Enhanced method and apparatus for deducing a correct rail weight for use in rail wear analysis of worn railroad rails

a technology of rail wear analysis and correct rail weight, which is applied in the field of rail maintenance, can solve the problems of manual entry of rail weight and associated unworn profiles of rails, and nothing in the art listed above solves or even addresses the problem, so as to facilitate selection and application of the appropriate rail.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

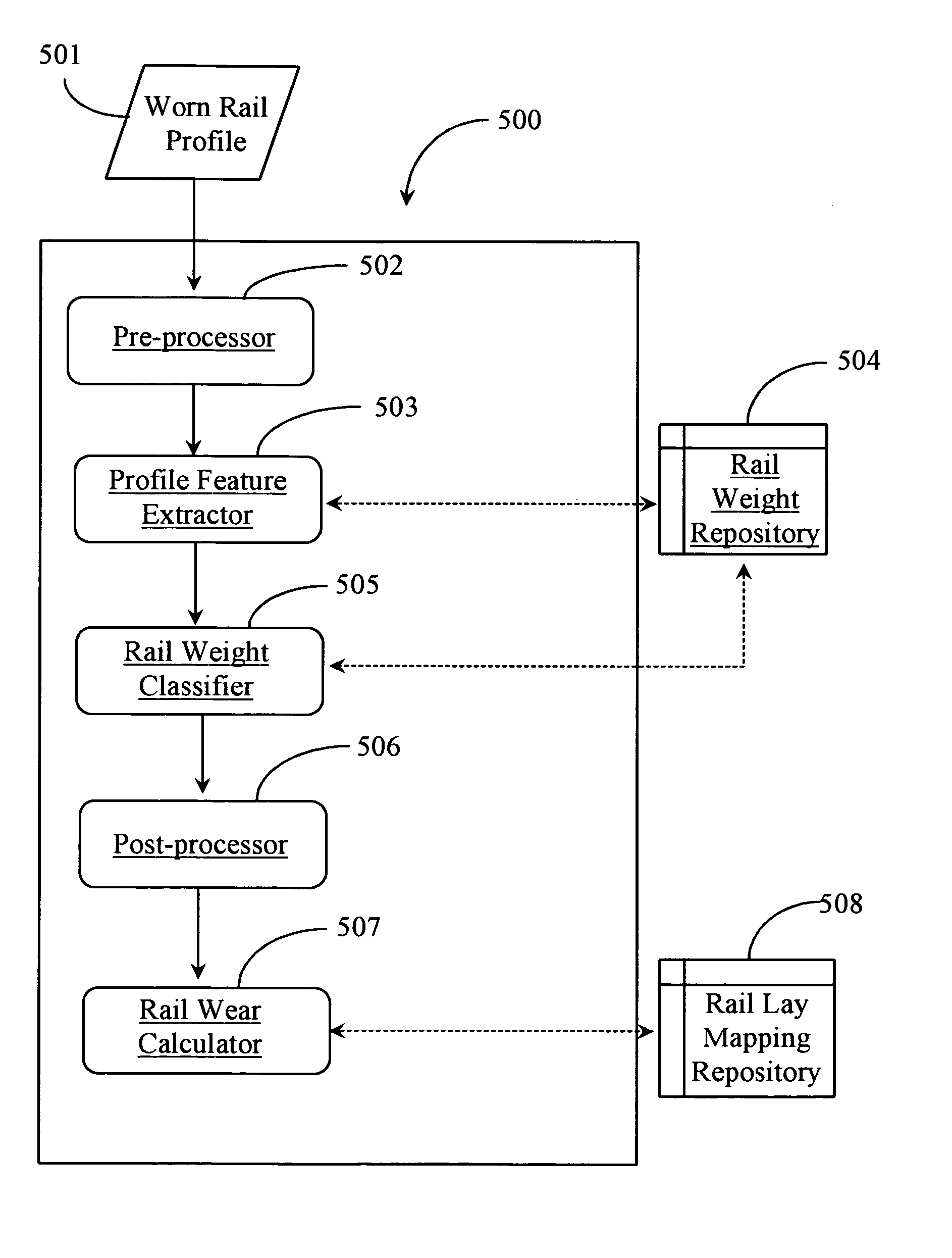

[0066] In accordance with embodiments of the present invention, the inventors provide methods and apparatus for automatic identification and selection of a correct rail weight for a worn rail using the worn rail profile as data input. The methods and apparatus of the present invention will be described in enabling detail below.

[0067] As was described in the background section above, prior-art methods for rail-wear calculation are adept at acquiring the shape of worn rails, which is the primary reason for their use in rail wear measurement. However, they may rely on user-specified rail weights for calculation of wear. Since in actual practice, the track is made up of several differing rail weights, a separate manual process involving visual comparison of rail profile shapes with that of standard profiles may be required to establish correct rail weights and calculate wear accurately. Some of the commercial systems listed in the background section above claim to possess automatic rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com