Tackifying particle for tackifying rail transit wheel-rail interface, and preparation method thereof

A rail transit and particle technology, applied in locomotives and other directions, can solve the problems of increased wheel and rail wear, surface damage, and increased railway maintenance costs, and achieve the effect of avoiding wheel and rail wear and increased damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] A method for preparing tackifying granules used for tackifying the wheel-rail interface of rail transit, comprising the following steps:

[0024] Step 1: adding silicon dioxide powder into water to form a premix; the mass fraction of the silicon dioxide powder in the premix is 40-60wt.%; the silicon dioxide powder is quartz powder, and the particle size range is 1-30 μm.

[0025] Step 2: Spray-dry the premix solution obtained in step 1 to form a green particle body; add a binder to the premix solution to agglomerate the silica powder during the spray drying process to form a green particle body with a particle size that meets the requirements. The binder is sodium silicate, and the amount added is 2 to 5% of the mass of the silica powder used.

[0026] Step 3: Sintering the pellet green body obtained in Step 2 to obtain finished pellets. The granule green body is sintered in an atmospheric pressure sintering furnace, and the temperature is raised to 1200 °C with the ...

Embodiment

[0028] Choose quartz powder with a particle size range of 1-30 μm as the material. At room temperature, mix 1 kg of material with 1.5 kg of water to prepare a premixed solution with a mass fraction of 40wt.%. After stirring the premixed solution for 20 minutes, add 50 g of sodium silicate and continue stirring 10min.

[0029] The uniformly stirred premixed liquid is made into green granules on a pressure spray dryer, and the green granules are heated in a sintering furnace at 20°C / min to 1200°C, kept at this temperature for 2 hours, then taken out and naturally cooled to room temperature to obtain The final finished pellets.

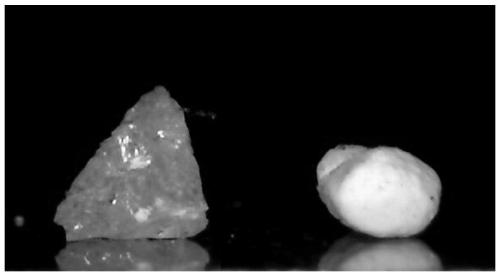

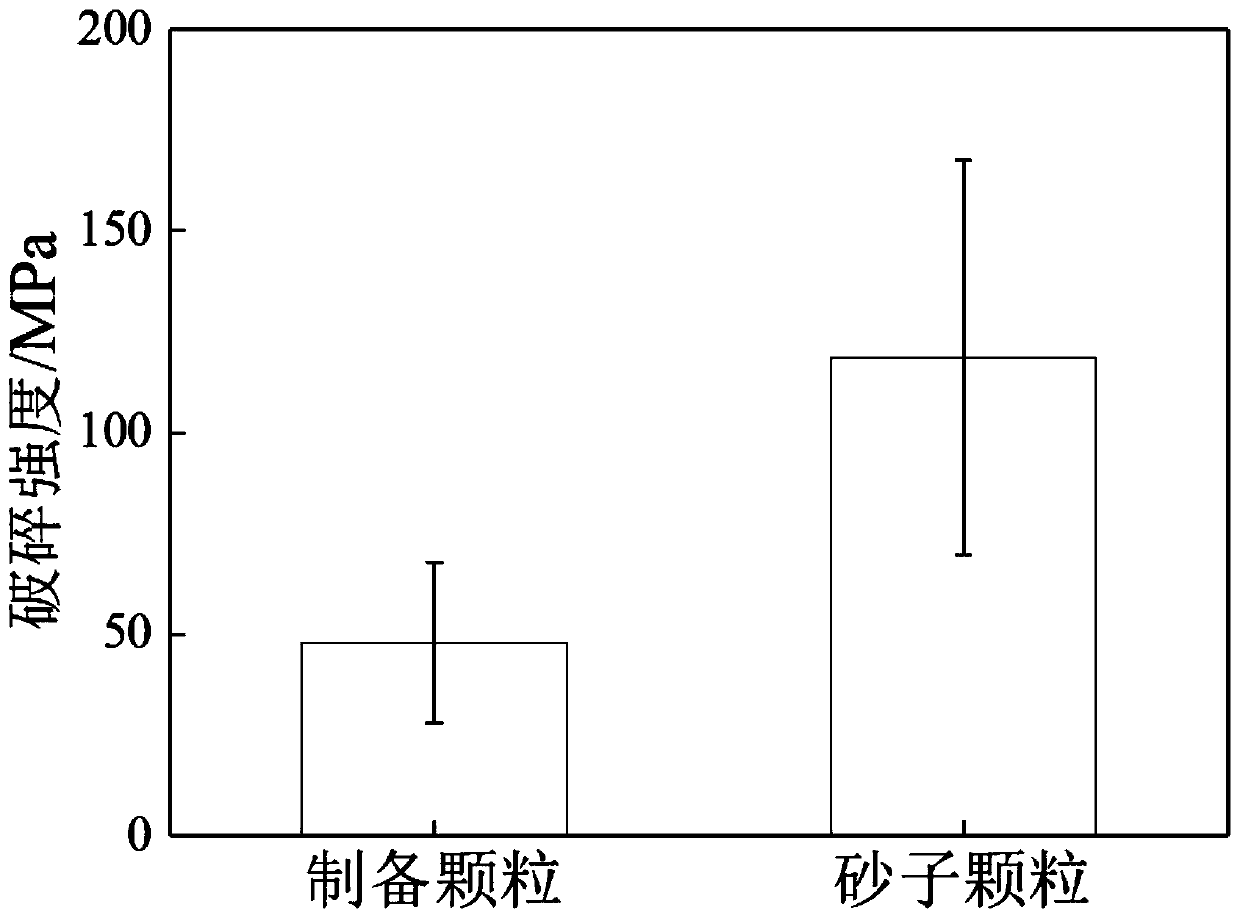

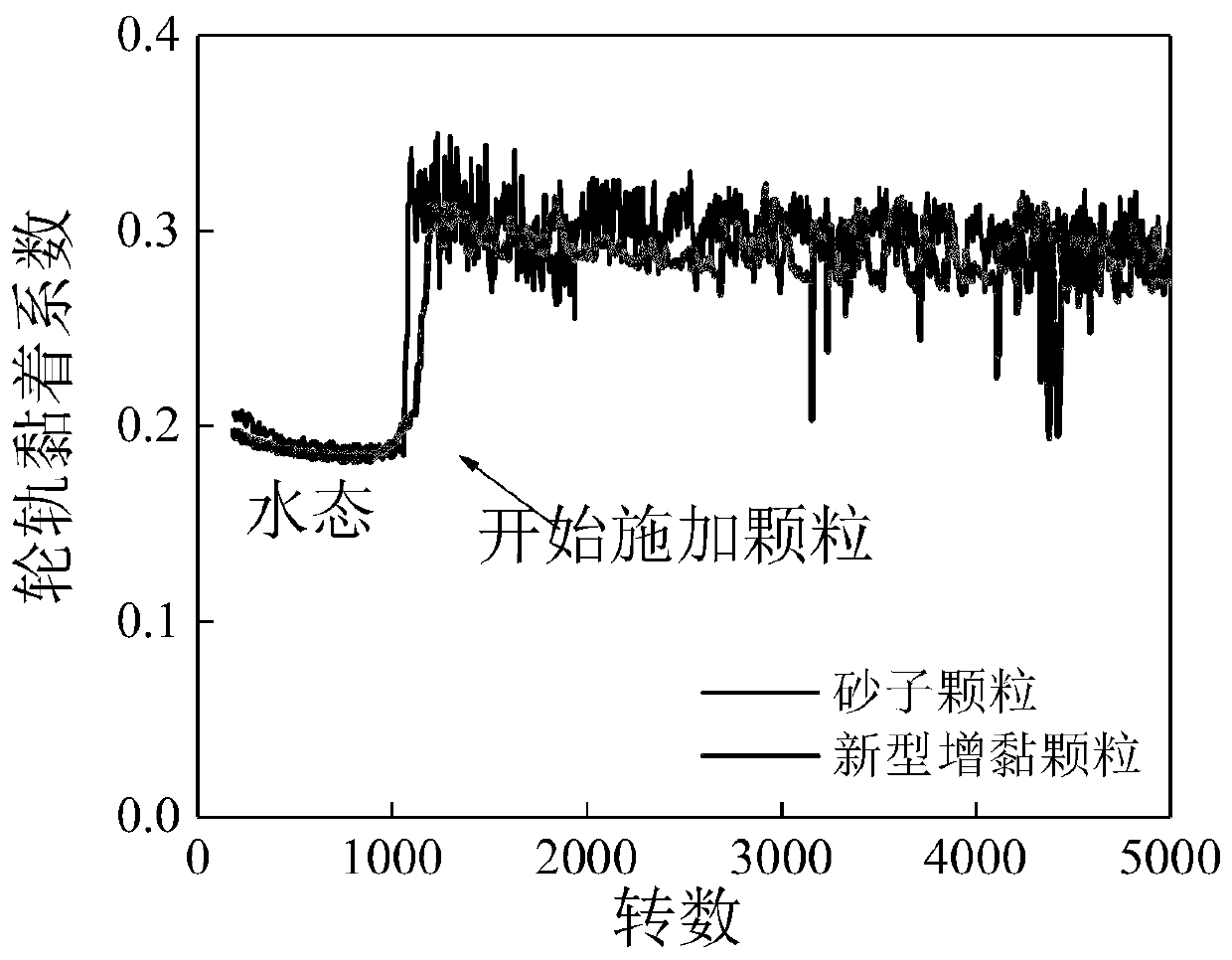

[0030] figure 1 The comparison chart of the viscosifying particles prepared in the above example and the sand particles of the same size shows that the shape of the particles prepared in this example is more regular and close to a sphere. Its characteristics are different from the crystal characteristics of sand particles, showing the characteristics o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com