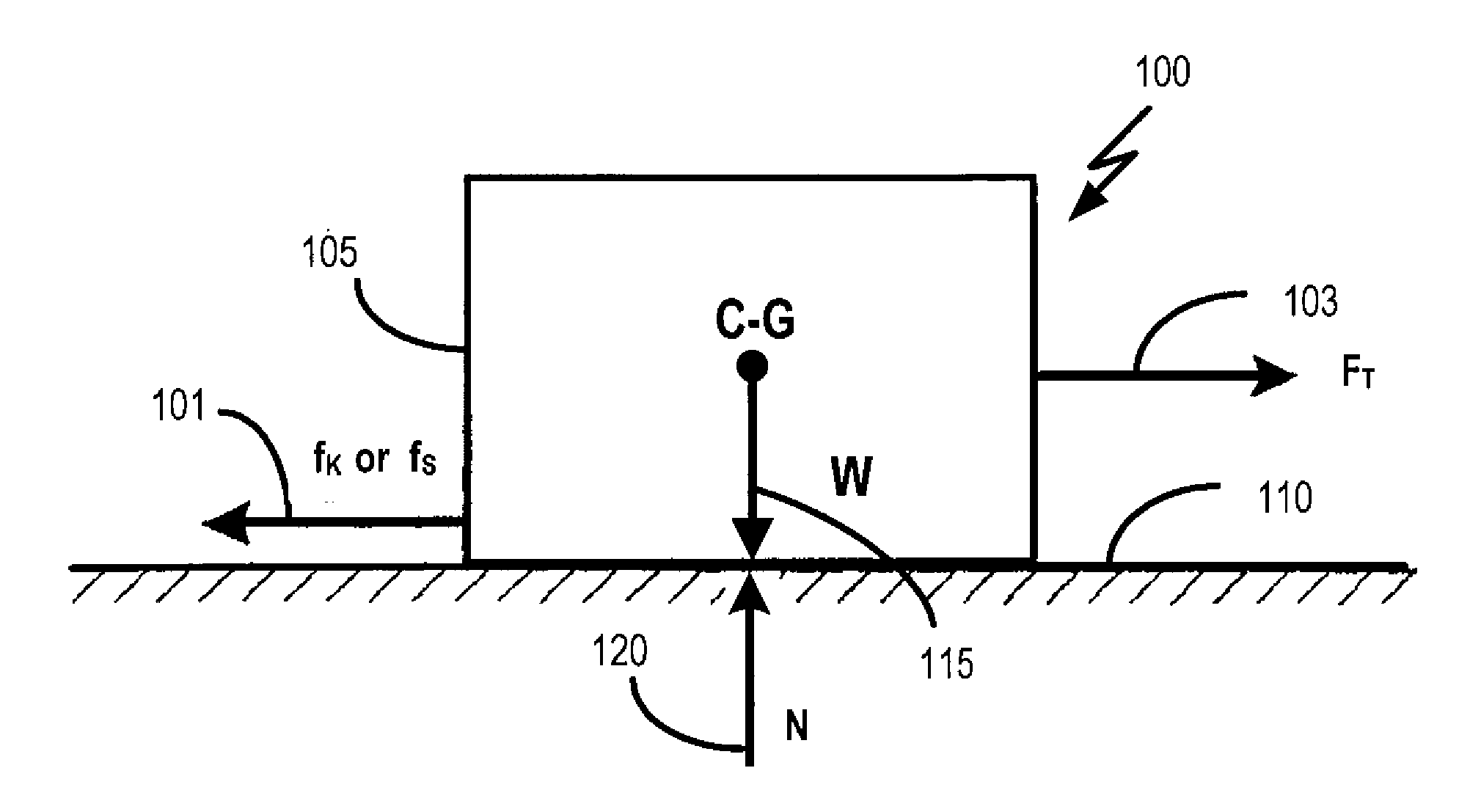

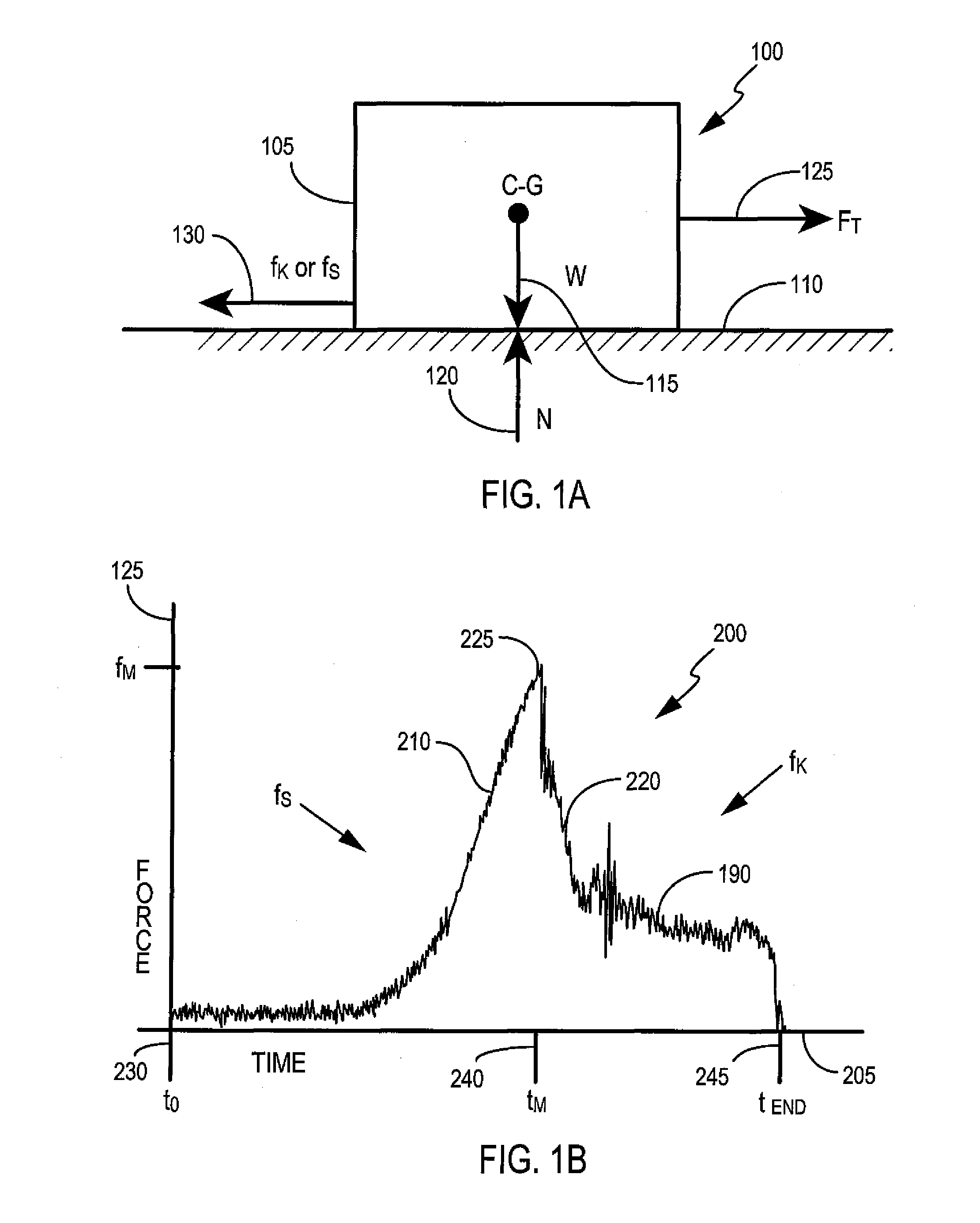

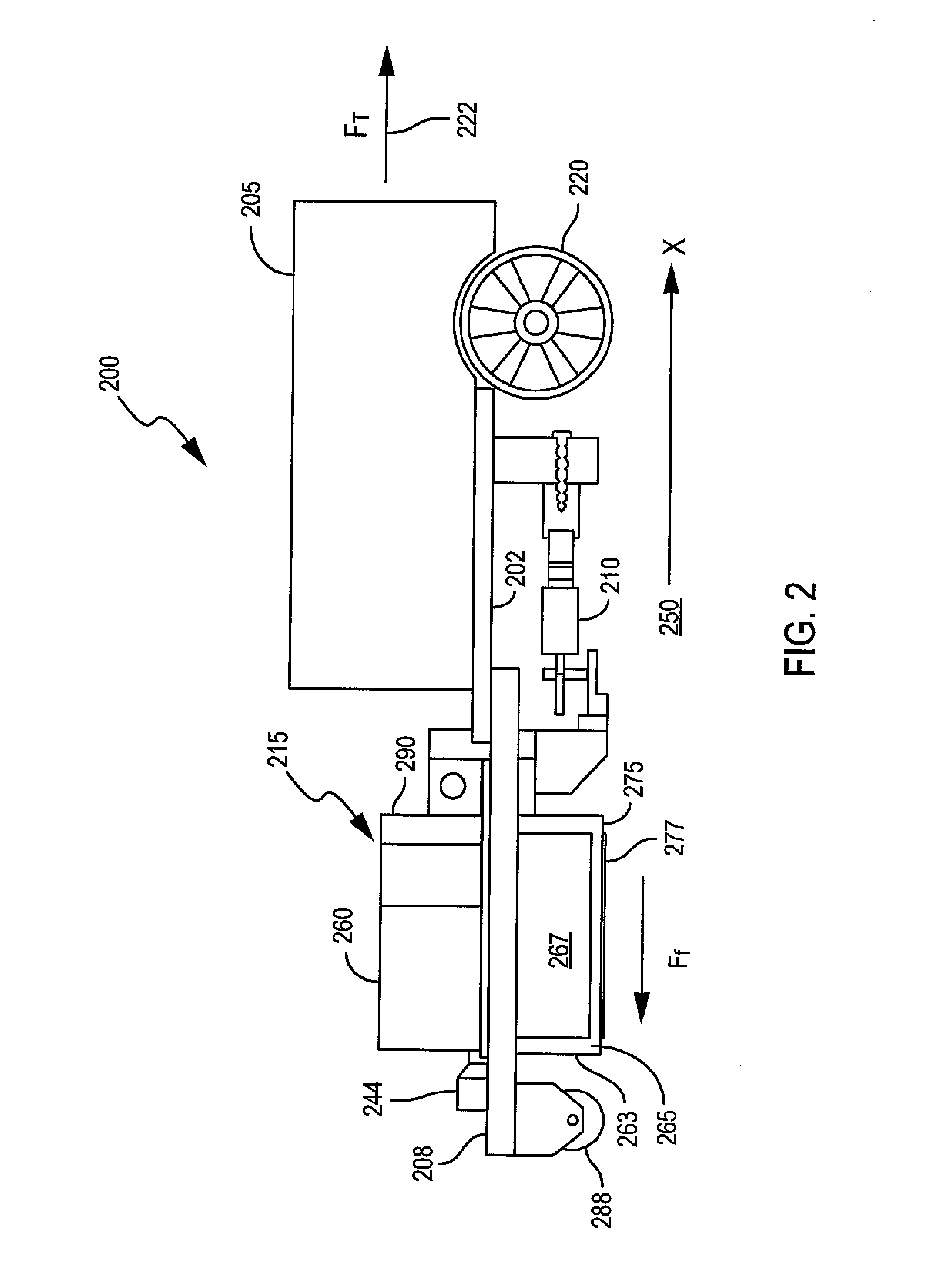

An automated tribometer for measuring the coefficient of friction of the tread and gauge surfaces of railroad rail is disclosed. A tribometer is provided that is pushed in front of a high-rail vehicle, wherein during operation, the tribometer extends a rail test assembly to contact the surfaces of the rail. The rail test assembly has a rail testing wheel that is urged towards contact with the rail to be tested, and eventually contacts the rail, and lastly applies a known load to the rail. The testing wheel is then dynamically braked to slow the testing wheel to the point of creepage. The automated tribometer then can calculate the coefficient of friction of the rail.

Owner:DIVERSIFIED METAL FABTORS

Intrinsically-calibrated tribometer

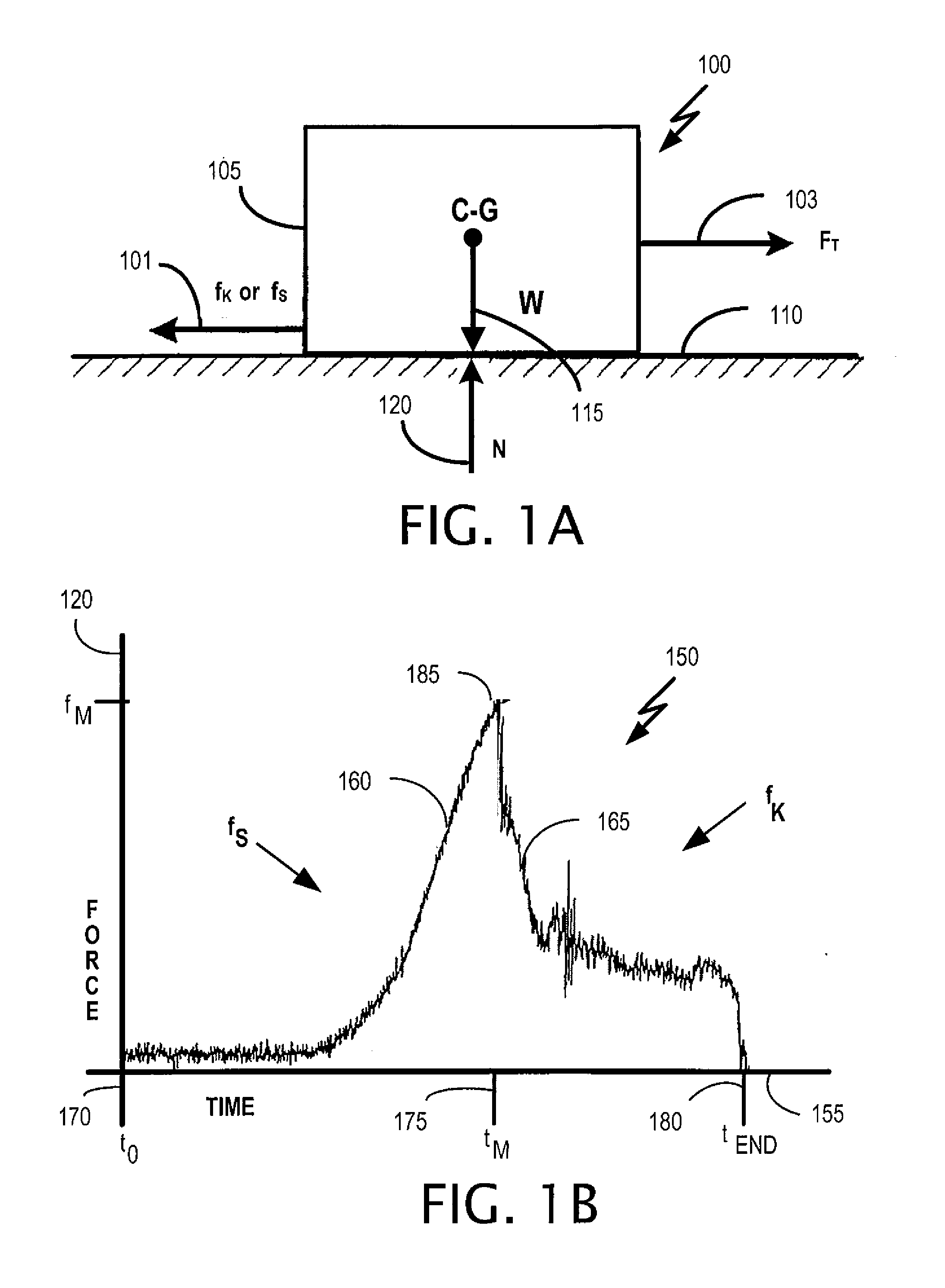

ActiveUS20120240660A1Using mechanical meansInvestigating abrasion/wear resistanceControl signalEngineering

Intrinsically calibrating friction mensuration device has a drive unit with controllable motive member, configured to receive a controllable propulsion force, and to apply tractive force to a test piece on a surface. A force engine couples to the motive member, and applies the controllable propulsion force. The device includes a controller imposing a propulsion control signal actuating the force engine to produce the propulsion force. A force sensor is between the drive unit and the test piece, producing a force signal responsive to a sensed force between the drive unit and the test piece. The drive unit can self-propelled or stationary. A method includes applying an increasing tractive force to a test piece at rest; measuring the tractive force; identifying the maximum tractive force applied at incipient motion; identifying the transition between the resting test piece and incipient motion; determining the SCOF; continue motion and determine the DCOF.

Owner:JOHNSON FRED M

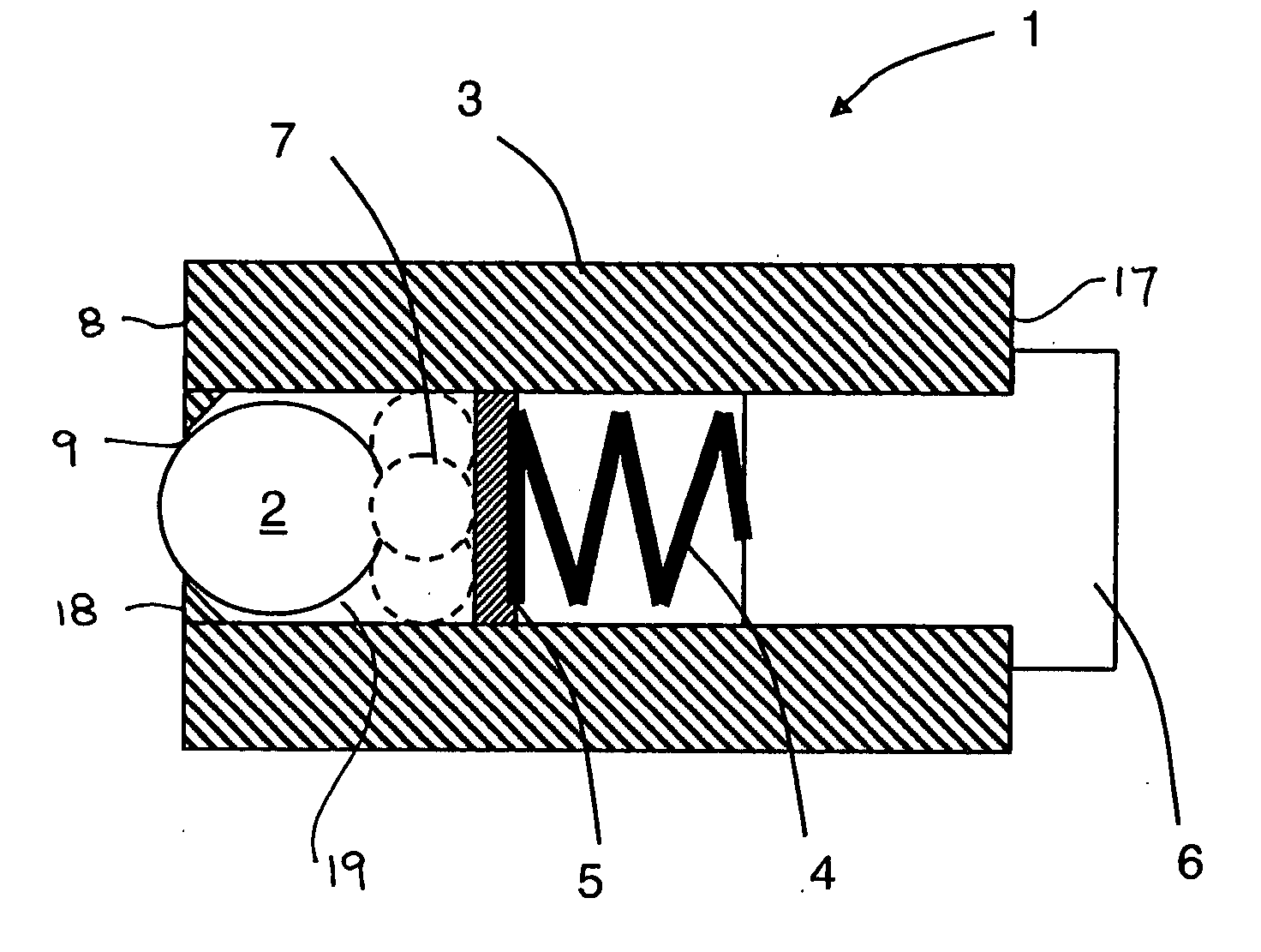

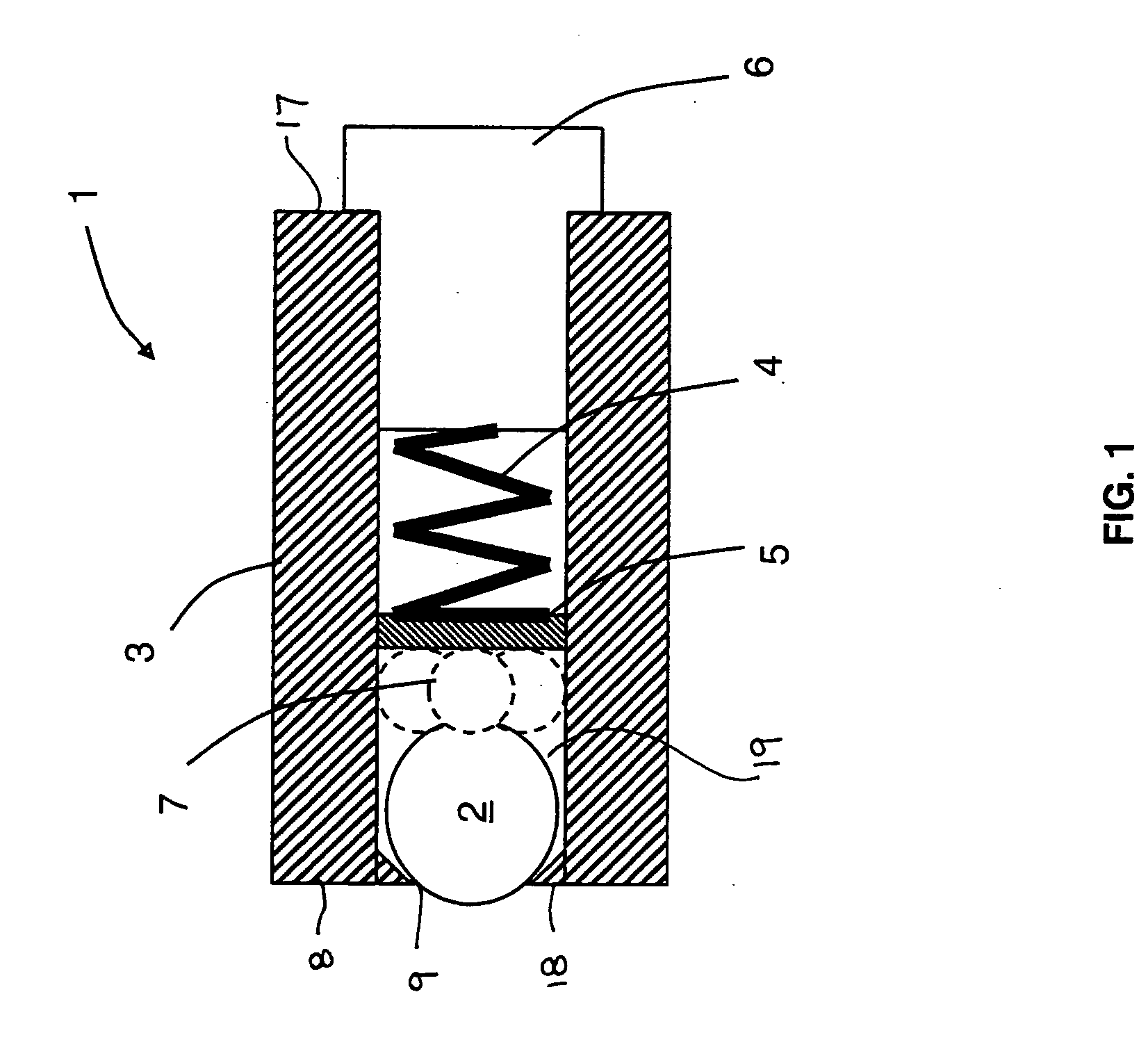

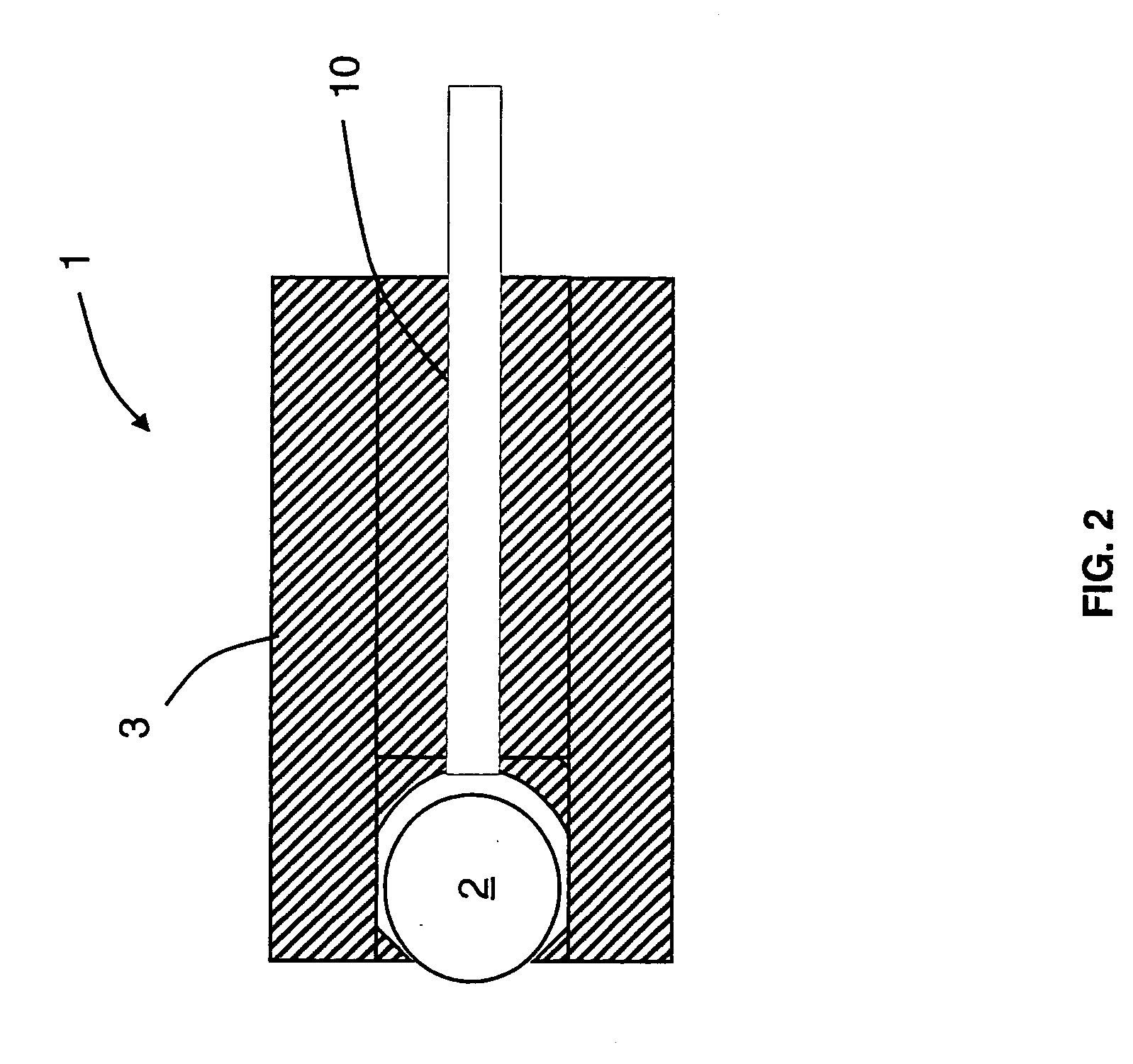

Tribometer

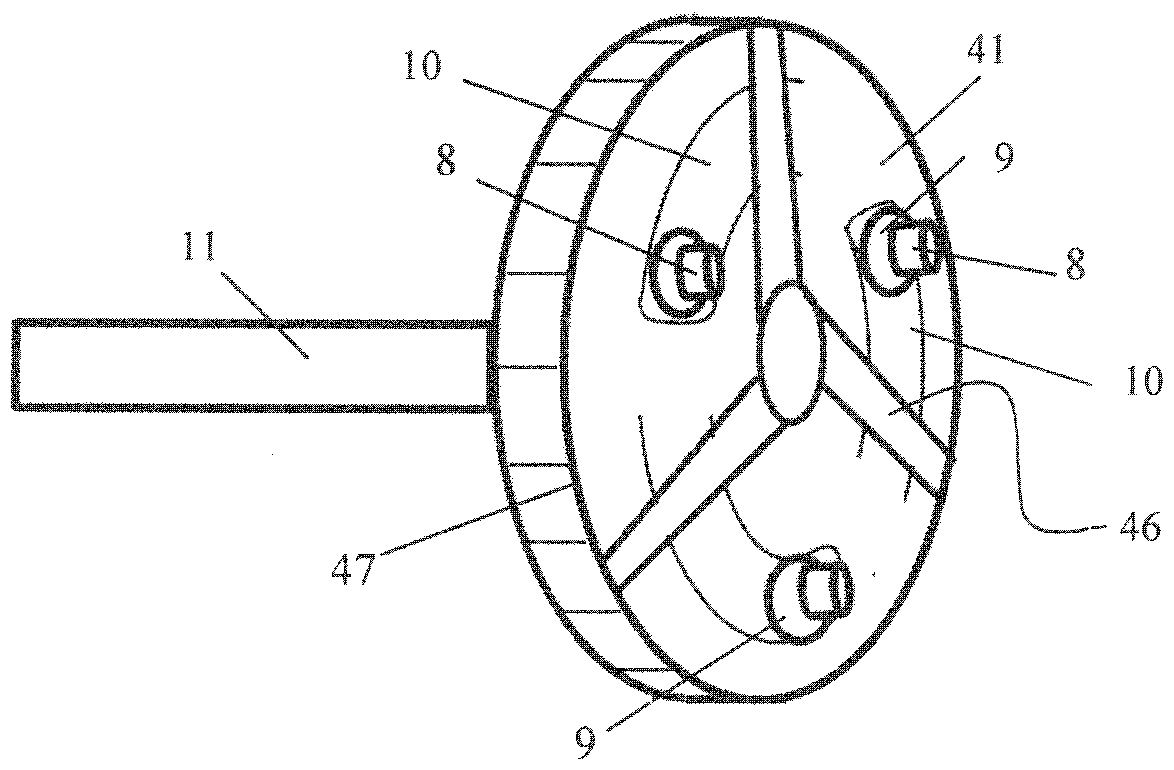

ActiveCN104458496AEasy to measureSimple way to measureFlow propertiesUsing mechanical meansResonance oscillationResonance

The invention relates to a method and a device that determine tribological measured values of samples (7, 8) with a rheometer (1). Wherein the measuring parts of the rheometer (1) are replaced by samples (7, 8) and the surfaces of the samples (7, 8) are moved into frictional contact relative to each other. Accordingly, it is provided that all parts of the rheometer (1) holding the samples (7, 8) in frictional connection and frictional contact or forming the rheometer power circuit, including the spring unit (3) pressing the samples (7, 8) against each other, are regarded as an oscillatory circuit. The oscillation properties of the spring unit are regarded as relevant to the oscillation properties of the oscillatory circuit (30), and that the oscillation properties of the spring unit (3) are adjusted taking into consideration the resonance oscillations or effects produced by changing, different measurement conditions expected with the respective measurement.

Owner:安东帕有限责任公司

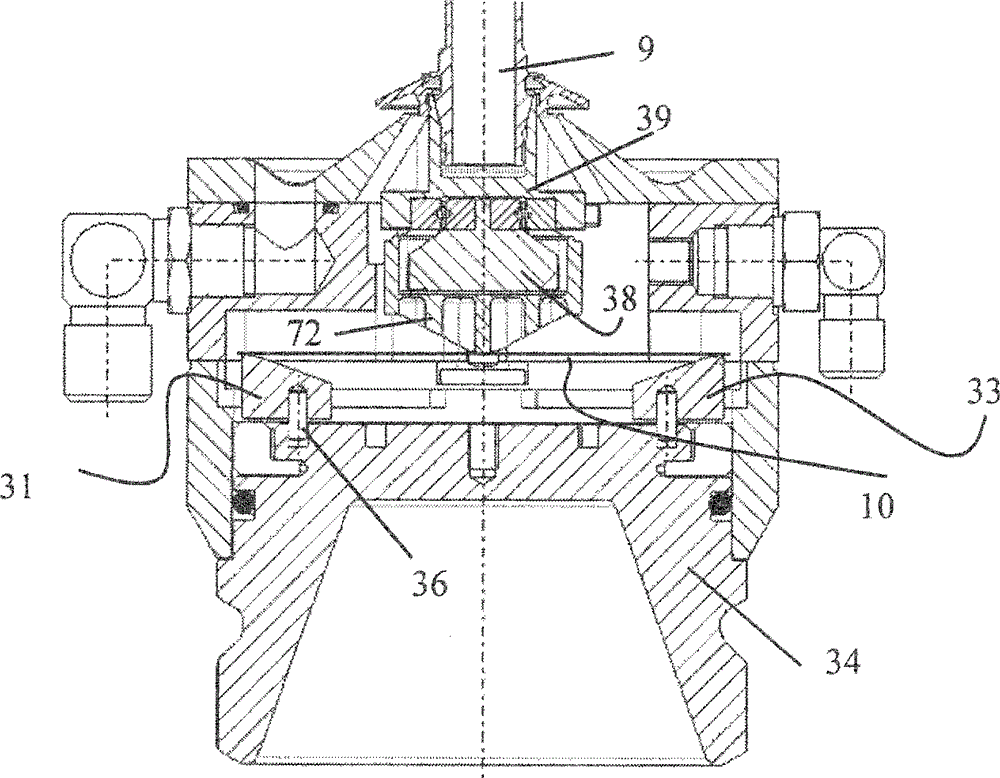

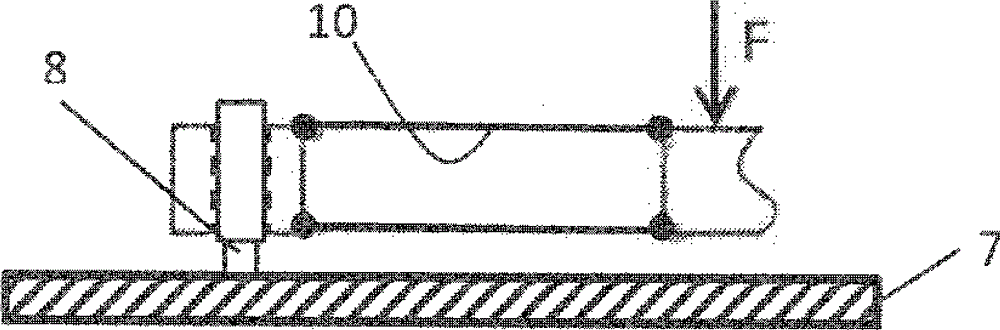

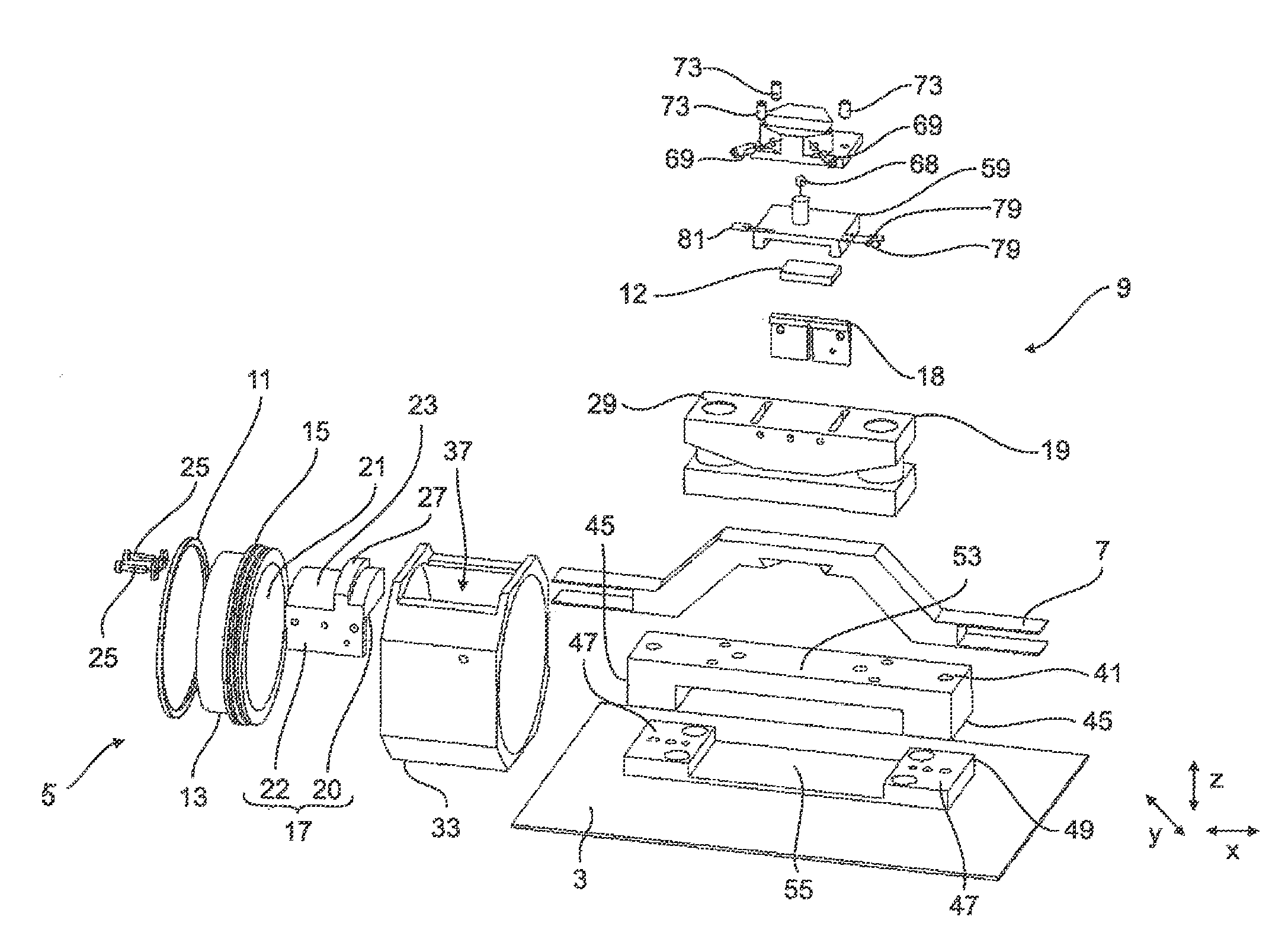

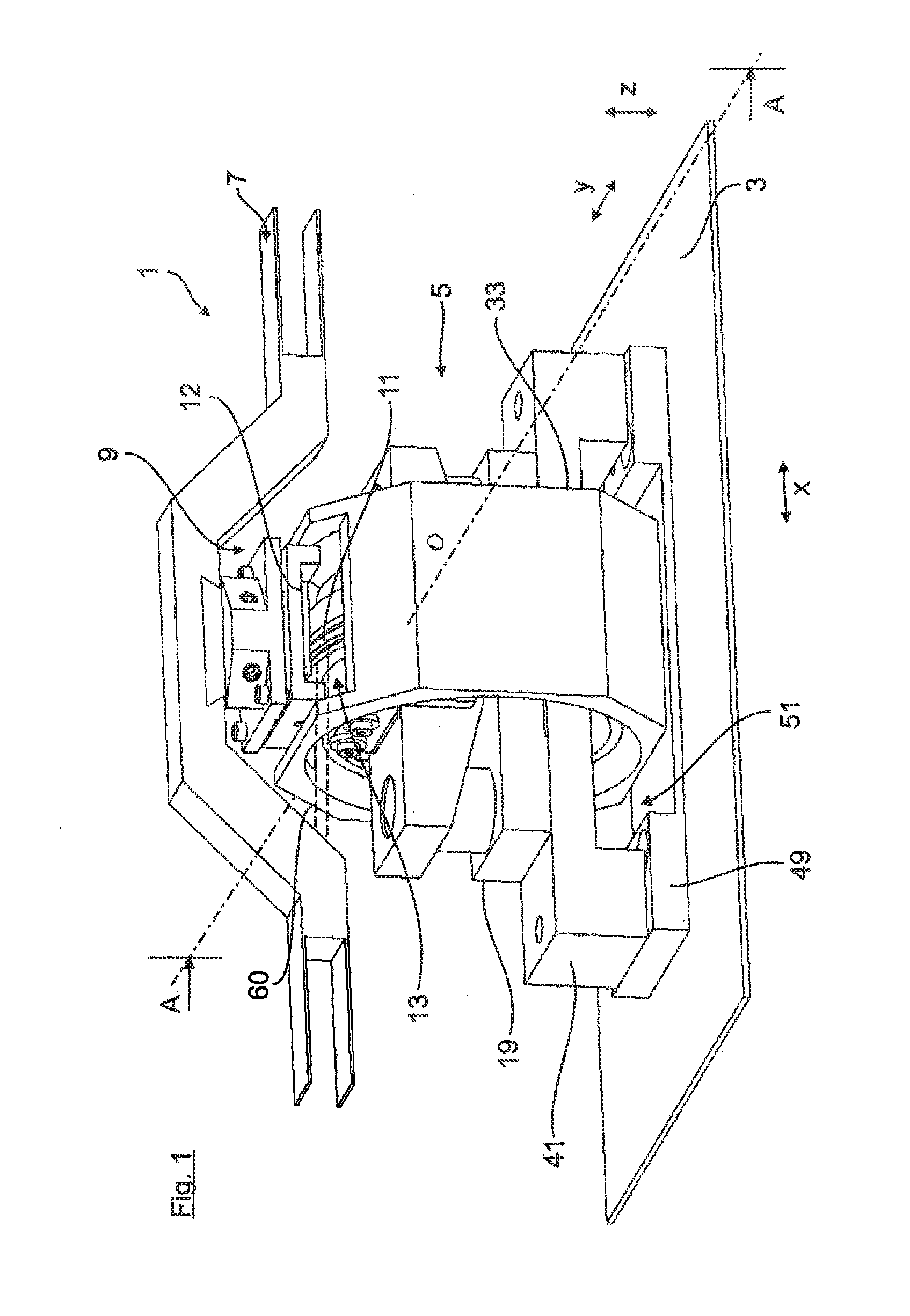

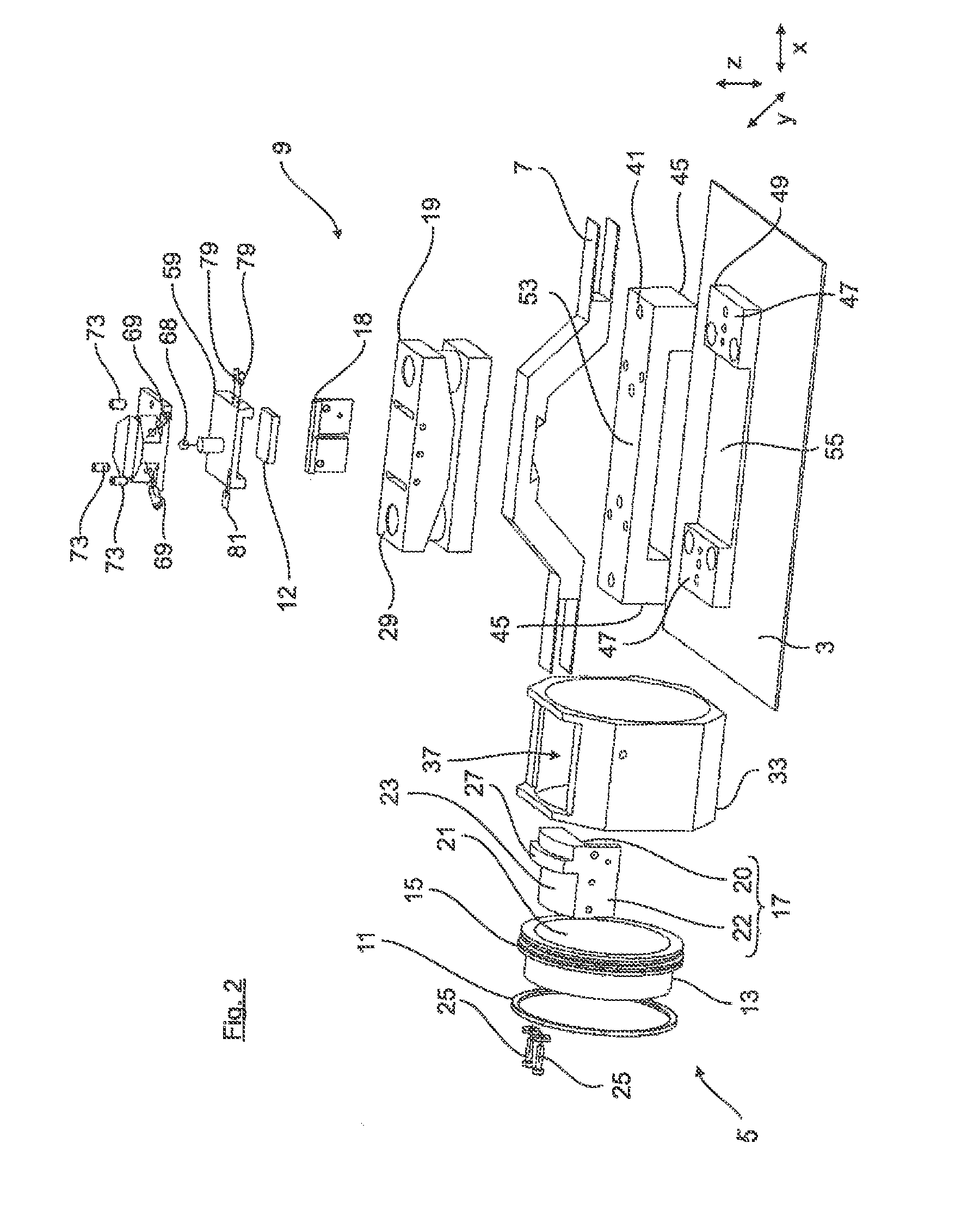

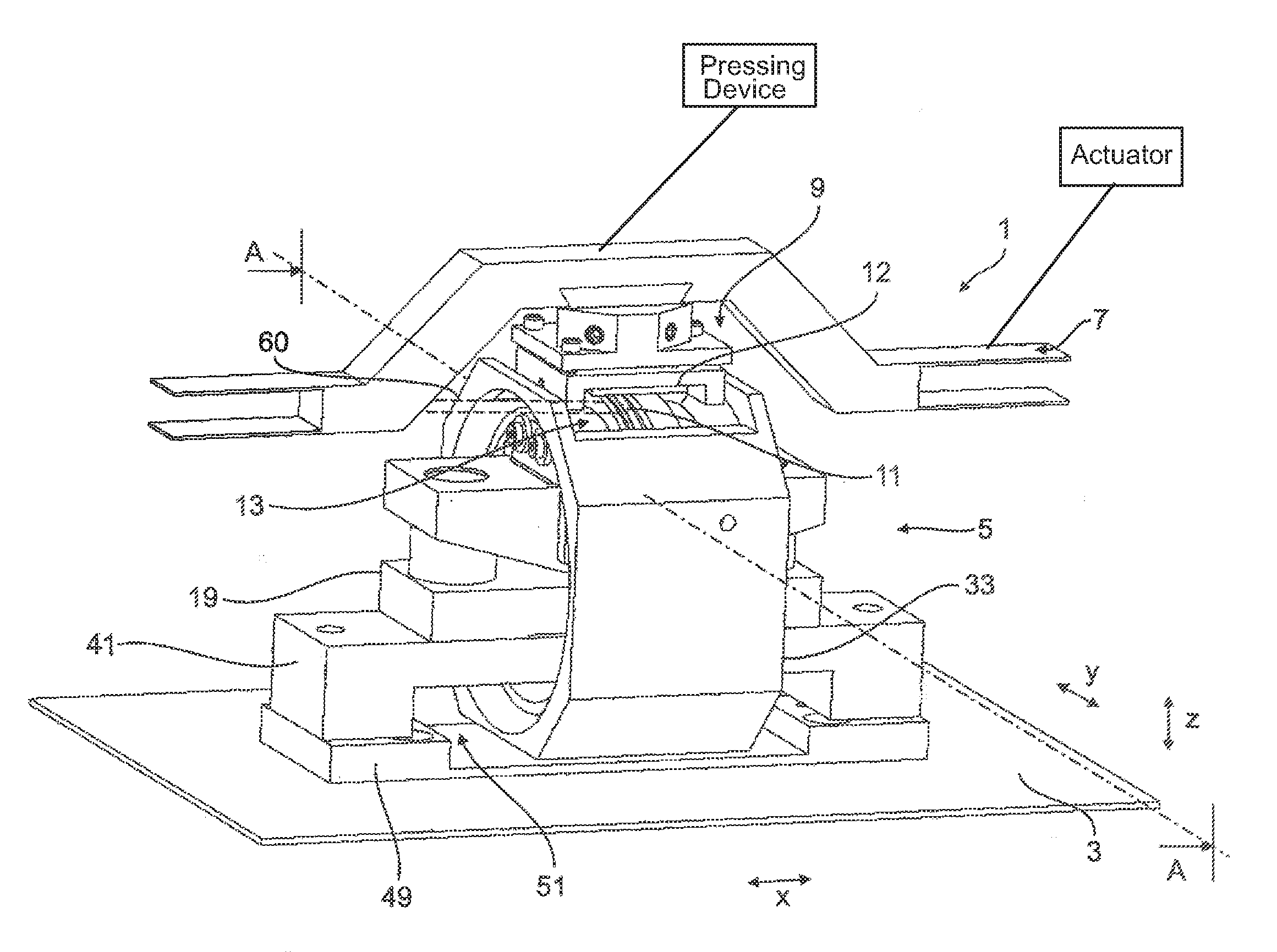

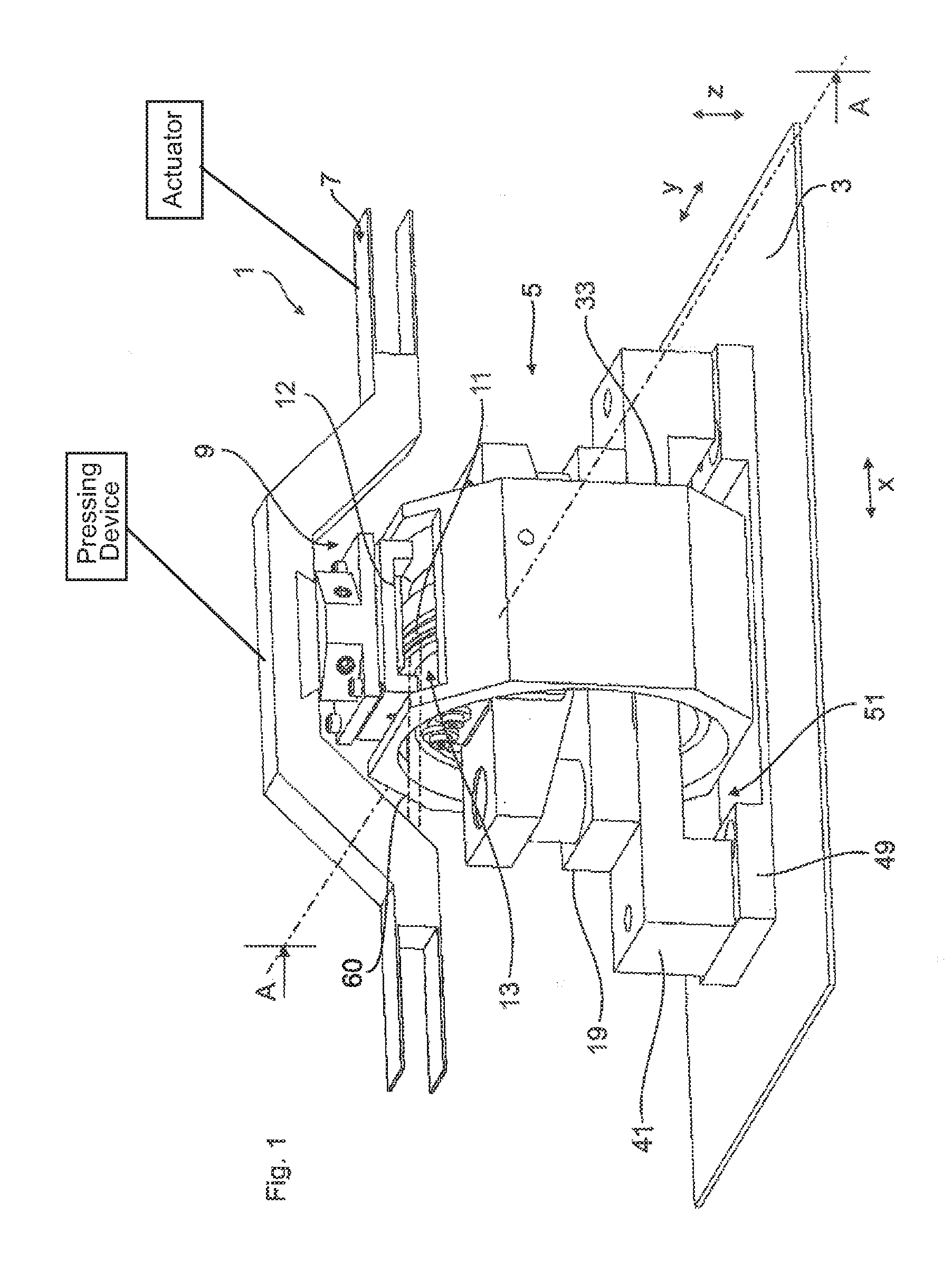

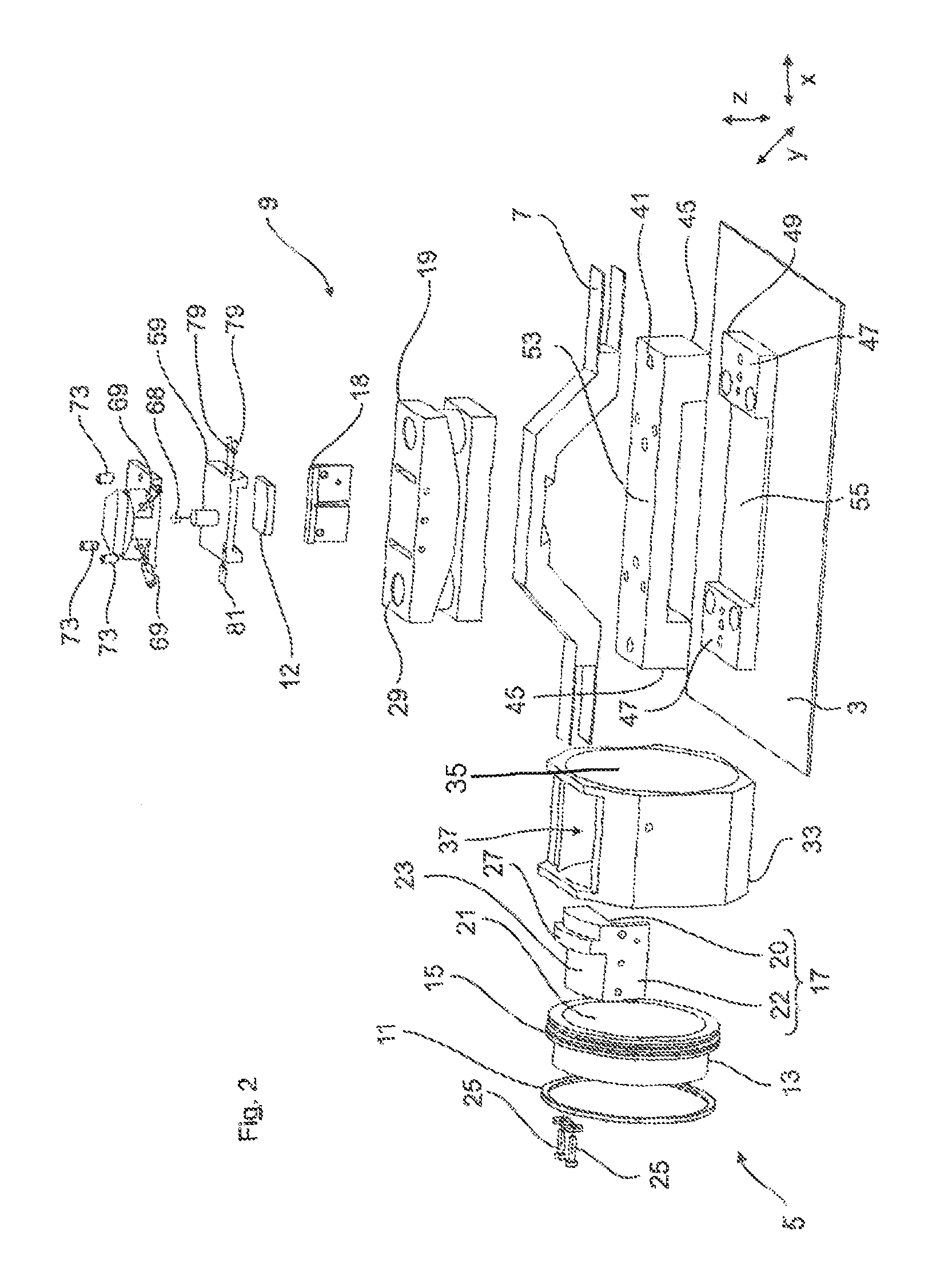

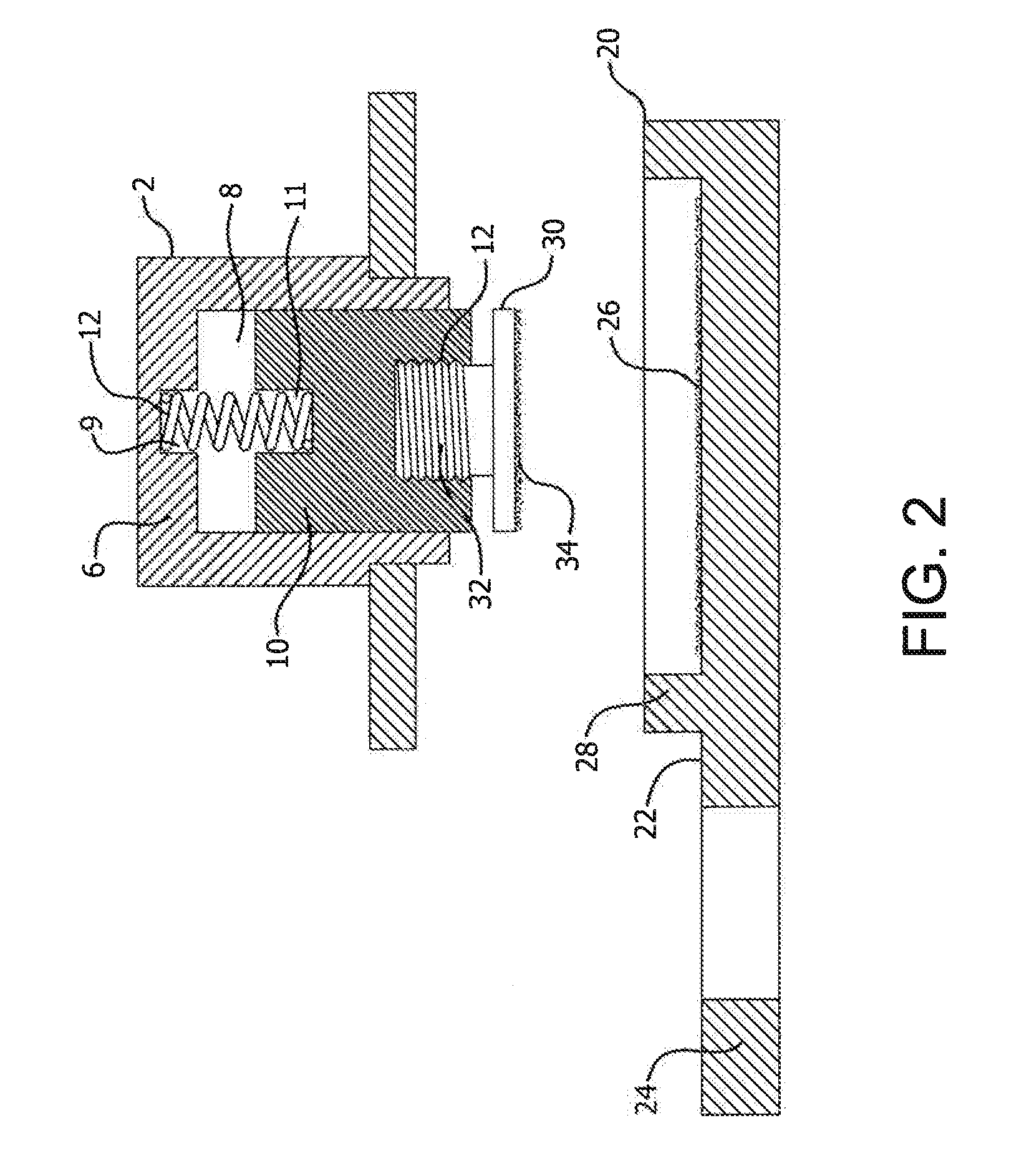

Testbench device, in particular tribometer, for piston ring / cylinder runway systems

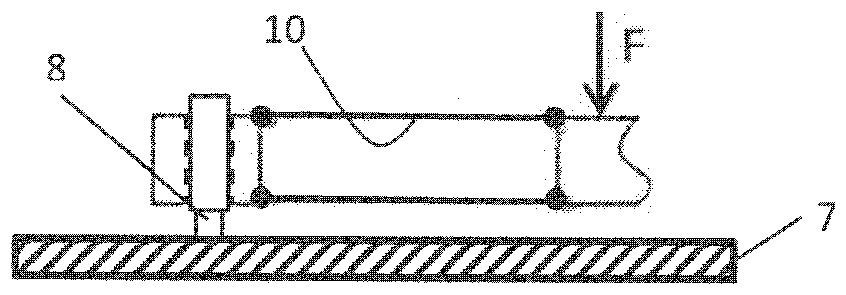

ActiveUS20150082860A1Good transferabilityMachine sealing rings testingUsing mechanical meansRelative displacementPiston ring

A testbench device for the analysis and / or optimisation of tribological properties in a piston ring / cylinder runway system, includes a cylinder segment-holding device for holding a cylinder runway segment as a testpiece, and a piston ring-holding device holding at least one piston ring element and capable of bringing the at least one piston ring element into bearing contact with the cylinder runway segment. An actuation device actuates the cylinder runway segment and / or the piston ring element such that relative displacement with respect to one another takes place in at least one defined direction of space, in particular in the form of an oscillating movement. The piston ring-holding device has a piston having a ring-shaped outer contour and with at least one circumferentially continuous piston ring groove, in which a piston ring is held as a piston ring element.

Owner:MAN NUTZFAHRZEUGE AG

Testbench device, in particular tribometer, for piston ring/cylinder runway systems

ActiveUS9581537B2Machine sealing rings testingUsing mechanical meansRelative displacementPiston ring

Owner:MAN TRUCK & BUS AG

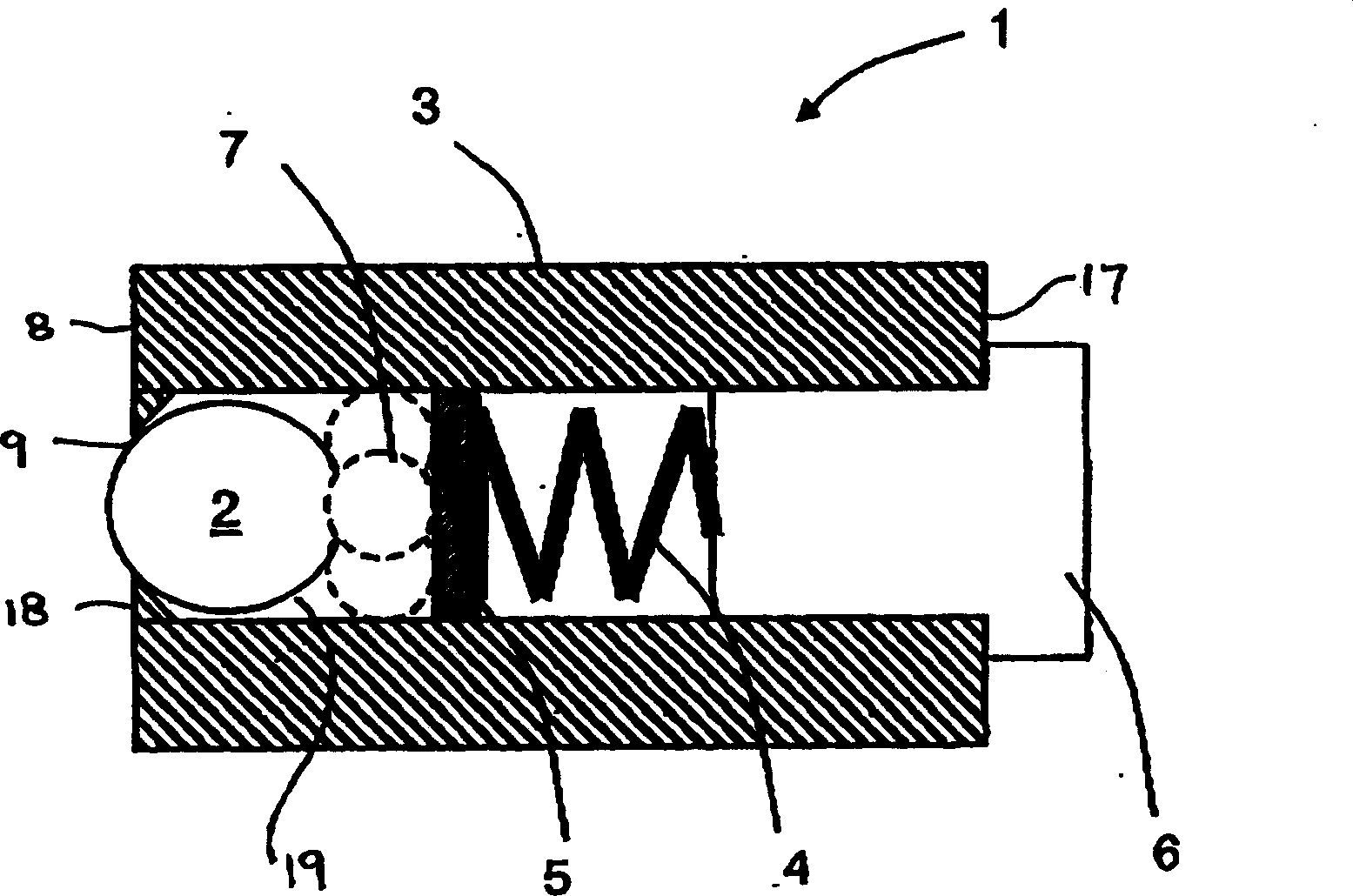

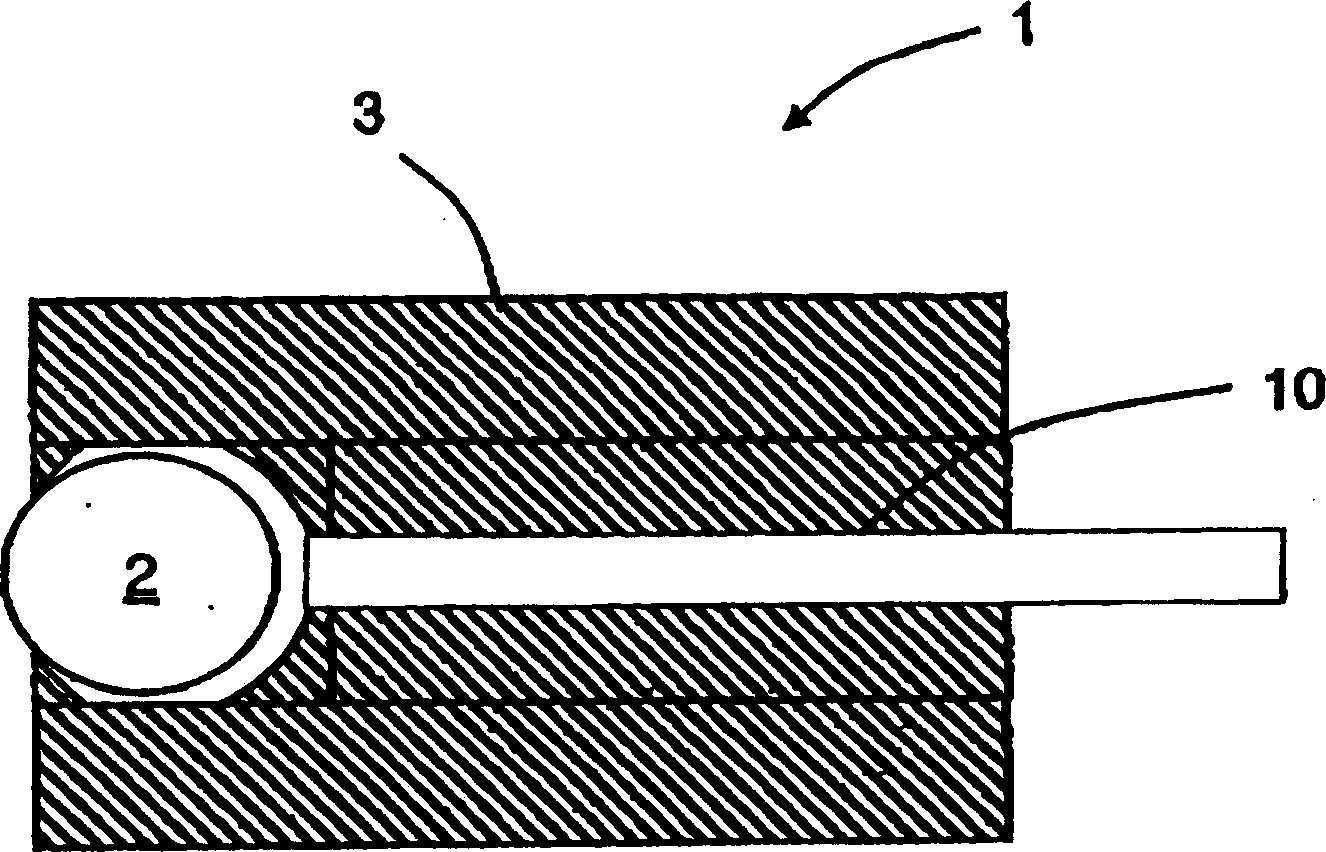

Rolling ball tribometer

InactiveUS20050276532A1Shorten assessment timeSimple and inexpensiveBall bearingsBearing componentsConstant forceEngineering

This invention is directed to a tribological apparatus and method incorporating a ball, a support, and means for maintaining a substantially constant force between the ball and a test surface. The ball rolls against the rotating test surface producing a wear track. Analysis relating to wear and fatigue can be performed on the test surface subsequent to producing the wear track.

Owner:AIR PROD & CHEM INC

Vinylidene chloride floor coating

The invention discloses a vinylidene chloride floor coating comprising the following raw materials in parts by weight: 100 parts of vinylidene chloride resin, 5-10 parts of melamine, 30-40 parts of dibutyl phthalate, 1-10 parts of formaldehyde, 25-35 parts of barium ricinoleate, 20-30 parts of butanol, 40-60 parts of deionized water, 35-45 parts of dimethylbenzene, 10-20 parts of pigment, 5-15 parts of titanium dioxide, 20-40 parts of antimony oxide, 15-25 parts of methanol, 10-30 parts of plasticizer, 25-45 parts of bentonite, 20-30 parts of talcum powder and 15-35 parts of styrene. The vinylidene chloride floor coating is good in wear resistance (up to 0.001-0.005g / cm<2> after being tested 1000 times by using a reciprocating tribometer), free of abnormalities after being soaked into 20-DEG C water for 10-20 days and capable of resisting to the temperature of 10 DEG C below zero for 10 hours without embrittling and cracking; in addition, a film has no abnormalities after being soaked into alkaline water for 5-7 days, so that the vinylidene chloride floor coating can be widely produced and used for continuously replacing existing material.

Owner:苏州靖羽新材料有限公司

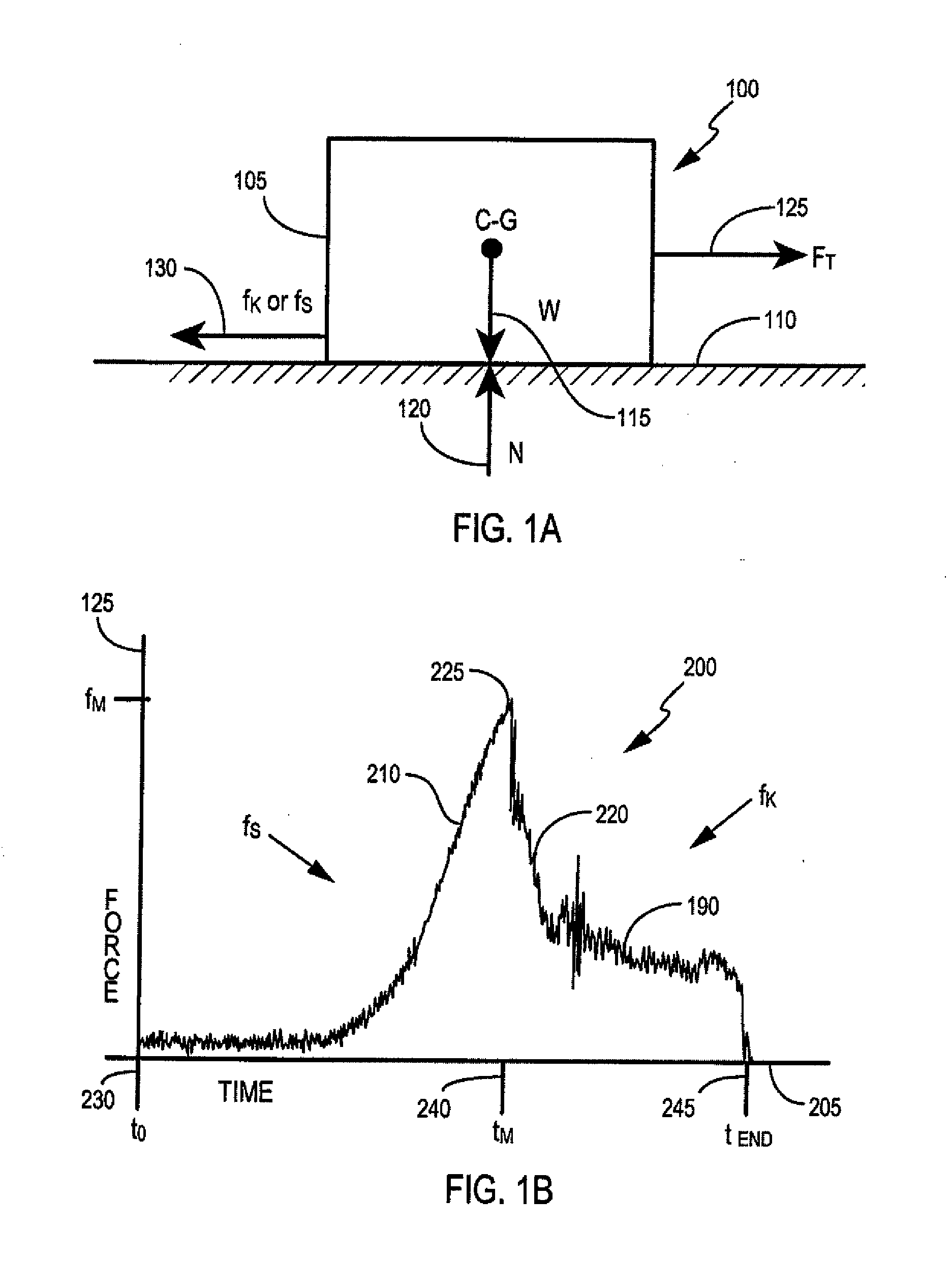

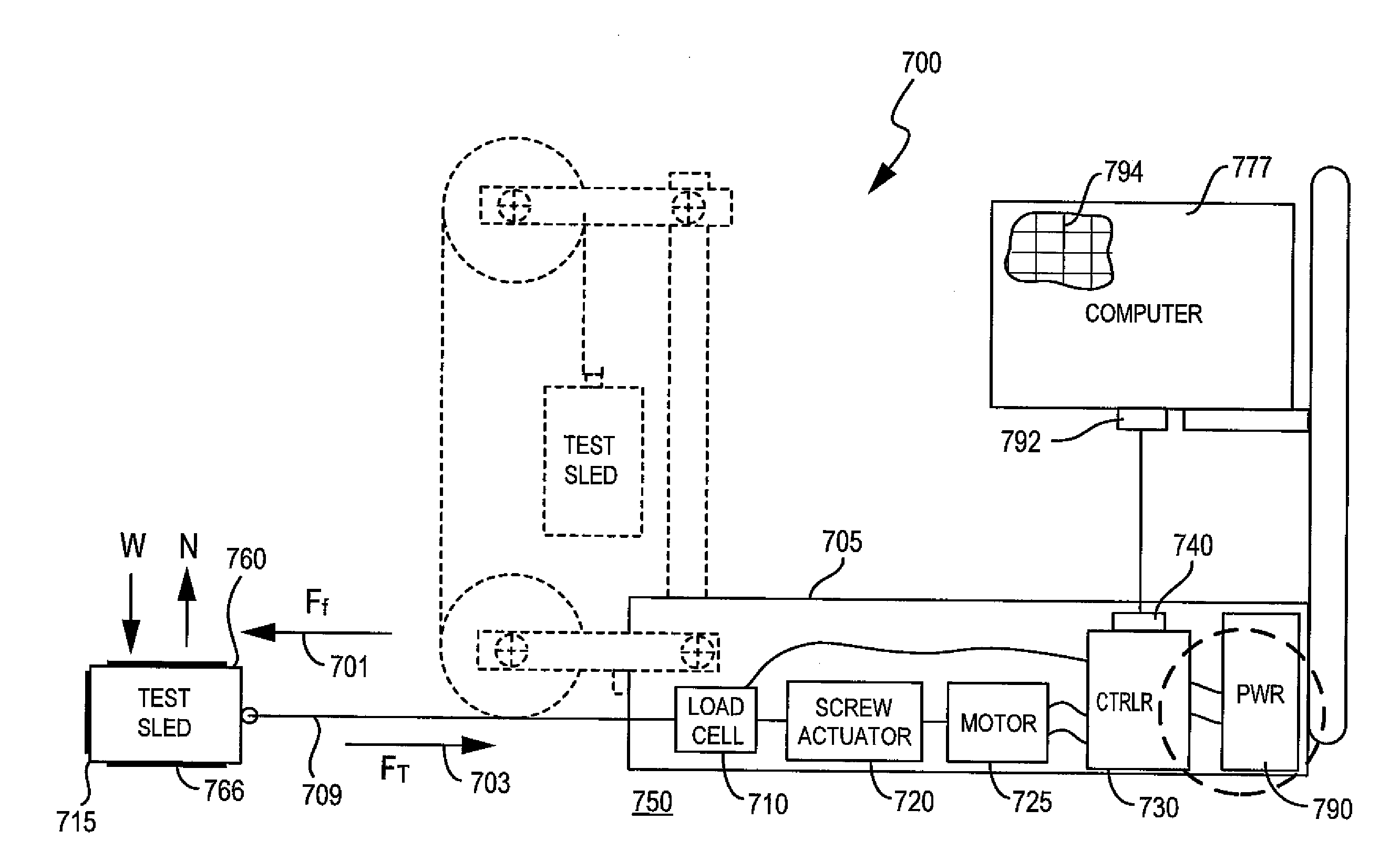

Intrinsically-calibrated tribometer

ActiveUS20140013822A1Using mechanical meansInvestigating abrasion/wear resistanceControl signalEngineering

Intrinsically calibrating friction mensuration device has a drive unit with controllable motive member, configured to receive a controllable propulsion force, and to apply tractive force to a test piece on a surface. A force engine couples to the motive member, and applies the controllable propulsion force. The device includes a controller imposing a propulsion control signal actuating the force engine to produce the propulsion force. A force sensor is between the drive unit and the test piece, producing a force signal responsive to a sensed force between the drive unit and the test piece. The drive unit can self-propelled or stationary. A method includes applying an increasing tractive force to a test piece at rest; measuring the tractive force; identifying the maximum tractive force applied at incipient motion; identifying the transition between the resting test piece and incipient motion; determining the SCOF; continue motion and determine the DCOF.

Owner:JOHNSON FRED M

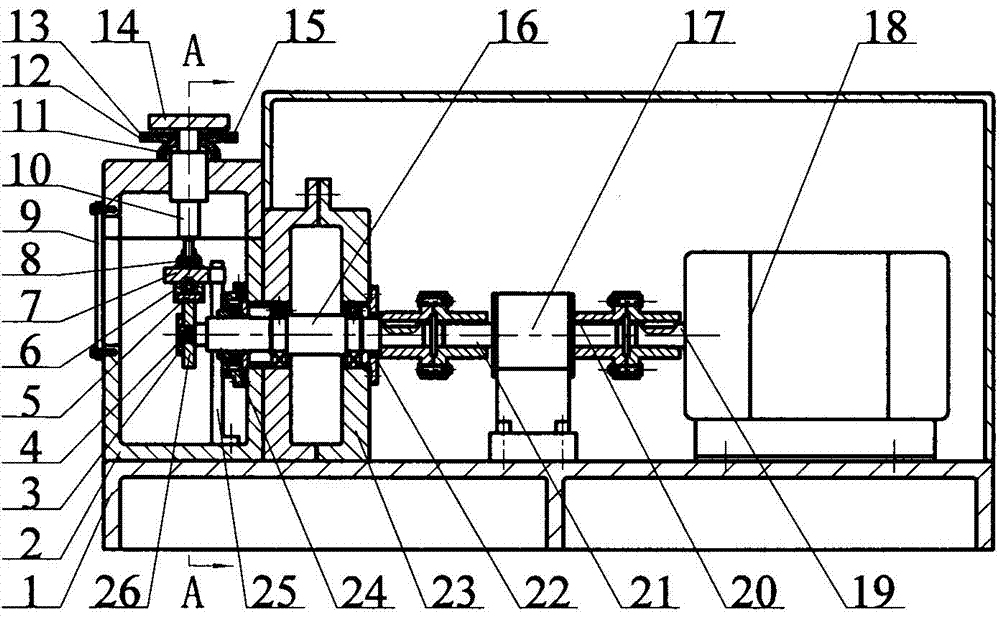

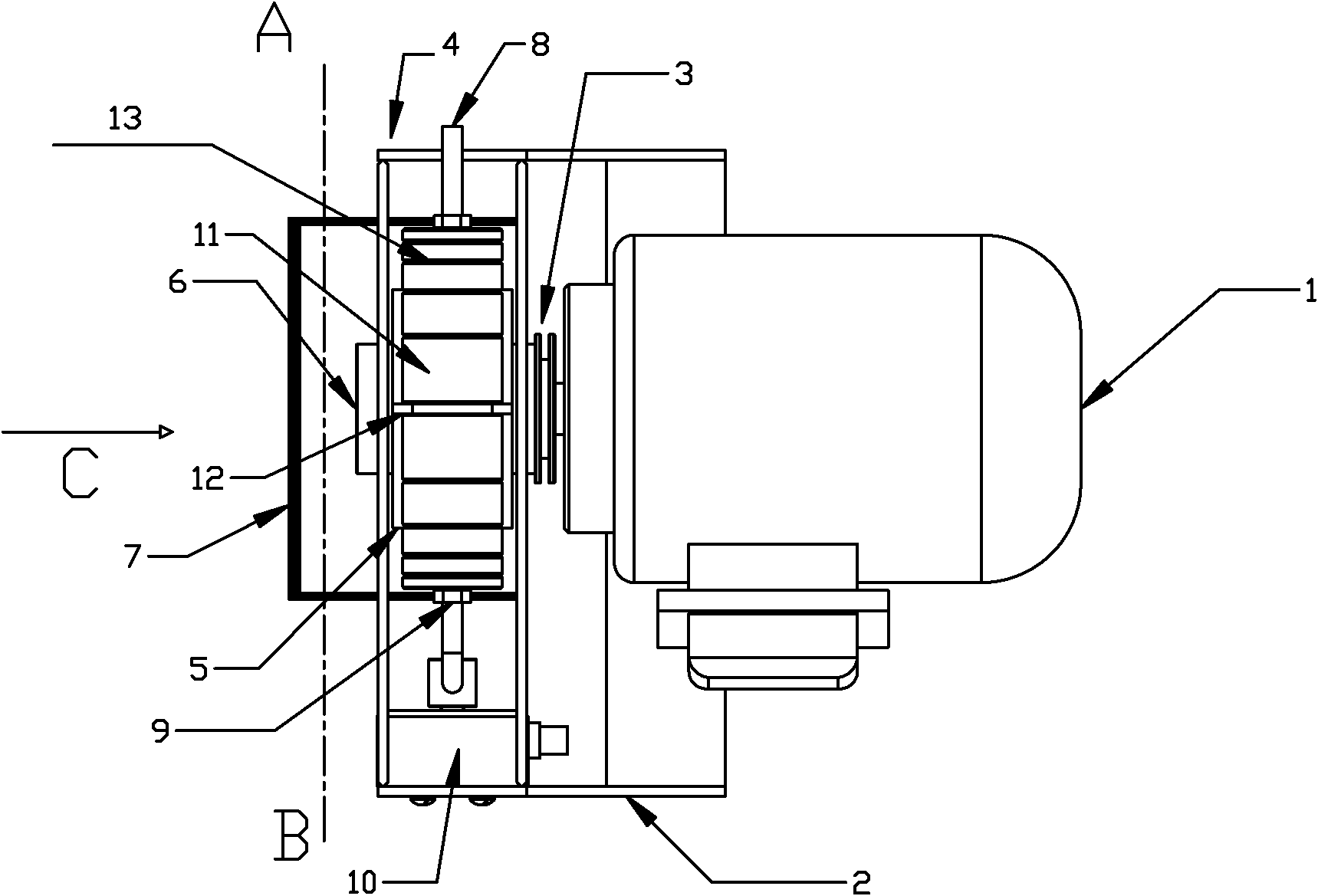

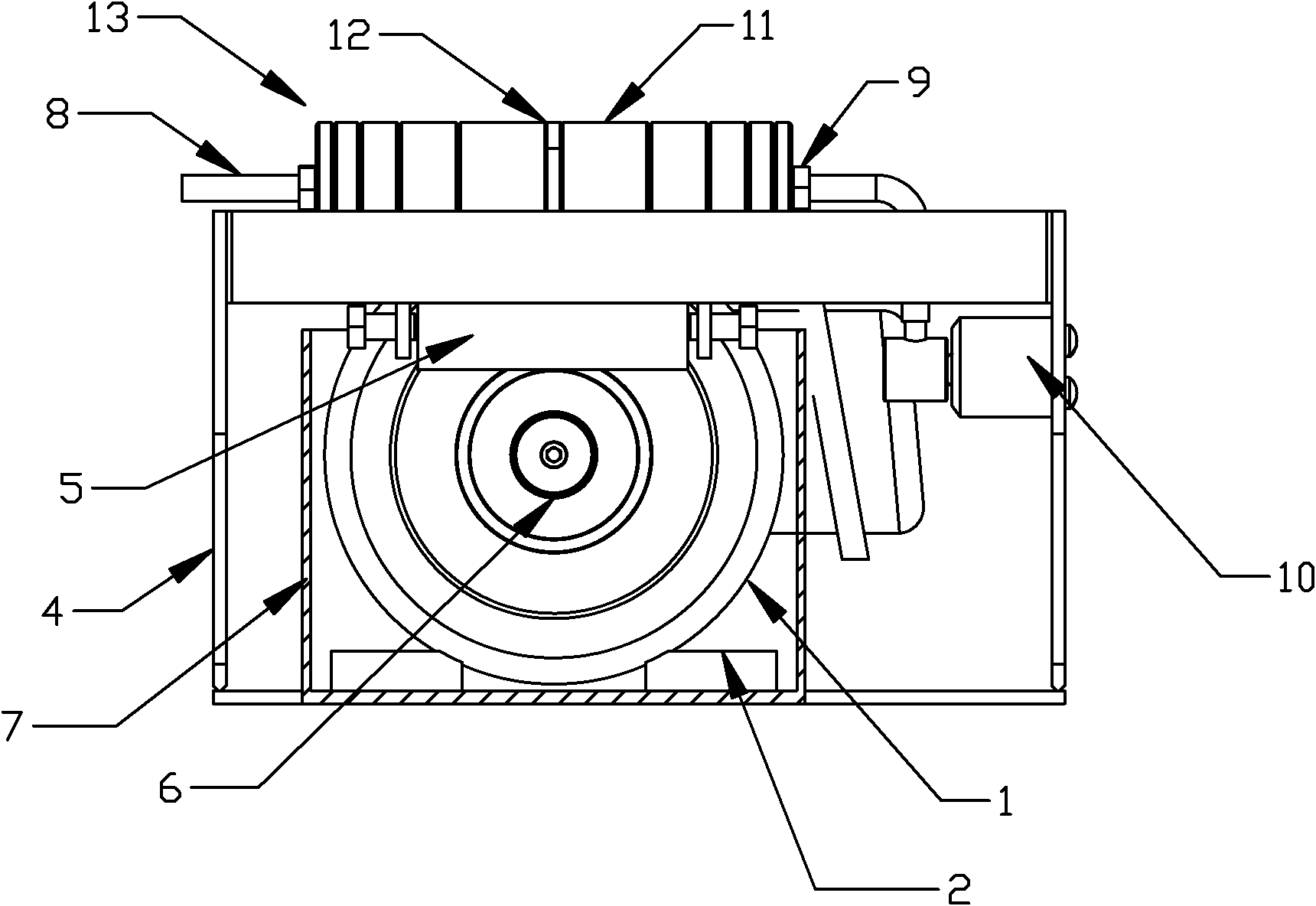

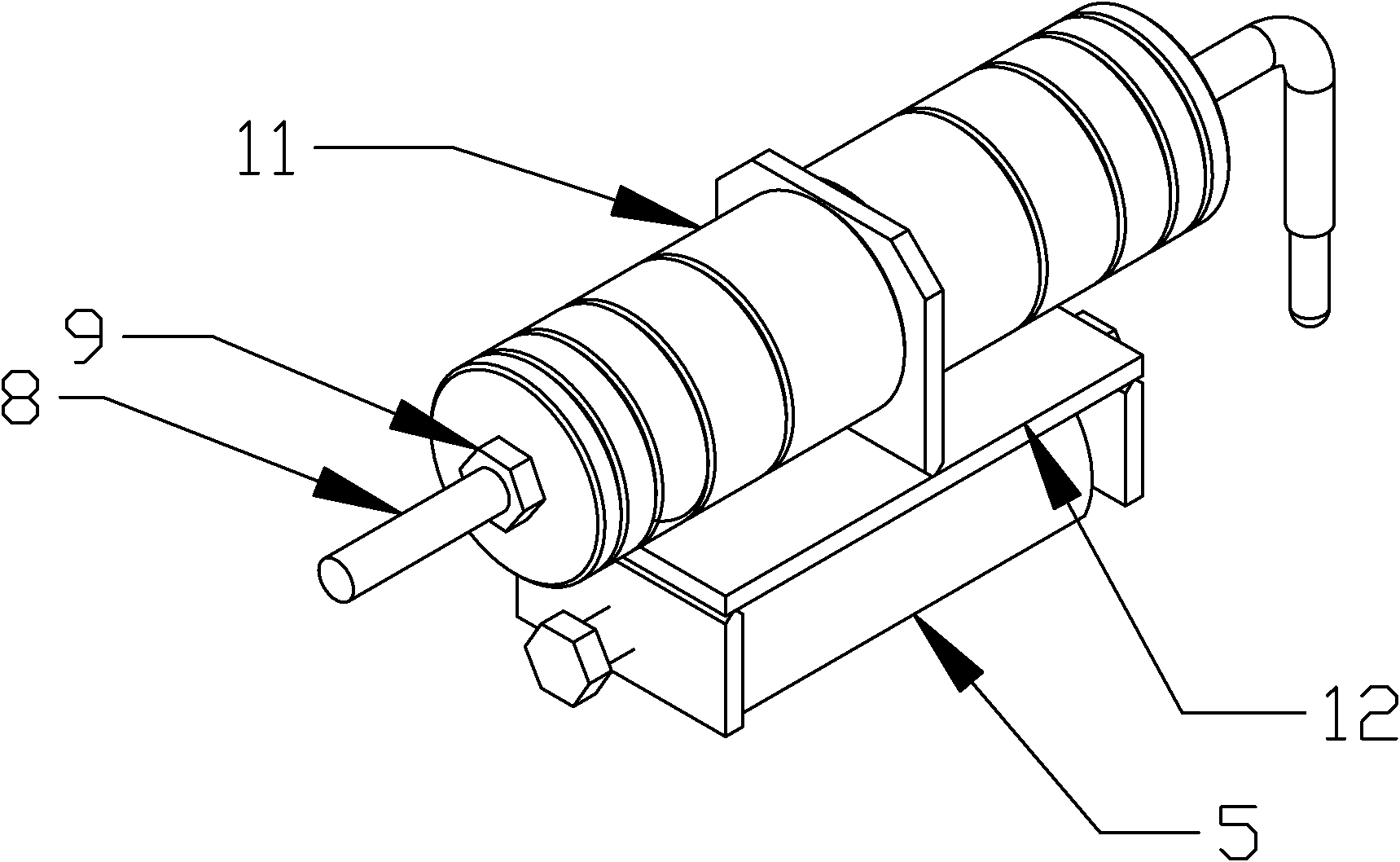

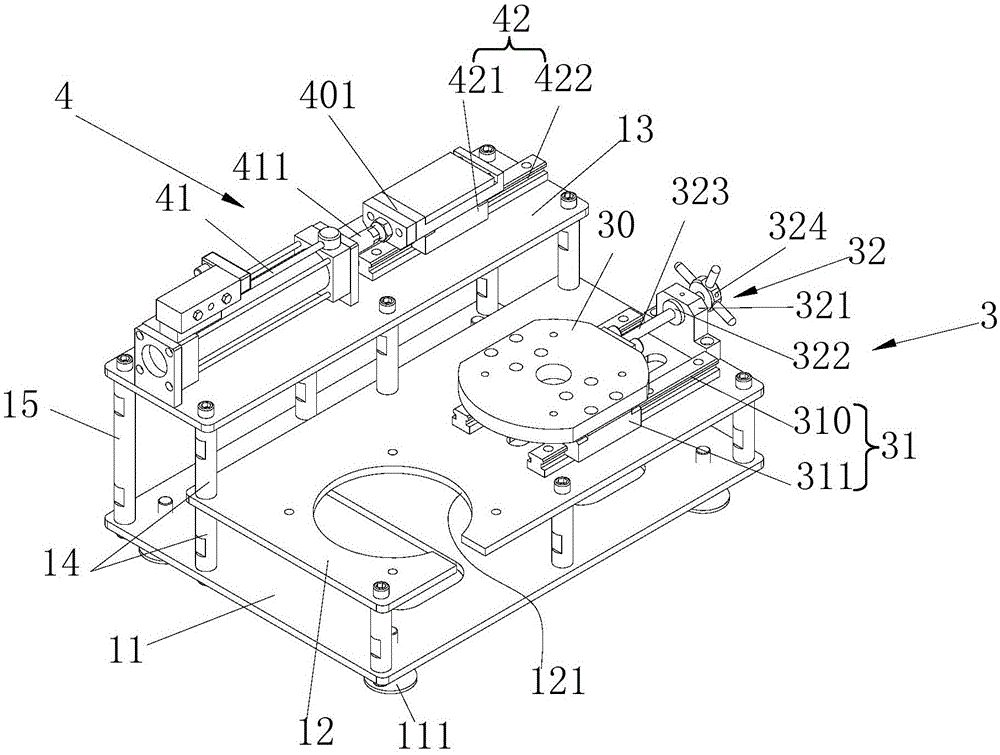

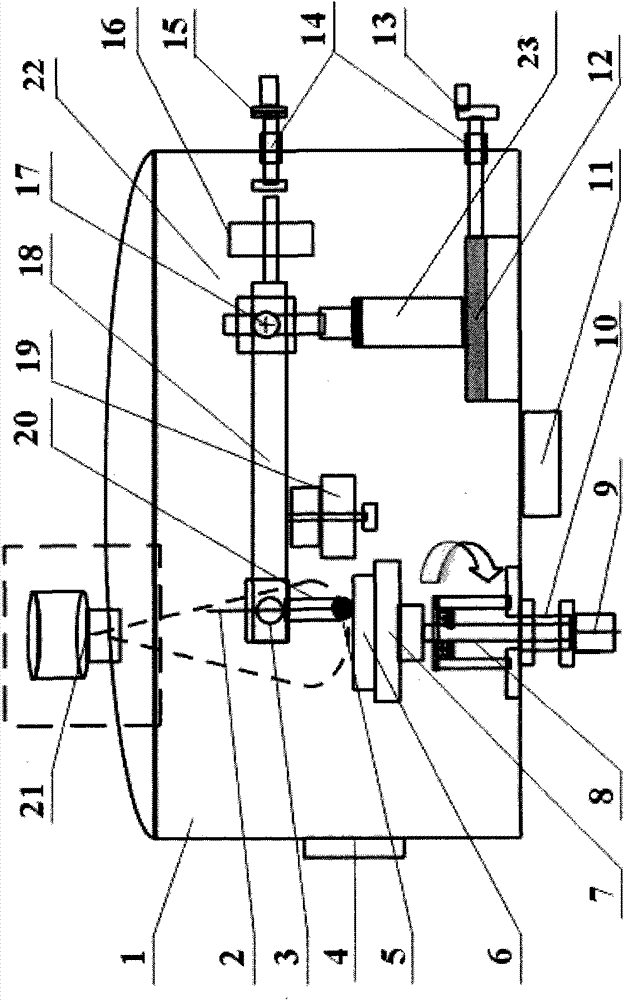

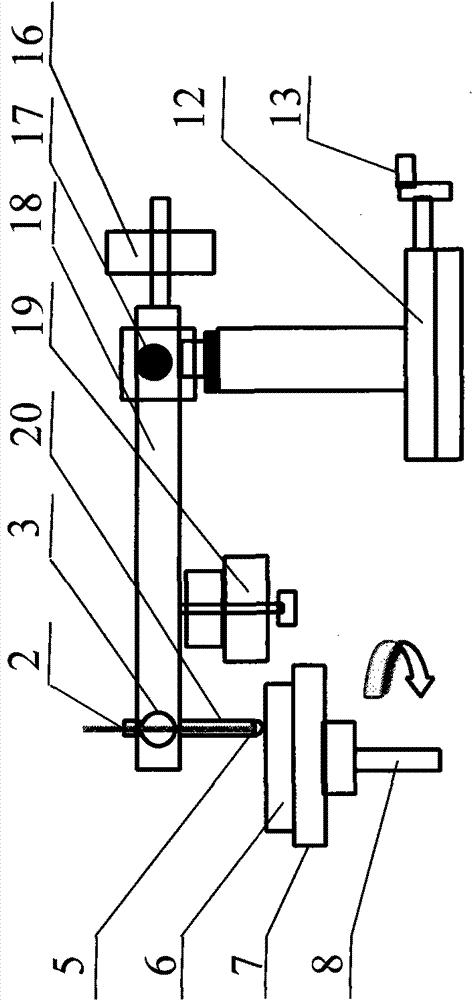

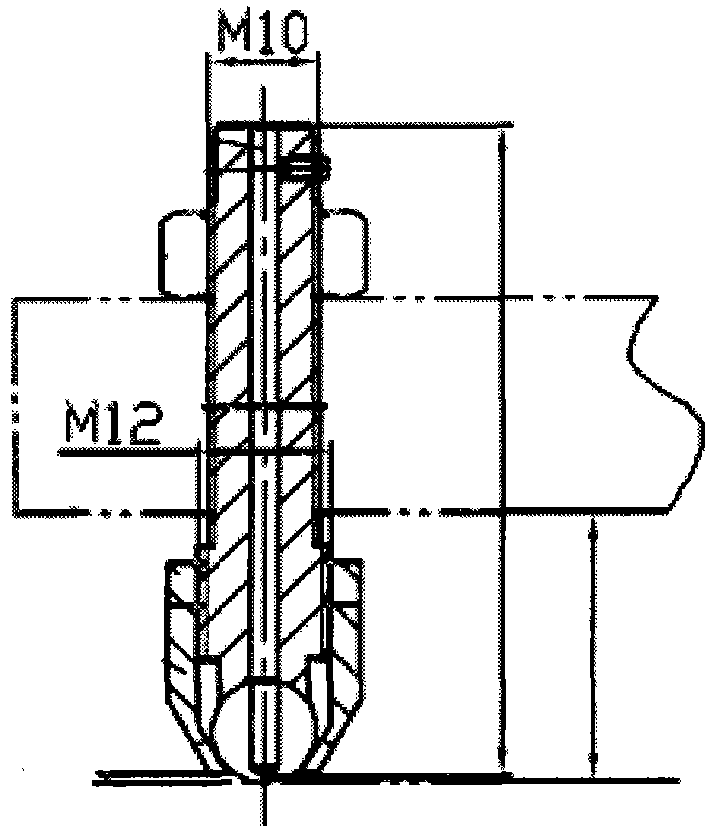

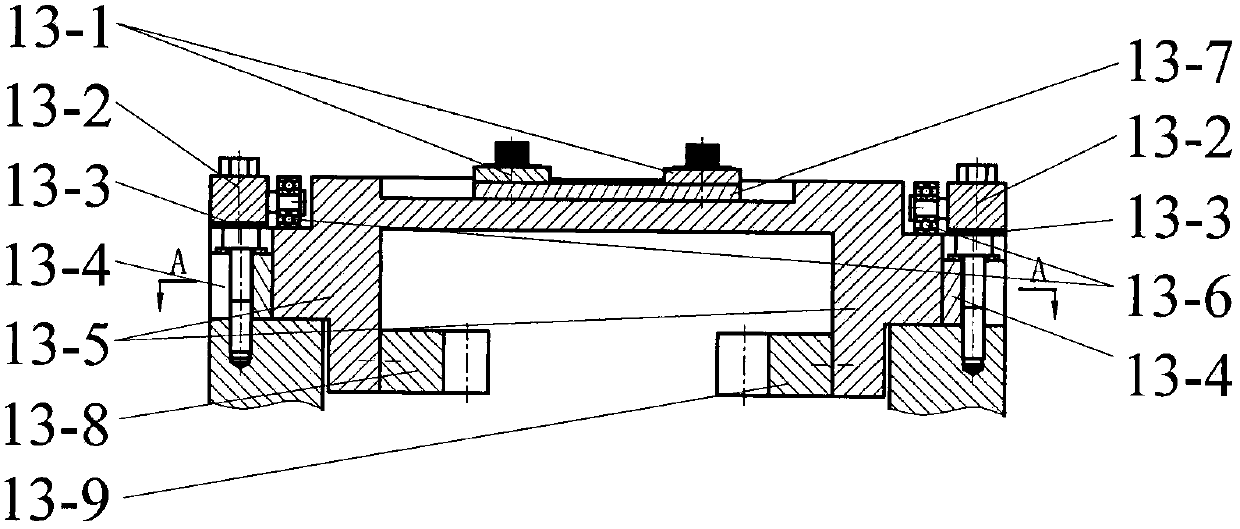

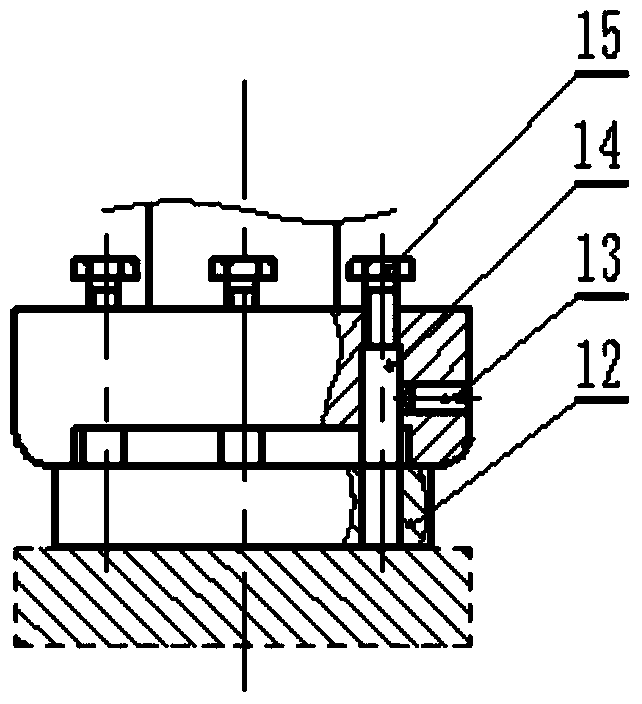

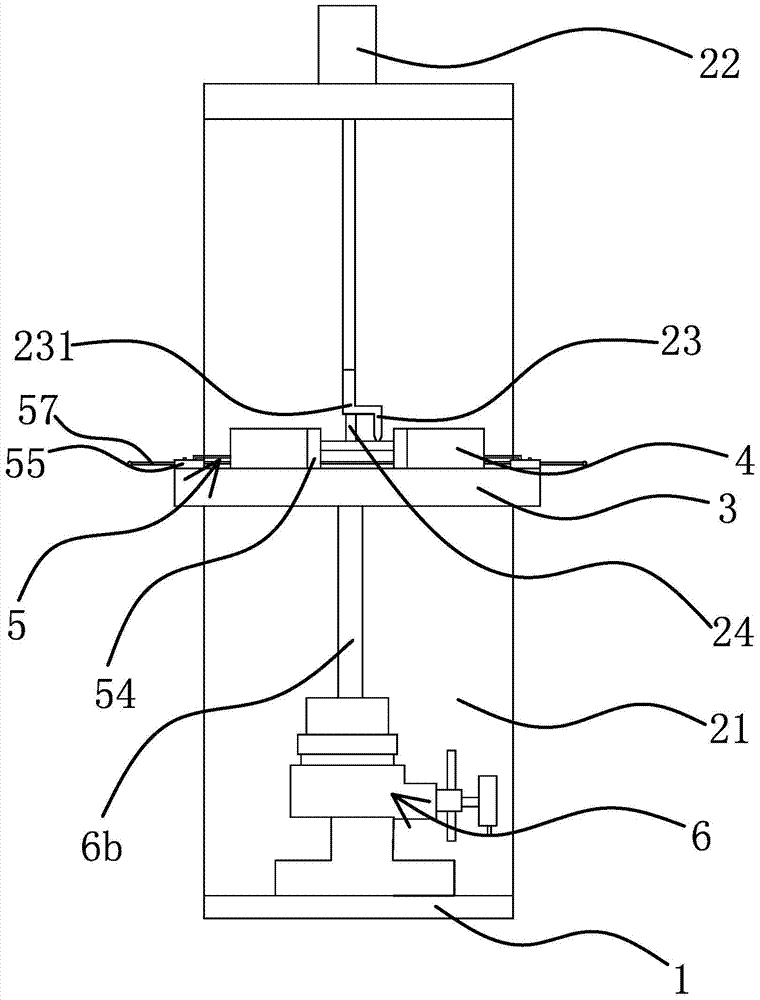

Wear gap adjustment ring block friction and wear testing machine

ActiveCN105158100BEasy loading and unloadingNot easy to damageInvestigating abrasion/wear resistanceEngineeringVertical load

A ring block friction and wear testing machine with wear gap adjustment solves the problem that the existing friction and wear machines cannot realize the loading and gap adjustment of the test ring and the test block on the same testing machine. It includes a machine base, a power and transmission mechanism fixed on the machine base, a material box provided with a loading mechanism and a testing mechanism, and a measurement control circuit. The technical points are: the loading mechanism includes an adjustment rod, a handle, a fine-tuning dial, a fixed seat, a guide seat with a fixture and a guide rail, the stud section of the adjustment rod matches the threaded hole of the material box to form a spiral pair, and the adjustment rod A handle is fixed on the top, and the handle can be rotated to achieve quantitative vertical loading and precise adjustment of the gap between the test block and the test ring, and it is fixed by a fixing device. It has reasonable design, simple structure compared with existing similar products, convenient loading and unloading of test ring and rubber test block, stable operation, easy gap adjustment operation, accurate spacing, and further improves the reliability of test results consistent with actual working conditions.

Owner:SHENYANG POLYTECHNIC UNIV

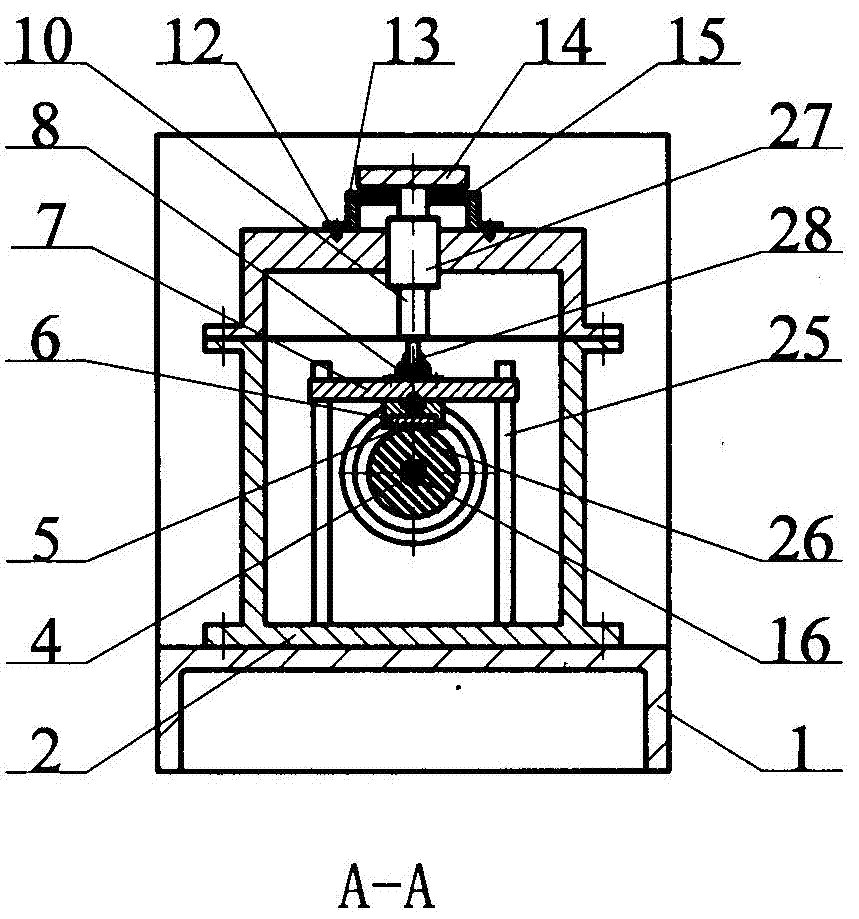

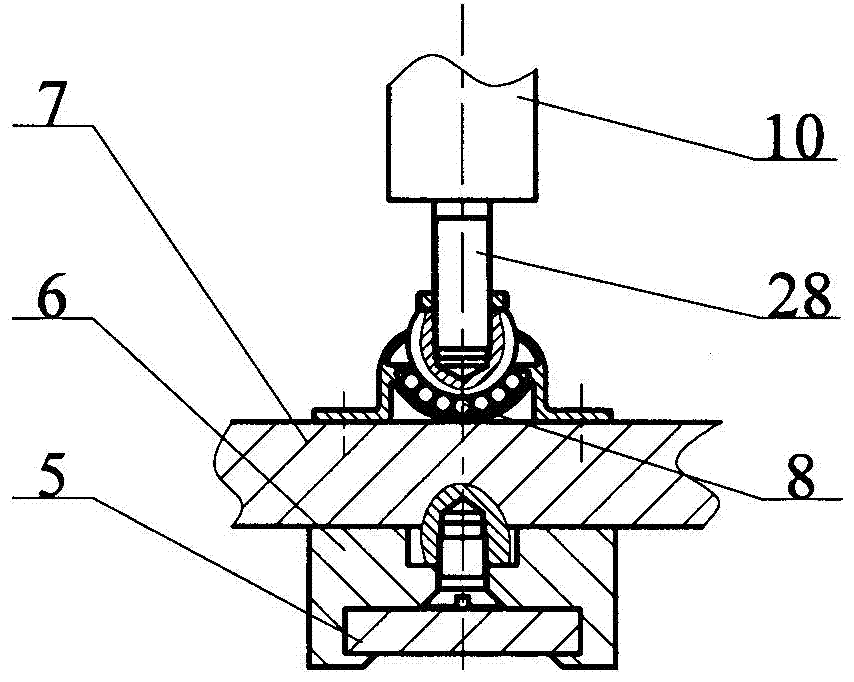

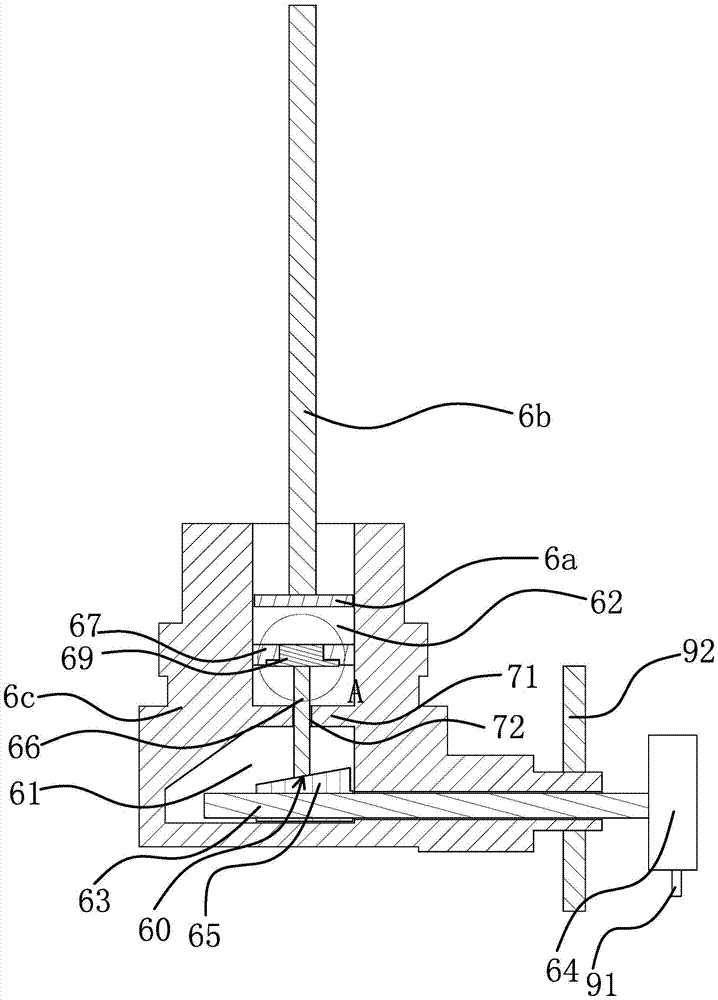

Sample fixing device for high temperature tribometer

InactiveCN107389435AEasy to operateImprove experimental efficiencyInvestigating abrasion/wear resistanceBiochemical engineeringHigh heat

The invention discloses a sample fixing device for a high temperature tribometer. The sample fixing device comprises a base and a plurality of fixing devices arranged on the base, wherein a plurality of fixing grooves and a plurality of fixing holes are symmetrically formed in the upper part of the base; a limiting groove is formed in each fixing groove; each fixing device is arranged on one fixing groove; each fixing device comprises a long nut, a V-shaped fixing part, a square fixing part and a large bolt; each V-shaped fixing part and the corresponding square fixing part are arranged on the corresponding long nut; each large bolt is arranged at the end part of the corresponding long nut; the plurality of V-shaped fixing parts are used for clamping circular samples; the fixing grooves and the limiting grooves are used for limiting the V-shaped fixing parts and the square fixing parts; each V-shaped fixing part consists of a fixing block, a connecting body and a limiting boss; each limiting boss is matched with the corresponding limiting groove; each connecting body is matched with the corresponding fixing groove. The sample fixing device disclosed by the invention is simple in operation and wide in application range; the experiment efficiency can be substantially improved.

Owner:JIANGSU UNIV OF TECH

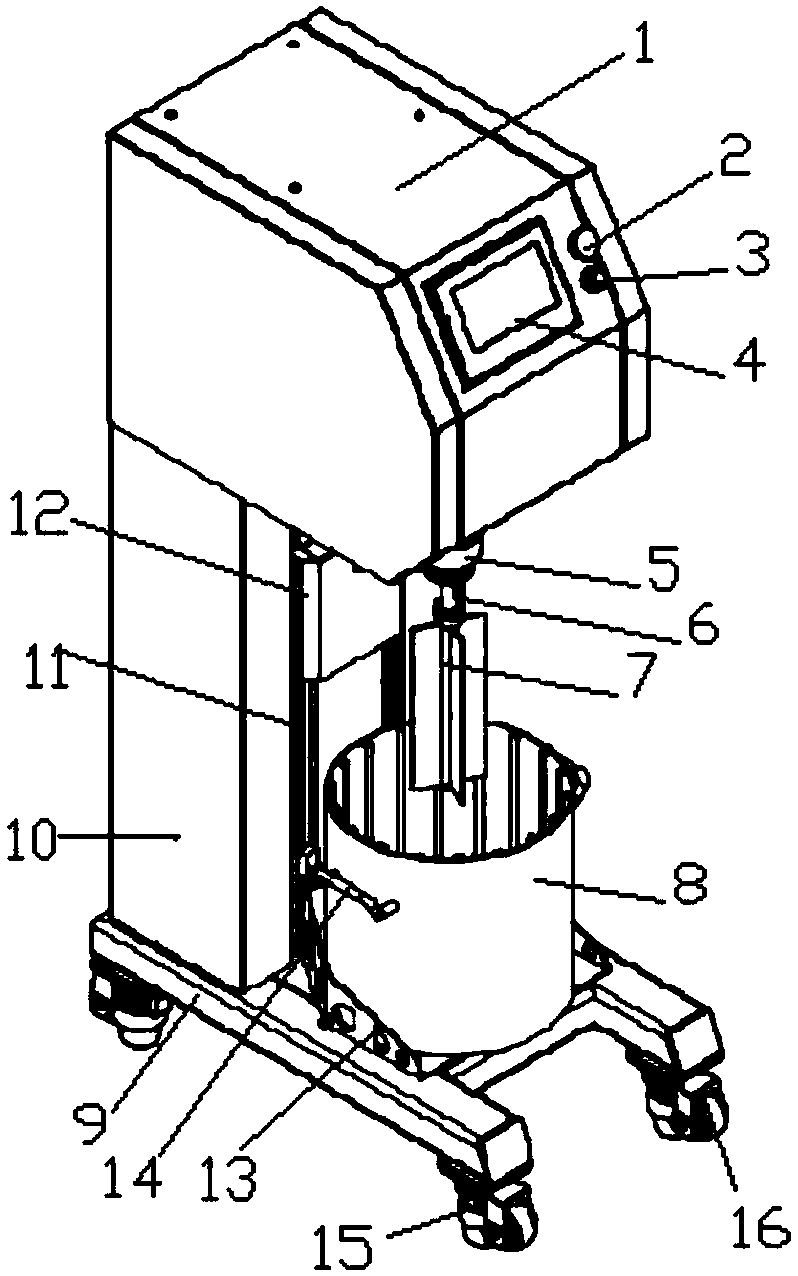

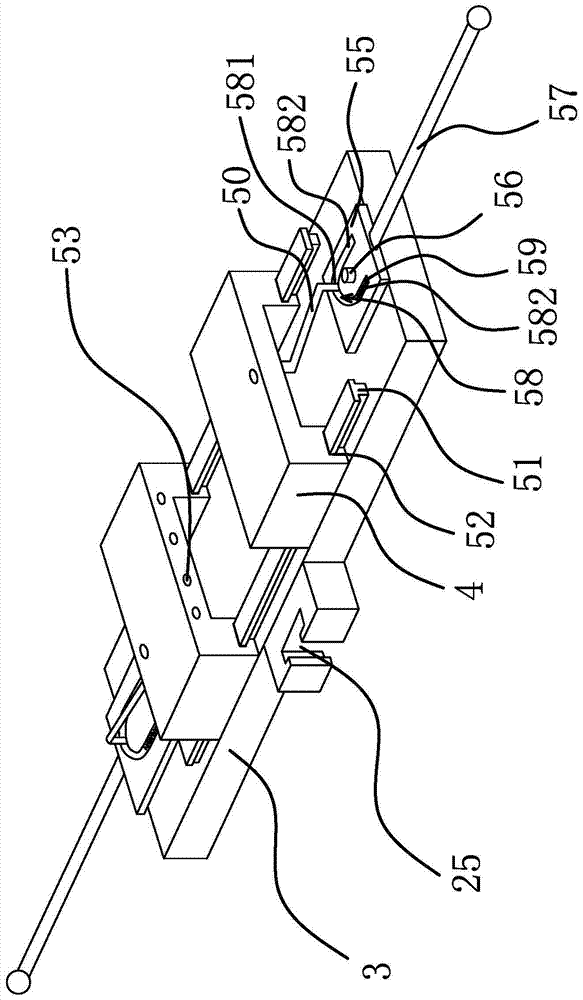

Dual-purpose testing device for rheometer and tribometer

InactiveCN108956379APrecisely control the depth of immersion into concreteFlow propertiesUsing mechanical meansEngineeringDual purpose

The invention discloses a dual-purpose testing device for a rheometer and a tribometer. The dual-purpose testing device comprises a device body which is formed by a rheometer detection braking tank, an emergency stopping button, a starting button, a touch screen controller, a torque sensor, a connecting device, a cross rotor, a stainless steel testing bucket, a support base, a lower instrument protecting cover, a stainless steel moving guide rail, a stainless steel mounting lining plate, a testing bucket positioning lining support, a stainless steel testing bucket handle, portable Foma wheel support seats and portable Foma wheels. The rheometer detection braking tank is arranged at the top end of the device body, the touch screen controller is arranged on one side of the rheometer detection braking tank, and the emergency stopping button is arranged on one side of the touch screen controller, so that the functions of the rheometer can be realized; by utilizing a cross, the dynamic yield stress and viscosity of pump concrete can be detected; secondly, the depth of a rotor penetrating into the concrete can be accurately controlled by the testing device; and by utilizing a cone-shapedrotor, the resistance applied by the concrete to the rotor can be accurately tested.

Owner:上海砼瑞仪器设备有限公司

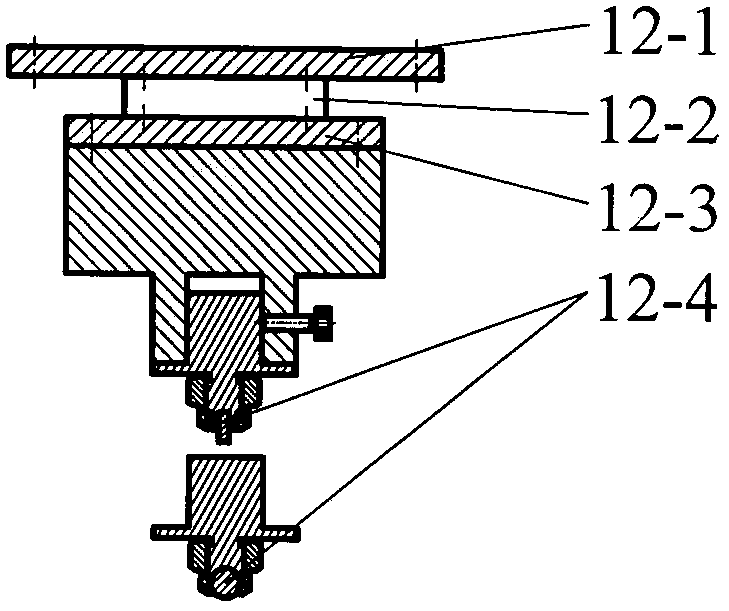

Digital display type drill rod and drill core tribometer

InactiveCN101915732AReduce destabilizing effectsIncreased sensitivityUsing mechanical meansMaterial analysisFriction forceDrill

The invention provides a digital display type drill rod and drill core tribometer. A drill core is fixed at the lower end of a pressurizing and holding device, the pressurizing and holding device is arranged on a support, and the upper end of the pressurizing and holding device is provided with a pressurizing cake. A simulation drill rod is connected with a shaft of a motor and rotates along with the shaft, the drill core is pressed on the simulation drill rod, and a guide rod for transmitting the friction force between the drill core and the rotating simulation drill rod is connected with a sensor after penetrating through the pressurizing cake. The digital display type drill rod and the drill core tribometer has convenient detection, small and exquisite structure and stable and accurate reading.

Owner:CENT SOUTH UNIV

Intrinsically-calibrated tribometer

Intrinsically calibrating friction mensuration device has a drive unit with controllable motive member, configured to receive a controllable propulsion force, and to apply tractive force to a test piece on a surface. A force engine couples to the motive member, and applies the controllable propulsion force. The device includes a controller imposing a propulsion control signal actuating the force engine to produce the propulsion force. A force sensor is between the drive unit and the test piece, producing a force signal responsive to a sensed force between the drive unit and the test piece. The drive unit can self-propelled or stationary. A method includes applying an increasing tractive force to a test piece at rest; measuring the tractive force; identifying the maximum tractive force applied at incipient motion; identifying the transition between the resting test piece and incipient motion; determining the SCOF; continue motion and determine the DCOF.

Owner:JOHNSON FRED M

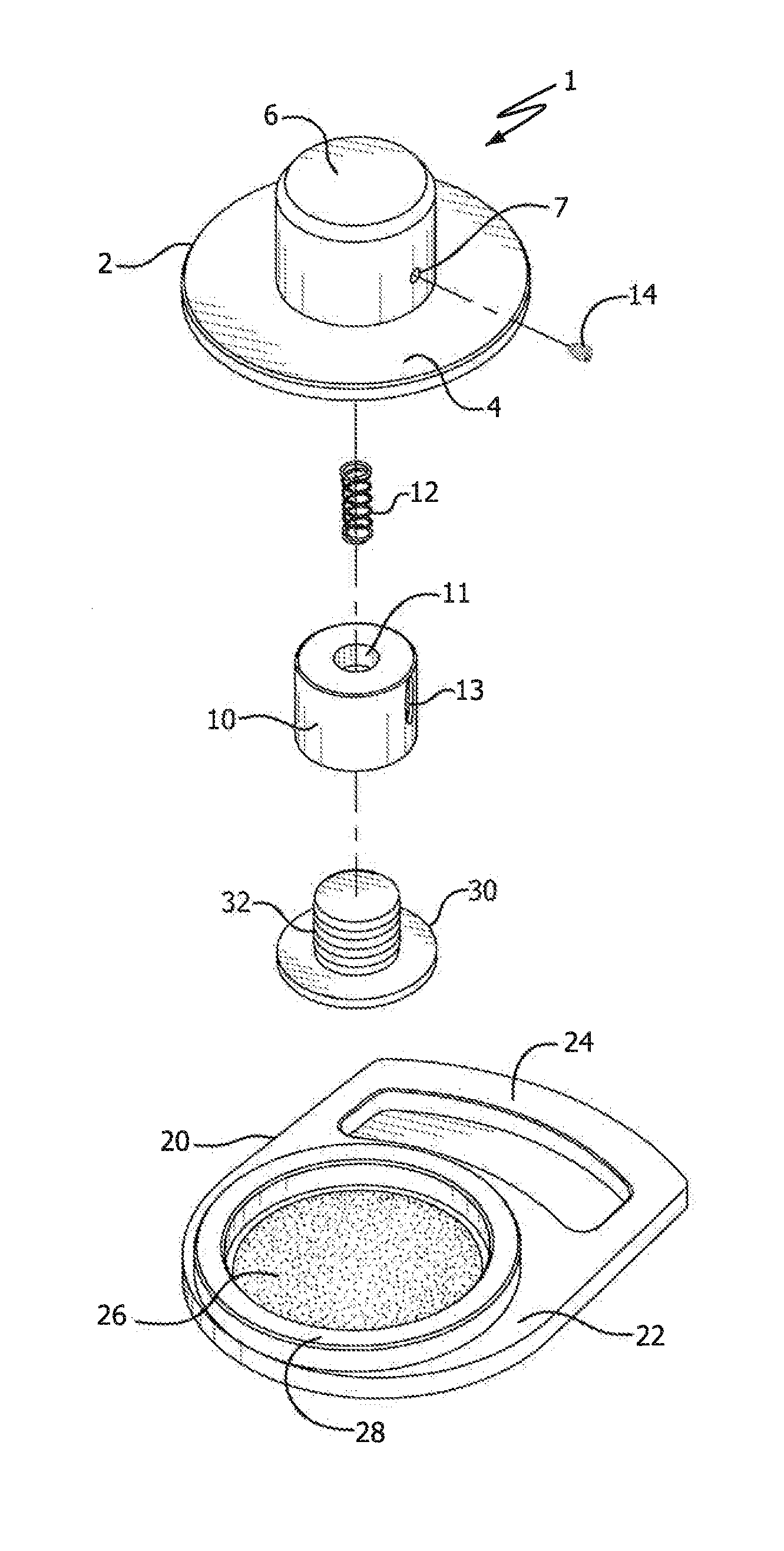

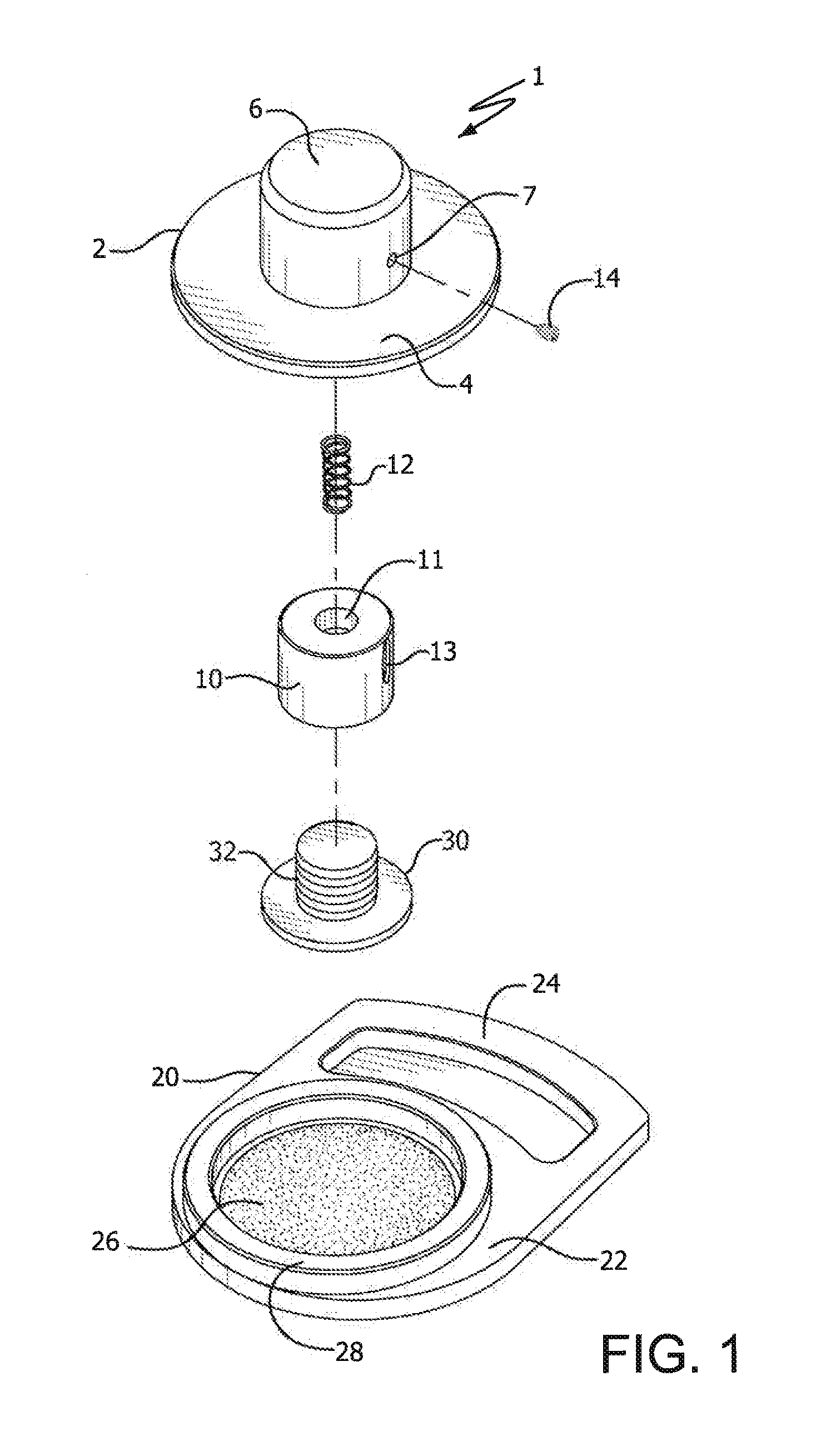

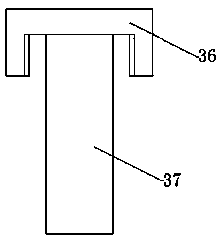

System for Calibrating a Tribometer Test Foot

InactiveUS20150185104A1Achieve correctionReliable resultsWeighing apparatus testing/calibrationUsing mechanical meansSanderEngineering

A system for the calibration of a tribometer test foot utilizes a uniquely designed sanding pad with a hard-back sandpaper surface, and a separate, independent sander member which has a top section with a test foot mounting element in the form of a piston having a threaded connection for securing the test foot. The sander member, with test foot attached, is configured to mate with the sanding pad to allow the test foot to be sanded to the required calibration. Calibration of the test foot is accomplished by pressing the sander member onto the sanding pad such that the test foot is compelled against the sandpaper surface of the sanding pad and rotating the sander member for the requisite sanding and thus accurate calibration of the test foot.

Owner:WIDAS III GEORGE P

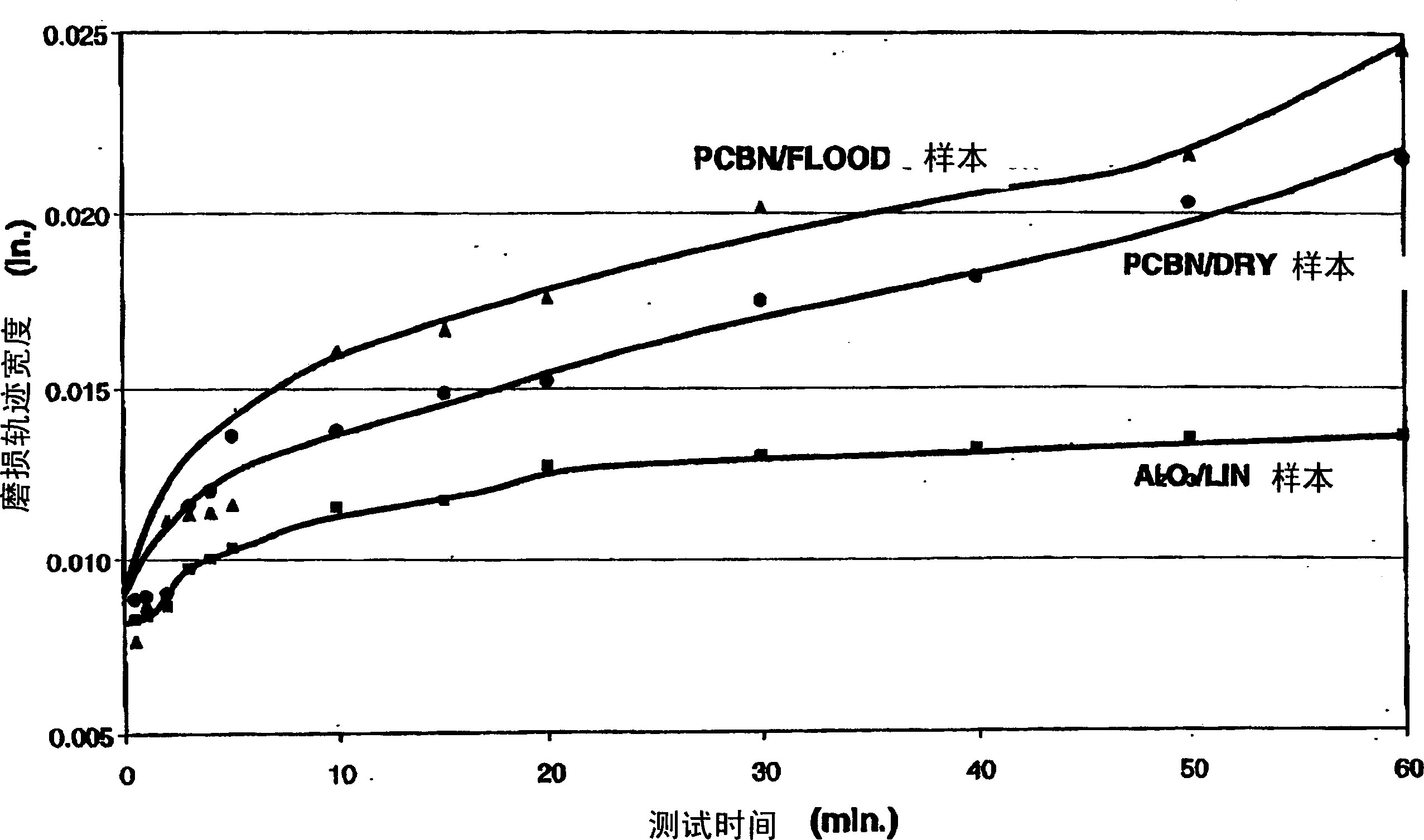

Rolling ball tribometer

InactiveCN1715868AShorten assessment timeSimple methodMachine part testingUsing mechanical meansConstant forceRotation test

This invention is directed to a tribological apparatus and method incorporating a ball, a support, and means for maintaining a substantially constant force between the ball and a test surface. The ball rolls against the rotating test surface producing a wear track. Analysis relating to wear and fatigue can be performed on the test surface subsequent to producing the wear track.

Owner:AIR PROD & CHEM INC

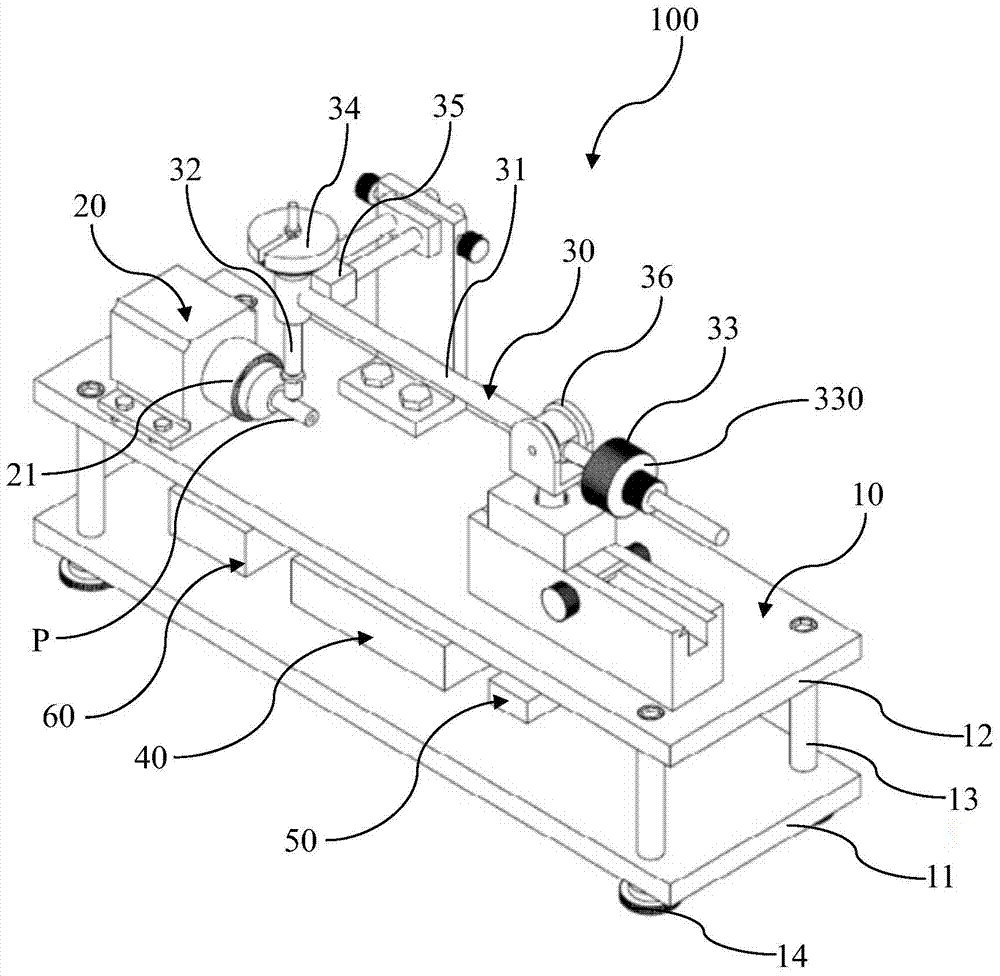

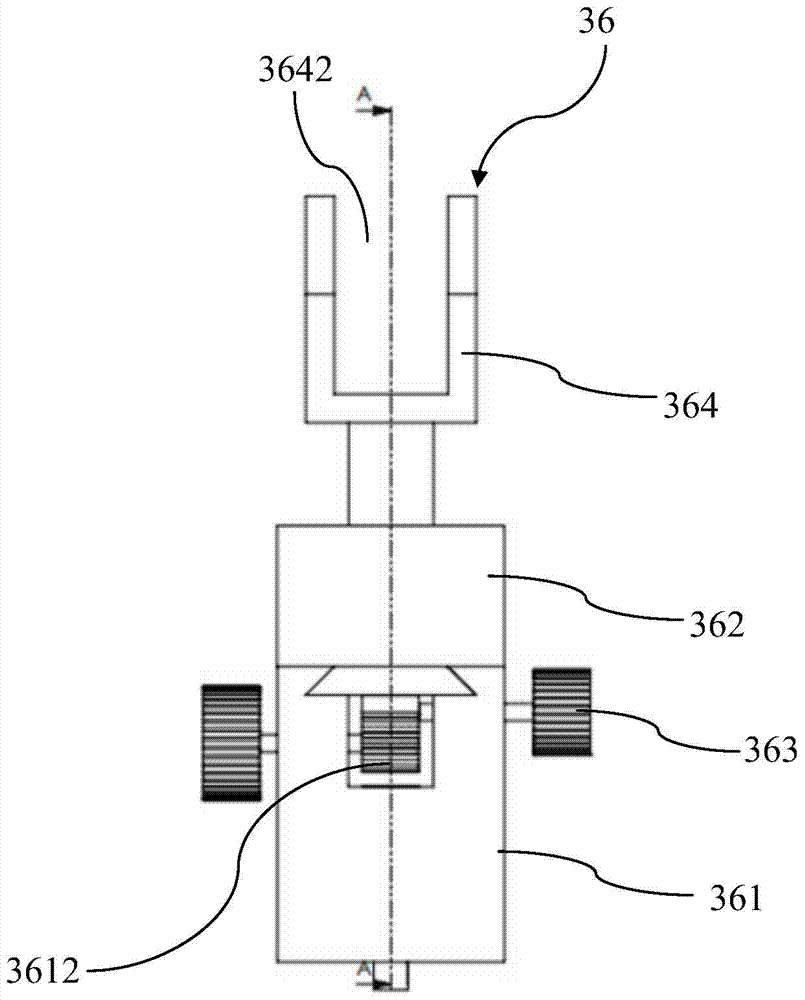

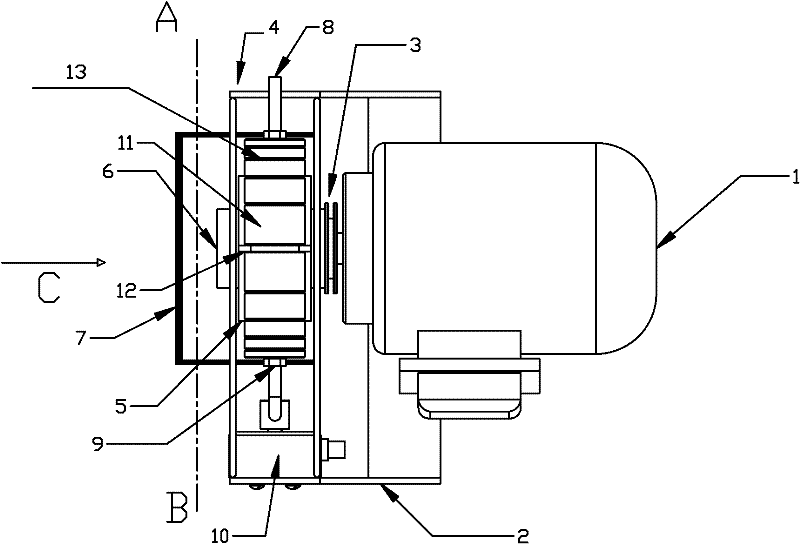

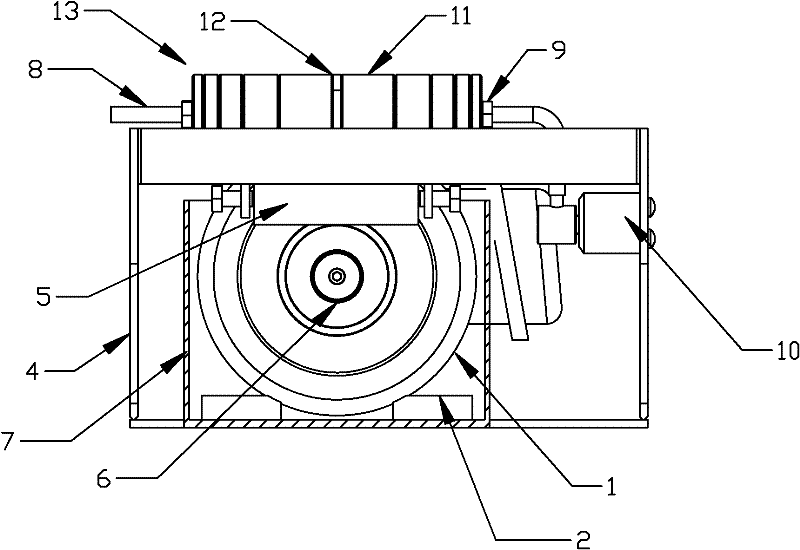

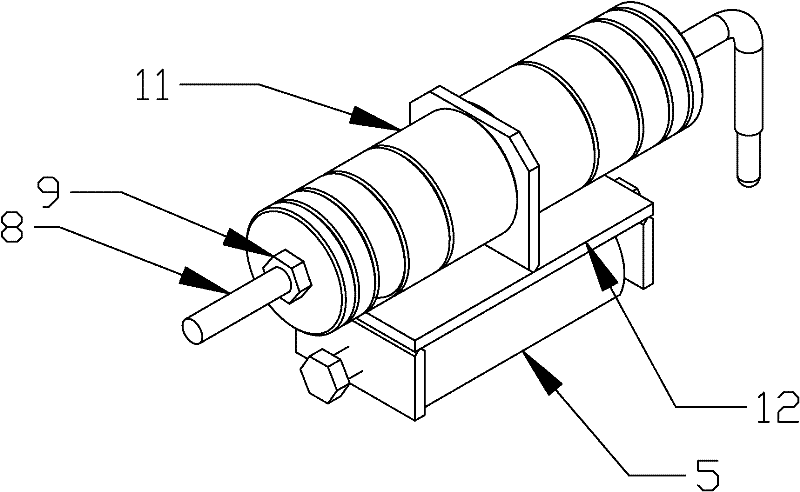

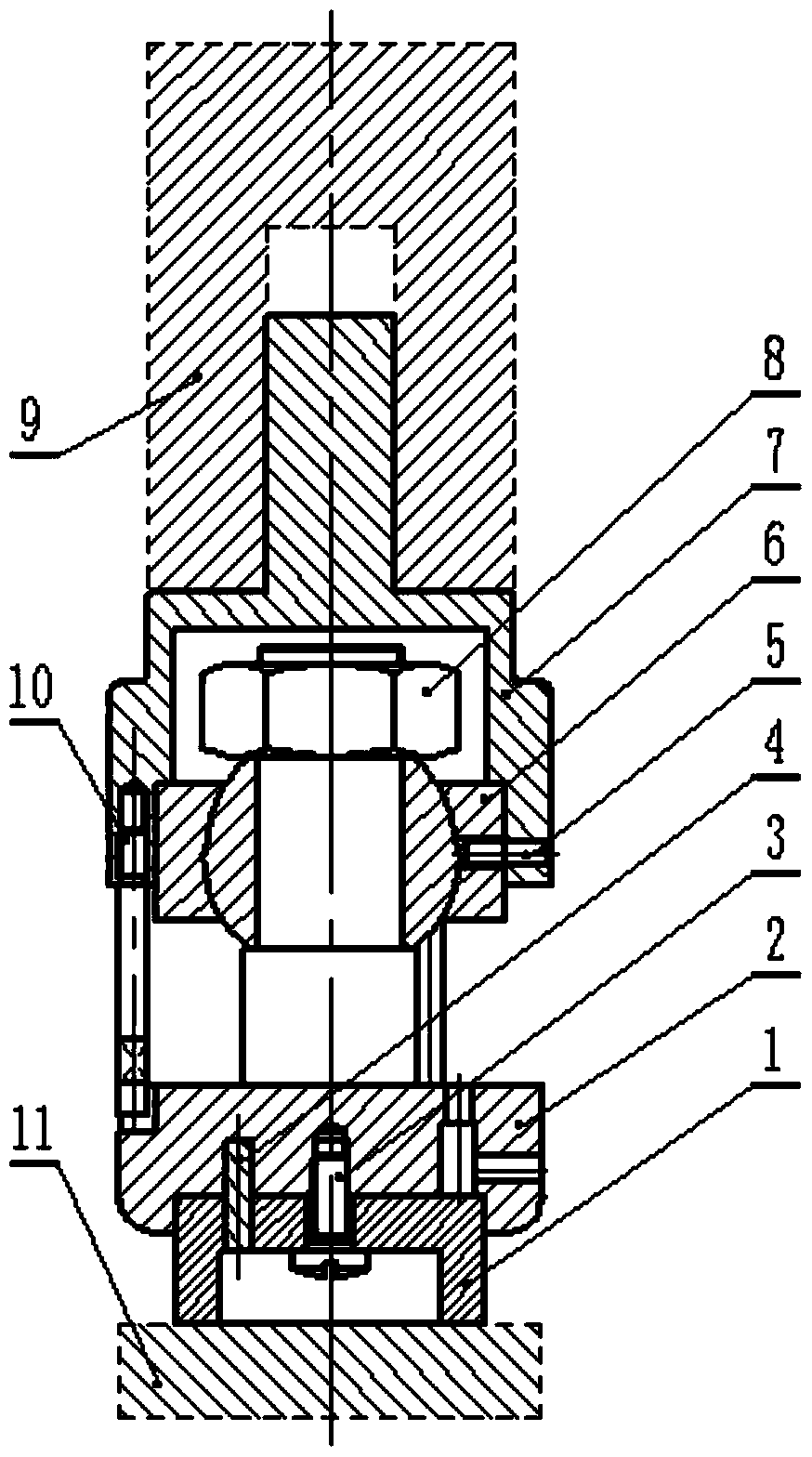

Shaft parts coating friction and wear testing machine

ActiveCN104406873BGuaranteed reliabilityGuaranteed coincidenceInvestigating abrasion/wear resistancePower switchingElectric machinery

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Method and system for abrasion testing of materials

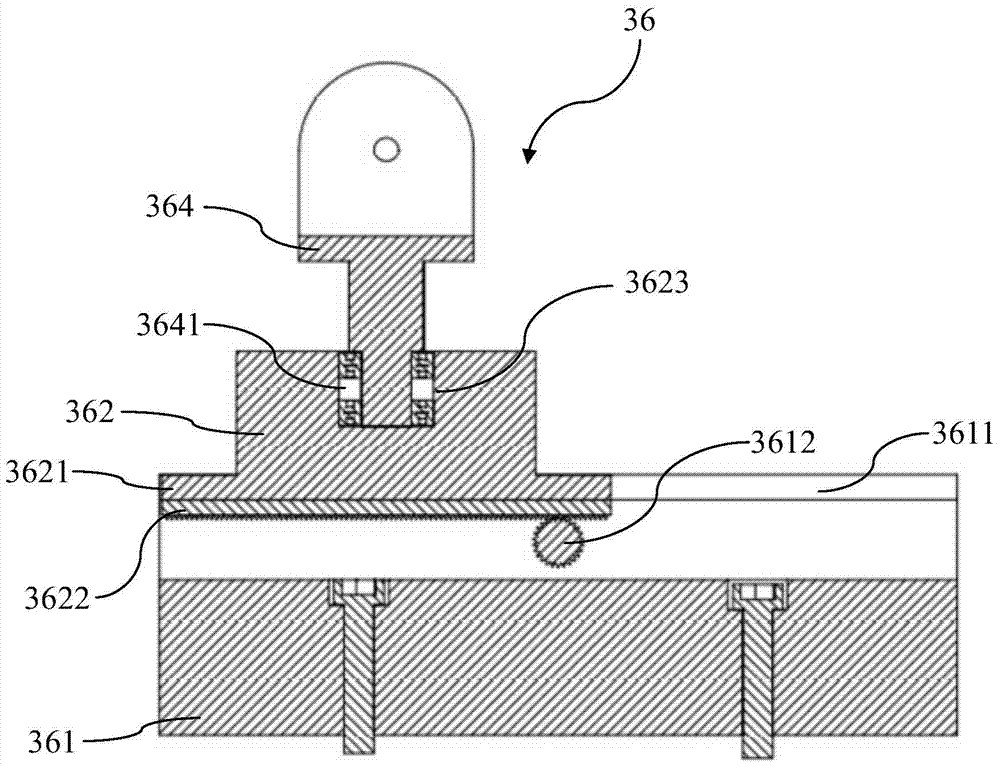

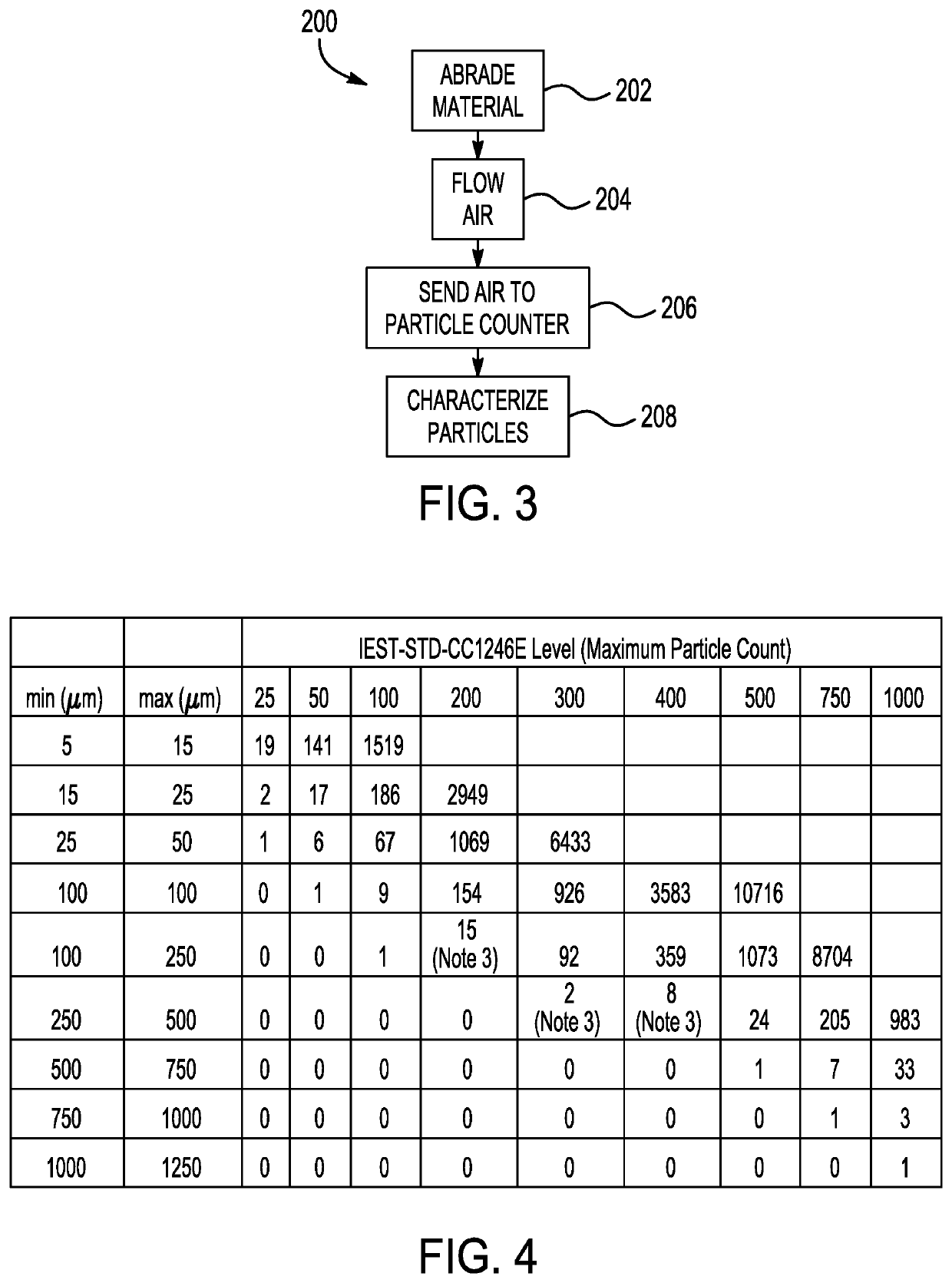

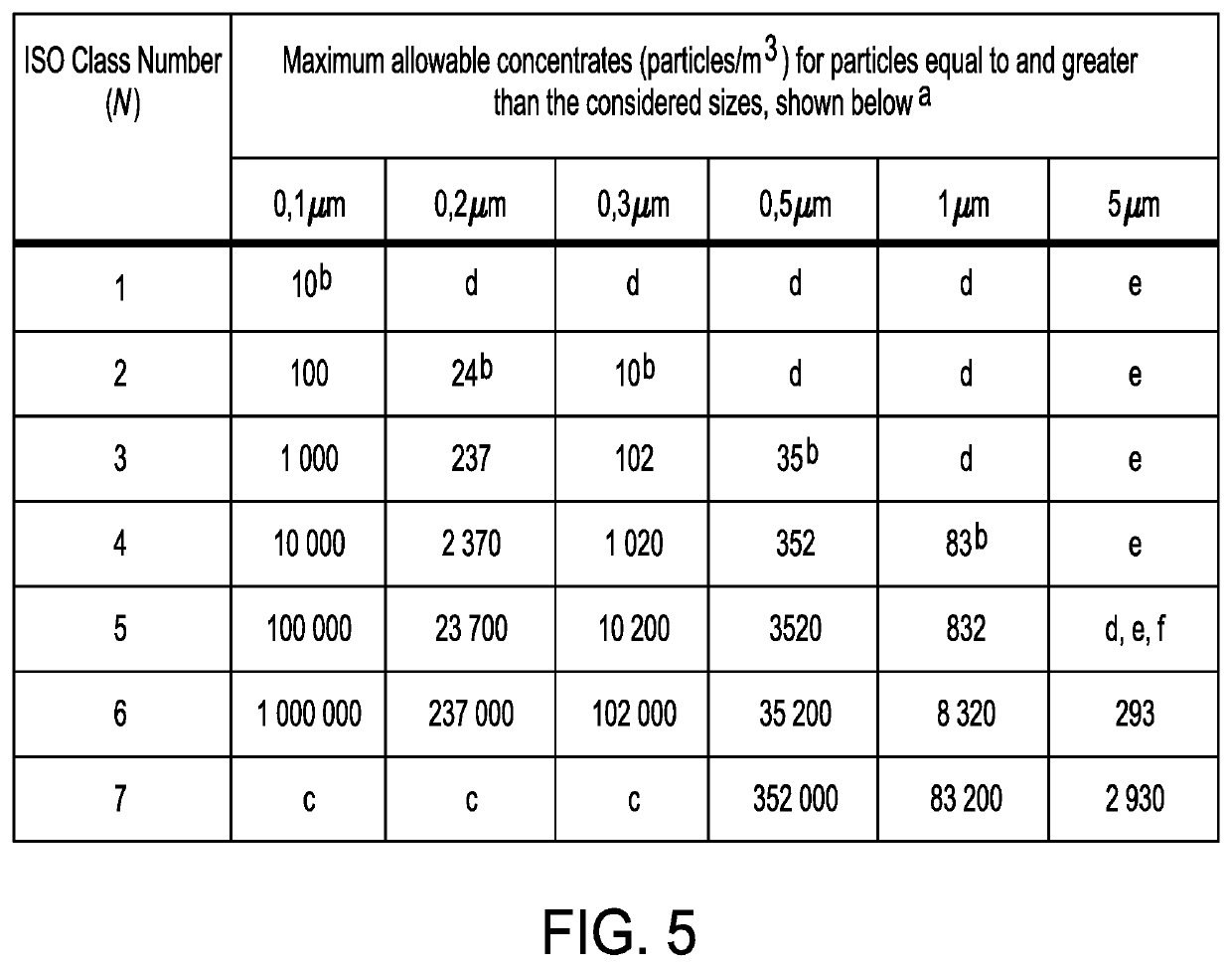

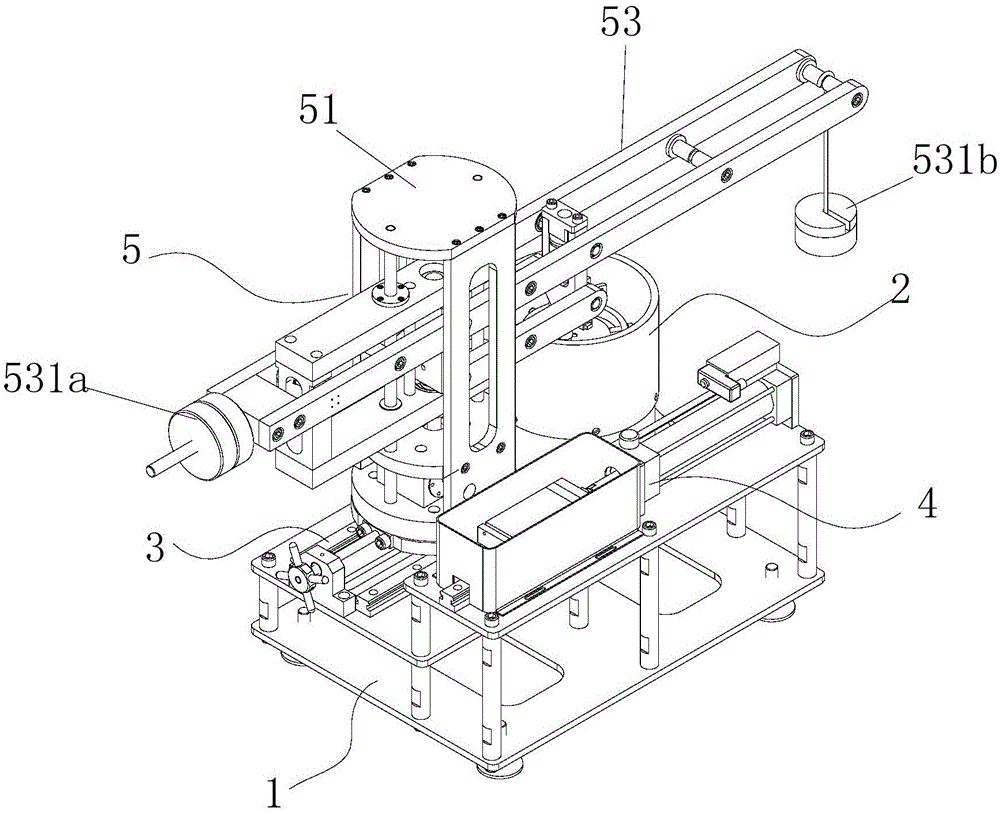

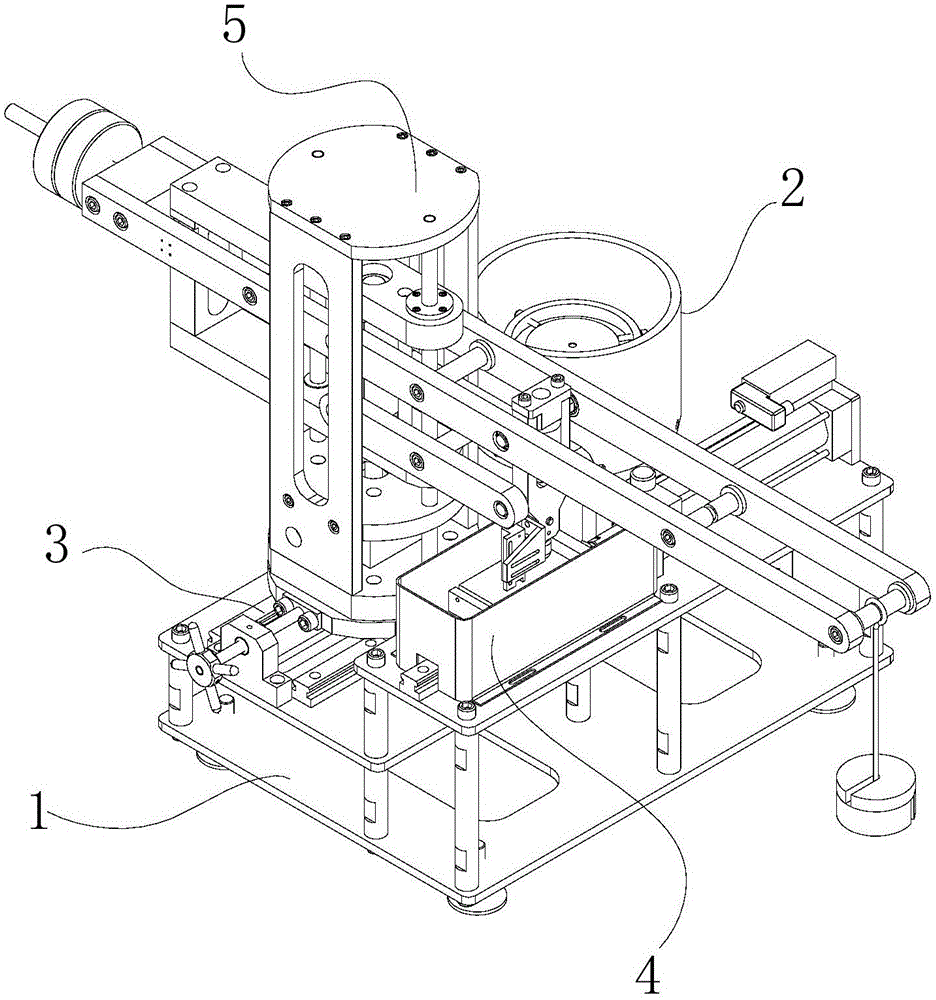

InactiveUS20210302302A1Maintaining laminar flowMaintain normal flowGas treatmentAdditive manufacturing apparatusHEPAEngineering

A method for abrasion testing of a material sample includes abrading a surface of the sample with a tribometer, then characterizing particles in a portion of the flowing air that is received in an airborne particle collector. The testing may be done in an enclosure or container, such as an enclosure in or simulating a clean room environment. The drawing of air into the enclosure may be done by a fan pushing in air through a filter, such as a high efficiency particulate air (HEPA) filter. The enclosure may have vents (or louvers) through which some of the outflow of air may be directed, to help maintain an even flow, for example a laminar flow, of air through the container, and in particular past where the tribometer abrades the test material. The method may allow for real-time characterization of the particles produced by the testing.

Owner:RAYTHEON CO

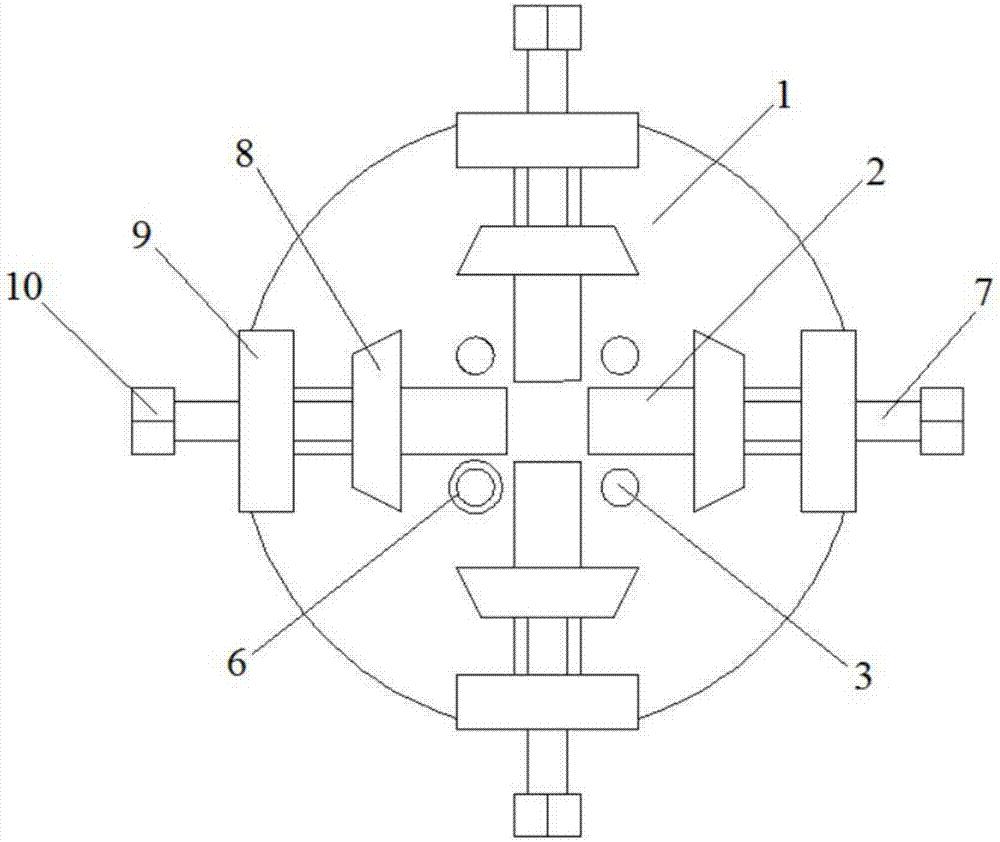

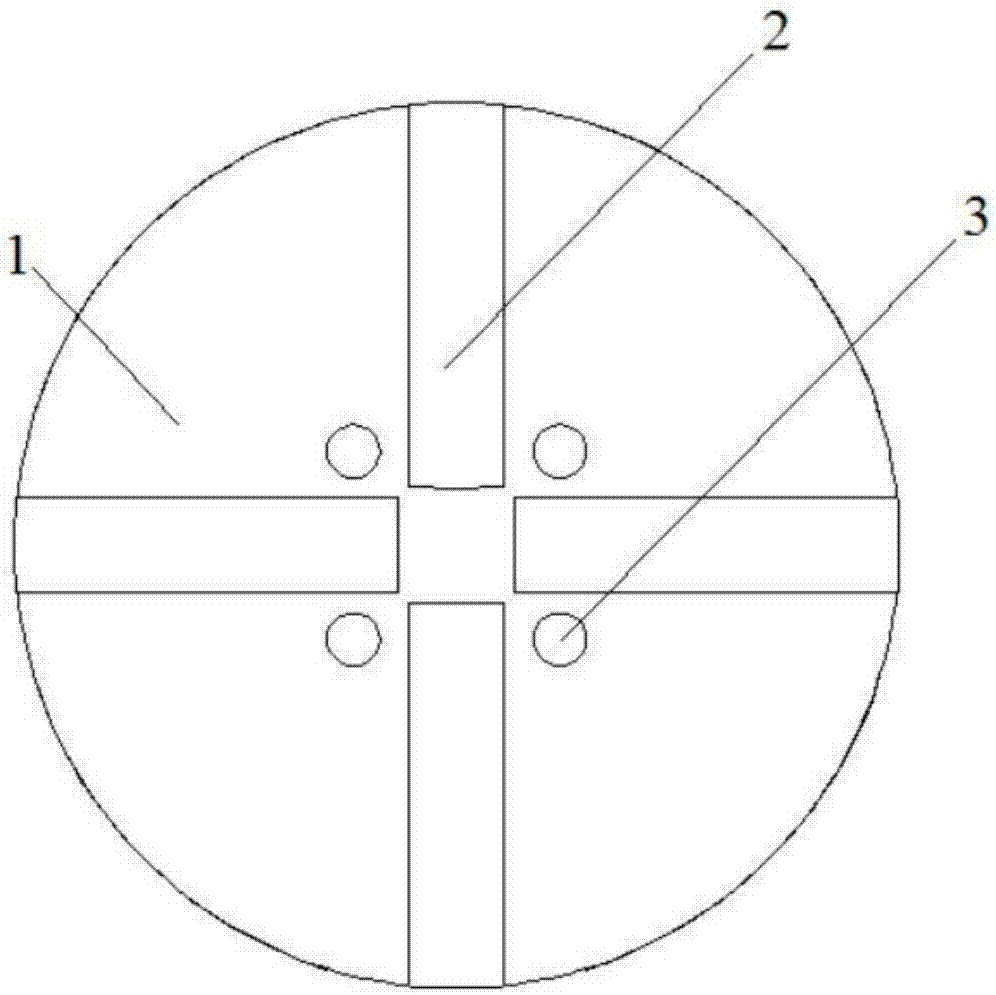

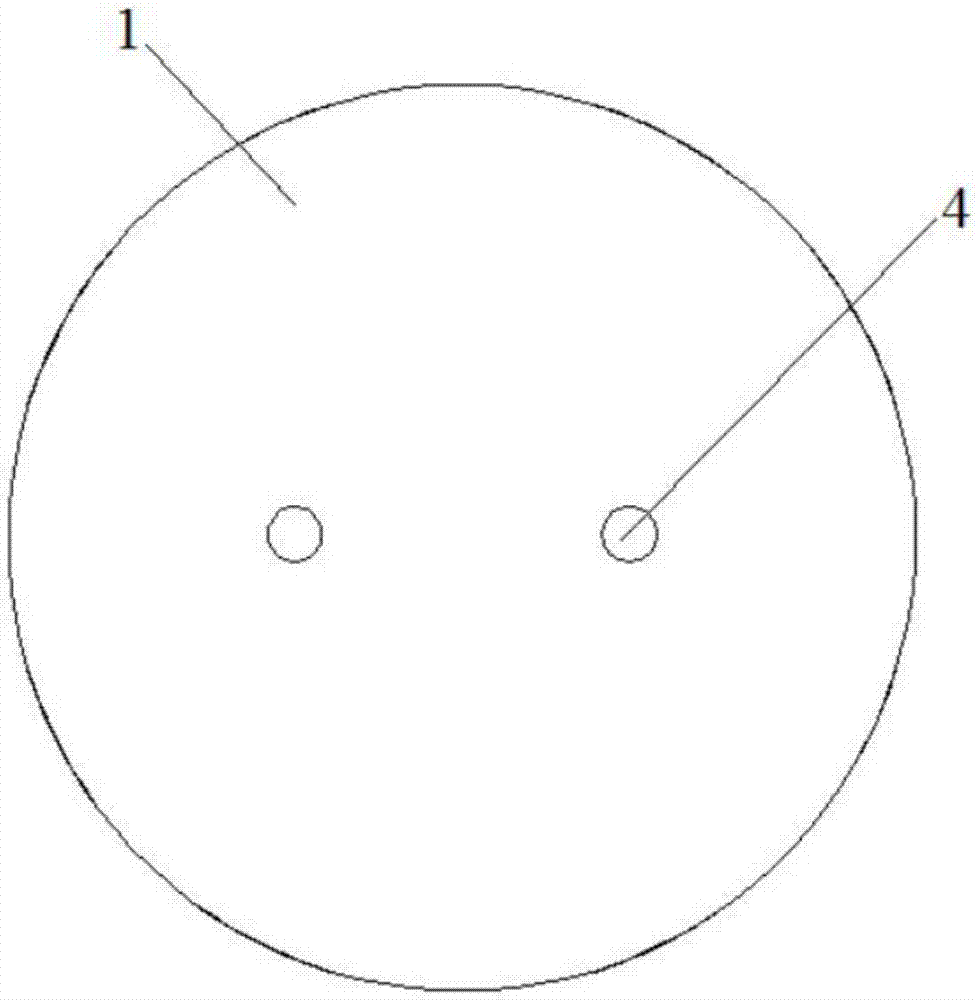

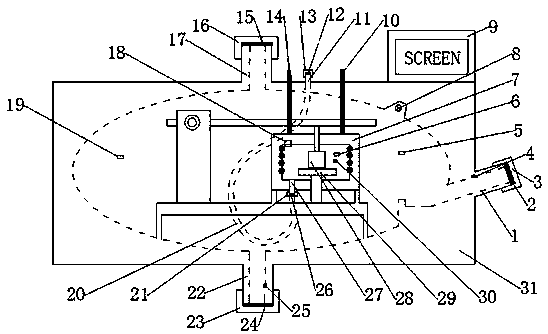

A magnetic shielding composite friction and wear testing machine

ActiveCN103792187BShield interferenceShielding from external magnetic field interferenceUsing mechanical meansMaterial analysisReciprocating motionEngineering

The invention provides a magnetically-shielded combined type friction-abrasion testing machine, which comprises a rack, a rotating mechanism, a horizontal adjusting platform, a reciprocating mechanism and a friction loading mechanism, wherein the rack consists of a bottom-layer platform, a middle-layer platform and a top-layer platform, and the middle-layer platform and the top-layer platform are positioned on the bottom-layer platform; the rotating mechanism is arranged on the middle-layer platform, the upper end of the rotating mechanism is connected with a rotating disc for placing samples, and a first magnetic shielding case is arranged at the outer peripheral side of the rotating disc; the horizontal adjusting platform is arranged on the middle-layer platform and arranged on one side of the rotating mechanism along a second direction, and the horizontal adjusting platform is provided with a turnplate seat capable of moving along the second direction; the reciprocating mechanism comprises a cylinder and a linear guide rail, the cylinder is arranged on the top-layer platform, a sample fixing seat is arranged on a slider of the linear guide rail, the linear guide rail and the horizontal adjusting platform are adjacent along a first direction, a second magnetic shielding case is arranged on the outer peripheral side of the linear guide rail, an extension rod of the cylinder is arranged on the second magnetic shielding case in a penetration manner and connected with the sample fixing seat and can drive the sample fixing seat to do reciprocating motion along the second direction; the friction loading mechanism consists of a support frame, a lifting platform and a loading assembly.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

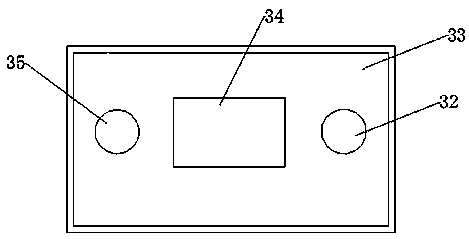

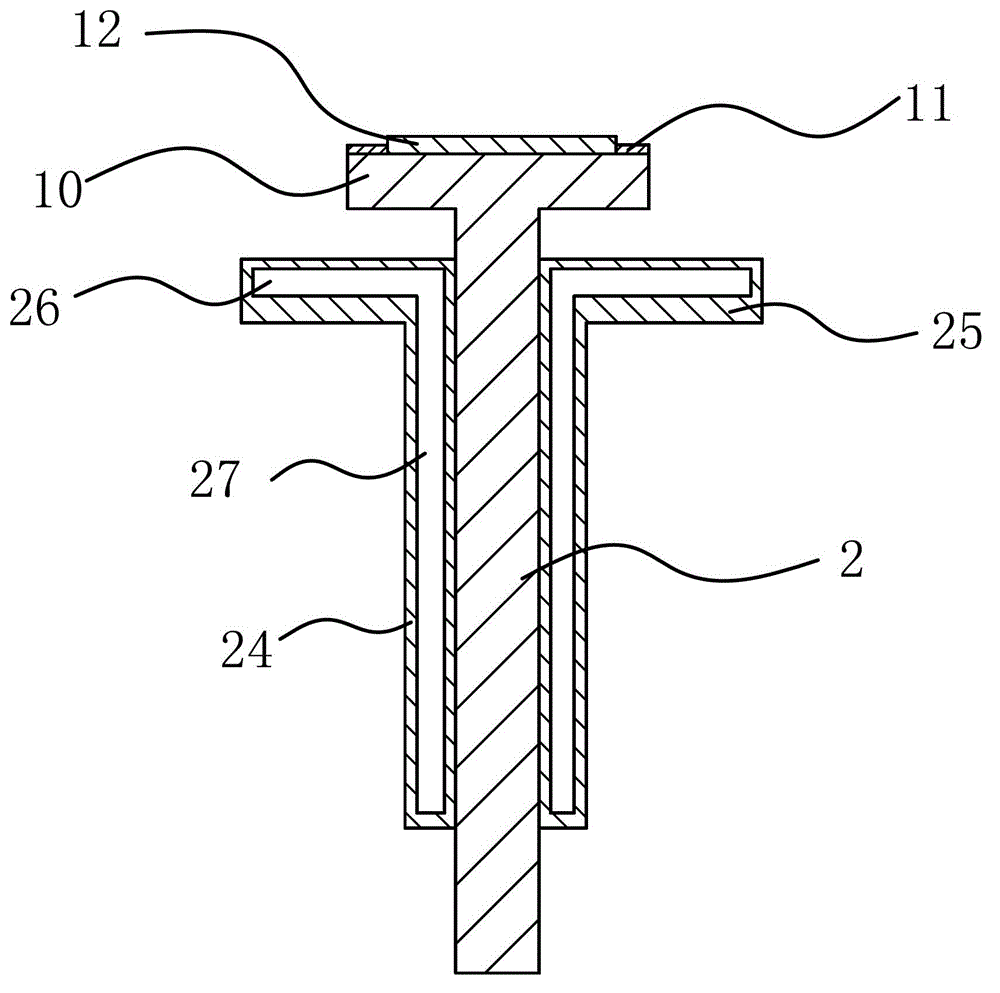

A double-layer insulation box structure for low-temperature friction and wear testing machine

ActiveCN106742559BSolve temperature problemsSimple structureDomestic cooling apparatusLighting and heating apparatusWorking environmentShielding gas

The invention discloses a double-layer heat-insulation box body structure for a low-temperature friction-wear tester. The double-layer heat-insulation box body structure is characterized by comprising an inner-layer heat-insulation box body, an endoscope and illumination system, an outer-layer heat-insulation box body, an outer-layer heat-insulation box door, an illumination lamp, temperature sensors, a control display module and humidity detection sensors, wherein the endoscope and illumination system is arranged in the inner-layer heat-insulation box body; the inner-layer heat-insulation box body and the illumination lamp are arranged in the outer-layer heat-insulation box door; the control display module is arranged at an upper part outside the outer-layer heat-insulation box door, and used for acquiring the signals of the temperature sensors, the humidity detection sensors and the endoscope, and displaying a temperature, a humidity and endoscope images. The double-layer heat-insulation box body is provided for the low-temperature friction-wear tester for a grinding tool for an ice pin, the problems of the temperature recovery in the box body and the thawing of the ice pin, which are brought during clamping and trimming for the ice pin, are solved, and a working environment fully filled with a protective gas can be provided.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

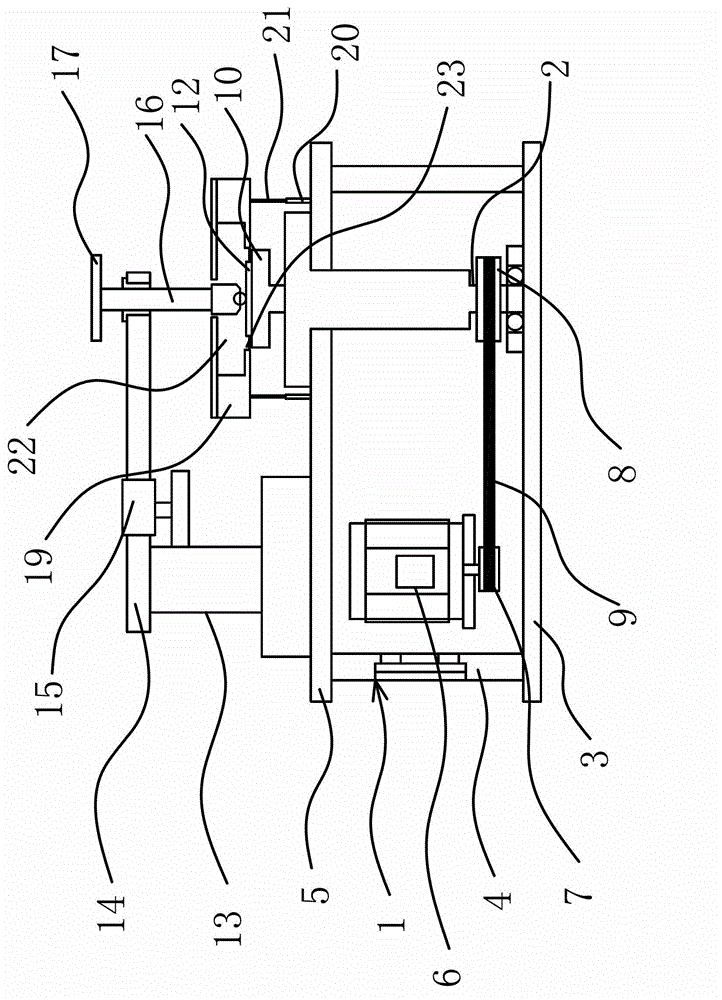

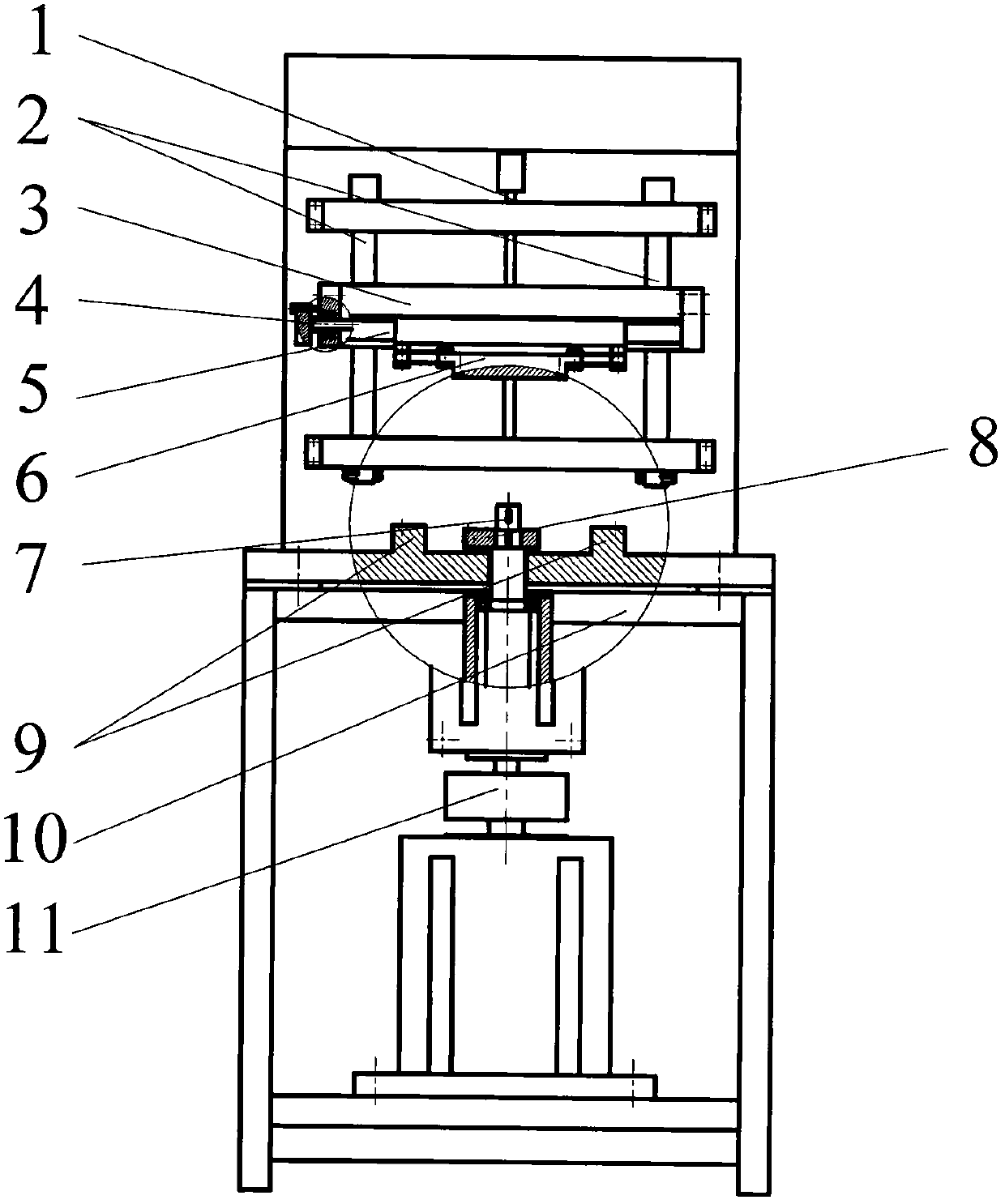

Multifunctional vacuum friction and wear testing machine

ActiveCN102759489BReasonably equippedShort vacuum timeInvestigating abrasion/wear resistanceDrivetrainEngineering

A multi-functional vacuum friction and wear testing machine, which can not only simulate special environmental atmospheres such as vacuum, radiation, and corrosion, but also perform tribological tests in a wide range of speeds and loads with various contact methods (ball-disk, pin-disc). test. It is mainly composed of vacuum system, friction and wear system, power transmission system, measurement and control system, etc. Each subsystem is highly integrated, and no other auxiliary devices are needed during the test. Wherein the friction and wear system includes a lever structure (22) that is used to fix the upper sample fixture (20) and can rotate freely in both horizontal and vertical directions, and lift up and down in the vertical direction, and the lever structure (22) includes A cantilever beam (18) and a vertical arm (23) that are vertically arranged, the cantilever beam (18) and the vertical arm (23) can be assisted by the glass observation window and the internal high-precision displacement platform on the vacuum chamber, through The manipulator (15) and the handwheel mechanism (13) running through the vacuum chamber can adjust the horizontal and vertical positions without breaking the vacuum degree of the control system, so as to realize the movement of the upper sample holder (20) in two degrees of freedom. Move with precision. A temperature sensor (2) and a pressure sensor (3) are installed on the upper sample fixture (20), and the temperature sensor is inserted into the center of the upper sample close to the friction interface to measure and calculate the temperature change during the friction test. The equipment is mainly used to test the tribological properties of materials and devices in a simulated space high vacuum environment.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

A cement floor coating

The invention discloses a cement floor coating prepared from the following raw materials in parts by weight: 100 parts of acrylic resin, 1-10 parts of methyl methacrylate, 45-55 parts of glass beads, 3-5 parts of methacrylic acid, 1-5 parts of soybean lecithin, 10-20 parts of isobutyl methacrylate, 5-15 parts of deionized water, 15-25 parts of hydroxyethyl acrylate, 20-30 parts of pigment, 10-30 parts of ethyl methacrylate, 20-40 parts of cobalt caprylate, 15-25 parts of ethyl acrylate, 25-35 parts of plasticizer, 15-35 parts of acetic ester, 30-40 parts of rosin and 35-45 parts of methylbenzene. The cement floor coating is good in wear resistance (up to 0.002-0.005g / cm<2> after being tested 1000 times by using a reciprocating tribometer), high in bonding strength (40-50MPa), free of bubbling and powder removing after being soaked into water for 15-20 days, free of bubbling and wrinkling after being soaked into 5% HCl for 2-3 days and free of falling off and bubbling in alkaline-resistant saturated calcium hydroxide for 5-7d, so that the cement floor coating can be widely produced and used for continuously replacing the traditional material.

Owner:吴江市远通混凝土制品有限公司

A high temperature friction and wear testing machine

InactiveCN103364296BImprove test accuracyExtended service lifeInvestigating abrasion/wear resistanceWear testingThermal insulation

The invention provides a high temperature friction wear testing machine, belongs to the technical field of material wear tests, and solves the technical problems that the test precision of the testing machines in the prior art is low and the like. The high temperature friction wear testing machine comprises a frame. The frame is provided with a rotating shaft, and is also provided with a driving device. The top end of the rotating shaft is provided with a tray, the surface of the tray is coated with a thermal insulation layer, and a friction disk is fixed on the surface of the tray. The frame is provided with a bracket, and the bracket is provided with a beam. The beam is provided a force value sensor, and a loading rod is arranged at one end of the beam. A specimen holder is arranged at the bottom end of the loading rod. The high temperature friction wear testing machine comprises a high temperature furnace. The high temperature furnace is provided with a heating cavity, and the bottom end of the loading rod is inserted in the heating cavity. An opening is arranged at the bottom part of the heating cavity, the tray is located out of the opening, and the friction disk is located in the heating cavity. The high temperature friction wear testing machine has the advantages of high test precision and the like.

Owner:JIAXING VOCATIONAL TECHN COLLEGE

A multifunctional friction and wear testing machine

InactiveCN104655511BSimple structureLow costUsing mechanical meansInvestigating abrasion/wear resistanceWear testingEngineering

A multifunctional friction and wear testing machine, including a horizontal lead screw, an upper friction pair connection seat, a rotating main shaft, an incomplete gear, a rectangular guide rail, a frame, a pin or ball upper friction pair assembly, a pin or ball upper friction pair, a reciprocating lower Features By replacing three different matching friction pair components on the same upper friction pair connection seat and rotating spindle, the upper friction pair on the pin or ball and the reciprocating lower friction pair, the friction pair on the end face and the lower friction pair on the end face, and the upper and lower friction pairs on the pin or ball are realized. Determination of the tribological parameters between the friction pair and the friction pair under the rotating disk. The testing machine can carry out tribological tests of three different types of friction pairs. Compared with the existing friction and wear testing machines, it has complete functions, simple structure and low cost.

Owner:NANJING FORESTRY UNIV

A kind of perchlorethylene floor coating

The invention discloses a vinylidene chloride floor coating comprising the following raw materials in parts by weight: 100 parts of vinylidene chloride resin, 5-10 parts of melamine, 30-40 parts of dibutyl phthalate, 1-10 parts of formaldehyde, 25-35 parts of barium ricinoleate, 20-30 parts of butanol, 40-60 parts of deionized water, 35-45 parts of dimethylbenzene, 10-20 parts of pigment, 5-15 parts of titanium dioxide, 20-40 parts of antimony oxide, 15-25 parts of methanol, 10-30 parts of plasticizer, 25-45 parts of bentonite, 20-30 parts of talcum powder and 15-35 parts of styrene. The vinylidene chloride floor coating is good in wear resistance (up to 0.001-0.005g / cm<2> after being tested 1000 times by using a reciprocating tribometer), free of abnormalities after being soaked into 20-DEG C water for 10-20 days and capable of resisting to the temperature of 10 DEG C below zero for 10 hours without embrittling and cracking; in addition, a film has no abnormalities after being soaked into alkaline water for 5-7 days, so that the vinylidene chloride floor coating can be widely produced and used for continuously replacing existing material.

Owner:苏州靖羽新材料有限公司

Digital display type drill rod and drill core tribometer

InactiveCN101915732BReduce destabilizing effectsIncreased sensitivityUsing mechanical meansMaterial analysisElectric machineFriction force

The invention provides a digital display type drill rod and drill core tribometer. A drill core is fixed at the lower end of a pressurizing and holding device, the pressurizing and holding device is arranged on a support, and the upper end of the pressurizing and holding device is provided with a pressurizing cake. A simulation drill rod is connected with a shaft of a motor and rotates along withthe shaft, the drill core is pressed on the simulation drill rod, and a guide rod for transmitting the friction force between the drill core and the rotating simulation drill rod is connected with a sensor after penetrating through the pressurizing cake. The digital display type drill rod and the drill core tribometer has convenient detection, small and exquisite structure and stable and accuratereading.

Owner:CENT SOUTH UNIV

A Specimen Fixture with Self-Adaptive Contact of Frictional Surface

ActiveCN105352794BGuaranteed Adaptive ContactHighly consistentStrength propertiesBall bearingSacroiliac joint

Owner:CHINA UNIV OF MINING & TECH

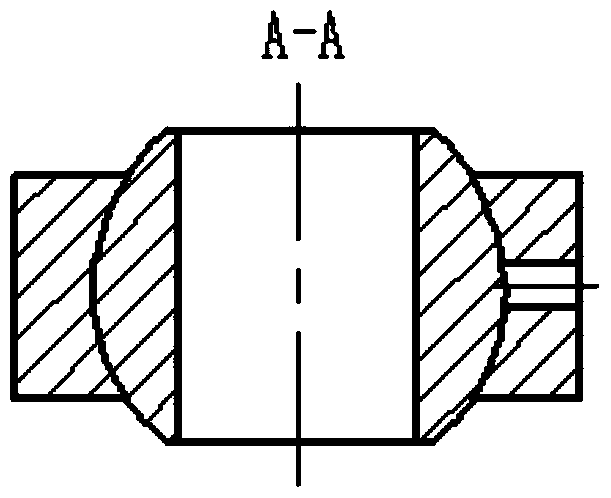

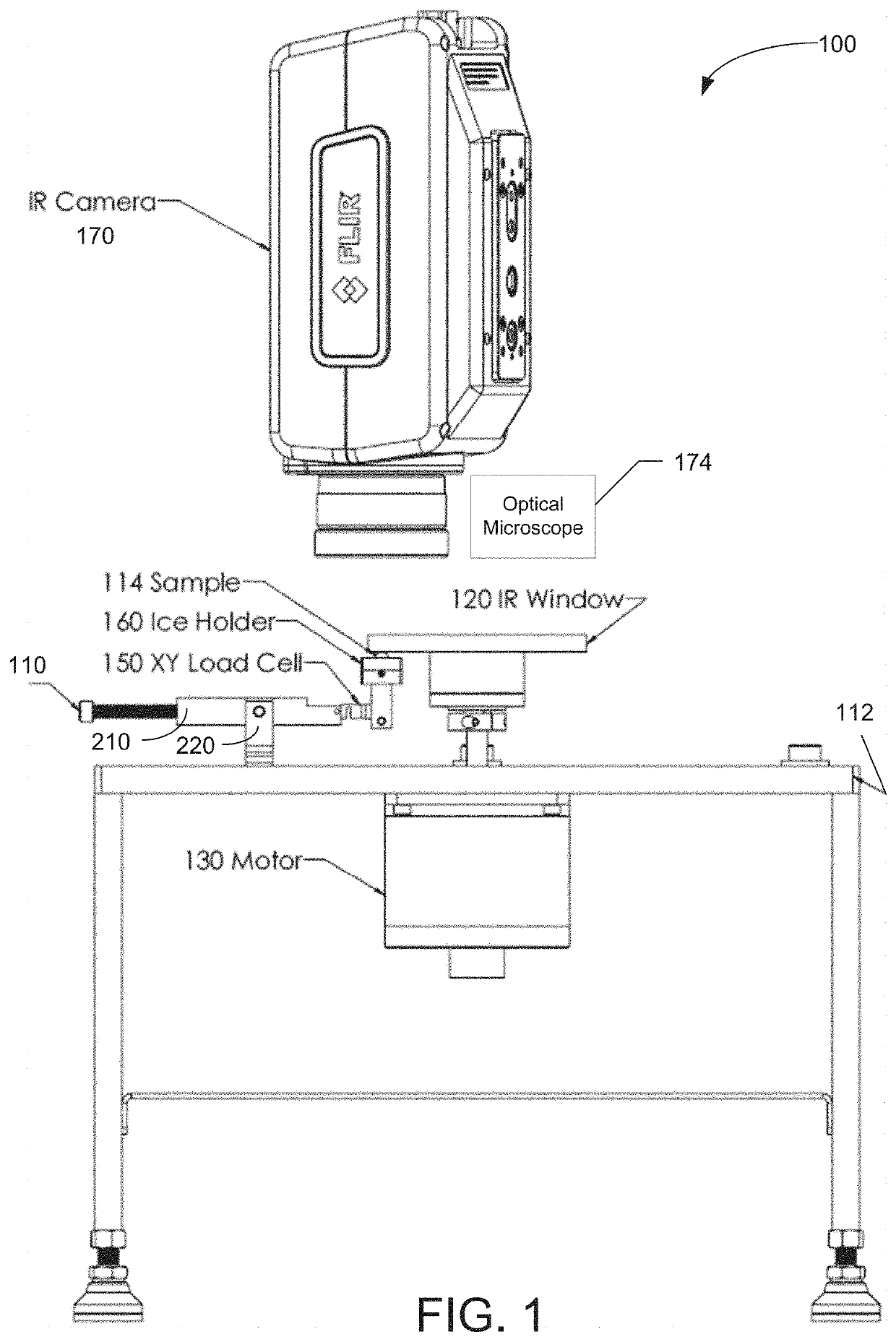

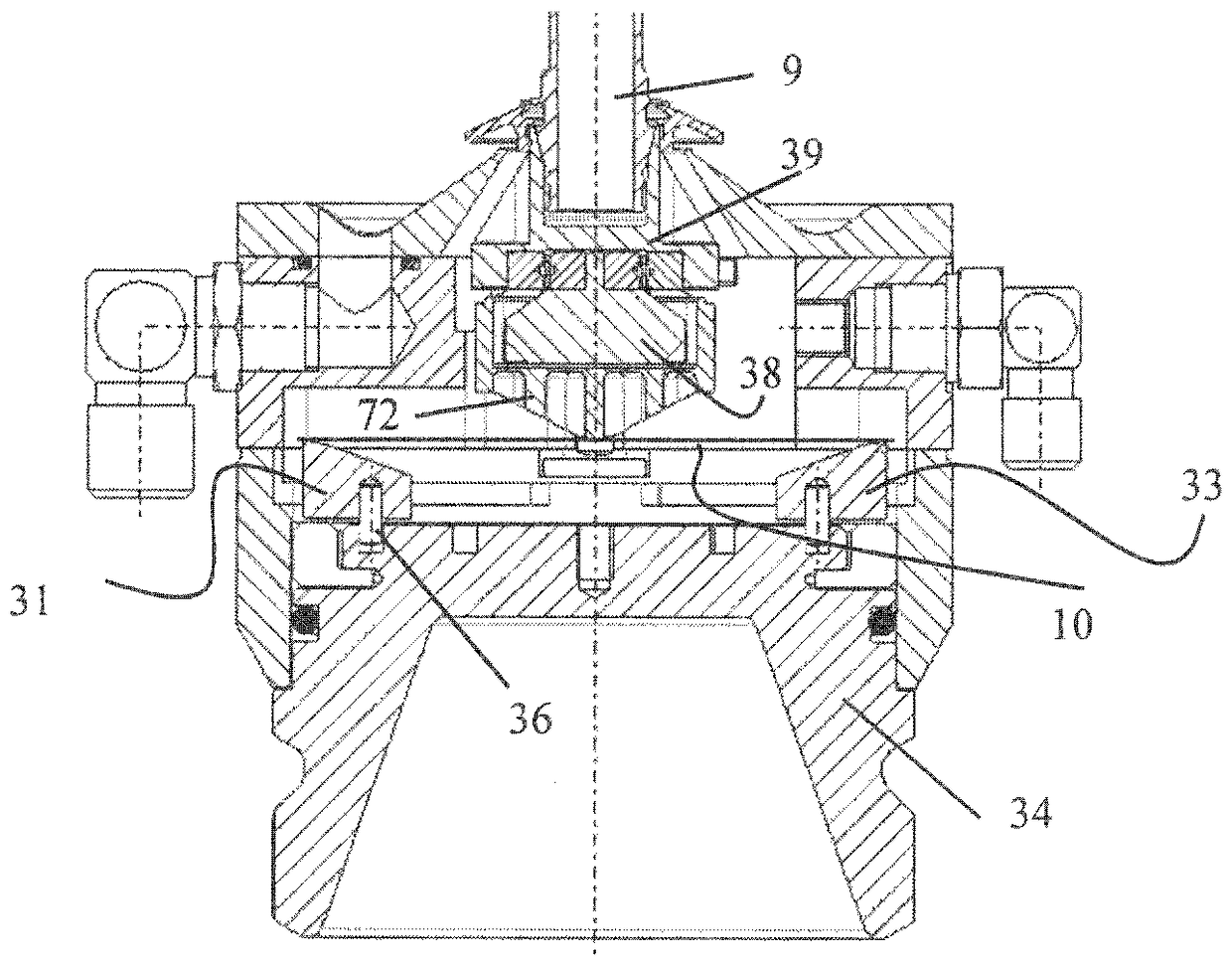

Tribometer with real-time observation of interface processes

PendingUS20220099558A1Easy to testEasy to controlMaterial analysis by optical meansUsing mechanical meansCircular discEngineering

In one embodiment, a tribometer comprises: an infrared (IR) transparent and optically transparent disk coupled to a platform, the disk having an observation side disk surface on an observation side of the disk and a contact side disk surface on a contact side of the disk; a motor coupled to the disk to rotate the disk around a rotational axis of the disk; a pivot support coupled to the platform; a pivoting member connected to the pivot support to pivot along a pivot plane; a sample holder configured to hold a sample and be coupled with the pivoting member to place the sample in contact with the contact side disk surface of the disk; and an IR camera and an optical microscope disposed on the observation side of the disk to observe the sample in sliding contact with the contact side disk surface of the disk driven in rotation.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

A friction and wear testing machine with improved structure

InactiveCN104614266BChange thrustRelieve pressureInvestigating abrasion/wear resistanceWear testingDrive motor

The invention provides a friction-wear testing machine with an improved structure, belongs to the technical field of machinery, and solves the technical problems of inaccuracy of testing and the like due to the fact that a conventional friction-wear testing machine cannot better clamp a workpiece. The friction-wear testing machine with the improved structure comprises a base, wherein a support panel is fixedly arranged on the base, a drive motor is arranged at the upper end of the support panel, a press head propped against the upper surface of the workpiece is fixedly arranged on an output shaft of the drive motor, and a slide track I is arranged on the support panel; the testing machine further comprises a clamping substrate, a chute I matched with the slide track I is formed in the clamping substrate, the clamping substrate is glidingly connected to the support panel, two parallel clamping blocks are glidingly connected to the clamping substrate, locking structures which can fix the clamping blocks on the clamping substrate are arranged on the clamping substrate, a loading oil cylinder is arranged at the lower end of the base, and the end part of a piston rod of the loading oil cylinder is fixedly connected with the clamping substrate. The friction-wear testing machine has the advantages of workpiece fixing firmness, accurate testing and the like.

Owner:HUBEI HONGLI HYDRAULIC TECH CO LTD

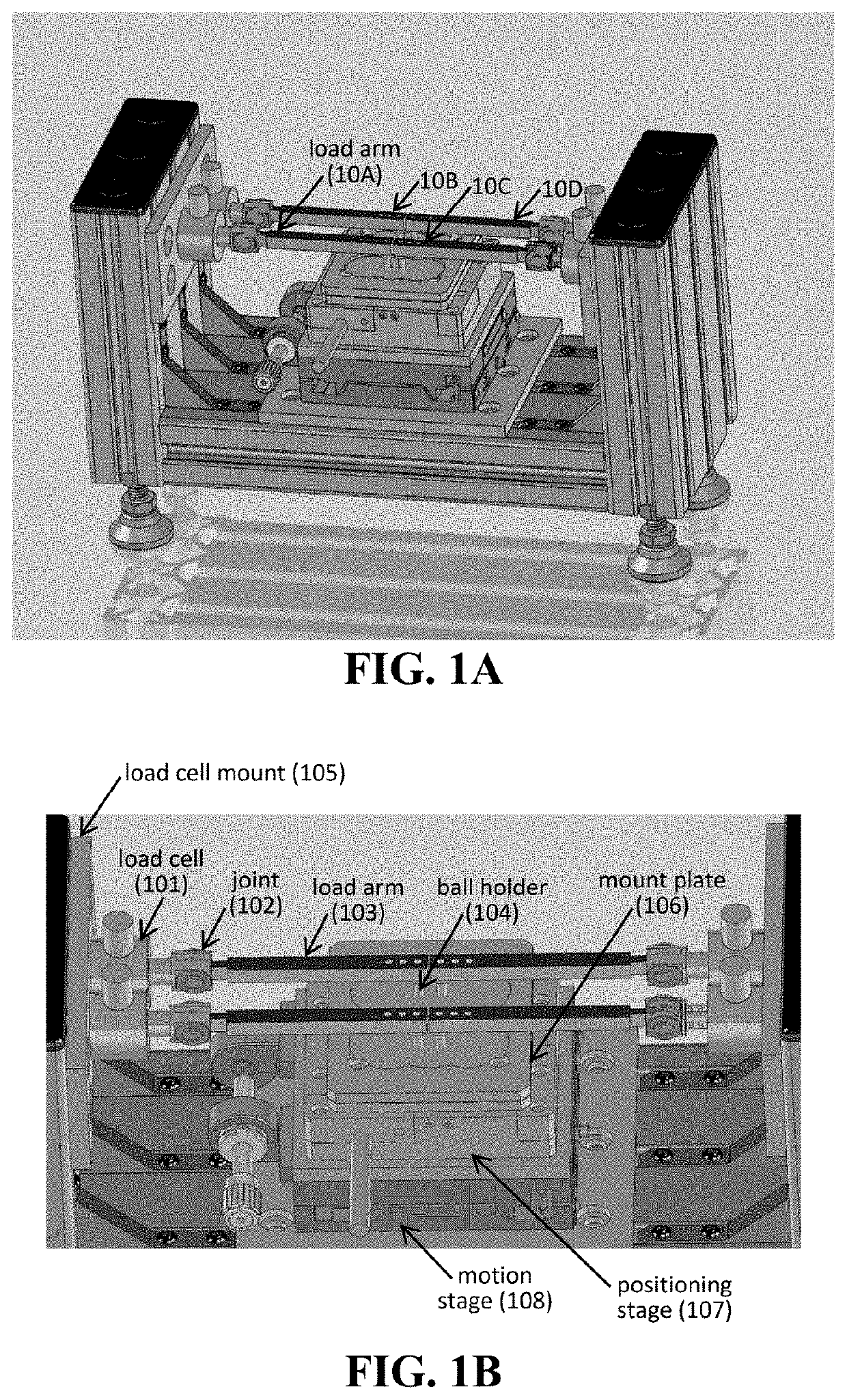

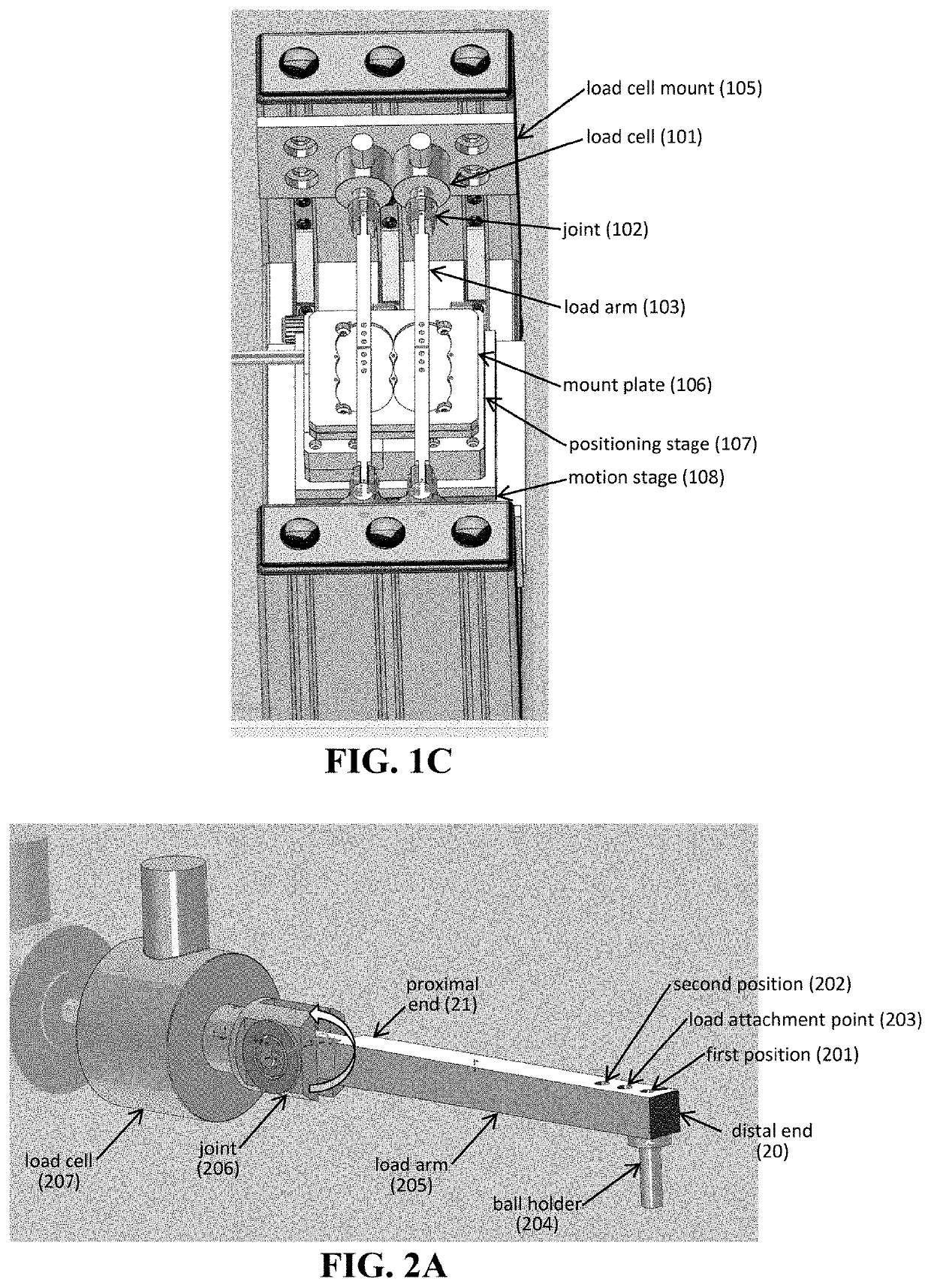

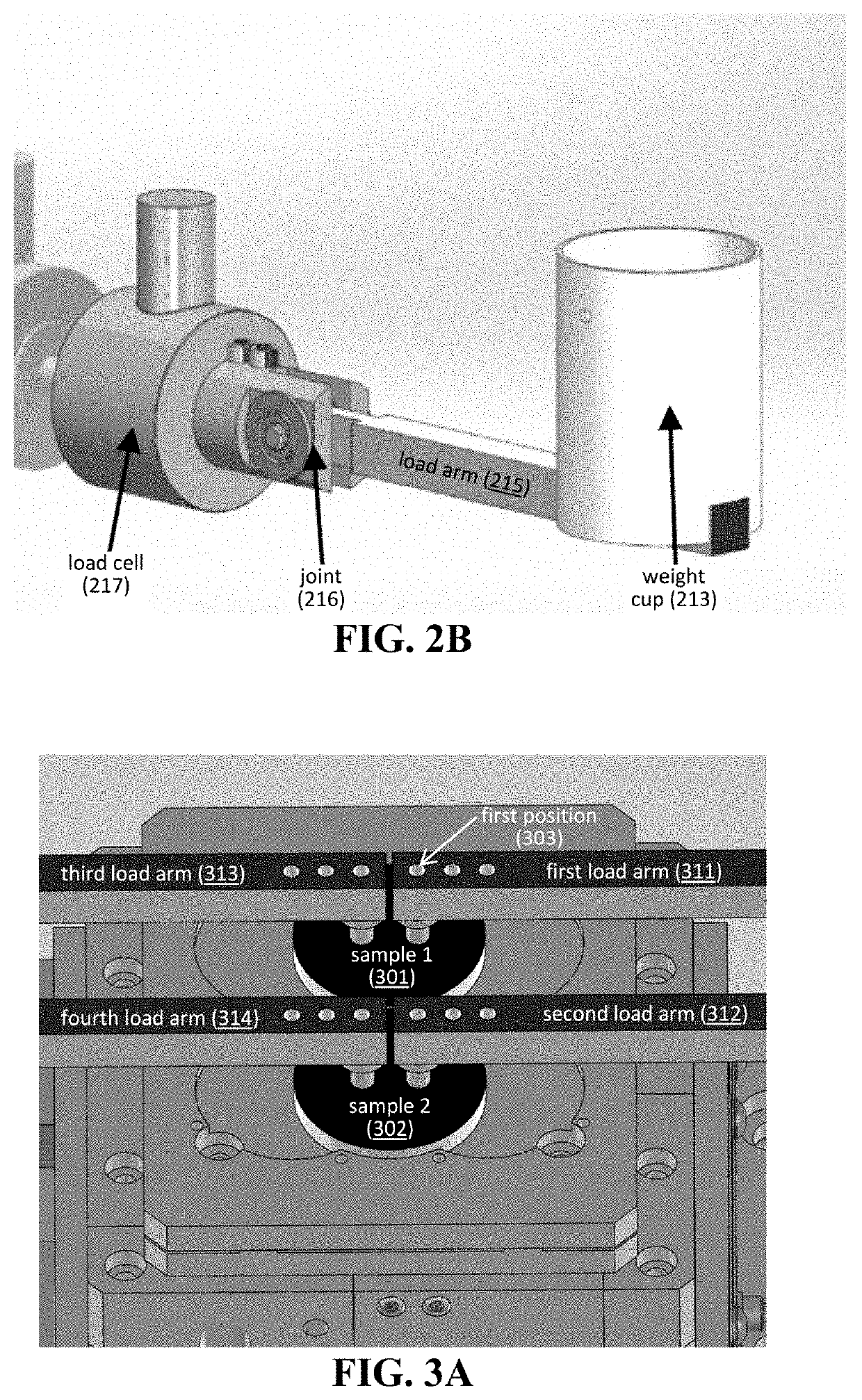

High throughput tribometer

PendingUS20220107254A1Material strength using tensile/compressive forcesUsing mechanical meansWear testingHigh flux

The present invention relates, in part, to systems for characterizing force (e.g., friction, and wear). In one embodiment, a tribometer allows for wear testing of samples in a high throughput manner.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

Tribometer

Owner:安东帕有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com