A double-layer insulation box structure for low-temperature friction and wear testing machine

A friction and wear test, thermal insulation box technology, applied in thermal insulation containers, applications, household appliances, etc., can solve problems such as temperature rise, ice pin melting, etc., to achieve the effect of simple structure and convenient manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following structural drawings and embodiments further illustrate the present invention.

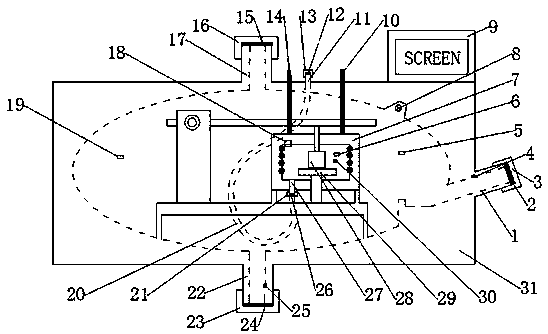

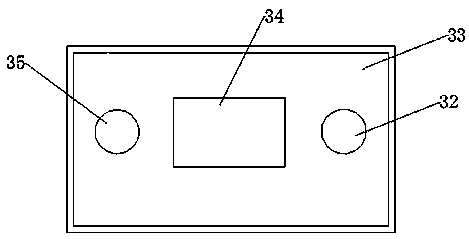

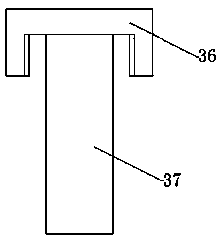

[0024] Such as Figure 1-3 shown.

[0025] A double-layer insulated box structure for a low-temperature friction and wear testing machine, which includes an outer insulated box 31, an inner insulated box 7, an endoscope and a lighting system 18, a control display module 9, a lighting lamp 8, and a temperature sensor 5, 6, 19, humidity detection sensors 4, 25, 30, the inner layer insulation box 7 is installed on the mounting frame in the outer layer insulation box body 31, and the endoscope and lighting system 18 are installed in the inner layer insulation box body 7 For obtaining the test situation, the control display module 9 is installed outside the outer layer insulation box body 31, and it is connected with the endoscope and lighting system 18, the temperature sensor installed in the outer layer insulation box body, the humidity detection sensor and the inner layer insula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com