Dynamic noncontact rail gauge measuring system and method thereof

A measurement system and track gauge technology, applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems of affecting measurement accuracy, limitations, complex equipment of photoelectric measurement methods, etc., and achieve the effect of improving detection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

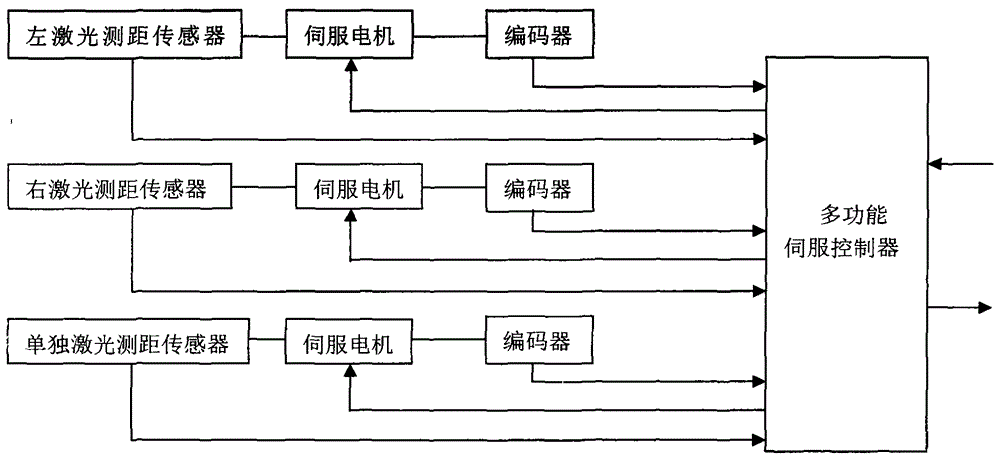

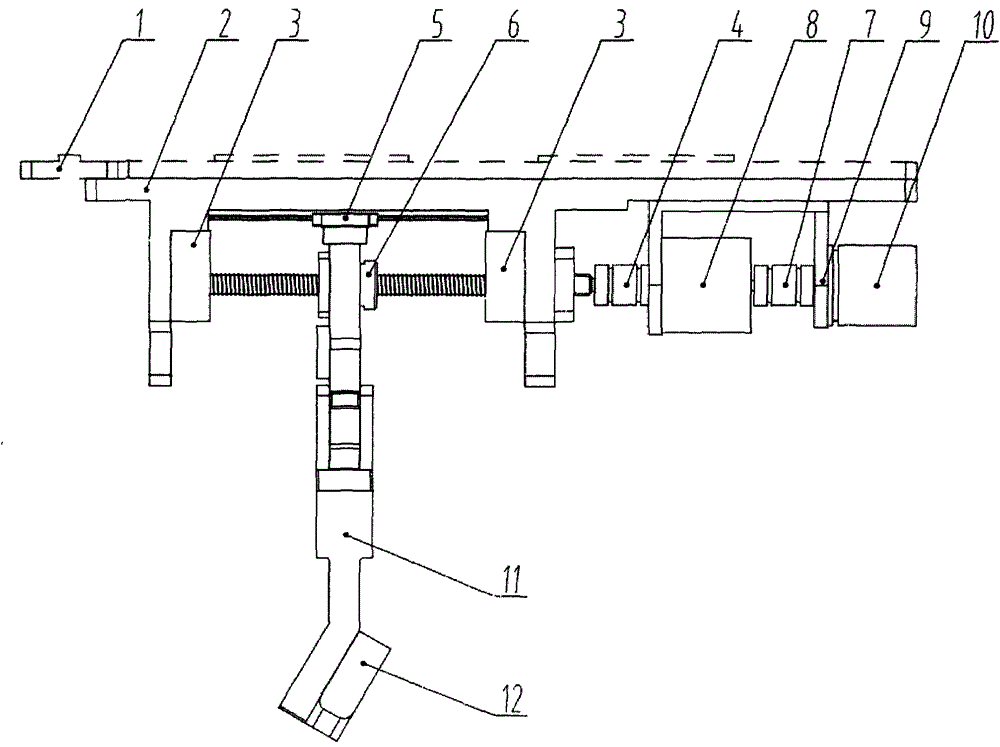

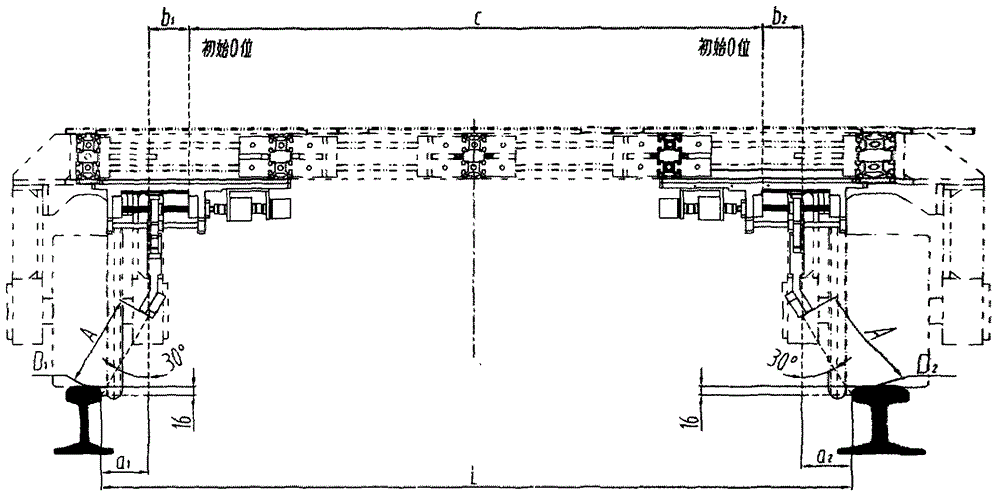

[0034] In this example, if figure 1 The principle block diagram of the track gauge measurement system is shown. The laser distance measuring sensor dynamic non-contact track gauge measurement system and its method are composed of three identical track gauge measurement components and a multifunctional servo that can simultaneously control the three same track gauge measurement components. The controller component constitutes. Each gauge measurement component includes: component base 1, guide rail seat 2, left and right limit stops 3, torque servo motor coupling 4, linear guide rail 5, lead screw 6, encoder coupling 7, torque Servo motor 8, motor bracket 9, encoder 10, laser ranging sensor moving bracket 11, laser ranging sensor 12.

[0035] According to the physical and mathematical model determined by the track gauge measurement system and its method, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com