Rolling ball tribometer

A support ball, ball contact technology, applied in the field of rotating ball tribometer, can solve the problem of expensive, time-consuming, non-practical parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

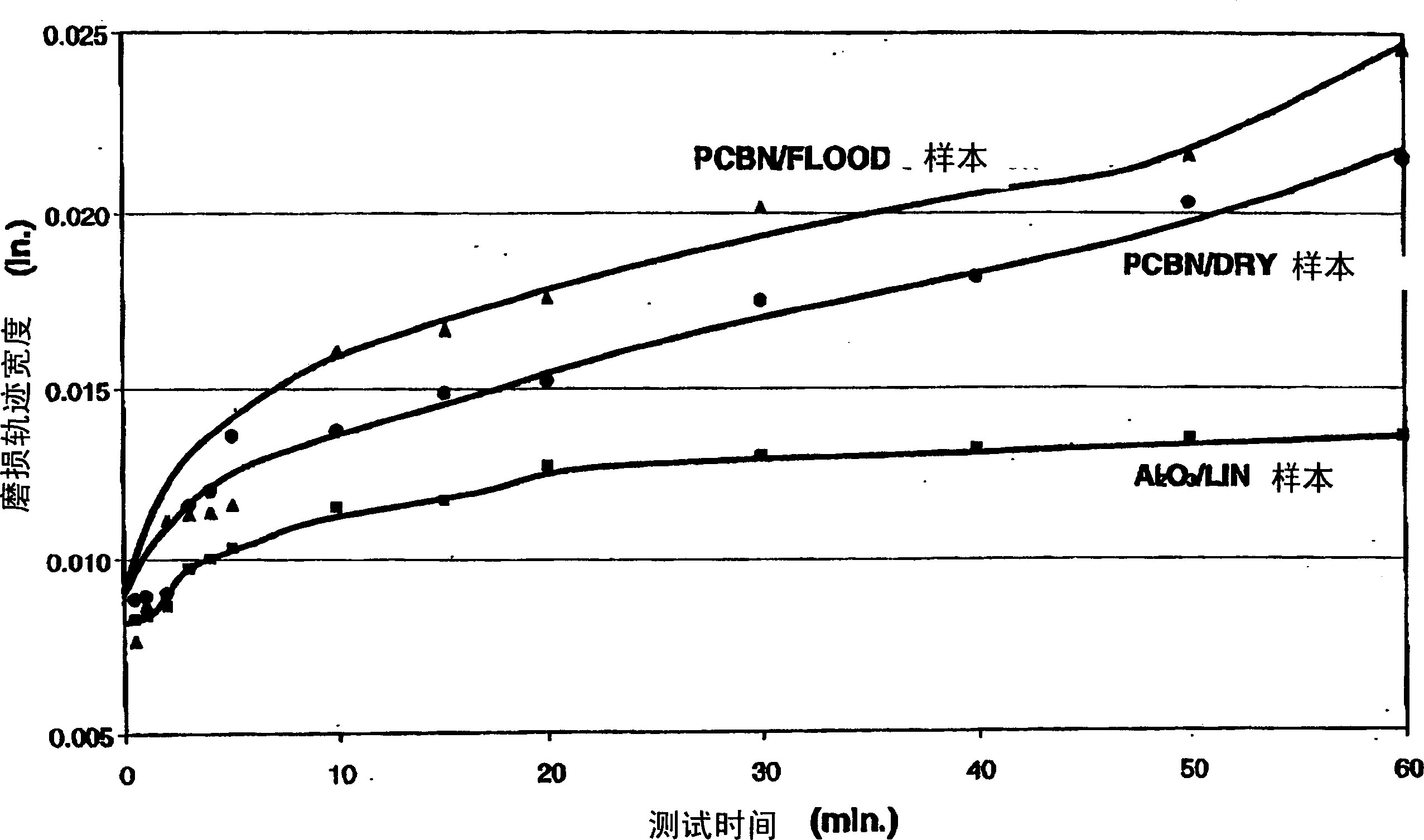

Examples

Embodiment Construction

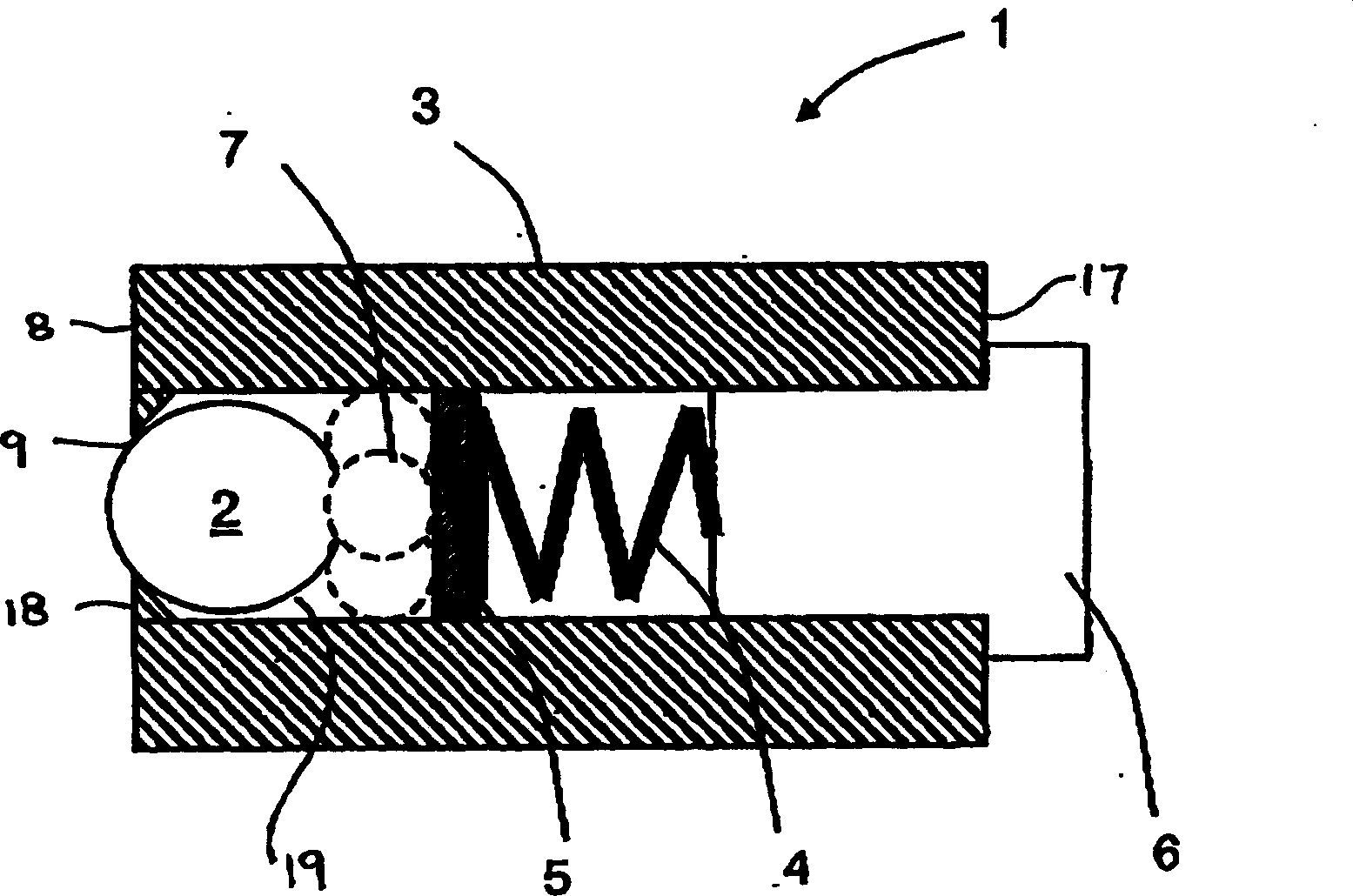

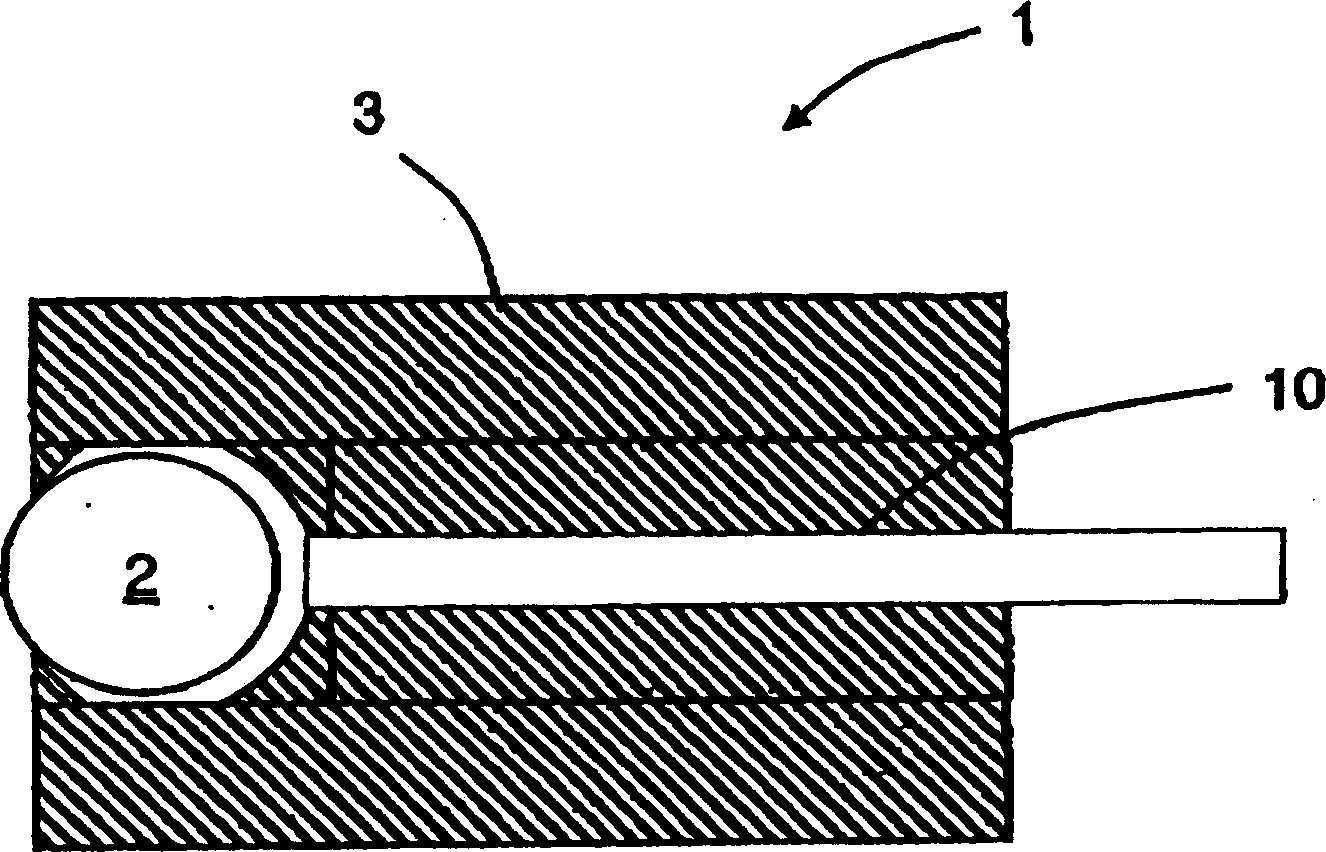

[0018] The invention relates to a friction device comprising a ball, a support, and means for exerting a substantially constant force on the ball against the part. Additionally, the present invention provides a method of influencing wear and / or fatigue of components for friction analysis. Although parts that have not been machined can be tested using the devices and methods of these inventions, these inventions are particularly useful for measuring parts that have been machined.

[0019] In order to facilitate the understanding of friction devices suitable for influencing wear and / or fatigue of components, reference is made to the accompanying drawings. (The same numerals are used in the figures to denote like elements in different embodiments of the devices shown.) Any component can be tested using the devices and methods of the present invention, including components that would withstand abrasion or sticking in normal (future) use. Connect worn parts. The parts to be teste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com