Steel rail wear laser visual dynamic measuring method

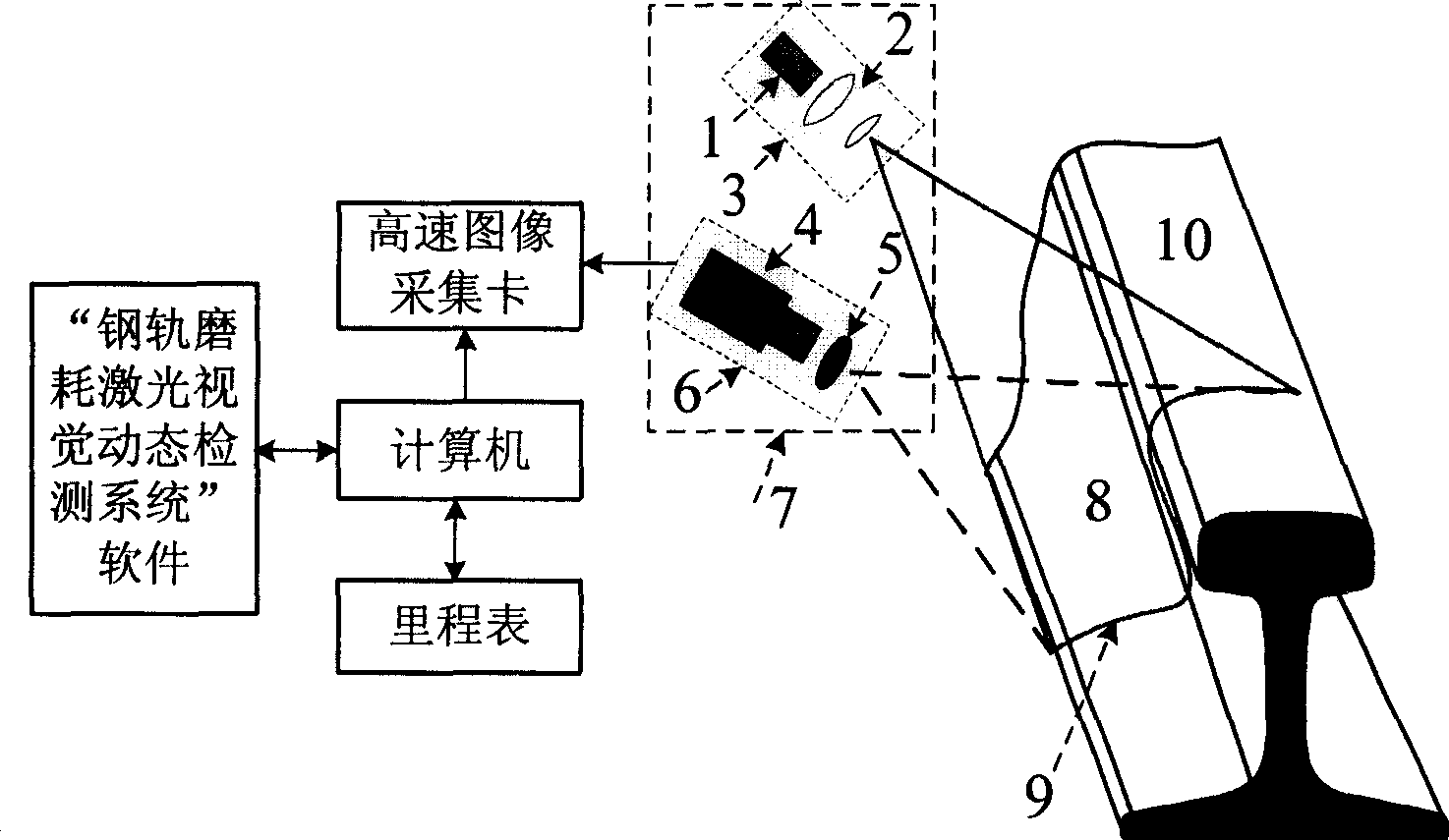

A technology for dynamic measurement and rail wear, applied in the field of measurement, can solve the problems that the measurement sensor cannot have large vibration, affect the accuracy and reliability of the measurement result, and the conversion link is not well solved, and achieves low cost and speed. The effect of fast and reducing equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

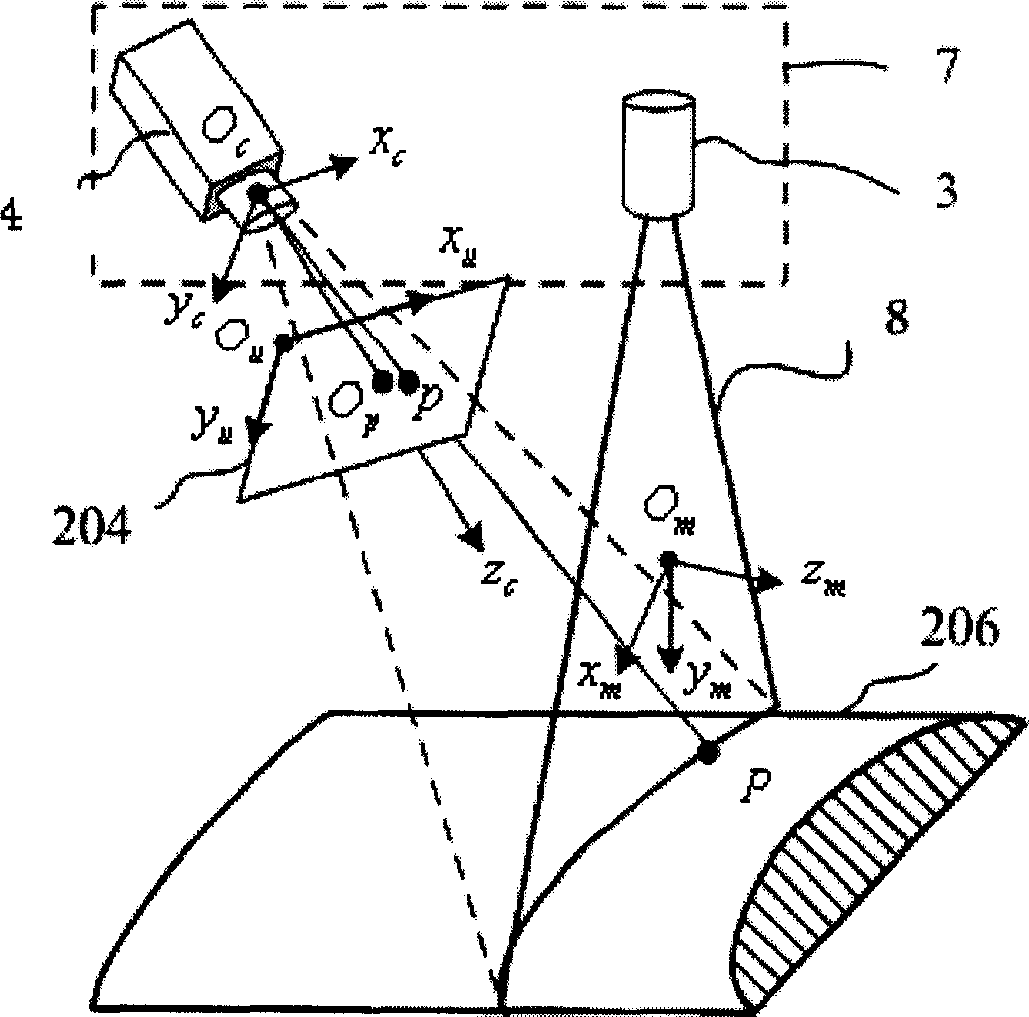

Method used

Image

Examples

Embodiment

[0096] Propose measuring device and measuring method according to the present invention, design actual laser vision sensor, carry out on-the-spot dynamic measurement to rail, the software interface of measuring system is as follows Figure 6 shown.

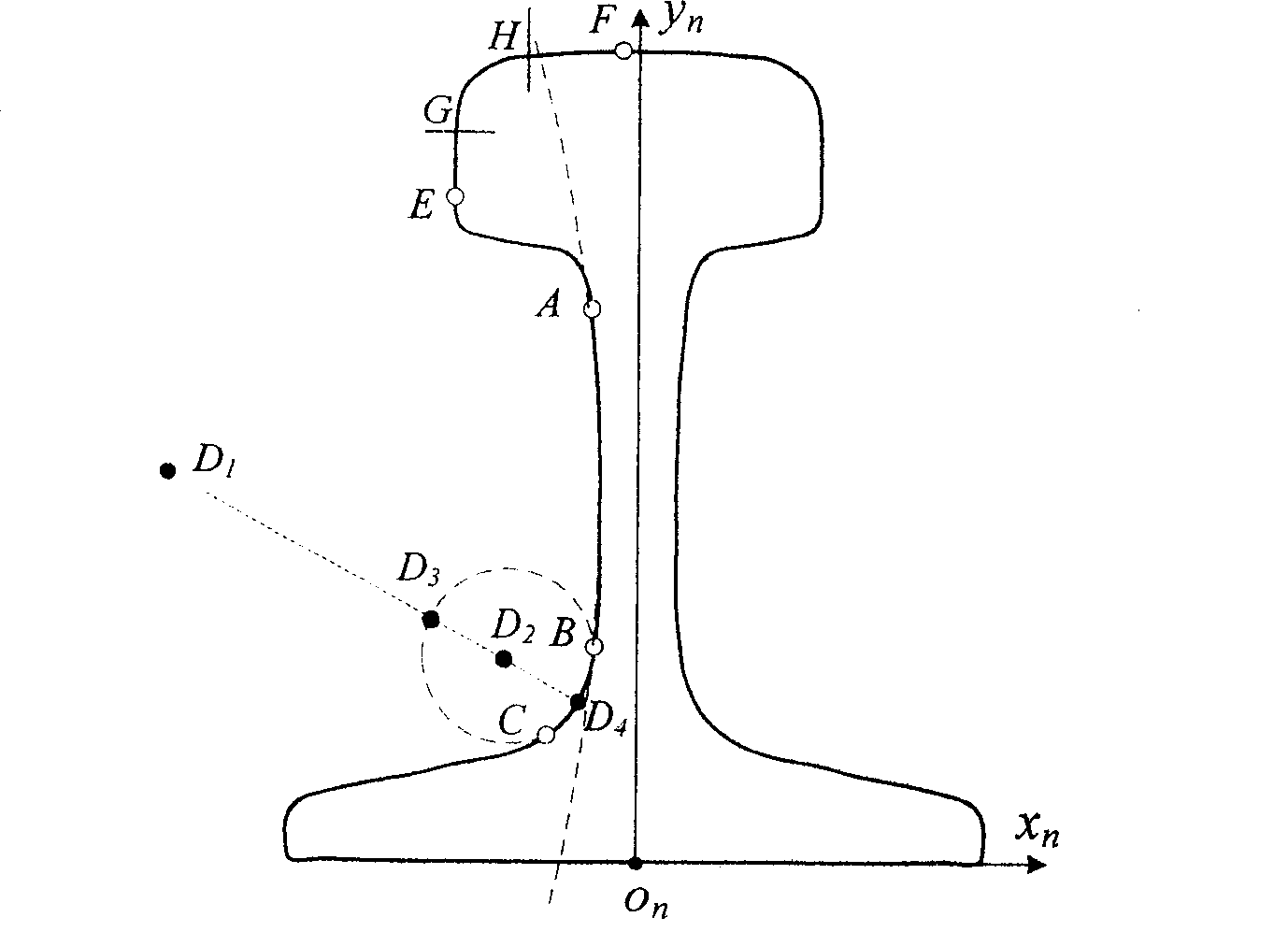

[0097] Figure 7 A measured image including a 50kg rail and the extracted contour feature image are given. Figure 8 is the profile of the rail section in the survey coordinate system and the profile transformed to the design coordinate system; Figure 9 After alignment, measure the profile and design the profile.

[0098]The final measured wear is: vertical wear is 1.9mm, side wear is -0.1mm, total wear is 1.8mm, and the rail type is 50R (50kg right rail). On the PIV3.0 computer, the single measurement time is 25.5ms.

[0099] Figure 10 When the train stops, the same fixed rail surface is measured continuously for 540 times, and the rail surface wear repeatability error curve is obtained. The RMS errors are: 0.10mm, 0.04mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com