A magnetic shielding composite friction and wear testing machine

A friction and wear test, a composite technology, applied in the direction of using mechanical devices, measuring devices, instruments, etc., can solve the problems of single friction pair, unadjustable upper and lower positions, and inability to monitor changes in surface magnetic fields and temperature fields. The effect of shielding the external magnetic field interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

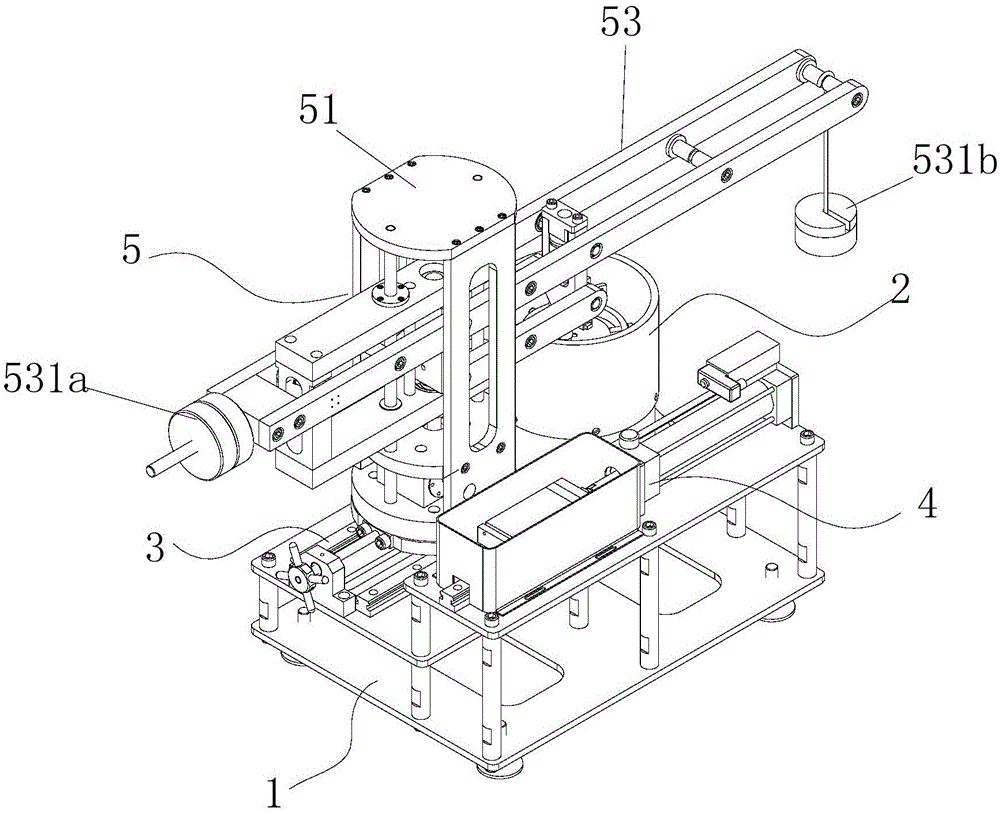

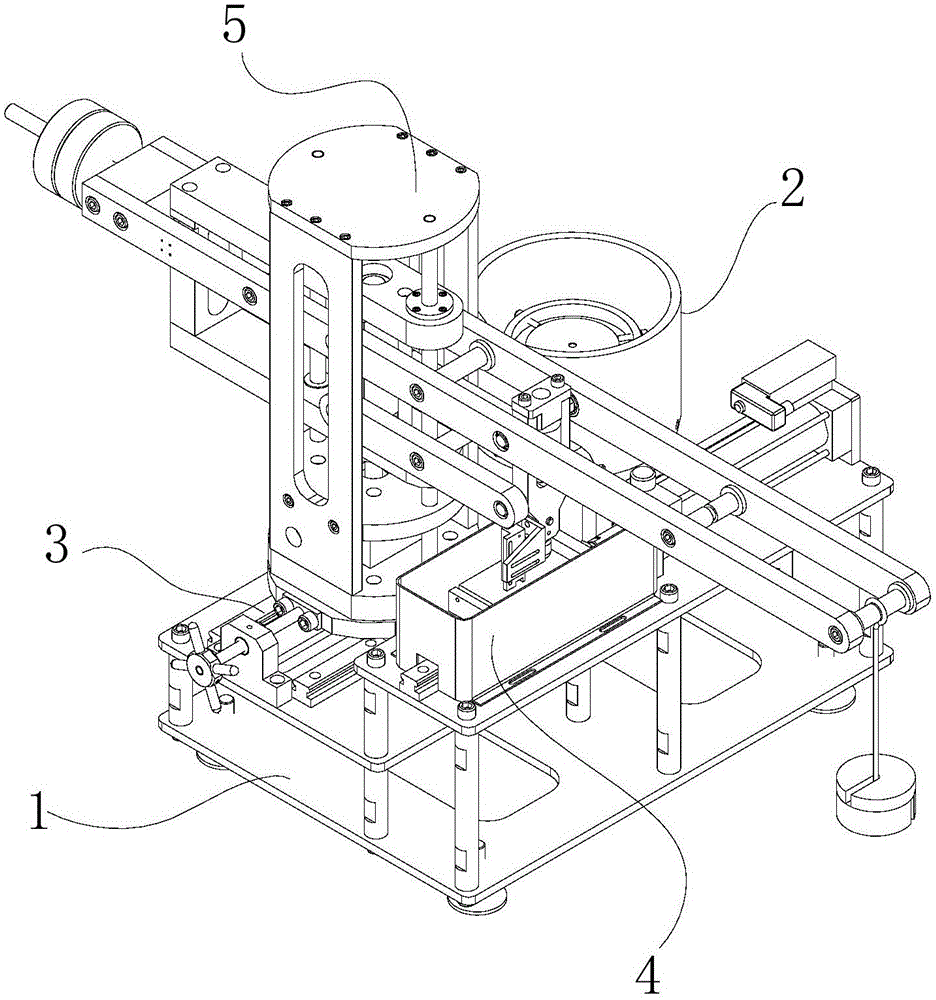

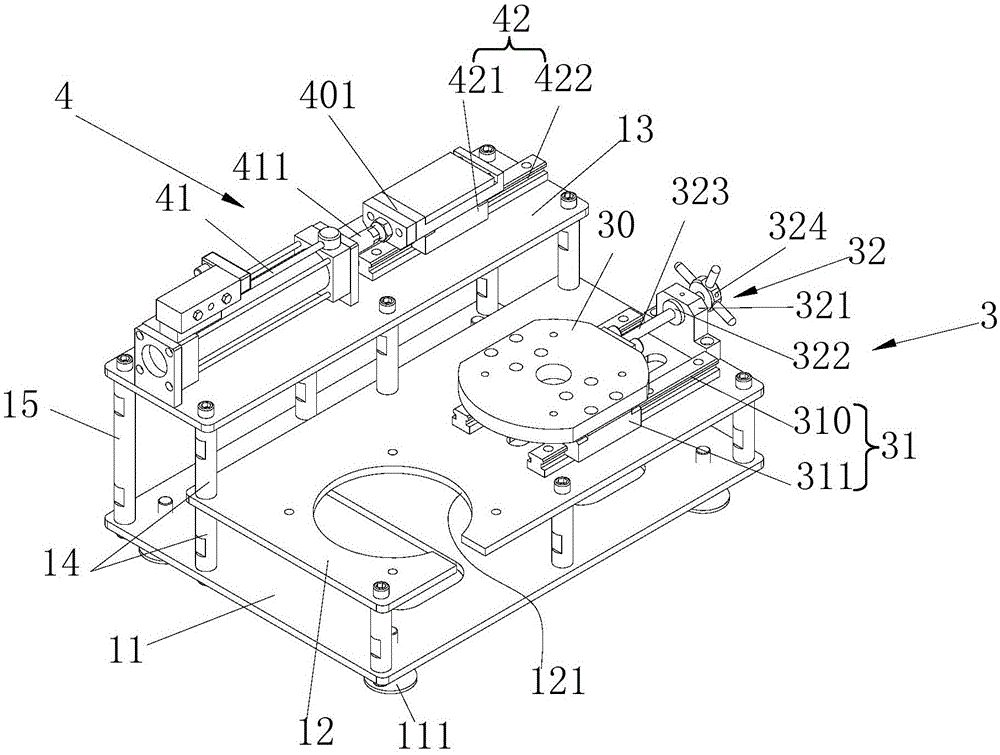

[0105]The invention provides a magnetic shielding composite friction and wear testing machine, which specifically includes: a frame, including a bottom platform, a middle platform and a top platform, the middle platform and the top platform are located on the bottom platform, and along the The first direction of the bottom platform is arranged in a step shape, and the two are extended in the same direction along the second direction of the bottom platform, and the first direction is perpendicular to the second direction; the rotation mechanism is placed on On the middle platform, the upper end is connected with a rotating disk for placing samples, the outer peripheral side of the rotating disk is provided with a first magnetic shield, and the lower end of the first magnetic shield is connected with the rotating mechanism; A horizontal adjustment platform, which is arranged on the middle platform, and is adjacent to one side of the rotation mechanism along the second direction, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com